Electric heated floor under linoleum: system advantages and installation instructions

To create a comfortable temperature in the room, various types of heating are used, among which underfloor heating, powered by electricity, has gained particular popularity. This system is compatible with various floor coverings, including laminate, linoleum, ceramic tiles and even carpet.

If your plans include making an electric heated floor under linoleum, then this is a completely feasible idea. And we will tell you how to implement it in practice.

The content of the article:

What are the benefits of electric heated floors?

In the cold season, the issue of heating a room becomes more relevant. An electric floor system can heat a room evenly and create the most favorable living conditions.

The temperature near the floor and under the ceiling with such heating has a slight difference, and the ability to adjust the temperature further expands the possibilities of using electric heating.

One of the advantages of electric heated floors is the fact that such a system does not dry out the air in the room. Moderate air humidity important especially for people with respiratory diseases. During activity in the room, as well as during sleep, the airways will not dry out.

From an aesthetic point of view, electric floor heating is the optimal solution. It is completely invisible and does not have to be disguised to create a harmonious interior. The system is installed under the floor covering, so it does not take up useful space in the room.

Electric floor heating can act as the main source of heat in the winter months, or it can be auxiliary.

The advantages also include the fact that electric heating allows you to save about 25-30% of standard costs on the main heating source. And complete safety for humans makes such a system universal.

What do you need for optimal performance?

First of all, for your floor heating to work flawlessly, you will need uninterrupted electricity. If your locality experiences frequent power outages, then additional equipment will be needed for electric heating.

You need to pay special attention to the installation process.

You can use one of the options:

- hire specialists who will install an electric floor heating system quickly and efficiently;

- understand the topic and tackle this matter yourself.

In the second case, it is necessary to delve into the specifics of working with each type of floor covering, which determines how the installation of the floor heating system will proceed. In particular, work with the installation of electric heated floors under linoleum must follow certain rules.

Features of installing electric flooring under linoleum

Infrared electric floor heating is the best option for linoleum among all types of floor heating. It will not require pouring a cement screed, which is required for laying electrical or water cables under the floor covering.

Ideal for linoleum infrared film, since it is quite thin and will not be felt under the main coating. In addition, linoleum requires special thermoregulation to maintain its structure, which infrared heated floors successfully provide.

If linoleum is exposed to high temperatures, it can:

- change color;

- become more elastic, which will lead to tears;

- emit an unpleasant odor and harmful fumes;

- deform.

It is better to leave work with electricity to specialists, since it will require correct calculation of materials, and the work itself may be beyond your capabilities. The rest of the work requires less preparation, so you can handle it without any problems.

Necessary Precautions

Before you start installing the STP under linoleum, you need to remember the basic safety rules when working with electricity:

- installation begins only after the power supply is turned off;

- you cannot test the system unless you have checked the quality of insulation of all channels;

- infrared film cannot be stacked on top of each other;

- the temperature value should not exceed 30 degrees so as not to overheat the coating.

By observing the listed standards, you can avoid accidents, as well as damage to the system and linoleum.

It is important to remember that for installation you will need a heat-reflecting coating, which is laid under the linoleum. If the material is made using aluminum foil, its use is strictly prohibited!

Selection of the necessary materials

For installation you will need the required amount of infrared thermal films, insulation, temperature sensors, thermostats, wiring, heat-reflecting material, linoleum and other building materials.

Linoleum, which will be laid on top of an electric heated floor, must have special technical characteristics. The main indicator is the thickness of the material.

Linoleum that is too thin can change its structure due to constant exposure to high temperatures, and such material can also become deformed due to unevenness of the base and take on an unsightly appearance. A denser coating will demonstrate worse thermal conductivity, but its structure will not change.

Before fixing the linoleum, you just need to spread it on the floor for a while and turn on the electric floor heating system.Then the material will warm up, take on a more natural shape, straighten out, after which it can be fixed.

Infrared floor installation instructions

An infrared heating system is the best option for flooring such as linoleum.

The first stage of installation is to establish the boundaries where the floor heating will be installed. Places under furniture and household appliances must be immediately eliminated. To have fewer points where wires will be connected, the film is laid out along the entire length of the room.

Electrical cables may run under the floor and should be kept less than 5 cm from the infrared film. If these are pipes or a fireplace, then at least 20 cm.

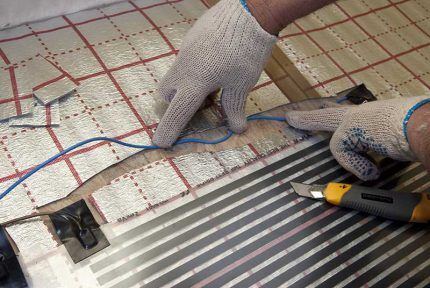

The next stage is cutting the film along the heating strips. They are designed to ensure that the internal structure of the infrared system is not damaged. When the film is cut into pieces, contact clamps are attached to it (they should be located in the place of the two-layer film and the copper strips through which the current passes). Using a hammer or other available means, a grommet is inserted into the hole.

