Safety valve for a boiler: design, operating principle and installation rules

Self-installation of a boiler is considered a responsible undertaking that requires maximum compliance with the rules and regulations of connection. A safety group must be involved in piping the water heater, which includes a safety valve for the boiler - a small but functionally important device.

In this article we will consider the types of safety valves and their design features. After all, in order to install the heater without errors, you need to understand the structure and operating principle of the valve.

We will also provide instructions for piping the boiler and tips for installing a safety valve, and give useful recommendations on choosing suitable equipment.

The content of the article:

Types of safety valves

Safety valves are often confused with check valves, and sometimes the term "check valve" is simply applied to them. In fact, these are two completely different devices, although they have common features.

The check valve is responsible for ensuring the movement of the medium inside the pipeline in only one direction, while the purpose of the safety valve is to protect the pipe and the units connected to it from destruction caused by an increase in pressure in the network above the standard value.

The replacement of concepts occurs because the second important function of the fuse is to create a barrier that prevents the movement of fluid in the opposite direction.

There are several types of locking mechanisms that protect complex technical devices from pressure surges. Among them are spring, magnetic-spring, lever, lever-load devices.

The choice of one type or another is explained by the purpose of the pipeline and the characteristics of the medium that moves through it: water, oil, hot steam, aggressive chemical solutions.

For the installation of an electric boiler, one type of valve is intended - spring valves. They may differ in appearance, but their internal contents look the same.

Design and principle of operation of the device

To begin with, we will analyze in detail the device and principle of operation of the safety valve.

Safety valve design

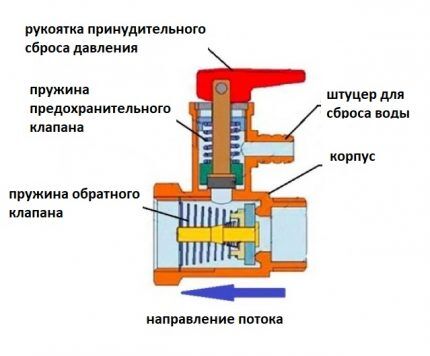

The safety valve, like other types of fittings, has a simple design and is a combination of two spring mechanisms housed in a common metal casing.

There is no fundamental difference between brass and steel products, but brass is a little more expensive and, according to reviews, lasts longer. The springs inside the case are made of chrome-plated steel.

Operating principle of the device

Both cylinders, located perpendicularly, have a similar design, but different purposes. The part located along the flow of water has a spring inside and a “plate” with an o-ring.

The spring keeps the mechanism closed and prevents liquid from returning into the pipeline. The end parts of the cylinder are equipped with male-female threads for insertion into the cold water supply system and connection to the boiler fitting.

A more powerful spring is installed inside the second cylinder, which is in a neutral state even with a slight increase pressure indicator.

If there is a sharp increase in pressure above normal in the line, the spring is triggered and opens a hole for the release of liquid. The outer end of the cylinder is covered with a plug, screw or lever device.

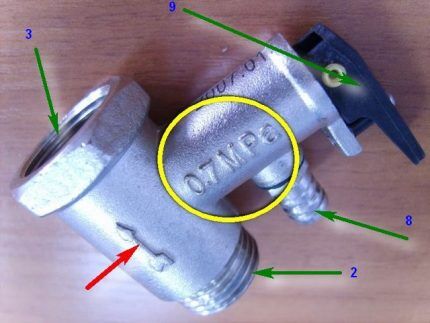

The yellow marker in the figure outlines the area on which the markings are stamped. It indicates the maximum pressure rating at which the valve operates. The pressure is indicated in MPa, but it can be easily converted to atmospheres: 0.7 MPa = 7 atm.

There is also an arrow on the body indicating the direction in which water moves from the cold water system to the heating tank.

Although it is convenient to drain water through the hole in the valve, experts recommend not using manual control too often.

It is necessary to use the lever for forced opening of the valve as rarely as possible, and for prevention or repair drain the water It is also possible in another way, for example, by unscrewing the water supply pipes.

Why is installing a check valve not enough?

The safety device is a component, so there is no need to search in stores and select spare parts for installing a new water heater. But during transfer, the part may get lost.

Apparently, this is why some craftsmen who install a used boiler install a standard one instead of a safety model. check valve, which is strictly prohibited by the instructions.

Anyone who starts operating a boiler with incorrect piping risks not only the equipment, but also the lives of people.The balanced thermodynamic action when heating water can get out of control, and then an ordinary water heater turns into a real explosive device.

Pressure increased to 5-6 atmospheres increases the temperature of the water inside the tank to the critical boiling point, and then even higher. A huge amount of steam accumulates and an explosion occurs.

When using a standard safety valve for a home water heater, everything is different: when a critical pressure level is reached, the spring in the device contracts and releases some of the liquid.

