Warm floor under linoleum on a wooden floor: step-by-step installation instructions

Classic heating systems are gradually being replaced by more economical types. Increasingly, country properties are being equipped with underfloor heating systems.A large number of owners of houses with wooden floors want to acquire alternative heating, which has become possible with the introduction of new developments.

We will tell you how to install heated flooring under linoleum on a wooden floor. In the article we presented, the design options for underfloor heating systems and the technologies for their implementation are analyzed in detail. Recommendations are given for laying linoleum over the heating circuit.

The content of the article:

Why should you choose heated floors?

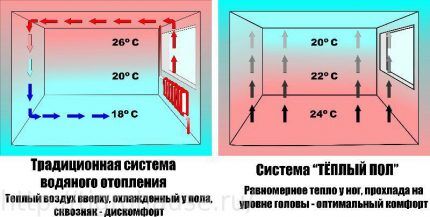

The classic use of heating systems involves the presence of radiators, which distribute their heat when heated, and then maintain warmth in the room. Typically, batteries are mounted at a certain height in the area placement windows or load-bearing walls. The air in the room gradually warms up.

Following physical laws, warm air masses rapidly rise upward. As a result, the top of the room becomes warm and the floor becomes cold. Thus, a large amount of energy is wasted inefficiently.

When using underfloor heating technology, heated air masses accumulate at the bottom, and slightly cooled ones accumulate in the upper part, under the ceiling. This option of temperature distribution with a difference of up to 2-4ºС is the most optimal and comfortable for humans.

The most efficient heating system

Home owners often think about which heating system to choose. A competent approach in this matter ensures the normal functioning of the project. Today there are two groups.

Option #1 - water heating scheme

Circulates through a reliable pipe structure coolant. This form of flooring is characterized by durability and efficient heat transfer.

The cost of a water system is lower than an electric one, but there are also disadvantages. For example, the path along the contours of a heated floor reduces the temperature of the coolant, so there is a limitation on the length of the lines.

But water floors are quite suitable for heating of individual housing, especially for the first floor. They are connected to the boiler, which creates a truly economical scheme.

The main feature of such a system is that its installation is carried out “wet”, in high-quality concrete screed. To do this, qualified installers maintain a given height and rules for the formation of a cement-sand layer on a wooden floor.

It is possible to place the screed on the subfloor, which will increase the load several times. In addition, here you will need to create high-quality waterproofing that will prevent the ingress of any amount of moisture. Thus, the floor height increases from 8 to 12 cm.

Option #2 - electric heating circuit

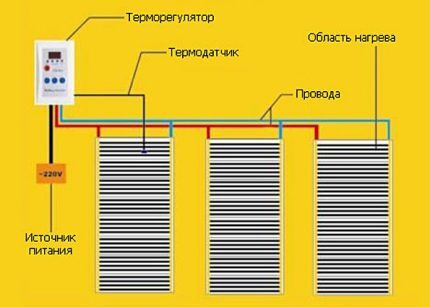

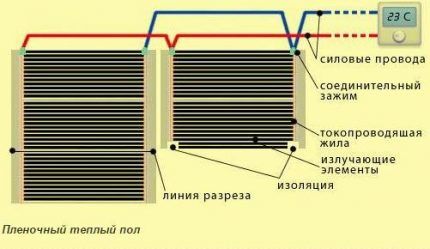

Infrared film products are a particularly productive and profitable option. The heating elements are flexible carbon-based heaters that have a laminated shell. In practice, a solid plate is obtained, symmetrically divided into heating sections.

The advantage of the film type of floor is that it transfers heat into the room evenly. The structure lasts a long time and does not require systematic and expensive maintenance.

Types of quality linoleum

The rational choice of floor covering is the fundamental basis for the successful implementation of a heated floor project.

The finishing material should be selected based on the degree of toxicity of the raw material.

Particular attention should be paid to the composition and safety of the special coating:

- Vinyl. The product is formed on a PVC base, which gives it a beautiful design. But when heated strongly, the material becomes a source of an unpleasant and pungent odor.

- Relin. The basis for the production of such linoleum is bitumen, synthetic rubber and high-quality rubber. The front layer has problems with heating, which does not allow its use in living rooms and premises.

