Infrared carbon heated floor: principle of operation and installation rules

To increase comfort in a country house or in a city apartment, underfloor heating systems are now actively used.An infrared carbon heated floor can create a favorable microclimate. If desired, the owner of the house can easily handle the installation if he knows how to install and connect it.

We will tell you how to set up an infrared heating system on your own. The article we presented describes in detail carbon options for underfloor heating and provides technological features. Taking into account our recommendations, assembling an IR heated floor will not cause the slightest difficulty, and the floor itself will work perfectly.

The content of the article:

What is IR underfloor heating?

Infrared heated floors can make a home more comfortable for its inhabitants thanks to the correctly selected temperature conditions.

Moreover, it can become the main type of heating if about 60% of the area of each room where heating is required is covered with carbon material.

Operating principle of IR heating

IR heated floors made of carbon heating elements pass current through them. As a result of this process, infrared radiation occurs in the range of 5-20 microns. It transfers its energy to objects in the room, bypassing the air.The decorative flooring and all the furniture will heat up from the radiant heat, warming the air.

Moreover, the floor will always be warm thanks to the film or system of rods laid underneath it. If this is the only source of heating, then you don’t have to worry about dry air. And infrared rays are not capable of burning oxygen.

Real benefit and imaginary harm from infrared radiation This is an article that we recommend site visitors to read.

Types of carbon systems

The growing popularity of IR underfloor heating contributes to the emergence of competition in the market, which has a positive effect on the price of the product. High-quality underfloor heating systems made from carbon materials are being improved, companies are producing improved models that allow you to get maximum benefits with minimal energy costs.

The following carbon heated floors have proven themselves well: Excel, Rexva Xica, Caleo, HOTmat, EcoOndol, Green Life, Ecoheat, Unimat, MONOCRYSTAL, HandyHeat, Q-Term, TEPLONOG, POWER PLUS.

According to the installation method, IR heated floors are installed:

- wet method;

- dry

The wet method is when a screed or a layer of tile adhesive is poured over the laid system. The finished floor can be used only after complete drying. For dry installation heating film nothing is filled with it. Therefore, you will have to wait a whole month for commissioning.

In appearance, infrared floors are:

- film;

- rod-shaped

The film is very thin - 0.3-0.4 mm. They are sold in rolls, the width of which depends on the model and manufacturer. This can be a range from 0.5 to 1 meter. The carbon heater layer is applied by the printer to one side of the film.

Based on the method of applying heating elements to the surface, the following films are distinguished:

- solid;

- striped;

- in the form of a honeycomb;

- with perforation.

Film with continuous carbon coating is the most advanced - it has the fastest heating rate and the most efficient consumption of electricity.

Perforated IR film has been developed to provide a strong adhesion to the surface when pouring the screed. There is no heating element in the perforated areas.

Striped is the most popular among buyers. On the market you can find a huge number of offers that differ in the width and length of the roll, the composition of the heating layer, service life and other characteristics. Its undoubted advantage is that it is convenient to cut during installation without touching the carbon strips.

An IR rod floor is a series of flexible rods connected in parallel with heat-resistant copper wire.Inside each is a heating element consisting of amorphous carbon, graphite and silver.

The IR heating system in the form of a rod mat has the ability to self-regulate. She is not afraid of a large sofa that will constantly stand in the same place. The rods located under the furniture will never overheat.

Rules for laying carbon heated floors

The effectiveness of any IR heated floor model depends on the correctness installation and connection. Even the highest quality and most expensive system will not work if you ignore the manufacturer’s recommendations given in the instructions.

How to lay the rod mat?

It’s nice to return home and take off your street shoes and feel the warmth under your feet. Correct enough for this install infrared underfloor heating. The most expensive option is the rod one.But it is characterized by a long service life - from 25 years. And the manufacturer’s warranty is good - about 10 years.

The most popular is the rod mat from Unimat. The manufacturer immediately provides detailed instructions for installing the system and all components. This makes it easy to do the installation yourself without wasting time searching for the right materials.

A rod-type warm infrared floor has the ability to independently regulate the temperature inside the system. This eliminates the risk of overheating and failure of individual rods located under heavy and bulky furniture.

For proper installation, you must first level the base of the floor. Then determine the location for installing the thermostat and temperature sensor. It is important that these 2 elements are in an accessible place and are not blocked by heavy furniture.

The temperature sensor should be placed in a groove cut in the floor. It is first placed in a corrugated pipe with a metal probe and a plug. Small debris remaining after making the groove must be removed.

