How to make a heated film floor under linoleum: instructions for installing an infrared heating system

Linoleum is a relatively inexpensive and easy-to-install floor covering.But it does not always tolerate heating well. Therefore, when choosing a warm floor for linoleum, you need to focus on a number of factors. It’s worth familiarizing yourself with these guidelines, don’t you agree?

We will tell you which version of the floor heating system is best to choose for installation under a laminate flooring. Here you will learn how to install it, what technological rules should be followed during assembly. Taking into account our recommendations, you can arrange a comfortable space for living with your own hands.

The content of the article:

Choosing the right brand of linoleum

There is an opinion that linoleum is a completely synthetic floor covering that, when heated, releases chemicals hazardous to health, such as phenol.

Linoleum is also reproached for its poor ability to withstand heat. When exposed to high temperatures, the coating may noticeably deform.

Finally, the material was originally created not to transfer heat, but to protect from the cold penetrating from below. All this is true, but only partly. Linoleum is easy to install and moderate in cost, which is why it remains an extremely popular floor covering.

Modern technologies and developments have allowed manufacturers to create new types of linoleum.Among them there are those that perfectly transfer heat, tolerate moderate heat without compromising their appearance and do not emit any dangerous fumes.

There are five main types of linoleum:

- alkyd or griftal;

- nitrocellulose, also known as colloxylin;

- relin or rubber;

- vinyl, or rather PVC;

- natural, known as marmoleum.

Without going into details of the production technology, we can immediately note that the first three options are categorically not suitable for use with heated floors. All of them react poorly to heat, and Relin is not at all suitable for use in residential areas.

The most popular version of linoleum is its PVC version. This coating is very diverse in design and thickness, relatively safe, and has a pleasantly moderate price.After installation, vinyl covering almost always emits a not particularly pleasant characteristic odor, which dissipates over time.

However, PVC linoleum is not dangerous; it is suitable for premises where people live. When purchasing, it is recommended to study the labeling of the material; there should be a mark on the packaging stating that this coating is intended for installation on underfloor heating systems.

For example, ordinary linoleum can be equipped with an additional layer of heat-insulating material, which is completely unnecessary over a heated floor.

Natural linoleum, also known as marmoleum, is a cutting-edge word in the flooring market. The material contains exclusively natural ingredients, such as crushed cork bark, pine resin and linseed oil, powdered limestone and natural dyes.

Of course, when heated, such material cannot emit any harmful substances, only natural fumes. Marmoleum is sensitive to strong heat, so the issue of choosing a temperature regime for such a coating must be approached very responsibly. However, this is also true for vinyl materials.

Marmoleum can only be blamed for its substantial price, but the high wear resistance and safety of the material fully justify such costs. Marmoleum does not change color over time and also effectively resists fire.

When choosing linoleum for a warm floor, you need to pay attention to the thickness of the material.A coating that is too thin will expose all the unevenness of the base; an excessively thick material will reduce the efficiency of heating the room.

Infrared film is an ideal option

As you know, heated floors are divided into two main groups: water and electric, one of the varieties of which is the infrared version. The system that produces infrared radiation is energy dependent, since its operation requires electrical energy.

The film operates in a range favorable for coating, which is why infrared heated floors are considered an excellent choice for installation under linoleum.

As already mentioned, linoleum is sensitive to excessive heat. Even if the consequences of surface overheating do not become obvious immediately, over time they will manifest themselves in the form of deformation, softening, swelling, etc.

The optimal thermal power for linoleum is about 150-230 W per square meter of heated area. Infrared film provides exactly these parameters.

This material received the name “film” because of its appearance. This is truly a two-layer polymer film, inside of which are carbon heating elements with a unique nanostructure. It is this content that emits infrared radiation that can heat surrounding surfaces.

The heating elements, which look like black strips about 15 mm wide, are connected by contact bars made of copper and silver. A layer of polymer reliably protects this structure from damage. Infrared rays are considered not only harmless, but also beneficial to humans to a certain extent.

Film heated floors are not difficult to install, since “wet” work of pouring the screed is not necessary.This system ensures uniform heating of the room, is perfectly adjustable in automatic mode and can be integrated into a “smart home” type system.

Another positive point is the easy dismantling of the heated floor. If necessary, you can simply remove the floor covering, remove the film and lay it on a new base, even in a different room. Electricity consumption when using film systems is approximately 30% less than when using an electric heating cable over a similar area.

