Brass ball valve - how to select and install the design

Of all types of shut-off valves, the brass ball valve is rightly considered the most used for steel and metal-plastic pipes. Although many craftsmen install such valves on polypropylene PPR pipes, knowing that the original polypropylene taps are less reliable.

The content of the article:

What is

In appearance, the valve looks like a metal cylinder or barrel with a rotary handle on the side surface. The ends have threads - internal or external. When viewed through the open state, the insides of the valve look like an ordinary pipe, without ledges or transitions. Therefore, it is correct to call the device a full bore brass ball valve.

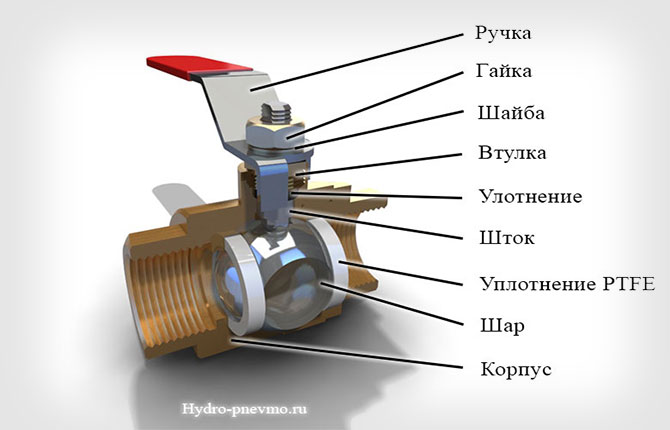

Structurally, the ball valve consists of four elements:

- brass body with or without protective coating;

- a metal ball is installed inside the body on a movable axis-rod;

- The ball element is sealed on both sides with sealing ring washers made of fluoroplastic.

- rotary handle.

Depending on the purpose, the handle on the rod of the ball element can be of a symmetrical shape (butterfly pattern). Blue color – for cold drinking water. Red is for hot. The remaining colors – black, green and white – are for technical fluids.

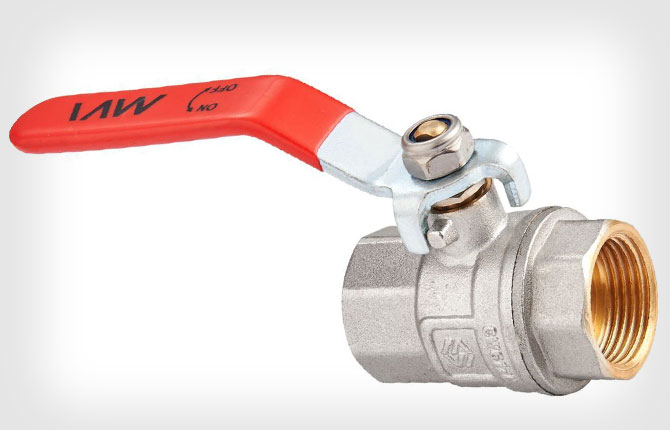

If the torque for opening the ball element is more than 2 N*m, then instead of the “butterfly”, a one-sided aluminum handle in a polymer case of the corresponding color is installed on the brass faucet. The rotary handle is fixed on the rod of the ball element with a hex nut.

Thread markings in inches are applied to the side surface of the brass faucet body. All other information - the brand name and the direction of rotation of the handle for closing and opening the ball valve - is applied to the polymer coating of the handle.

Ball valve body

The brass body may or may not have a nickel plating. In the latter case, the tap is made of brass alloy grade LS59; it is easily distinguished by its darker yellow tint. In this case, the ball element is made of alloy steel, and the sealing rings are made of fluoroplastic.

Most of the high quality imported full bore valves are stamped according to the European Union standard EN12165 from CW617N brass alloy. The new technology makes it possible to obtain housings with thinner walls, but the corrosion resistance is somewhat reduced.

Therefore, nickel plating is used to protect the brass surface. In this case, the thread and the rim above the threaded area are left without nickel. This helps not to confuse a brass faucet with models made of zinc-aluminum alloy TsAM or industrial valves made of AISI 316 standard stainless steel (08Х17Н14М3).

