Infrared film for heated floors: types of films, how it works, installation rules

Warm floors in a house or apartment have long ceased to be considered an excess.Users appreciated the practicality and convenience of the unique heating system, and new heating methods began to appear.

Infrared film for heated floors is recognized as one of the most popular technologies, combining operational efficiency, versatility of use and ease of installation. Different types of thermal film have similar principles of operation and installation technology.

The content of the article:

Advantages and disadvantages of “film” heating

In search of an alternative way to heat rooms, scientists paid attention to the heat exchange in the environment that occurs due to the action of infrared rays. The interpretation of the natural process formed the basis for the creation of IR film.

The film coating releases thermal energy in the infrared range. Long waves of radiation heat surrounding objects, which in turn accumulate and transfer heat to the air.

The use of infrared film for installing heated floors has become widespread due to a number of advantages:

- Versatility. Almost any floor covering can be laid on top of the heating layer. Using film you can insulate walls and ceilings.

- Easy to install. To create a heated floor system, you do not need to dismantle the old base, and you can perform the procedure yourself. No specialized equipment is required.

- Heating temperature adjustment. A thermostat with a wide range of modes is connected to the heating system. Additional control settings are possible: timer function, dividing the room into different heating intensity zones, etc.

- Mobility of a warm floor. When moving to another place of residence, the structure can be easily removed and spread on another surface.

- Compactness of the system. The thickness of the IR coating (up to 0.5 mm) has virtually no effect on the height of the floor, which is especially important for rooms with low ceilings.

- Low inertia. The film “turns on” quickly and the effect becomes noticeable within a few minutes.

- Uniform heating. The entire room is heated; there are no “hot” or “cold” zones.

- Maintaining a healthy microclimate. IR rays do not dry out the air and do not burn oxygen. Manufacturers of “film heating” point to the therapeutic effects of infrared radiation. The air is ionized and cleansed of bacteria.

Thanks to modularity, the breakdown of one section of the film does not lead to a malfunction of the entire system.

Innovative technology also has negative qualities:

- The electrostaticity of heated surfaces increases, and objects begin to attract more dust.

- After turning off the heating system, the room quickly cools down.

- When installing, it is important to consider the placement of furniture. Where bulky furniture and large appliances will be located, IR film is not installed. Failure to comply may result in system overheating.

- The operation of a heated floor leads to an increase in energy consumption.

- The coating is resistant to moisture and contact with sharp objects.

Installation of “film” heating must be done carefully and in compliance with safety standards.

Design and principle of operation of IR film

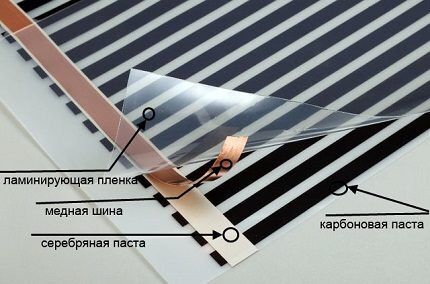

Infrared film is made of durable polymer. During the production process, carbon-graphite strips are applied to the flexible fabric. The semiconductor sections are connected by copper and silver busbars.

Functions of the main layers of IR film:

- Carbon paste or carbon fiber sheet is a heating element that converts electricity into heat.

- Foil strips (copper bars with silver) form a heating circuit and evenly distribute thermal energy over the surface of the film. This element is controlled by a temperature sensor - when heated to the desired temperature, the supply of electricity stops.

- The laminating coating is a protective electrical insulating and heat-resistant layer (melting point of the material is 210°C).

The carbon nanostructure has unique parameters. The atoms of the substance, formed into a hexagonal network, give the material the ability to emit in the IR spectrum.

Operating principle of infrared floor film:

- Electric current is supplied to the system.

- The current passing through the heating elements (foil strips) is converted into thermal energy.

- The nanocarbon components are heated and generate infrared waves, the range of which is 5-20 microns.

- The rays hit interior items, walls and furniture. The heated elements warm up the air in the room.

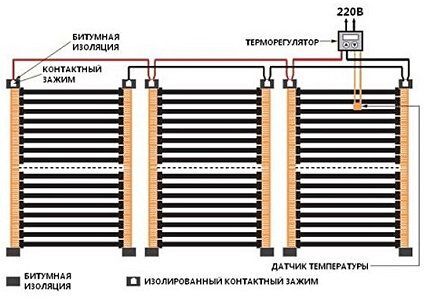

In addition to the film, the infrared heated floor system includes: thermostat, temperature sensor, contact clamps and insulating materials.