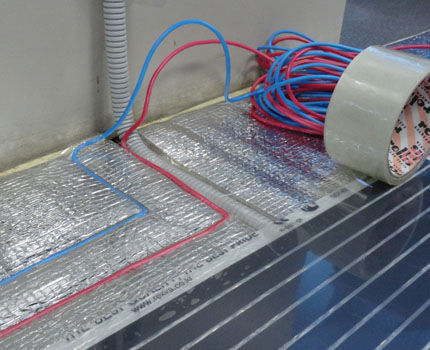

Then you have to spread the heat-reflecting material with the foil part facing up. All joints of individual parts of the roll must be carefully connected to each other with adhesive tape. Also, using tape, a stapler or glue, you will have to attach this layer to the primary floor. Now you can start laying out the mat of carbon rods.

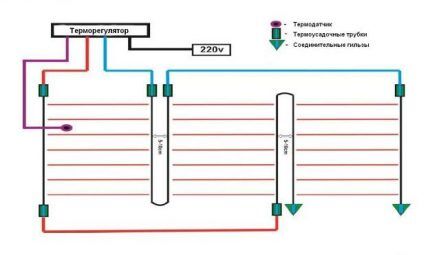

It is correct to start unwinding the roll from the side where the thermostat is installed.To turn the mat in the opposite direction, you need to cut the connecting wire exactly in the middle between the 2 rods. This can be done until the entire area for laying the heated floor system is covered, but not longer than 25 linear meters.

All that remains is to carefully fix the laid structure with tape and cut holes in the heat-reflecting material over the entire area. This will ensure reliable adhesion when pouring screed or applying tile adhesive.

The next stage is connecting and insulating the carbon heating system. Here it is important to follow the recommendations given by the manufacturer in the instructions and use the materials included with the heated floor.

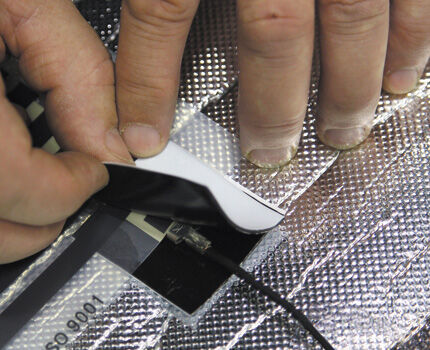

It is necessary to connect the strips of carbon mat with installation wires, stripping the insulation at the connected ends. For their reliable fixation, sleeves in heat-shrinkable film are included. Each sleeve is placed over the bare wire of the mat and connecting wire and clamped with crimping pliers.

The insulating film located on top of the sleeve takes on its working condition after using a technical hair dryer. Another insulating film is put on top, which is also shrinked with a hairdryer. This double insulated connection is strong and reliable. It is not afraid of moisture.

The next step is to connect the ends of the connecting wire to the terminal block thermostat according to the diagram attached to it. It is important not to confuse the supply wires with the neutral and ground wires.Don't forget to connect the temperature sensor.

The most important moment remains - to test the performance of the carbon mat. To do this, set the desired temperature and turn on the system. Wait 15-20 minutes and evaluate the result. If everything is in order, then you can proceed to the final stage - pouring the screed or covering it with tile adhesive.

The following photo gallery will illustrate the process of installing rod floor heating:

To assemble a system from carbon rods, you need to make a plan in advance, for example, like this:

After laying out the carbon heating, we proceed to the final stages of the device:

Basics of Heating Film Installation

Film IR underfloor heating is installed according to all the recommendations specified by the manufacturer in the instructions. The installation technology is similar to the rules for laying a rod mat. The main distinguishing feature is that the future location of the furniture should be taken into account. There is no need to lay carbon film under furniture.

It is important that the IR panels do not overlap each other. You need to maintain a distance of 5-10 cm between them. The same rule applies to laying the rod mat - two or more rods should not be allowed to intersect each other.

When the heat-insulating layer has been laid out, the carbon film has been laid out and attached to it, there is no need to cut holes for better adhesion of the screed. You just need to insulate the cut points of the copper busbar with bitumen insulation, completely covering the silver contacts along the entire cut.

There will be some differences here - contact clamps are installed on the copper bus, into which the ends of the connecting wire, stripped of insulation, will be placed.

Another difference from the installation process of the rod version is that the temperature sensor does not fit into the groove, but is attached with adhesive tape directly to one of the heating strips, if it is a striped film. The sensor must be carefully immersed in the heat-insulating layer, cutting through the appropriate cell. This will further eliminate unevenness when laying the decorative coating.

