How to make an infrared heated floor with your own hands: installation and connection of a film floor

The film-type infrared heated floor system is one of the innovative and unique developments that allows you to solve problems that arise when arranging home heating.

Let’s take a closer look at how to choose the right components for the system and install an infrared heated floor with your own hands.

The content of the article:

How does the IR system work?

Infrared heated floors are a rather complex system that you cannot make yourself at home.

The system is based on a unique nanostructure that is capable of generating infrared radiation invisible to the human eye.

Film systems are made of strips of carbon paste - high-strength carbon fiber, which are hidden under a heat-resistant polyethylene film.

All strips, the thickness of which does not exceed ten millimeters, are located at an equidistant distance of 10-15 mm and are parallel connected to each other by flat current-carrying busbars protected by a silver coating.

The core systems are based on graphite-silver rods, inside of which carbon material is laid. They are connected to each other by stranded wires and sealed in a protective copper sheath. The systems are produced in the form of individual cables or ready-made coils.

Infrared rays in such systems act linearly, and therefore cause heating not of the surrounding air, but of objects located inside the room: flooring, furniture, walls and ceiling. Thanks to this property, the speed of infrared heating is much higher than traditional analogues - electric and water systems.

Among the undeniable advantages of infrared film heated floors are:

- Environmental friendliness. Infrared rays are similar in effect to sunlight and therefore have a beneficial effect on all living organisms. They have no side effect.

- Easy to install. The design features of the system make it possible to carry out high-quality installation with minimal cost and effort, possessing only basic construction skills.

- Compatibility with different types of coating. Installation of infrared heated floors can be done immediately “dry” under carpet, parquet boards, linoleum or laminate.

Due to the fact that the heating elements in the film system are tightly laminated with a polymer layer, they are not afraid of accidental dents and punctures, as well as exposure to moisture. But even if one of the carbon strips is damaged, due to the parallel connection circuit, the remaining elements will continue to work.

The thickness of the thermal film does not even reach 5 millimeters, and therefore practically does not “eat up” the height of the room. Thanks to this, it can be safely installed under almost any covering.In addition, such film can be placed on vertical surfaces, fixed to walls and ceilings, providing zonal heating of the room.

For this reason, film material is laid only in those areas where large equipment and furniture will not be placed. Caution should be exercised when using IR systems in damp areas, as there is a risk of electric shock.

Electricity consumption for operating an infrared heated floor directly depends on the operating mode of the system and the working area of the room. We also recommend that you check out our other article, where the film type of heating for rooms is described in detail.

Selection of system components

In addition to carbon heating strips sealed in Mylar film, the film floor system requires a thermostat equipped with a temperature sensor.

Film options

There are many options for film flooring on the modern market. And they all have approximately similar characteristics: power consumption from 25 to 80 W/h, and operating temperature from 30 to 50 °C.

There are two types of film systems on sale:

- solid – in them the film is completely covered with carbon material;

- striped – in them, carbon material is applied to the surface in the form of strips 15-20 mm wide.

The difference between them is that in continuous systems the material is applied by rolling it over the surface in the form of a paste, while in striped systems it is applied by fragmentary spraying.

The thickness of the material can vary from two microns to 0.4 millimeters. The roll length is 50 meters.

There is an opinion that it is better to choose the thinnest films. But, as reviews show, the smaller the carbon layer, the faster the system fails. Therefore, it is more advisable to purchase material no thinner than 3 mm. For example, for European countries and the USA, the optimal option is a material thickness of 0.338 mm.

Such systems are not cheap. The average price range of film IR systems from leading manufacturers varies between $20-25 per square meter. You can read more about the types of film heated floors in this material.

Calculation of the required quantity

Installation of film flooring with infrared heating is carried out only in the usable area of the room.

The percentage of area covered depends on whether the IR system acts as the main or additional heat source:

- 80% area – as the main heating;

- 40-50% area – as a complement to radiator heating.

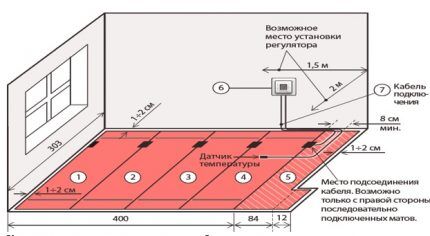

A pre-drawn diagram of the system zones layout on a sheet will help determine the total length of all strips. By calculating the length of each fragment and adding up their number, it is not difficult to calculate the required total length of the coating.

