Pipe cutter for copper pipes: types, tips for choosing, rules and nuances of use

A copper pipe cutter is a mechanical (manual or semi-automatic) device, the use of which provides easy and convenient processing of copper pipes. Most often, a pipe cutter for copper pipes is used in working with climate control equipment, for example, in repairing household air conditioners.

However, beyond this area, copper pipe tools also have applications in home plumbing work. We will talk in detail about the design features of equipment for cutting copper pipes, types of pipe cutters and outline the main criteria for their selection.

The content of the article:

Pipe cutter design features

The tool is designed to perform cutting operations in the same way as, for example, a hacksaw for metal has a similar purpose.

But if a cut made with a hacksaw cannot be obtained exceptionally smooth, without burrs and metal filings, cutting with a pipe cutter shows a completely different result:

- neat cutting of edges;

- strict perpendicularity to the pipe axis;

- smooth ends of the circle;

- absence of metal filings.

The last factor in the list is of particular importance when using a pipe cutter in refrigeration and air conditioning equipment. Small metal filings that get inside the refrigeration system contribute to rapid wear of the equipment.

If the pipes are installed in a plumbing system (for example, copper plumbing), the presence of metal filings inside the water supply system is a risk of blockages during operation.

Working with a tool for cutting pipes is characterized by low labor costs in terms of time. Relatively little physical effort is required from a mechanic (plumber, mechanic).

Products, as a rule, are small-sized and light in weight, and are placed in a work case. In general, devices produced in different designs look like convenient and practical devices.

Review of pipe cutter designs

It should be noted that the choice of tools by design is relatively small, despite the apparent variety of proposals in general. This choice covers no more than five engineering solutions, which differ from one another in some nuances.

The following structures are usually used for cutting copper pipes:

- clamps,

- telescopes,

- rollerballs.

Let's consider all types.

Option #1 - clamp cutters

Clamps resemble a similar tool widely used in plumbing and carpentry. The simple design of the clamp consists of a bracket and a screw mechanism.

This tool is usually used to fasten any parts.But in relation to copper pipe cutters, the configuration of the devices has changed somewhat. In the working area between the clamp legs, a thin disk cutter and support rollers were additionally introduced. This made it possible to easily and simply cut pipes, including copper pipes, usually thin-walled and of small diameters.

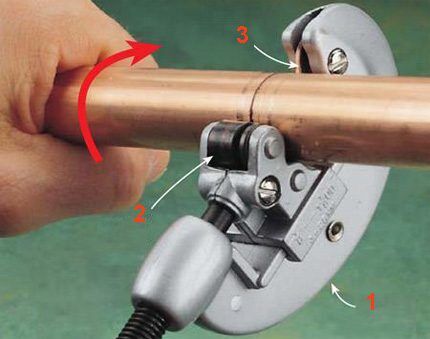

The operating principle of a pipe cutter clamp is simple:

- Copper pipe is placed in the area between the cutter and the support rollers.

- Using a screw mechanism, a block with rollers presses the pipe to the cutter blade.

- The master performs 1-2 turns of the clamp with his hands around the axis of the pipe.

- The pipe is again “tightened” to the cutter with a screw and step 3 is repeated.

Using a clamp-cutter, a complete cut of a thin-walled pipe is obtained in two or three technological passes. However, you should not strive to cut the material as quickly as possible, with a minimum number of passes. On the contrary, the smaller the “tightening” step of the support rollers is chosen, the better the quality of the cut.

Option #2 - telescopic cutters

Telescopes are among the most common designs for cutting copper pipes. The principle of their operation resembles the functionality of clamps. True, unlike the first designs, telescopes are designed to “pull” the cutter blade to the pipe body, while the module with the rollers remains stationary.

Telescopic cutters are usually used for working with small diameter pipes (up to 52 mm). Therefore, they are structurally more compact, lightweight, and convenient.

Example of using a telescope:

There is a copper pipe with a diameter of 34.92 mm and a wall thickness of 1.2 mm.It is necessary to cut off part of the pipe to install the fitting.

- By rotating the screw counterclockwise, move the cutter away from the support rollers by 40 mm.

- Place the pipe cutter on the pipe body and pull the cutter close to the pipe surface by turning the screw clockwise.

- Moving the tool along the pipe, position the cutter blade exactly on the cutting line.

- Tighten the cutter with the screw until it stops and another 0.1-0.2 mm.

- Rotate the pipe cutter around the pipe axis 1-2 times.

Then repeat operations 4-5 until the cut is complete.

Both telescopes and cutting clamps - both designs are traditionally equipped with an auxiliary device - an internal deburr. The device is used for additional processing of pipes after cutting or before soldering.

Telescopic pipe cutters usually have a deburring element as a retractable element, and in clamp designs this same element has a folding design.

Option #3 - roller cutters

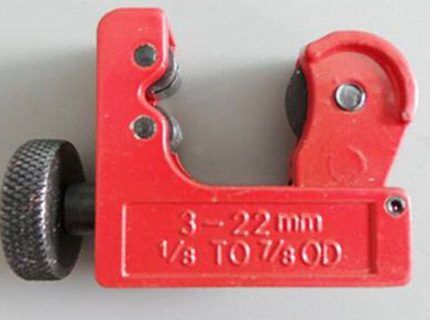

A relatively new type of pipe cutter can be characterized by rollers, which are more practical in design compared to the two previous designs. Rollers are intended mainly for processing copper pipes of small diameters (no more than 22 mm).

Thanks to their small dimensions and disc-shaped body, the rollers fit comfortably into the palm of the master. The mechanics of the device are designed to support automatically changing pressure force on the cutter as the pipe cutter rotates around the pipe axis.