Thanks to this, the pressure inside the system is balanced and the equipment continues heating as usual. For this reason, installation of a fuse is mandatory and is regulated by installation requirements.

Thus, the safety device performs a number of functions important for the normal operation of the boiler.

Boiler manufacturers strongly recommend professional installation of water heaters. If this is impossible, then that's it installation steps must be carried out strictly according to the instructions, in compliance with all standards and the mandatory installation of a safety module.

Tips for choosing a valve model

As mentioned above, water heaters go on sale with a safety valve. In this regard, when purchasing a new model, especially a branded one, you do not need to worry about selecting parts.

The need to purchase arises in three cases:

- you received a used boiler without piping elements;

- the fuse was lost during a move;

- the valve is broken or worn.

Knowing the boiler model, you can easily select a new element. In the equipment operating instructions you can find the maximum pressure parameters - the same ones should be stamped on the body of the new part.

The thread diameter must match the dimensions of the mounting fitting and the cold water pipeline. In addition to the device itself, you will need a linen thread for the pipe or a rubber gasket if a flexible liner is used.

Sometimes a valve is installed between the boiler pipe and the fuse to drain the water. This is an acceptable, permitted piping scheme, but under one condition - the valve must be mounted on a horizontal outlet from the water supply main.There should be no shut-off devices between the safety valve and the water heater.

Installation instructions for boiler piping

Installing a safety safety valve is one of the stages of boiler piping. Minimum set of parts for supplying the cold water line – polypropylene pipe and safety valve.

But we will consider another option, in which, in addition to the named elements, a tee, a drain valve and an American connection are involved. In addition, you will need PP fittings in order to move the water supply lines towards the wall.

A complex security node is not always used. Some installers believe that one safety valve is sufficient. This is the minimum option for piping a boiler.

If tees or other adapters are not used, the fuse is fixed directly on the boiler pipe. It can be hidden behind the body or lowered 1-2 cm, which is more convenient for connection.

All that remains is to provide a drain for water through the hole in the fuse. To do this, use a flexible plastic tube of suitable diameter. It can be white, colored or transparent.

One end of the tube is put on the mini-pipe of the valve, the other is taken out into the sewer tee or directly into the outlet. Let's consider possible installation options.

Imprudent homeowners lower the drain pipe into a bucket or jar - this is wrong. If the container saves you, it will only be from constant digging.

In an emergency, the volume of water moving through the tube increases, and the capacity may simply not be enough. The only correct solution is to divert the drain into a sewer pipe by inserting it into a tee or a separate inlet.

Professional installation advice

Even such a simple procedure as installing shut-off valves is based on the implementation of certain rules. For example, the design of a room often requires camouflage of the pipeline and security group.

You can hide devices, but subject to three conditions:

- the length of the flexible line or pipe from the fuse to the tank should not exceed 2 m, otherwise there will be excessive additional pressure on the valve spring;

- the ideal installation of the fuse is directly to the boiler fitting, and if this does not work, then installing a tee is still excluded;

- To service the fittings, a technical hatch should be equipped.

Many people worry when they see drops of water on the valve connection. This is a normal phenomenon and indicates that the device is working properly.

From time to time, small pressure surges occur in the line, which provoke a minimal discharge of liquid. You need to worry when water either does not appear at all or pours continuously.

It should be remembered that independent modernization of safety devices is strictly prohibited. If you need a 0.8 MPa valve, then you need to purchase just such a new product, and not try to somehow remake or adjust the 0.7 MPa device.

If there is any doubt about the functionality of the safety valve, you should dismantle it and check whether the spring or seal is clogged. Are you having problems with your water heater itself and don’t know what to do? We recommend that you familiarize yourself with the frequent boiler breakdowns and repairs. If you lack skills, invite a specialist from the service center.

Conclusions and useful video on the topic

To ensure that the process of installing shut-off and safety valves proceeds smoothly, without errors and misunderstandings, before installing the valve and other devices, familiarize yourself with the experience of experienced boiler owners.

Once again about the design and principle of operation:

A few points to take note:

Like any fittings for piping, the safety valve is a necessary device for the proper operation of the water heater. It should not be confused with a check valve and should only be installed as directed..

If you have any difficulties with selection or installation, contact experienced specialists who will have your boiler fully ready within half an hour.

Do you want to understand the purpose of the safety valve and the intricacies of its installation? Maybe you still have questions after reading our article? Feel free to ask our experts for advice in the comments section.

If you specialize in the installation of boilers, their maintenance and repair, and have noticed an inaccuracy in our material or want to supplement what has been said with practical recommendations, please write your opinion under this article.