Preparing to lay heated floors

Before starting installation, you need to carefully prepare for the work. On a regular sheet of paper, you should draw up a plan of the room, marking on it the places in which stationary pieces of furniture or large household appliances that fit tightly to the floor will be installed. There is no point in laying infrared film here.

Then they draw up a plan for laying the film strips. The fewer cutting lines there are, the fewer connections will be needed, and the easier the installation will be. Therefore, strips of film are laid along the long side of the room. Once the plan is drawn up, you can calculate the length of the film and the number of connectors needed for installation. The plan should also indicate the installation locations of temperature sensors and a thermostat.

The delivery package for a heated film floor under linoleum usually includes infrared film and connectors, which are supplied in two pieces, temperature sensors and a thermostat, as well as bitumen tape, which acts as an insulator.

Additionally you will have to purchase:

- electrical cable;

- thermal insulation material;

- film for waterproofing the base;

- contactors (for work with high power systems).

To connect a film floor, a copper cable with a cross-section of at least 1.5 square meters is usually used. mm. As a waterproofing material, you can put a layer of polyethylene of at least 0.1 mm. The list of thermal insulation materials that are suitable for film flooring is quite extensive.

Can be used extruded polystyrene foam, cork materials, liquid composites, etc. Foamed polyethylene or laminated isolon is successfully used under linoleum.

In any case, you should study the labeling of the heat insulator to make sure that the material can be used with heated floors. The use of heat-insulating material with a metal foil coating is unacceptable.

The most complex tool that will be needed during installation is a special device for crimping contact connectors. But with some skill, ordinary pliers are suitable for this.

In addition, you need to prepare a screwdriver and wire cutters, scissors and a mounting knife for cutting the film, as well as insulating materials, a hammer, etc. Thus, infrared floor heating device Linoleum can be laid using the most common construction tools.

System Installation Guide

If the film layout plan has already been drawn up, and all materials and tools have already been prepared, you can begin work by preparing the base.It needs to be made clean and as smooth as possible.

The film itself is very thin, less than 0.5 mm. If the material is laid on an uneven base, the heating elements will be subjected to additional stress, which may cause damage.

In case of extensive damage, additional work should be carried out to level the base, for example, pour a new screed over the old base. But if the subfloor is initially fairly level, it is enough to clean it from dirt and dust and eliminate individual differences in height, if necessary.

A layer of thermal insulation material is placed on the prepared base. If it is a rolled material, then usually the strips are laid end-to-end and the joints are secured with tape. The insulation should lie very evenly; if the base is properly prepared, problems in this regard usually do not arise.

Cutting the infrared film into strips of suitable length is a crucial moment. There are special places for cuts, indicated by a dotted line. If you cut in other places, the film will probably be damaged.

The narrowest piece of film cut along the dotted line can be less than 20 cm, and the longest can be about 8 meters. This allows you to make strips of the required length in the required quantity. The fewer cuts, the easier the installation.

Cut strips of infrared film are laid out according to plan on top of a layer of thermal insulation material. In this case, the copper strip must be placed with the side up indicated by the manufacturer in the instructions.

The film should be carefully leveled so that it fits snugly to the base. The presence of an air gap between the heating strips and thermal insulation is unacceptable. After the film strips are laid, you can begin installing the contacts.

The connecting clamp is installed on the copper strip and clamped using a special tool or ordinary pliers. The connectors should be installed in such a way that one part of the element is between the layers of the film shell and attached to the copper busbar, and the second part is outside.

After this, you need to hide under pieces of bitumen insulation all the places where the bimetallic bus is connected to the power line. All strip contacts that are not connected to wires also need insulation. They are located on the side opposite the connection side.

After the insulation work is completed, you should use tape to fix the position of the film on the floor so that it does not move while laying the linoleum.

Now you need install a thermostat. It is usually hung on the wall in an easily accessible place.The connection must be made in accordance with the diagram. Inexperienced electricians should consult a specialist at this stage. Thermal sensors are placed under the film and connected to the thermostat with wires.

To hide the cable leading from the thermostat, you can make a groove in the wall. If the repair has already been completed, the cable is laid on top of the wall and covered with a decorative plastic box. Below, a plinth is used to disguise the cable. The edges of the cable providing power are connected using connectors and pressed with pliers.

Then the connection point is isolated. Thickening will appear where the insulation is installed, as well as where the temperature sensor is attached to the film. They can complicate further installation of the floor covering.

To prevent this from happening, you should use a mounting knife to cut out recesses in the layer of heat-insulating material. This will eliminate the difference in height, and the surface of the film will become even again.