- Nitrocellulose (colloxylin). The material has a high level of moisture resistance, but is easy to burn.

- Glypthal (alkyd). Fabric-based flooring cannot withstand high temperatures, which leads to significant deformation.

- Marmoleum. The environmentally friendly material has high quality workmanship, which gives it fireproof and antistatic characteristics.

Professional builders agree that linoleum is suitable for creating a water-heated floor marmol or vinyl type. A more economical option is alkyd modifications with a special film coating.

An important factor is the ability of linoleum to conduct heat. If this indicator is low, then there is no point in using it. Beware of purchasing flooring made from jute, various felts and foamed PVC.

Between the film heater and the relatively thin linoleum it is necessary to place a solid base, for example, plywood. By ignoring this recommendation, you will ensure that all flaws will be visible to the naked eye.

Preparing a wooden base

The builders claim that warm water floor It is also possible to lay it on an old structure. However, this will require careful preliminary surface preparation.First of all, it is necessary to eliminate cracks and gaps of different sizes. Otherwise, the system will not provide the expected operational efficiency.

Brief instructions:

- We sand the old coating.

- We mask cracks and gaps.

- We lay sheets of plywood.

- Having adjusted the fragments, we fix them with self-tapping screws.

The newly formed base must be treated with an antiseptic solution and allowed to dry.

Experienced craftsmen use functional scraping or a flat covering (plywood, chipboard sheet, etc.) to create a thin but durable base. With the second option, you should carefully ensure that the edges of the canvas fit tightly together.

Competent installation of electrical devices for STP

Careful preparation of all necessary materials for construction is an important point. When assembling a floor heating structure, it is necessary to purchase a high-quality film element. The product is laid at a distance of 50 cm from the walls.

If large objects on top do not allow heat to pass through, then it gradually returns back to the source. As a result, the conductor may burn out or become partially deformed. The exact amount of film is determined based on the technology and installation features.

For continuous operation of the heaters, clips are required that secure the contacts (2 units per separate strip). But first you need to lay thermal insulation material with a high reflection coefficient, as well as install thermostats and prepare copper wires.

Laying thermal insulation

Laying the thermal insulation layer does not take much time, but it is a very important step. The event is mandatory, since heat without a protective barrier will go up and down. As a result, a large amount of energy is wasted irrationally.

Each strip is attached to the base using stapler and double-sided tape. The strips are joined together without any gaps. The joints are carefully taped with tape.

Rules for forming a film floor

Process rolling out infrared film carried out above the insulator at a distance of 50 cm from the wall. In this case, the placement of the copper strip should be clearly at the bottom. If necessary, cut the material into equal strips based on the markings of the film sections.

Carbon based heaters must not be damaged. If you find scratches or tears on the product, then such places should be treated with bitumen-based mastic.This option is also excellent for insulating copper electrodes. The joints of the materials are securely fastened with special clamps.

The parallel connection diagram has the following sequence:

- The placement of the first contact on the surface of the electrode is carried out inside a special film. The second contact is carefully applied on top;

- strong and reliable connection is achieved due to tight pressing down electrode with a clamp using pliers.

After detailed laying of all strips of infrared film, a common web is formed by gluing with tape.

High-quality gluing of the fabric around the perimeter prevents slipping.

We bring to your attention the article - Is linoleum laid on parquet?.

How to install the thermostat correctly?

Installation thermostat in each room allows you to operate the floor heating system as efficiently as possible. Separate thermal sensors are glued to the IR film strips using mastic. In this case, each device must be securely fastened to a carbon thermal element.

The sensor wires are routed to the nearest wall. To avoid unevenness, a groove is cut out in the heat insulator for the cable.

In order to increase the efficiency of electrical protection, all devices with a power greater than 2 kW are connected to a separate circuit breaker.Setting the floor temperature to 30°C, wait until the film warms up.

In this way, the state and functioning of the system can be studied. If serious deficiencies are discovered, they are eliminated.

The last stage includes the installation of insulation - a polyethylene-type film that reliably covers the heated floor system. The product is carefully rolled out on top of the heating elements and fixed with small screws to the wooden base. This procedure should be performed carefully so as not to snag the electrodes.