The cuts at the locations of the clamps and all the routes of the wires are made in the same way. The laid wires are sealed with tape. All that remains is to connect the system to the thermostat using the diagram given in the instructions. If the power of the infrared floor is more than 2 kW, then it should be connected to the electrical network through a separate machine.

After connecting, you need to carefully check the functionality of the system, the quality of the connection of individual elements and the heating of all strips by connecting it to the network. If everything is done efficiently, you can complete the installation by laying a special laminate backing or protective polyethylene film on top of the heating film.

All that remains is to lay the decorative covering and enjoy all the benefits of adjustable heating. Film heated floors are most often covered with laminate, linoleum or carpet.

In cases where the decorative coating is easily deformed, it is necessary to lay a dense protective layer - plywood or sheets of other material 3-5 mm thick. They need to be securely fixed without damaging the layer with the heating film.

Having completed all the steps correctly, you can use film IR heated floors for about 10 years. Each manufacturer indicates the service life in the instructions. It ranges from 10 to 50 years.

Pros and cons of carbon flooring

Infrared heated floors have their positive and negative sides. Before deciding on the advisability of purchasing and installing it, you should take a closer look at all the features of this system.

What's wrong with carbon heating?

The use of carbon rods or films when installing a heated floor system in a house or apartment has the following disadvantages:

- high cost;

- fakes;

- complex repairs;

- need for additional insulation.

Original systems offered by reputable manufacturers are not cheap at all. Especially when it comes to carbon rod mats. Not every buyer who wants to install infrared heated floors in their home is able to shell out a large sum.

The second drawback smoothly follows from the first drawback - the appearance of a large number of fakes on the market. They are distinguished by their low price and questionable quality.

The difficulty of the repair lies in the need to remove all the decorative covering to get to the heated floor system. There is no other way to replace the broken section. If tiles are laid on top, this complicates the repair even more.

The need for additional insulation of a house or apartment will be in the case when infrared heating is the main one.If energy saving work has not been carried out, then the heated floor will spend a lot of energy maintaining the desired temperature in the room and may not cope with this task.

Insulating a house, cottage or apartment can significantly reduce costs not only with infrared, but also with other types of heating. In such a room it is easier to maintain a comfortable temperature with the help of heated floors, spending a minimum of energy on their operation.

Advantages of infrared heated floors

A warm floor made of carbon film or rods has a number of advantages. This:

- fast;

- easily;

- available;

- economically;

- Beautiful;

- safely;

- without repair.

The first point implies the speed of installation of carbon heated floors. If the area to be laid is small, then all the work can be completed in 1 day. If you invite masters, then everything will take even less time.

Setting up an infrared heated floor system is easy - just a simple set of tools, as well as the materials that come with carbon film or rods.

The price of film material is affordable. If we compare the cost of all the parts and components needed when installing water or steam heating, then infrared significantly wins here - you don’t need to buy pipes, radiators, a boiler and other expensive equipment.

It is beneficial to use carbon heated floors both as an additional and as a main source of heat. If the system is installed correctly and the house/apartment/cottage is insulated, then energy consumption will be minimal.Costs will directly depend on the area covered with infrared film or mats.

The beauty of this type of room heating is that once installed, the heated floor is not noticeable in the room. It does not take up useful space, like, for example, heating radiators. The thickness of the entire system, including the heat-insulating layer, is less than 2 cm.

Infrared heated floors are completely safe. It is not afraid of water and can be placed in the bathroom and kitchen. If any section stops working, then nothing will happen to the entire system - it will continue to heat up as usual.

Carbon film floors are installed in kitchens, living rooms, bedrooms, living rooms, and children's rooms. They are being laid down under linoleum And under laminate, used in the installation of heated floors under floor tiles.

All heating elements are located in parallel, which eliminates the possibility of failure of the entire system at once. This is convenient, because the loss of one working strip will not fundamentally affect the operation of the entire system.

Features of system operation and repair

A warm floor made of carbon film or rods certainly makes the room more comfortable. Therefore, there are more and more adherents of this type of heating. But questions about the likelihood of breakdowns and possible repairs worry potential users of the equipment.

Rules for using heated floors

In order for a warm floor made of carbon material to last the entire period declared by the manufacturer, you must adhere to the rules of its operation. All this is described by the manufacturer in the instructions for the specific product.It is important that the underfloor heating system has all the documents and certificates of conformity confirming its quality.

After all, each manufacturer has its own technical characteristics of the material. But there are general rules, the observance of which is advisable not to neglect.

