Pipe cutter for metal-plastic pipes: types, which one is better to choose and how to use it correctly

There is no such thing as too many construction tools.Anyone who repairs professionally or as an amateur will agree with this statement. Most operations can be performed manually using a minimum of tools, but is there any point in this?

Any job is easier to handle if you choose the right equipment. And a pipe cutter for metal-plastic pipes is no exception - it is inexpensive, but significantly speeds up the process of laying pipes. But how to choose the right equipment and not get confused in the range of tools on the market?

We will examine these questions in our article, looking at the main types of pipe cutters and the best offers on the market, their features and characteristics. We will also talk about the intricacies of choosing suitable equipment and discuss the rules for cutting pipes at home.

The content of the article:

In what cases is a pipe cutter needed?

A metal-plastic pipe is a prefabricated structure of at least 3 layers: a thin layer of aluminum - a frame, and two layers of polypropylene. The elements of the layered structure are connected by laser welding.Metal-plastic is used in plumbing work for laying water pipes, as well as for wiring the heating circuit.

The pipes are quite soft and cutting them is not that difficult. A hacksaw or even a regular knife with a serrated blade will do. Of course, it is possible to make one cut with such a tool, but not a single builder would agree to do this on an ongoing basis.

Builders also often make do with an angle grinder - Bulgarian. Yes, a metal disc easily passes through thin aluminum foil, but a lot of debris and waste remains at the workplace.

It is noisy, you need to connect the power supply, and each time clamp the pipe itself in a vice to fix it. And if you need to cut off part of an installed pipeline in a hard-to-reach place, you definitely won’t be able to get there with a grinder.

It is not advisable to cut a pipe with a non-professional tool. And this is not just a matter of difficulty in terms of physical labor. The cut is not smooth, with jagged edges and chips. It will have to be cleaned additionally, otherwise the system will malfunction.

Advantages of manual and electric pipe cutters

Tools for cutting metal-plastic pipes can be of 2 types:

- manual;

- electric.

A manual pipe cutter works due to the muscular strength of the person using it. It can be used in any conditions, there is no connection to the availability of power, there are no restrictions on operating time depending on the battery capacity and there are no other inconveniences associated with using a power tool.

However, no one will argue that for large volumes of work, hand tools may not be enough. This is especially true for thick-walled, large-diameter metal-plastic pipes. Of course, such materials are rare in household construction, but for a professional plumber this is a very real situation.

An electric pipe cutter with a battery is a real salvation when cutting on an industrial scale. In the case of a power tool, a person only makes a mark where the cut is to be made, then secures the part so that the mark on the pipe and in the pipe cutter window coincide as accurately as possible, then turns on the power and gets a neat, perfectly even cut.

Of course, it's not just about convenience. The cost of a cordless pipe cutter for metal-plastic pipes is several times higher than the cost of a hand tool. No one wants to overpay, unless, of course, you use the device in professional activities almost every day.

Types of tools by type of cutting element

Depending on the design of the cutting mechanism, the following types of pipe cutters for metal-plastic pipes are distinguished:

- roller (with one or more rollers);

- ratchet;

- guillotines;

- with clamp latch.

A pipe cutter is usually made of durable metal - carbon or alloy steel. The handle can be made of plastic or rubberized.

Type #1 - ratchet pipe cutter or scissors

The easiest way to cut a piece of metal-plastic is with special precision scissors. This pipe cutter is designed for diameters up to 100 mm. The cutting element is a sharpened steel blade. The pipe is placed in a special holder - a semicircular metal holder. When the material is firmly installed, a mark is applied and a cut is made.

A pipe cutter works on the principle of scissors: by closing the ends of the handle, you lower the cutting element and make an even, smooth cut.A special gear rack-ratchet is responsible for the reverse motion of the blade. If it was not possible to make a cut in one go, it will not allow the knife to return to its original position, but will fix it to continue working. This significantly saves the worker’s effort.

Due to the design features of the metal-plastic pipe, the material at the end can bend and lose its shape. For leveling, use a calibrator or carry out the procedure manually.

If you plan to cut pipes only during renovations or wiring in the bathroom, there is no point in buying an expensive automatic device; precision shears with a ratchet will do. Most likely, after completing the installation of the plumbing or heating system, your pipe cutter will go into the drawer with the rest of the tools for a long time.

It's another matter if you need a pipe cutter for work. When working with scissors, your hand gets very tired; it’s difficult to handle a large volume at once alone.

For professional use, it is better to pay attention to other types of tools. In addition, this model copes well with soft metal-plastic pipes, but it cannot be called universal. If you have to cut steel or copper products, this option will not work.