To prevent premature failure of the floor system, it is necessary to distance yourself from the central heating pipes and risers when laying them out. The laid strips should not intersect or overlap each other.

When placing fragments on the plan and calculating their length, also keep in mind that the length of each strip should be a multiple of 17-18 centimeters, since it is in these places that the cutting lines are located.

Thermostat for temperature control

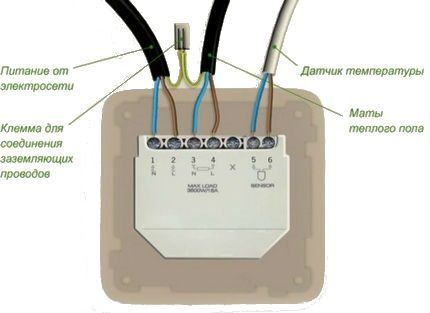

The operation of the IR system is controlled by the thermostat. The temperature sensor included with it is placed between the heating elements and connected to the device through contacts. The sensor reads the temperature from the surface of the film and transmits the data to the thermostat, which, in turn, operates and puts the system into operation.

There are a huge variety of options for modifications of regulators that differ in functionality on the market today.

All of them are divided into two types:

- Mechanical – equipped with keys and mechanical wheels and suitable for arranging small systems.

- Electronic – equipped with push-button control and display, suitable for small, unzoned rooms.

Programmable models are equipped with touch screens, with which you can set 4 time modes at once, thereby saving up to 50% of energy consumption.

Temperature sensors, depending on the type of device and type of floor covering, come in two versions. For soft surfaces they are available in the form of compact plastic containers.For hard ones - in the form of larger elements equipped with gel protection against the impact of adhesive compositions on the strips and to prevent mechanical damage.

When choosing a device, you should focus on the power of the thermostat. It is calculated based on the fact that one square meter of film consumes on average 50-70 W. To determine the required value, the indicator is multiplied by the size of the working area covered with heating elements.

Budget models operating from the network often suffer from the fact that in the event of a power outage they cannot resume operation on their own. Therefore, it is better to give preference to models that have a battery. Read more about choosing and installing a thermostat for heated floors Further.

If the film system is supposed to be combined with a porcelain stoneware or tile coating, you will need to build a cement-sand screed

Installation of infrared heated floor

Installing an IR system under a particular coating has its own characteristics. So, if you plan to use soft materials such as linoleum or carpet as a finishing coating, you should lay sheets of fiberboard or plywood as a layer between the heating strips and it.

The hard layer will protect the film from “injury” due to the coating being pressed through by the legs of heavy furniture or women’s heels.

In any case, the installation of an infrared heated floor system is carried out in several stages.

Purchasing materials and tools

In addition to the IR film itself, it is also necessary to purchase a roll of thermal insulation material, as well as metallized or single-sided construction tape to fix it. The film itself is attached to the base using double-sided tape.

To carry out the work you will need a set of tools:

- grinder equipped with a disc for stone;

- perforator;

- knife or scissors;

- pliers or pliers;

- construction mixer;

- notched spatula;

- wide brush;

- container for mixing the solution.

If you have not yet drawn up a layout diagram at the stage of choosing the material, you need to do this now, taking into account not only the size of the room, but also the width of the strips used.

The location of the films can be either longitudinal or transverse. The best option should be chosen based on material savings. But still, experts recommend placing stripes in length. This allows you to minimize the number of connection points.

Preparing the base base

When preparing the base for laying the IR system, it is not at all necessary to dismantle the old coating. Dismantling will be required only if the base base is severely damaged and the surface is “strewn” with deep cracks and potholes.

According to the standards, the permissible height difference of the base base under the film system is only 0.2-0.3 cm per linear meter, regardless of the direction of the control rod or building level applied to the surface.

The technology for laying an IR system involves installing a heat-insulating layer, the main task of which is to prevent heat leakage through the floor slabs, thereby increasing the efficiency of the system.

The best insulation material is:

- Izolon or Penofol– roll insulation made of foamed polyethylene. They have excellent waterproofing qualities, because... during the foaming process, closed cells that do not allow water to pass through are formed;

- Cork backing – compressed particles of cork wood mixed with the binder suberin.

When installing heated floors, priority is given to substrates with a lavsan metallized or foil shell. It enhances heat transfer due to its own reflective effect.

The structure of the listed materials will prevent the absorption of moisture, performing the function of a waterproofer, and the reflective surface will direct the generated heat directly into the room, and not to the underlying floor.