On this laying heated floors under linoleum can be considered complete, all that remains is to check the characteristics of the system before installing the floor covering. To do this, power is supplied to the film. First, you need to use an electrical tester to verify the reliability of the insulation; you should check the absence of voltage in each isolated area.

After this, the degree of heating of each individual strip is checked. If there is no heat, or if some areas are colder or hotter than others, it means the installation was done incorrectly. Possible errors should be found and eliminated.

Problems usually arise from such violations as laying film strips not end-to-end, but overlapping; such a position of the heating material is unacceptable. You should also not cut the film too close to the copper busbar, as this may cause insulation damage. Complete or partial lack of insulation is one of the most common causes of underfloor heating failure.

Features of laying linoleum

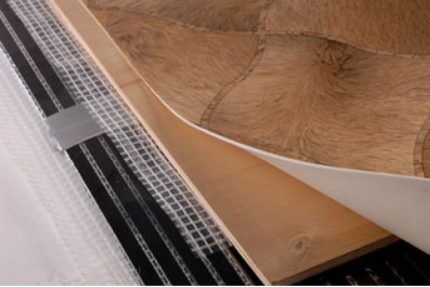

You will also need to prepare a base for the linoleum. First, a layer of polyethylene is laid on top of the infrared film. This material performs waterproofing functions.

Separate strips are laid with an overlap of 10-20 cm and secured with tape. In this case, you need to move along the surface of the infrared film very carefully so as not to damage the integrity of the graphite heaters.

Next, install a flat surface made of fiberboard. This material will reliably protect the heated floor and will become a suitable base for linoleum. This type of flooring is supplied rolled into rolls, so it is recommended to spread it out and leave it for several days before installation.

In the case of heated floors, the process can be improved. Linoleum is laid on a fiberboard base without fastening, and then the infrared film is turned on. Under the influence of heat, the leveling process will proceed faster. The thermostat should be set to 28 degrees or slightly less.For linoleum, this temperature is considered optimal.

After the coating becomes sufficiently smooth, all that remains is to secure the linoleum to the base. This operation is performed using double-sided tape or glue.

The use of an adhesive composition is considered more suitable for use with heated floors if dismantling and relocation of the equipment is not planned. The adhesive ensures a tight fit and uniform heating.

With the specifics of the design of floor heating systems on a wooden base And on concrete floor you will find out by reading our recommended articles.

Conclusions and useful video on the topic

This video demonstrates in detail and clearly the process of laying an infrared floor:

Film heated floors are an excellent choice for laying under linoleum. Installation of such systems does not seem too complicated, but it is deceptively simple.

When laying infrared film, you must strictly adhere to the work technology and strictly follow the manufacturer’s recommendations. This will allow you to avoid mistakes and install the system correctly to ensure a long service life.

Would you like to talk about how you built a floor heating system with your own hands? Would you like to share information that will be useful to site visitors? Please write comments in the block below, post photos related to the topic of the article, and ask questions.

I thought that linoleum was a thing of the past, but it turns out that such interesting varieties have appeared. I have to choose linoleum because my daughter does ballet and trains a lot. We equipped a whole room for it in our country house.At the same time, the best floor covering is linoleum. You have to work out in light clothes, well, in general, we dreamed of the opportunity to make a warm floor and combine it with linoleum. Of course, we won’t install it ourselves; we’ll involve specialists. Now we choose marmoleum and we will begin creating our heated floor.

Hello. Marmoleum has low thermal conductivity, so its installation on TP is not always rational.

I always thought that heated floors and linoleum were incompatible, but it turns out that progress has come a long way. They even came up with a special linoleum for such purposes.

But I don’t see the point in this, to be honest, except as a necessary measure, like Elena’s. Linoleum is good only because it is cheap, and if you buy a special one, then even this advantage is lost. So, it’s better to do it the old fashioned way, with laminate.

I have a film floor, with thin linoleum on top so as not to retain heat. Without glue, because glue vapors are harmful to inhale. And why glue it if we just put it on film without plywood?

Due to thermal expansion, the linoleum swelled along the edges of the film - that is, you can see where the film lies and where it is not... the linoleum swelled up in such islands. But these waves don’t bother me, it’s almost not noticeable.

Hello. Glue fumes are harmful (although there are different glues), but the fumes, combined with constant heating from ordinary linoleum, are also not environmentally friendly.

Is plywood required for linoleum?