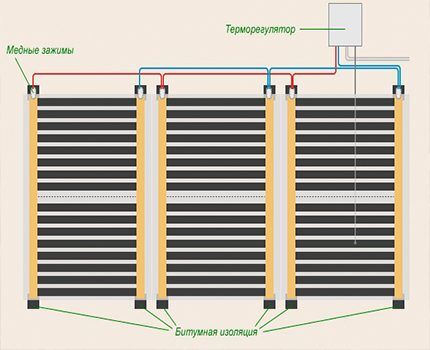

Next, the sections of the infrared contact strips are insulated. Copper wires are passed to the tip, clamped and insulated using a waterproofing strip. The film elements are attached parallel to each other so that they do not overlap in any way.

There are situations where the total system power exceeds the 3500 W limit.In this case, you will need to install a separate wiring harness with a separate circuit breaker to remove more load from the main wiring. It is important to use a magnetic starter here.

After working with the film, insulating material with a heat-reflecting layer is laid. This material is attached with tape. Heating elements are laid on top. They should be positioned with the copper strips facing down.

You should avoid touching the two strips, as this will lead to overheating of the system at the point of contact. To attach heating elements, a stapler or tape is most often used, less often furniture nails. Such fastening methods will ensure that in the future the strips will not move or fall on top of one another.

Rules for laying heating elements:

- attached only to a transparent border;

- the heating element must be located at a distance of at least 0.5 cm from the area through which the copper wiring passes;

- the main wires must be routed under the baseboard;

- In order for the insulation to lie flush with the floor, it is necessary to make cutouts for the thicker areas.

After completing the work steps, the system needs to be checked in detail. First of all, you should pay attention to the quality of the wire insulation and their fastening. Next, you need to eliminate the possibility of short circuits in the system, and, if necessary, correct the problems.

Next, you need to attach the temperature sensor to the thermostat. This procedure is carried out using tape, and the fastening is done in a place where there is no heat.Then the thermostat turns on and waiting a small amount of time to understand whether it is functioning correctly. If everything is done correctly, then you can feel the warmth emerging with your hand.

If the entire system is working properly, then it is covered with a special material that regulates the release of steam. The material is attached with tape. Sheet plywood or Fiberboard. They are attached to the base with screws and perform the function of leveling the floor.

The plywood should be positioned so that its fasteners touch the transparent part of the infrared film and do not touch the copper gasket. The fasteners should be located no closer than 0.5 cm from the insulated parts of the film through which electricity passes.

Depending on the base on which the heated floor is laid, the technology for its installation may differ slightly:

Having selected linoleum with optimal technical characteristics (moderately dense, quite elastic, which is not subject to deformation due to high temperature), it is worth laying it correctly, eliminating the possibility of an uneven surface that may result.

Next, fastening is performed using adhesive mastic or double-sided tape. In this case, mastic will be a priority, since it will make the floor more uniform.

Linoleum must have good thermal conductivity, while being very durable and resistant to fading.A good example is multilayer linoleum made of polyvinyl chloride, which is not afraid of heat.

Conclusions and useful video on the topic

Even more useful information about various types of heated floors is in the videos below.

Useful optional materials:

The nuances of film-type installation:

It is possible to make an electrical STP under linoleum with your own hands, the main thing is to follow safety precautions and carry out the work in the right sequence. It is better to entrust electrical work to specialists, but laying the upper layers of the system can be done without outside help. Be patient and have the necessary materials, and you will spend the cold season in comfort, without depending on the general heating system and other factors.

If you have had to do things on your own installation of heated floors under linoleum, please share your own experience with visitors to our site. Perhaps you know the subtleties of installation that we did not mention in this material? Leave your comments in the communication block located below the article.

We installed heated floors in the living room, the whole family liked it, it was a necessary thing, especially in a private home. It was done by a team of craftsmen, since I don’t know much about this. Of course, an electric floor will cost more, but it is possible to turn it on at any convenient time, be it summer or early autumn. In general, we are happy with everything, especially considering the fact that we are thermophilic.

A good idea: first let the linoleum sit on a working heated floor. It can also stretch under the influence of heat, and if you first tuck it under the baseboards, deformation may begin.It's good that I read this before I started work.

In principle, there is nothing complicated in laying infrared film, it is easier than pipes, but these little tricks will come in handy.

Isn't it dangerous for your health to lay linoleum on heated floors? Will it release chemicals when heated - formaldehyde, etc.?

Hello. I am an opponent of such materials and try to use them in as small quantities as possible in everyday life. In fact, and this has long been proven, any finishing materials made of PVC cause enormous harm to health. Stretch ceilings (even supposedly fabric ones, in fact they are not made of fabric), plastic panels, cheap low-quality linoleum, and so on. Although they are used everywhere and their environmental friendliness is advertised everywhere. Everything has been proven a long time ago, even using the example of owners of such repairs. Chlorine, toluene, phenol, heavy metals that have been released into the air for years... As for GOSTs... well, Rollton also has GOSTs.

However, no one is stopping you from purchasing eco-linoleum or marmoleum, although it is expensive and its installation on the TP is thermally irrational.