Firstly, you need to wait for the time after installation recommended by the manufacturer. This means that you can use the heated floor only after the specified period has expired. For example, for rod mats laid under tiles, the waiting period is from 28 days. Only after complete drying can you begin to use infrared heating installed in the floor.

Secondly, it is important not to ignore the installation requirements specified in the instructions. If the system is not equipped with a thermostat and temperature sensor, then you must definitely purchase them. Otherwise, nothing worthwhile will come of the idea of installing infrared heated floors.

It is important to install the temperature sensor according to all the rules. Also, you cannot place furniture on top of it - this is fraught with malfunctions in its operation and receiving unreliable information about the temperature conditions in the entire room.

Thirdly, when using film material, it is better to avoid placing it under bulky furniture - cabinets, sofas, chests of drawers. In the case of a rod floor, you don’t have to worry about the future arrangement of the furniture - this system is more advanced and capable of self-regulation.

Fourthly, cleaning can and should be done. Cleaning a room with heated floors should be done as it was before their installation.Material laid under tiles, laminate or parquet is not afraid of wet cleaning and treatment with special products intended for the care of decorative floor coverings.

Troubleshooting

The question of possible failure of carbon heated floors worries not only real, but also potential users. Although the manufacturer guarantees 10 or more years of trouble-free operation of the system, thoughts about repairs come in advance.

Due to the design features of the infrared floor, if a certain section fails, the entire system will not be affected. A breakdown will only affect the lack of heating of the floor under the broken segment. All other coverage will work as usual.

When several sections of the system, the functioning of which is extremely important for the consumer, have stopped working, repair work has to be carried out.

If we are talking about the rod version, then, when purchasing high-quality original equipment, the warranty is about 10, and the service life is from 25 years. But if you purchase a cheap analogue, you can observe the failure of individual rods within 1-1.5 years. As a result, 3-4 years after the start of operation, half of the heated floor may cease to be so.

To fix everything, you will have to completely remove the decorative coating and change parts of the mat or completely dismantle the entire system. This is a rather labor-intensive process, because the installation was done “wet”. Therefore, when choosing a rod carbon heated floor, you should carefully check the accompanying documentation so as not to buy a fake.

Repairing an infrared film heating system will not require a huge investment of time and money. In this case, you will have to remove the laminate or linoleum and replace the part that has failed. It is easy to do such actions if the carbon film was installed dry.

We invite you to familiarize yourself with the rules and principles of the device infrared heating country house. They are described in detail in the article we recommend.

Conclusions and useful video on the topic

Video #1. Step-by-step video about laying carbon film under laminate:

Video #2. Features of installing a carbon rod heated floor are given in the video instructions:

Video #3. Test on the performance of infrared solid and striped films with a carbon layer:

Video #4. Installation technology for continuous underfloor heating film:

Video #5. Prohibited and permitted techniques when laying heated infrared floors:

Having understood the main types of carbon heated floors, you can choose the most suitable option for your home. Installation features are described in detail in the instructions, which makes it possible to carry out the work yourself. Quite simple rules for installing such a heating system allow you to do without calling installation specialists.

Would you like to tell us about the installation of an infrared floor you completed yourself? Do you know the technological nuances of installation that are not described in the article? Please write comments in the block below, share your impressions and photos on the topic of the article, and ask questions.

Well, if you cover 60% of the room with infrared carbon heated flooring, then you can be left without panties, it will cost such a pretty penny. I agree, now, due to the growing popularity and the emergence of new players in the market, their price is gradually decreasing, but here the technical issues of installing IR heated floors arise. Due to the fact that many of our builders have their hands growing in the wrong place, it is not even technically possible to install them in every new building, not to mention Khrushchev and Brezhnev buildings.

I did not see figures for the maximum specific power consumed during the operation of floors, and, accordingly, for its (operation) high cost or, conversely, efficiency. As for central heating in multi-storey buildings, I don’t know if there is a way to completely abandon it (in warm regions) and switch to autonomous heating. I haven't heard of anything like this.

There are no problems with installation either in apartments with a new layout, or in Khrushchev or Stalin buildings. And very inexpensive.

And if we apply the resolution of the Ministry of Energy on special tariffs for the use of electrical energy for heating and hot water supply in residential buildings (apartments) that are not properly equipped with centralized heat and gas supply systems, then the costs of maintaining the system will not greatly affect the family budget.

It will be possible to pay energy sales at reduced tariffs if you have a separate (additional) individual device electricity consumption metering.