He will familiarize himself with the types of carbon heated floors used in the design of residential premises and the peculiarities of their installation. next article, which we recommend reading.

Material Specifications

The data below on infrared film for heated floors is of an overview, average nature. The specific characteristics of the product must be clarified when purchasing.

The proposed data is sufficient for planning the location of the canvases, marking the base, and calculating power. Based on the technical features, you can understand whether the IR system is suitable for use in specific conditions.

Thermal film performance:

- Roll width is 50-100 cm. For domestic purposes, as a rule, coverings with a width of 50-60 cm are used. When arranging a bathhouse, office or industrial facility - 70-100 cm. The total energy consumption is almost the same, but wider material will cost more.

- Strip length – 6-50 m. The maximum permissible value is determined by the manufacturer. In a long room, it is advisable to make separate connections in halves with the installation of two thermostats.

- Power supply is 220 V. A household single-phase power supply is used.

- Peak power consumption – up to 150-230 Vm. The parameter depends on the manufacturer and type of film. On average, to maintain the room temperature at 21-24°C (30°C on the surface of the film), energy consumption will be 25-45 W/sq.m.

- The melting point of thermal film is 210-250 °C.If all rules for laying heated floors are followed, the surface temperature of the IR coating will never reach critical values.

After switching on, the film heats up to maximum temperature in 2-3 minutes.

Types and features of choosing thermal film

In structure and principle of operation, infrared films are similar to each other. The main difference is the composition of the heating element and its maximum heating temperature. In addition to these parameters, when choosing, special attention should be paid to quality “assemblies” of thermal film and the reputation of the manufacturer.

Types of IR films for heated floors

Depending on the type of heating element, films with a carbon or bimetallic heating element are distinguished.

Features of the structure and use of carbon IR coating:

- heating elements are made of carbon fiber (carbon paste with additives);

- graphite-coated specimens are highly durable and have a long service life;

- The coating is based on a wear-resistant, elastic and durable Mylar film with good dielectric properties.

Carbon film is used for arranging horizontal and vertical surfaces.

The disadvantage of carbon-graphite material is its high cost.As a more affordable alternative, you can use bimetallic thermal film.

Features of infrared heated floors with “bimetal”:

- the heating element contains two metal layers: aluminum and copper;

- the basis of the material is double elastic polyurethane film;

- A grounding wire cannot be connected to the system, so the elements are connected through an RCD or RCBO - this complicates the installation of a heated floor.

IR film with a bimetallic element cannot be laid under ceramic tiles. It gets along well with other coatings.

According to the heating level, thermal films are divided into two categories:

- High temperature ones provide heating up to 55°C. Their use is relevant in rooms where underfloor heating is the main source of heating. This material can be used under tiles, expanded clay covering, when installing infrared saunas or as baseboard heating.

- Low-temperature models heat up to 25-27°C. Optimal use is installation under laminate, linoleum, parquet and carpet.

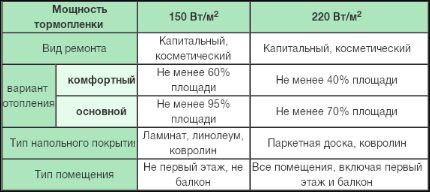

The variety of IR films is conventionally classified according to power consumption. The choice of this parameter is influenced by the purpose of the material and the heating area.

Power density ranges:

- 130-160 W/sq.m – heating a small area, laying under “light” floor coverings;

- 170-220 W/sq.m – film for porcelain stoneware and tiles, as well as for spacious rooms;

- over 220 W/sq.m – installation of a heated floor system in industrial buildings, car paint shops and infrared saunas.

When choosing power, you must also take into account the height of the ceilings. The smaller it is, the more cost-effective and efficient the heating will be.

Signs of a quality product

When choosing IR film, experts recommend carefully inspecting it.

The quality of the coating can be determined by its appearance:

- The milky shade of the base indicates the use of a fireproof and high-strength polymer. A completely transparent base is a cheaper alternative that can be thermally deformed.

- Conductive strips must have clear boundaries. No show-through or damage is allowed. The silver part can protrude beyond the copper bus by 1.5-2 mm, the minimum strip width is 1.5 cm.

- Copper and silver strips must be connected in a “dry” way - under high temperature (90°C) and pressure. The “wet” method is less durable - the elements are fixed together with conductive glue.