Secrets of water-type heated floors

The implementation of installation work for this system format involves the formation of a special wooden base with grooves. This is where the pipes will be placed. An alternative option is to install them in polystyrene mats that are tightly covered with heat exchangers.

Complex of preparatory work

As a rule, logs are laid on a wooden base, on which a full-fledged floor is subsequently formed. The wooden elements are placed at the same distance of 60 cm and with equal height.

If you ignore these recommendations, the finishing linoleum surface will be skewed. A layer of protection against steam, condensation and water is evenly laid between the beams under the insulation.

The use of high-quality and original materials is the key to the successful implementation of the assigned tasks. Therefore, if you use regular film, the steam will accumulate in the insulation itself and gradually destroy it.

A wide layer of insulation in the form of mineral wool with a density of 40 kg/m3 or another type of product is placed on top of the waterproofing. At the end, the structure is covered with a special film with high-quality insulating characteristics.

However, do not forget to leave a small margin. So, for example, for a 16 mm pipe, a groove measuring 20*20 mm is perfect. The end of the base should have a narrow slot with rounded edges in the form of loops to provide rotation for the thermal channel.

Features of the pipe assembly process

There is one important rule at this stage installation of underfloor heating pipes. Flat foil should be placed on top of each longitudinal type groove. All elements must be tightly wrapped in metal “paper” and securely fastened at the edges stapler to the blackboard.

After such actions underfloor heating pipe It is attached to the floor with special plates on a metal base. This prevents the part from slipping out of the groove.

To save money in advance calculate the exact quantity required material. At the same time, they adhere to the established limit, in which the contour should not extend beyond a certain area. In practice, this leads to a lack of pressure for normal coolant movement and “locking” of the circuit.

Therefore, for a 16 mm pipe, a maximum pipe length of 70-80 m is recommended, and for 20 mm – 110 m. If the estimated length is not enough, then it is rational to split it into several circuits.

Communication with the heating system

One of the last stages of forming a water-based floor heating system is connecting to the heating unit. This operation can be implemented in several ways.

After connecting the elements, the process of crimping the pipeline is carried out. The procedure is mandatory, as it minimizes the risks of leaks and swelling of the coating. Preparing the base for installation of linoleum or laminate involves laying plywood sheets.

How should linoleum be laid?

The process of laying polymer material is carried out in several successive stages, namely:

- before installation, the product is kept indoors for about 24 hours;

- if the need arises, the linoleum is cut into strips and spread over the surface without fastening;

- turning on the heated floor, let the universal floor covering sit for another 48 hours;

- secure the material in the most practical and appropriate way.

When choosing options for attaching linoleum, you should give preference to adhesive mastic. The resin must be of high quality and original (from a reliable manufacturer) so that the heat is distributed evenly over the surface.

It should be remembered that infrared type film floor stands out for its ease of installation, and a competent water structure for its efficiency, reliability and durability.

You will become familiar with the rules and guidelines for installing heated floors under laminate flooring on a wooden base. next article, in which all stages of the full cycle of work are analyzed step by step.

Conclusions and useful video on the topic

To avoid mistakes when installing a heated floor, we suggest watching informative and useful videos.

Features of laying heated floors on wooden flooring:

Professional recommendations for installing FSW under linoleum:

By analyzing the above information, you can rationally determine which heating is right for you. You can carry out the installation yourself, but if you are not confident in your capabilities, just invite professionals. Qualified specialists will efficiently carry out projects of varying levels of complexity, while you will save personal time.

Do you have experience installing heated floors in a house with wooden floors? Maybe you have technological subtleties in your arsenal that will be useful to site visitors? Please write comments in the block below, ask questions on controversial issues, post photos related to the topic of the article.

I’ve heard about the “warm floor” system for a long time, but I didn’t think that it would be more effective than conventional pipe heating. Having visited a friend, I realized that in a house with small children, heated floors are a very good alternative to conventional heating. Heat comes from below and rises to the top. I decided that this season I will install an electric heating circuit under the linoleum in the children's room. It seems to me that it distributes heat more evenly.

The best option, in my opinion, is to combine heated floors with radiators. Because, for example, electric heated floors are sensitive to furniture. I have radiators in the corner rooms and hallway, and everything else is heated only by underfloor heating.Even in the coldest weather the house is warm.