I recently installed a boiler in my house. I didn't buy it very expensive. Installed it, everything seemed to be normal. But it worked fine for me for about a week. Then it started dripping right next to the valve. At first I just saw a drop, but then the unit began to flow. I immediately blocked everything off, didn’t use it anymore and called a repairman. After inspection, it turned out that the safety valve was bad. If I had not paid attention to this, there could have been trouble. But the valve was replaced, and now everything is fine.

Ivan, hello! You did not specify whether you installed the boiler yourself or called a specialist from the gas service? After all, this should be done by professionals!

And you also didn’t write where the valve was leaking from: from under the thread or from the valve itself? Perhaps the thread was simply packaged poorly? You understand that it is profitable for the master you called to take money for an additional type of work, and not just strengthen the thread seal.

what place, a gas service technician, a gas technician, or does it make no difference to you who installs and connects the boiler, a gas technician, a doctor, etc., as long as he is a professional, no matter what field?

Under what circumstances can such critical pressure accumulate in a boiler that it can explode? Is this some kind of critical malfunction or does this happen periodically, the safety valve just trips in time and the pressure is released?

Hello. An explosion can occur when certain boiler devices fail or are installed and operated incorrectly.

For example, the temperature sensor breaks down, the boiler continues to heat the water beyond the critical temperature, turning it into steam and gaining pressure above normal. In this case, it will help if the pipes from the boiler are made of metal-plastic, since they will simply vomit at the fittings under increased pressure (most likely), and also if an additional safety temperature sensor is installed, as on modern, expensive models of water heaters.

In case of breakdown of protective devices - a gearbox or safety valve, as well as failure of a check valve (exposure of the heating element), with a sharp increase in pressure in the system.

If the part that turns off the heating element does not work when the temperature reaches a sufficient level.

Hello! Is this type of installation of a safety valve allowed? Pipeline throughout the apartment - safety valve - ball valve - flexible connection 50 cm long - water heater.

Hello. The rules for installing a safety valve are as follows:

1. The device is always mounted on a cold water pipe.

2. It must be located between the shut-off valves and the inlet to the water heating device, and no other devices should be installed in the space between them.

3. The maximum distance from the boiler entrance to the valve is 1.80 m-2.20 m.

Alexey, I’m talking about the valve itself - is it possible to install it in a horizontal position?

(directly to the tank, but through the corner. I feel that yes, but I want to clarify. I just care about the centimeters of space at the bottom of the tank.)

Like this from the bottom of the tank?

Hello! Here’s a question: water is flowing from the valve tube (not dripping, but pouring). Replacing the valve helps for a couple of months, then the water flows again (I have already changed the valve three times in a year). The pressure in the system is 0.5 MPa. I bought valves for 0.6 MPa, because... The tank is designed for this pressure. What should I do? Is it possible to install a valve at 0.7 MPa and will this solve the problem?

The original valve with the boiler lasted much longer, and those sold in stores quickly fail. I think it's all about the spring - over time it stops holding. Or, as an option, maybe tighten the bushing a little, which will compress the spring, and the valve will at least start to drip (which would be the norm)?

It is very likely that the tank capacity becomes cluttered over time, which means that the water also becomes filled with light microscopic debris - this debris ends up under the drain valve. And then everything happens according to your description.

The overall effect is to purify the water.

Specifically - turn off the tank, drain the water, remove the heating system (heating element and others like it), clean it and the inside of the tank, reassemble it, replace the valve. And, perhaps, the cold water supply should be made through a coarse filter, a fine filter, or a softening filter (like for a washing machine).

Hello! My scheme for supplying cold water in the bathroom: reducer-tee - then from the tee, a flexible hose to the boiler and corrugation (1.5 m) - then after the corrugation, a water shock absorber, followed by a toilet, shower mixer, and washing machine through the tees. After the flexible hose, a mandatory safety valve is installed on the boiler, set at the factory to 3 and 6 atm, respectively.

The flexible hose twitches noticeably when flushing the toilet or opening and closing a lever mixer, or when the washing machine is running. I assume that in these cases, the pressure in the pipeline first drops sharply, and then returns to its original value.

Question: is it possible to install an additional check valve between the tee and the flexible hose of the boiler in order to eliminate pressure surges in this hose? Thank you in advance for your response.

I bought a water heater in July 2019, 100 liters, safety valve 7-MPa was included. Everything was fine, water was dripping from the safety valve through the tube.

Six months passed, and the water flowed in a stream through the tube. I bought a new one, exactly the same, the water also runs.I bought it again at 8.5-MPa, installed it, but the water stopped flowing through the tube altogether. The water heater heats the water and turns off.

Tell me what should I do? Just describe everything in order and clearly.

Is it possible to install the safety valve horizontally instead of vertically?

Burned this way to secure the safety valve?

Thank you, out of 20 sites of NEDOmasters and instructions, this site is really clear and explained every point..