The substrate is spread over the entire area of the room close to the walls. The joints of the strips laid on the floor are fastened together with masking or aluminum tape. If the thickness of the material is small, the strips laid with a slight overlap can be secured with construction staples.

Laying the film system

In accordance with the markings, the film is cut into separate fragments, taking into account that the maximum length of a solid panel should not exceed eight meters. Cutting can be done with scissors or a knife. The cut strip fragments are sequentially laid out on the substrate according to the drawn up diagram.

The film pieces are laid face up or down in accordance with the manufacturer's instructions. The IR system strips are placed strictly according to the instructions. For example, strips of Caleo film flooring are laid with a side overlap so that there is a gap of 1 cm between adjacent copper bars.

If there are brands whose manufacturers recommend laying strips without overlap and with a more impressive distance between the tires. When laying, it is not allowed to bend the carbon strips at an angle of 90°, as this may damage a fragment of the system.

If necessary, the strips are trimmed along the perimeter of the room, making cuts in the places strictly marked with a dotted line on the film. Approximate dotted stripes for the incision are usually located every 18 cm.

To fix the film to the surface, use double-sided tape. This solution allows you to prevent the elements from shifting relative to the markings and each other.In the process of laying strips of infrared heated floors, it is important to prevent damage to the material, which often happens when tools used during installation accidentally fall on them.

We also have other materials with a detailed description of the process of laying the film system, depending on the type of flooring. We advise you to familiarize yourself with them

- How to make a heated film floor under linoleum: instructions for installing an infrared heating system

- Warm floors under laminate: installation and installation of an infrared film system

- How to make an electric heated floor under tiles: film and cable options

System connection diagram

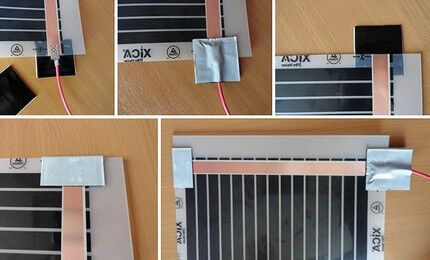

Each strip is equipped with a copper clamp that securely connects to a conductor made of the same material. To connect the terminal, you will have to separate an area of 8-10 mm from the cut from the lamination, and carefully separate the silver and copper busbar at the edge.

The contact is inserted strictly in the middle of the end of the conductive busbar so that one of its sides is in contact with it, and the other is adjacent to the inside of the film. The contacts are crimped with pliers, trying to prevent sparking.

Current-carrying wires with the “tails” of the conductors stripped by 10-12 millimeters are brought to the contact terminals and connected: to one – “0”, to the other – “phase”. The connected terminals are carefully clamped with pliers or pliers.If it is possible to use soldering, the wires can simply be soldered to the busbars, and the joints can be sealed with insulation.

After connecting each piece of film, you need to check the fixation of the clamp by lightly tugging on it. It should not move relative to the film.

The strips are connected using a parallel circuit. This means that the wiring will only be connected on one side. For “powering”, stranded copper wires with a cross section of 1.5 sq. mm are used.

The connections between the clamp and the wires after crimping with pliers, as well as the cut areas of the copper bus on both sides, must be insulated with pieces of vinyl-mastic tape, which is always included with the system.

At the free ends of the wires attached to all sections of the heating film, the circuit resistance is measured. Ideally, the calculated load value should be 20% lower than that declared by the manufacturer of the selected thermostat model. If the resulting load corresponds to the maximum permissible value of the selected thermostat, proceed to connect it.

Installation of the control device

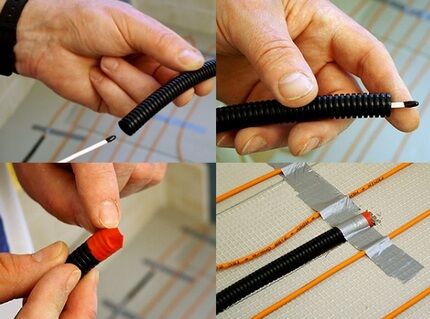

In order for the heat regulator to work correctly, a temperature sensor is fixed to the underside of the heating sheet using tape. Its installation is carried out using a 16-mm corrugated pipe, included in the factory package.

To prevent a bump from forming at the point where the temperature sensor is installed, it is recommended to make shallow grooves in the base and the heat-insulating layer. The location of the device is chosen as close as possible to the thermostat.The distance from the wall should be at least 30 cm.