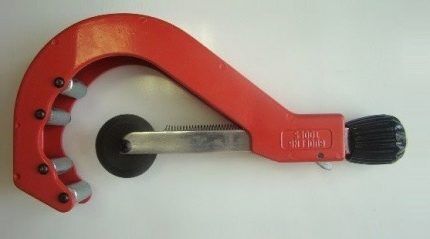

Type #2 - roller tool

A roller pipe cutter for metal-plastic is much more versatile. Depending on the diameter of the “C”-shaped clip and the number of rollers, there are models for cutting small pipes (up to 50 mm) and thicker ones (up to 125 mm).When working with large diameters, models with several rollers are used.

The principle of operation of a manual roller pipe cutter is that the part is clamped in a holder, and the cutting element is located close to it. Guide rollers are placed inside the cage itself.

The worker rotates the pipe cutter around an axis, with each turn the cutter moves closer to the center. Due to the fact that the blade rotates and does not simply press on the wall of the metal-plastic pipe, the cut is cleaner.

The advantage of this type of pipe cutter is that working with it does not require much effort on the part of the operator. Anyone who has ever made preparations for the winter and used a seaming wrench can imagine in general terms how to work with a pipe cutter for roller-type metal-plastic pipes.

One of the main disadvantages is that the cutting is carried out in jerks. They lead to minimal displacement of the part in the holder, and this entails the appearance of burrs on the cut. After cutting, you will have to process the sections of metal-plastic pipes. Expensive models have a smooth telescopic motion, which eliminates the appearance of irregularities.

Type #3 - guillotine for uniform cutting

A guillotine is a tool that cuts evenly over the entire cross-sectional area. A pipe cutter with this operating principle ensures a perpendicular and clean cut without burrs. Uniform distribution of the load eliminates the possibility of deformation of the metal-plastic pipe during operation.

There are several types of implementation of this idea.The most primitive and inexpensive option - the blade is lowered by rotating the handle and gradually lowering the rod. A more advanced model is in the form of a pistol. The guillotine lowers when the operator pulls the trigger.

A pipe cutter with a guillotine mechanism can handle pipes up to 100mm wide, but most models are limited to a 7cm diameter. For domestic use, this is usually sufficient.

View #4 - model with clamp latch

Another type of device for cutting metal-plastic pipes is a pipe cutter with a clamp latch. The principle of operation is similar to the roller model, the main difference is that the part is not simply clamped in a holder by turning the handle, but is fixed tightly on all sides.

In this case, the cutting discs (usually 2 of them) are placed along the lower edge of the “C”-shaped cage. The main advantage of this type of tool is its compactness. The design can be used even in places where there is nowhere to turn, let alone rotate a large pipe cutter.

Tips for choosing the right pipe cutter

When choosing a good pipe cutter for metal-plastic pipes, it is worth finding out what functions, in addition to the main one - cutting, they may have. Some models can not only make a perpendicular cut, but also chamfer 15-30 degrees, sometimes even simultaneously with cutting. Chamfer simplifies installation of fittings.

Roller pipe cutters can leave behind burrs - unevenness and roughness that spoil the appearance of the cut and performance characteristics.

A good tool will be equipped with a special deburring attachment. It resembles the surface of a file, is put on instead of a rotating disk blade, and the cut is processed according to the same principle as cutting - by rotating the device around the pipe.

The blade can become dull and, most often, this happens at the most inconvenient moment, when work is in full swing and you don’t want to waste time sharpening the pipe cutter. In this case, such a standard item as a spare roller will be very useful. A sharpened spare tire will always help out in an emergency.

Ergonomics - this criterion is one of the fundamental ones when choosing a manual pipe cutter for metal-plastic pipes. A tool that you will use often and in large quantities should be comfortable, fit well in your hand and not slip. The work is carried out with one hand, and you should not feel tired.

Top models on the instrument market

The most commonly found tool in the toolbox in a DIYer's garage are pipe cutters and scissors for metal-plastic pipes.

In order not to rack your brains while understanding the variety of tools in construction departments, it is better to immediately familiarize yourself with the ratings of popular high-quality models of different price categories and make a choice based on the experience of other buyers.

Budget tools for home use

Among inexpensive equipment for cutting pipes, pipe cutters of the Sturm and WMT brands are in greatest demand.

Practical equipment from the Sturm brand

Sturm is an inexpensive and practical option for home use. The device is equipped with a blade made of hardened steel. Metal parts are coated with a protective substance against corrosion.

The handle is made of comfortable plastic with a non-slip surface. The cost of a pipe cutter from Sturm ranges from 400-450 rubles.

A short video review of a pipe cutter of this brand in the following video:

Inexpensive solution from WMT

Another budget pipe cutter is produced by WMT. This tool will cost you no more than 300 rubles.

For that kind of money you can’t count on additional functionality and other nice little things, but the device does its job within reasonable limits. It cuts metal-plastic pipes up to 42 mm.

Review of a budget model for minimal money:

Professional pipe cutting equipment

Among professional tools, models from the brands RIDGIT, Milwaukee and KALDE stand out with good reviews.