Rod and O-rings

The durability of a full bore valve depends on the design of the axis-rod of the ball element. The ball itself can be made of alloy steel if the ball valve will be used for pumping hot water or aggressive liquids.But more often, full bore models with a brass body use low-carbon steel balls with a chrome finish.

The ball element can be mated to the stem using a fixed or sliding fit. The second option is considered more preferable, since in this case the forces when turning the handle are not transferred to the ball and sealing rings made of soft fluoroplastic.

High quality brass faucets use an additional seal and a locking nut on the stem. A ball valve with a pressed rod serves 2-3 times longer than conventional models without leakage.

O-rings are made of fluoroplastic or its imported analogue - PTFE polymer. For larger sizes with threads up to 2”, Teflon with anti-friction additives can be used.

Performance characteristics

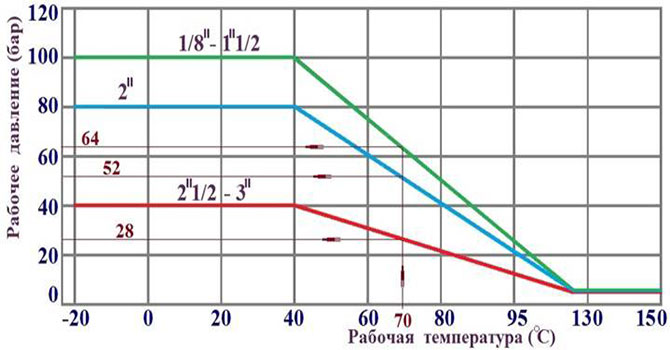

A standard brass ball valve made of L59 alloy is designed for a working pressure of 25-30 At. Branded models ½”-2” with a special rod seal and reinforced housing can withstand pressure up to 100 At. In this case, the temperature of the pumped liquid should not exceed 40 OWITH.

With increasing diameter, the maximum pressure decreases to 40 At. The brass ball valve for hot water can withstand no more than 6 At. The reason for the decrease in performance is the weak mechanical resistance of fluoroplastic rings to high temperatures.

Where is it used?

The main area in which valves with rotary balls are used is related to the supply of cold and hot water in domestic water supply networks, heating systems, irrigation systems, and pumping technical fluids.

Models

The most common is the coupling brass ball valve. It is easy to distinguish by the design of the case.The inlet or outlet has an external thread for connecting a pipe using a coupling.

In addition to the coupling circuit, the body can have a double internal thread for drives, or for “American”.

Since the ball valve is actively used to introduce water supply into the apartment, the conventional coupling version is often replaced with a model with a built-in filter.

There are also models with a shut-off valve for lifting water from the well, with a collapsible body. In the latter case, an expensive product can be repaired by replacing the ball or sealing rings with new parts.

For drinking and industrial water

The standard coupling model is suitable for connecting a home water supply to a riser. Firstly, a compact body without protruding parts, such as an old water valve made of cast iron or bronze. Secondly, you can use a model with a built-in coarse filter.

The following are connected using a ball valve:

- water supply outlets for plumbing fixtures - compact waste cistern, faucet in the kitchen sink, in the shower cabin of the bathroom;

- heating system on metal-plastic pipes.

In this case, you will need to select a model with threads for connecting fittings. Before buying a ball valve, you will need to familiarize yourself with the markings on the cylindrical band.

In addition to the pipe size and operating pressure, the model will be “registered” in the marking. This will allow you to check the possibility of using a ball valve for hot water using the manufacturer’s catalog.

For technical liquids

A valve with a ball system is also used for pumping corrosive media.They are installed on drainage pumps for pumping groundwater, in plant spraying systems, in food pipelines for juice, tinctures or decoctions.

The body of such a valve is usually made of brass alloys with a double galvanic coating of zinc and nickel. The threaded sections of the valve are mounted on a block with a ball using a flange method with an additional seal with sealant. As a result, the ball valve turns out to be collapsible with the possibility of replacing the inlet under the fitting with a coupling mount.

Why is the brass ball valve so widespread?