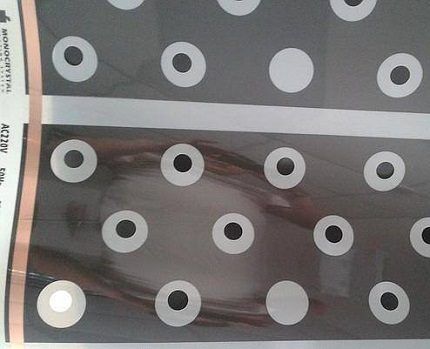

- The optimal arrangement of carbon-graphite emitters is solid or striped. Non-standard variations of spraying are a marketing ploy. The efficiency of the film does not increase with complex geometric strip shapes.

- Wide canvases are easier to install. In addition, the risk of overheating is somewhat lower compared to narrow counterparts.

The outer lamination of the IR film must be made of the same polymer as the base. It is permissible to use a coating of less thickness.

Review of popular IR film manufacturers

Wide demand for heated floors has provoked an increase in the number of IR film manufacturers. The principle of operation of the offered products is the same, so the main criterion when choosing is the ratio of quality and price.

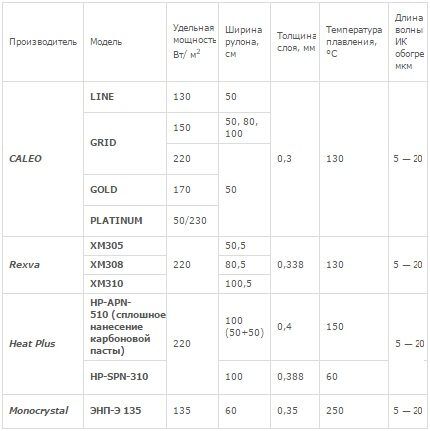

The following companies have proven themselves well in the market: Caleo, Rexva, Heat Plus, Monocrystal, Devi, Ensto Electrification, Teplolux, etc.

Caleo (Korea). The company has developed a line of thermal films - from simple solutions to ultra-modern self-regulating systems.

The manufacturer offers four modifications of thermal film:

- Line – budget low-power option for compact spaces;

- Grid – high reliability at an affordable cost; a patented technology for using anti-spark silver mesh has been introduced;

- Gold – models with a silver grille and a self-regulating effect – after heating, energy consumption is reduced by 20%;

- Platinum- energy-saving films with variable power - power consumption is reduced by almost 6 times.

Caleo Platinum thermal film can be installed under furniture without the risk of overheating.

Rexva (Korea). The heating element consists of carbon strip rods with a high-strength polyester coating. The ultra-thin film is installed under the finished floor, on the ceiling or behind a wall panel.

Heat Plus (Korea). The company produces striped and solid thermal film. Uniform application of carbon fiber on a polyester base allows you to avoid “dead” zones, expand the heating area and increase the efficiency of the system.

Monocrystal (Ukraine). A product of joint development by employees of NPK Monocrystal and scientists from Kharkov based on Korean technologies. The peculiarity of the material is the presence of a thicker carbon layer, which made it possible to abandon the use of silver paste. This alternative does not affect the stability of the electrical contact.

To get a more complete picture of thermal film from different manufacturers, it is necessary to compare product characteristics.

One of the characteristic representatives of film heating systems is PLEN brand products, we recommend that you familiarize yourself with the principle of operation, varieties and installation of which.

Rules for laying heated floors

The process of installing a heated floor from thermal film is quite simple. However, obtaining an effective, safe and durable heating system is possible if a number of rules are observed at each stage of the work.

The standard installation procedure includes a number of traditional steps that are mainly used for installing any type of carbon film floor:

If the inspection reveals weak connections or incorrectly applied bitumen insulation, we correct the errors, and then proceed to assembling the system.

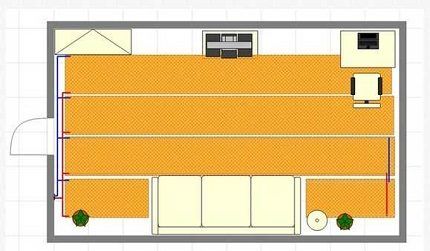

Project development and calculations

Before installing the coating, calculations are made and a film layout project is created. The first step is to draw a floor plan and highlight on the sketch areas for furniture installation - thermal film does not fit in these areas.

When calculating, some nuances are taken into account:

- If the film floor is the main heating system, then the area of the IR film should be 70-80% or more of the surface of the entire room. When a heated floor is an auxiliary heat source, its coverage area cannot be less than 40%.