Reliable grip of the device by the hand of the master is ensured by the figured ribs of the body. All the mechanics of the pipe cutter are contained in a strong metal shell. As the cutting disc wears out, this element can be replaced.

Sufficiently wide support rollers and a sharp, thin cutter guarantee cutting quality and accuracy.

Example of use in practice:

- Place the device onto the pipe through the inlet groove.

- Adjust the position of the blade at the cutting point.

- Grasp the body tightly with your palm.

- Perform several rotational movements around the axis of the pipe.

There is no need to perform any additional actions until the cut is complete.

Pipe cutters with a cutting roller are the tools most in demand when assembling pipelines for heating and water supply systems:

Mini pipe cutters for copper pipe

Rollers belong to the category of compact mini-pipe cutters, which make it easier and more convenient to perform work in hard-to-reach places. In the same category of tools you can find slightly different mini-designs, for example, from the “MiniCut Pro” series of tools from the famous company Rothenberger.

MiniCut Pro pipe cutters can process copper pipes with a diameter of 3 to 22 mm. The cutting radius of 38 – 45 mm allows you to work with pipes located in close proximity to the walls of buildings or in the presence of other obstacles.

With this type of pipe cutter, equipped with two guide rollers with a cutting groove, cutting can be easily done close to the flange. The tool is equipped with at least 5 spare cutting blades.

There are several more articles on our website that are devoted to the selection of devices for cutting pipes from various materials, we recommend reading:

- cutting polypropylene pipes.

- Uncover steel pipes.

- cutting metal-plastic pipes.

Mechanism selection criteria

When trying to determine which type of copper pipe cutter is better, you should pay attention not only to the shape and material of the cutter blade.

It’s clear here - the preferred choice is always:

- alloy steel;

- constant small working radius;

- sharp thin blade;

- possibility of replacing the cutting element.

The quality of the cut of a copper pipe is largely influenced by the support roller mechanism and the telescopic guide.The more support rollers there are in the pipe cutter design, the better and more reliable the device operates.

Also important for the design of a copper pipe cutter is the size of the width of the rollers and the presence of a cutting groove between them. With a larger width of the rollers, better stability of the position of the copper pipe during the cutting process is guaranteed, and the presence of a cutting groove enhances the cutting accuracy function.

The telescopic guide, traditionally part of the design of telescope cutters, must provide precise movement without the slightest lateral shift.

The design of a telescopic guide with automatic rollback is considered more convenient and practical. True, again, the reliability of such a system depends on the quality of the automatic rollback mechanism.

Adding accessories - this point is adopted by many manufacturers of copper pipe cutters. This addition, of course, does not change the technical characteristics of the design.

However, having spare parts on hand is also an important argument for the user in case of determining the best designs. Accessories (usually a spare cutter) are usually placed in the inside area of the propeller handle.

Pros and cons of electric models

Many professional craftsmen prefer manual pipe cutters if there is a need to work with copper pipes. Meanwhile, in addition to manual models, there are more technically advanced electrically driven devices.

In this case, the electric drive receives energy either from the built-in battery or from the network. That is, the tool does not lose its mobility properties, which is already an attractive point.

The cordless tool is equipped with an automatic material picking mechanism. The range of pipe diameters available to the cordless pipe cutter is 12-28 mm. The body of the device has backlight elements, which makes cutting convenient in poor visibility conditions.

An electric pipe cutter, of course, significantly reduces the user’s physical workload. All the owner of such a device needs to do is hold the 1.5 kg device in the desired position for a few seconds in cutting mode. For example, the MILWAUKEE C12 model, at an operating speed of 500 rpm, cuts a piece of pipe with a diameter of 12 mm in three seconds.

But the high cutting speed, and even in automatic mode, somewhat limits the quality indicators. Thus, the device does not allow cuts of copper pipes shorter than 12-15 mm, according to the instructions.

If you have no experience working with an electric pipe cutter, it is rarely possible to get a perfect cut due to vibrations from the motor. Finally, the working mechanism of an electric pipe cutter creates noise at a level of 70 dB (the permissible noise standard according to SNiP is 55 dB).

Therefore, for craftsmen (especially in the field of refrigeration technology), manual pipe cutters look like the best tool with all the available advantages of electric models. A manual cutter gives the master the opportunity to “feel” the stroke of the blade, set the optimal speed and depth of penetration into the body of the pipe.

As a result, the cut is smooth and of high quality, ideal for rolling or soldering.

Conclusions and useful video on the topic

The short video clearly demonstrates the process of cutting a copper pipe, and also gives tips on how to perform the steps correctly.

Selecting the right tool from the existing range of copper pipe cutters is easy. The market offers a lot of models of different designs, among which there is always the best option. The main thing is to have an idea of what criteria to use to select a device and what pipes a pipe cutter is needed to work with.

Still can't decide which pipe cutter to use for copper pipes? Or are you already using similar equipment? Please tell us about the advantages and disadvantages that you noticed while working with the device. Leave your comments and ask questions in the block below the article.

I very rarely deal with copper. I had to somehow repair the heat exchanger in the gas water heater. It’s clear that you can saw off anything with a grinder, but it won’t work with copper, you need the right cut.

I didn’t splurge on an expensive instrument; there’s no reason to do it once or twice.

I bought a Chinese mini roller, a little bigger than a box of matches. What’s interesting is that it cuts like a charm, very evenly due to the fact that the knife is sharp and does not make an oval. But still, a calibrator will not hurt; sometimes the geometry is broken.

Can you recommend a specific pipe cutter for 15 mm copper? I bought some nonsense from Leroy Merlin, so he bent a pipe inside for me, with a cross-section of 15 mm. became 12.

Take well-known and well-proven brands - Rems, Rothenberger, Reed. But in general, any roller pipe cutter bends the pipe inward to one degree or another.