RIDGIT pipe cutters popular among users

RIDGIT is one of the market leaders in pipe cutting tools. This manufacturer offers professional equipment that can work in any conditions. RIDGIT PC 1375 ML is one of the most popular models of this brand.

Lightweight (only 320 g) steel body and durable cutter cuts the pipe in just a few seconds. A wide range of working diameters (up to 42 mm) allows you to work with the most popular pipe sizes.The cost of RIDGIT PC 1375 ML starts from 3600 rubles.

Another popular model from RIDGIT is the TC-40. This is an automatic pipe cutter. It is equipped with a 0.75 kW motor and a 12 V lithium battery. The device easily copes with pipes from 3 to 42 mm, just press a button.

There is such a nice addition as backlighting for working in dimly lit places. Since the metal-plastic pipe is multilayer, the manufacturer took care of a special adapter for this type of material. The price of an automatic tool is from 18,000 rubles.

Reliable Milwaukee models

Professional Milwaukee tools from the USA are a guarantee of high-quality and reliable work over many years of service.

The Milwaukee ProPEX Tubing Cutter model is a pipe cutter for small diameters - up to 25 mm. It is made of durable steel and does not corrode. The comfortable handle has a high level of ergonomics. But the price for a high-quality pipe cutter is appropriate - from 2300 rubles.

Wide selection of KALDE pipe cutters

The Turkish brand KALDE offers a wide range of scissors for metal-plastic pipes. For example, KALDE (40-63) is a model for cutting large diameter pipes - from 40 to 63 mm. The blades are sharpened very well, the tool does not bend metal-plastic pipes, does not bite the edges and does not leave chips.

All KALDE products are manufactured in accordance with European quality standards. The price for a specific model in stores is about 4,300 rubles.

How to cut metal-plastic pipes correctly?

Cutting metal-plastic pipes requires experience. Only after cutting several tens of meters of material does confidence appear in your hands, and the movements become automatic.

To get two pipes from one, you need to perform the following sequential operations:

- Mark where the cut should be made. It is important that the mark is strictly across the pipe and not at an angle. Then the blade will pass perpendicularly.

- Secure the pipe using a pipe cutter clamp. Some models grip the part using a spring, others are installed by lowering the rod, and in others you just need to lay the material and hold it with your hands.

- Make sure that the mark is strictly aligned with the blade.. If it is a roller pipe cutter, it makes sense to perform the first rotation of the tool to check the accuracy of the installation.

- Cut the pipe: close the ends of the scissors handle, pull the trigger, lower the guillotine rod or make a few turns of the roller tool - it all depends on the chosen model of pipe cutter.

A distinctive feature of cutting metal-plastic pipes, in comparison with cutting of polypropylene products, is that accuracy in this case is very important. The polypropylene pipeline will be connected using high temperature, the plastic will melt a little and thus hide all possible inaccuracies.

But this will not happen in the case of metal-plastic pipes. The ends are mounted in special cuffs and every mm of discrepancy threatens a loose fit and the occurrence of leaks.We have provided detailed instructions for installing metal-plastic pipes in the next article.

After the cut, you need to blow through the resulting section. Aluminum or plastic shavings remaining inside the pipe after installing the entire system can damage the equipment that is connected to the pipeline or cause a blockage.

Conclusions and useful video on the topic

The video will help you understand how the tool for cutting metal-plastic pipes works - watch how to cut a metal-plastic pipe:

With such a wide range of construction tools, both manual and electric, choosing a pipe cutter that will cope with its function, but will not cost more than the heating system itself, is a very real task.

Knowing what types of devices there are, as well as getting acquainted with the most popular models, you can easily choose and buy equipment for working with metal-plastic pipes.

Would you like to add useful comments to our material or share your own experience in cutting metal-plastic pipes? Or do you want to talk about the pros and cons of your pipe cutter? Write your opinion and recommendations under this article, add unique photos of your model of pipe cutters or the cutting process itself.

In my work I often use a manual one, because I have to deal with standard pipes of small diameter. When it comes to larger diameters or thick-walled pipes, I take an electric one. Of course, it’s easier for them; you don’t need to apply any force, and the cut is always clean. But you depend on the nearest outlet. If this is not a problem at home, then outside you often still have to do everything manually.

If 5 years ago I had been offered to buy a pipe cutter for metal-plastic pipes, I would have been surprised why I needed it. However, pipes turned out to be surprisingly convenient for various purposes and became widespread. Now I am planning to buy both a pipe cutter and a soldering iron for pp pipes. Of course, the average person doesn’t need an electric pipe cutter, but a ratchet one is worth buying. Especially for residents of private houses.

Now, if you need to cut a lot of pipes and profiles, then you cannot do without laser cutting; one machine can replace an entire processing workshop.