There are no special requirements for installing a thermostat. It can be placed in any accessible place, hidden from direct sunlight. However, you should choose a place for its installation in advance, because... It is better to lay the strips of the film system with the contacts facing the wall on which the control device will be mounted. This method reduces the length of connecting wires.

The installation option can also be anything:

- outer – in which the device is fixed directly to the wall surface;

- hidden – involves creating a recess in which the device will be hidden.

To perform hidden installation in the wall, using a grinder or a hammer drill, grooves 20 mm deep are made into which the electrical wiring is laid.

The technology for installing a thermostat is not much different from the process of installing a conventional electrical outlet. To create a “nest” in the wall, use a crown to make a niche into which the socket box is buried. Place the device at a height of 80-90 cm from the floor level.

Having connected the thermostat, all that remains is to connect the free end of the temperature sensor placed in the corrugated pipe to the sensor terminals.

Trial run of the IR system

After completing the installation and connection of the infrared heated floor, it is necessary to check the functionality of the system. Before starting, you should check the reliability of the insulation of the connection points. First, the test is performed using a tester. System performance must correspond to those specified by the manufacturer.

After starting the system, you should carefully check the uniform heating of each element. If problems are detected in individual fragments, they are eliminated or sections of strips are replaced with new ones.

If, when turned on, everything heats up evenly, and the contacts do not “smell” or spark, you can proceed to the stage of installing the floor covering. It is better to save the installation plan for the IR system by attaching it to the product passport or sketching it on the back of the warranty documentation.

We also invite you to familiarize yourself with our other material, which describes in detail the rules for installing and operating infrared heated floor.

Conclusions and useful video on the topic

Installation kit for laying the system:

Construction of the substrate and laying of heating strips:

Installation of sensor and thermostat:

The film type system is not difficult to implement. Therefore, even without the appropriate skills, installation can be done in just one day. The main thing is to strictly adhere to the installation technology. This will protect you from an emergency and premature failure of the system.

Are you thinking about installing an infrared floor system, but don't know where to start? Or do you have experience in installing such systems and can give practical advice to our readers? Please leave your comments, ask questions, and share your experience of using the film floor system in the block below.

Of course, you can make such a warm floor with your own hands, but only if your hands grow from the right place and you have at least rudimentary knowledge of electrical systems and installation of systems. At first, my husband also got excited about the idea of building it himself. I read everything I could, watched all the training videos, purchased the material. And in the end, he said that he would not take responsibility and hired installation experts. They did everything quickly.

To be honest, I am concerned about the safety of infrared “warm floors”. Yes, it talks about their environmental friendliness, but is that really the case? Still, this is some kind of radiation... We have small children, so I am seriously puzzled by the choice of the type of heated floors. But still I look specifically towards IR systems, because... They heat up faster than water and electric, this is a huge plus.

Hello. Infrared radiation, roughly speaking, is a way of transferring heat from a heated source to a colder one. The sun, heating radiators, the human body and so on, as Alexander already said, are all sources of infrared radiation.

The only thing that can be dangerous is its intensity. That is, the amount of energy it transmits. It is clear that if you spend a long time under the scorching sun in extreme heat, you will overheat or even burn your body. Any heated floors, heating radiators, etc. can be brought to this state by setting the wrong temperature range. A hot kettle on the stove is also dangerous; if you lean your hand against it, it will cause a burn. As a rule, the heater is not cranked up to this temperature :)

On the other hand, IR floors receive energy from power supply with electricity, which emits electromagnetic waves, the effect of which on humans has not yet been fully studied. However, standards have been established that are absolutely safe for health, including...

The truly dangerous radiation is cell phone radiation. There is such a set of damaging factors that in the modern world they try to “forget”, hiding behind the phrase “insufficiently studied.” Everything has been studied a long time ago; when I did my diploma in the early 90s, I studied this topic; there was more than enough literature. My opinion is to talk less on your cell phone and protect your children from it.

A very environmentally friendly option, don’t hesitate for a minute!

very soft and comfortable warmth comes, it is scientifically called soft IR radiation.

There is no electromagnetic field here, just as there are no turns and coils.

So I recommend it, I have already installed it on all my country houses.

Inna, infrared radiation is thermal radiation. Those. all heated surfaces emit infrared radiation including: a kettle, the human body, a cast iron battery, etc.

Florimol and plinthusville were pleased in the advertisement. After the whiskey, you see, they didn’t like the floor in an unfamiliar place. It’s a bit harsh. It’s uncomfortable to sleep.