The ball valve has practically replaced the previously widely used valves and plug valves. Despite the fact that the last two varieties also used brass and rods. A brass faucet with a steel ball turned out to be simple and inexpensive, easy to install with your own hands, and does not require maintenance or repair.

The main advantage is that at a low price, a full bore valve provides minimal hydraulic resistance to fluid flow. For low-pressure water pipes, for example, in the heating circuit, in irrigation systems, in hydroponics, the absence of losses is a decisive factor when setting the water flow.

The cost of the ball valve turned out to be low enough to give up attempts to replace the most worn part - fluoroplastic rings. On the other hand, the use of a coarse filter retains more than 90% of all microparticles and abrasive suspensions. Therefore, with proper installation and regular purging of the filter element, a brass ball valve can last no less than a traditional water valve.

How to install at home

The easiest way is to install a faucet during the assembly of the water supply system.You can use any model you like with external or internal thread. It is best to choose the option with external and internal threads. Install it with the internal thread forward.

To install, screw a brass lock nut onto the pipe. Wrap sealing tape or tow along the external thread of the pipe, then turn the tap on with a wrench, grabbing the part by the hexagon made on the brass body.

On the opposite side, screw on the coupling with the drive. Wrap the body with a clean rag and lay FUM tape along the threads. Grab the housing with one hand and screw the coupling on with the other. After the first two turns have been captured, you can continue screwing the coupling with a coccygeal wrench.

The same method is used if a ball valve needs to be inserted into the gap between two pipes with finished threads. The only difference in the coupling is that in this case you need to use a part with left and right internal threads at opposite ends.

What to consider when purchasing

The best solution is to purchase a ball valve from a well-known brand, for example, VALTEC. It is necessary to clarify what kind of water this model is suitable for. Most brass alloys used contain lead, most commonly CW617N.

According to EN 12165 standards, the lead content should not exceed 2%. In the brass alloy CW617N, as well as in its domestic analogue LS59, the content ranges from 1.5-2.5%. Therefore, if you plan to use a ball valve for drinking water, the lead content must be clarified using the passport or certificate.

| Alloy grade | Content Cu,% | Content Sn,% | Content Fe,% | Content Al,% | Content Pb,% | Content Ni,% | Content Zn |

| CW627N | 57-59 | 0,3 | 0,3 | 0,05 | 1,6-2,6 | 0,3 | rest |

| LS59-2 | 57-59 | 0,3 | 0,4 | 0,1 | 1,5-2,5 | 0,4 | rest |

| CW614N | 57-59 | 0,3 | 0,3 | 0,05 | 2,6-3,5 | 0,3 | rest |

| LS58-3 | 57-59 | 0,4 | 0,4 | 0,1 | 2,5-3,5 | 0,5 | rest |

For process water, valves made of brass alloys CW614N are used. Such a ball valve can be used to connect plumbing or discharge wastewater.

Another nuance: a ball valve made of brass with a nickel coating can easily be confused in appearance with a similar product, but not brass, but made of ZAM. You can distinguish a zinc-aluminum body from a brass one by weight. Brass has a density of 8.4-8.6 g/cm3, TsAM – 6.7 g/cm3. In addition, TsAM is much softer, so it scratches easily.

A brass ball valve is much more convenient to use than a regular water valve. The device does not require maintenance and is easy to install with your own hands. But problems still exist.

Ball valve: video.

Share your practical experience in installing or servicing brass ball valves in the comments. What problems did you encounter? Is it worth using it in the home? Save the article to bookmarks and share it on social networks.

Buy cast models from LS59, imported ones - this is all for once. Most serve well for many years, but if you need to remove them and move them to another place, most likely nothing will work. Usually the body gets stuck to the thread on the pipe and at the slightest attempt to unscrew it, it bursts in the area under the thread. You can, of course, buy a ball valve with reinforced walls, but why bother, if you can take a domestic one made of brass LS59, it will definitely not burst.

From practice, I want to say, if you installed some Valtek, be prepared to close and open it at least once a month for preventive purposes. Otherwise, the ball element sours and sticks to the liners. Then you won't be able to open it, you'll just break the handle. The rest is all good, at least it doesn’t leak from under the stem.