- The distance between the wall and the thermal film is 10-40 cm. The minimum distance to furniture is 10 cm.

- The cutting of the material must be done so that the length of one blade does not exceed 8 m.

When calculating the power of the system, you should take into account the volume of repair work, heating option, type of room and floor covering.

Requirements for foundation preparation

Preparing the site for installation includes the following steps:

- Grooving the wall for wires and installing a temperature sensor. The wiring must be in a plastic corrugated pipe.

- Checking the evenness of the base. Permissible horizontal deviation is 3 mm. Small differences and chips can be removed using a thin layer of self-leveling floors.

- The surface must be clean. The subfloor must be vacuumed, washed and dried.

- Laying waterproofing film.The layer will protect the IR system from moisture penetration from below.

- Insulation of the base. The requirement is relevant when installing heated floors in a private house or in an apartment on the ground floor. Foil insulation is suitable as a heat insulator - installation is carried out with the metallized side down.

It is necessary to check the tightness of the junction of the floor and walls. Minor cracks can lead to significant heat loss. All recesses, defects and chips must be “embroidered”, cleaned and filled with construction foam.

Installation and connection of the system

Laying of infrared film is carried out in the following order:

- Make markings for placing the sheets, taking into account the distance between the edges of the thermal film - 5-10 cm. Overlapping of the coatings is unacceptable.

- Cut the film into strips of the required length. The incision is made along the cut line indicated by a dotted line or scissors.

- Lay the canvas according to the markings with copper strips down.

- Secure the film to the base with tape - not in a continuous strip, but in small squares.

During installation, it is necessary to minimize walking on the IR film, do not place heavy objects on the coating and do not drop tools.

Connection sequence for the heated floor system:

- Connect clamps to the ends of the copper busbar.

- Install the wires, observing the requirement of parallel connection - left with left, right with right.To simplify the task, you can use wires of different colors.

- Install a temperature sensor in the center of the heating strip, deepening it into the insulation. The distance from the wall to the meter is at least 50 cm.

- Insulate all connections. Tarmac pads are used on both sides of the terminals. By analogy, process the ends of the copper busbar in the cut areas.

Finally, the wires are connected to the temperature controller, which is then mounted on the wall.

The thermostat is installed at a height of at least 20 cm from the floor, optimally 1 m.

Safety measures when performing work

When installing an infrared heated floor, you must follow safety precautions:

- The heating film roll must not be connected to the power supply;

- during installation of the coating, the network must be de-energized;

- it is necessary to exclude contact of the thermal film with fittings and communications;

- It is better to refrain from installing film heated floors in places with a high risk of moisture;

- Do not bend, break or cut the heating cable;

- The film is laid at positive temperatures.

Warm infrared floors must not be placed near heating devices: stoves, fireplaces, etc. It is unacceptable to use screws and nails to secure the covering.

He will familiarize himself with the types of electric heated floors, the rules and features of installing systems. next article, which we recommend reading.

Conclusions and useful video on the topic

Video #1. Operating principle, technical and operational characteristics of IR film in a heated floor system:

Video #2.Types of infrared film and recommendations for choosing material:

Video #3. Rules and procedures for installing heated floors with thermal film:

The operating principle of infrared film is based on natural heat generation processes. The material has a lot of advantages and is highly appreciated by consumers - the scope of application of IR film is multifaceted.

The coating is most in demand when installing heated floors. By observing all technological requirements, you will be able to install an effective heating system yourself.

Please write comments in the block below the text of the article. Tell us how you selected and installed the film heating floor. Ask questions, share useful technological nuances, post photos on the topic.

We chose this option for the apartment; for us it turned out to be the most optimal solution. We made the bed in the living room, and now in winter the problem with cold feet has disappeared. They hired a specialist to install it. The main difference is that installation and connection are simple. They installed it in the shortest possible time and put a laminate on top. Regarding energy, I won’t say that he eats a lot.

Even if used as an additional source of heating for something, it takes not so little electricity. But the thing is convenient, you can’t argue with that.

We have long wanted to make heated floors in the kitchen and bathroom. The store recommended that we do it using infrared film and told us which manufacturer was better. My husband doesn’t trust anyone, so he installed it himself, and as it turned out, everything was simple. We turn it off at night to save electricity.And in the morning, as soon as we get up, we immediately turn it on, a couple of minutes and the floor is already warm. Very comfortably.