Installing heating radiators: technology for correct installation of radiators with your own hands

A variety of heating systems provide a comfortable air temperature inside residential premises.The basis of the vast majority of heating concepts are special heat transfer devices, commonly called batteries. You can install them yourself if you know the nuances of the work.

We have collected and systematized for you all the information about connection options and methods. Taking into account our recommendations, installing heating radiators with your own hands will be carried out without the slightest difficulty. All readers of the article we presented will be able to cope with it without any problems.

A detailed description of connection options and technologies is supplemented with visual diagrams, photo collections, and video instructions.

The content of the article:

Heating parameters for selecting appliances

An initial knowledge of the modes and operating conditions of heating devices will help you understand what battery designs are needed.

Below is a summary of information about the parameters of heating systems that are important when choosing batteries:

1. Internal pressure. The value required for the correct selection of a device that can withstand the pressure in the heating circuit:

- Private house (autonomous) = 1.5-2 atm.

- Private house (centralized) = 2-4 atm.

- 5-storey building (centralized and autonomous) = 2-4 atm.

- 9-storey building (centralized and autonomous) = 5-7 atm.

- House over 9 floors (autonomous) = 5-7 atm.

- House over 9 floors (centralized) = 7-10 atm.

If the technical capabilities of the battery are lower heating circuit pressure, there is a possibility of depressurization of the device with other negative consequences.

2. Permissible heating temperature. A characteristic indicating the upper temperature limit, above which the battery may fail:

- Autonomous = up to 90⁰С.

- Centralized with plastic wiring = up to 90⁰С.

- Centralized with steel wiring = up to 95⁰С.

Operation in violation of the temperature regime leads to melting of the seals, deformation and loss of tightness of the device.

3. Degree of coolant contamination. A parameter that interests mainly owners autonomous heating systems and water supply:

- Autonomous private home = high, medium, low when installing filters.

- Autonomous multi-storey building = high, medium, low when installing a filter system.

- Centralized = low, in rare cases medium.

Water supplied by centralized networks to municipal heating systems undergoes comprehensive purification. The content of sand and clay suspension in water extracted from private wells, wells, and open sources may exceed the permissible limit.

Traditional battery installation locations

For further selection of battery designs, it is necessary to determine the points installation of heating devices. They are placed in places of greatest penetration of cold. This is done to minimize the impact of drafts on the indoor microclimate. They also focus on ensuring availability for the purpose of periodic maintenance.

Battery Location Areas:

- Window niches. The most common location for heating appliances.

- Extended spaces between windows. One of the popular additional options.

- Corners and “blind” walls of corner rooms. It is used to enhance heating of rooms with increased heat loss due to intense exposure to winds.

- Bathrooms, storage rooms, bathrooms, one or two sides of which are combined with a solid load-bearing wall.

- Unheated entrances, hallways of private houses.

- Apartment corridors of the first floors of high-rise buildings.

Modern designs of heating devices fit under a balcony door or entrance to a loggia.

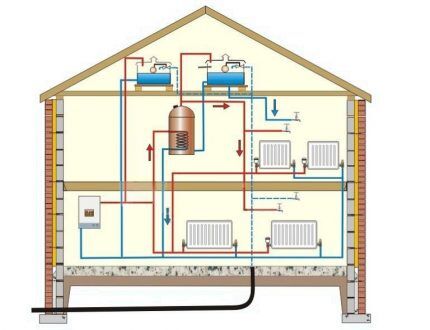

An example of the location of heating radiators in one house:

Design specifics of heating devices

Structurally, batteries are divided into groups: radiators, convectors and registers.

Review of popular heating devices

Radiator is the most common type. This is a heating device consisting of vertical separate compartments. In classic collapsible products, sections are independent working elements. They are joined in the required quantity using threaded internal connections. This assembly scheme gives the batteries versatility.

Before installing, possibly completing, a heating radiator, it is required perform calculation according to the required heat output. According to calculations, the number of sections of prefabricated batteries is selected. The horizontal cavities of radiators obtained by connecting sections are called collectors. Top and bottom.

Modern technologies have mastered the production of less versatile, but more reliable non-separable radiators using welding and solid casting methods. They do not have joints and seals characteristic of collapsible radiators. Design - for every taste.

A convector is a one-piece heating device made of a tubular or cavity heat exchanger with rows of heat-removing fins. Convectors are available in the following versions:

- Wall-mounted.

- Floor (duct)

- Skirting.

A register is a non-separable heating device made of straight, smooth horizontal pipes, arranged and combined in a certain way.

Details about the types of radiators

Radiators differ in the material used for their manufacture.

The heating appliance market can offer:

- Radiators are cast iron. The ancestors of the batteries of this group. Relatively inexpensive. Can withstand each operating mode. They serve up to 50 years. The main disadvantage is that they are heavy, which, however, helps retain heat for a long time when the heating is turned off.

- Steel radiators. Such batteries are structures made of steel pipes. They work in any conditions, but are less durable than their cast iron counterparts. They have low heat transfer.

- Aluminum radiators. Made from lightweight, aesthetic material, these batteries dissipate heat better than anyone else. They are resistant to all operating temperatures, but are afraid of water hammer. Aluminum is very demanding on the quality of the coolant.

- Bimetallic radiators. Steel insides clad in aluminum – that says it all. The main characteristics are the same as those of steel, heat transfer is almost like that of aluminum. The price is steep.

- Copper radiators. These are “eternal” heat emitters for any room. Their only and most significant disadvantage is their extremely high cost.

- Radiators are plastic. Innovation in the radiator family. So far they are suitable only for autonomous heating systems of private houses with a coolant heated to no more than 80⁰C.

The most sensitive to operating conditions aluminum appliances. These radiators reliably serve only 15 years. Their use is only possible in autonomous heating systems.

Externally, popular models of radiators made of different materials are similar:

Characteristics of the convector variety

Convectors are significantly inferior in heat transfer to radiators, but in some cases they successfully complement or replace them:

1. Wall convectors. Batteries in this design are usually made of steel, so they are cheap. They are not resistant to water hammer, and their use in centralized heating systems is undesirable.

But made in the form of pipes bristling with plates, such batteries are only suitable for installation in utility rooms.

2. Floor convectors (duct). An excellent solution for creating a thermal curtain at the door of a balcony or loggia. Made from durable, corrosion-resistant materials, they are unpretentious to operating requirements.

3. Skirting convectors. Capable of operating in all conditions and modes, these batteries are ideal for creating a microclimate where all other heaters would look cumbersome.

The baseboard type is appropriate in bathrooms and storage rooms adjacent to cold street walls and unheated entrances.

Brief description of heating registers

Once upon a time, batteries of this group were made handicraft using conventional welding.Registers can be used in any heating systems, but due to their unsightly appearance they are used mainly in auxiliary rooms: garages, storerooms, basements. Sometimes they can be seen in the entrances of old high-rise buildings.

Modern manufacturers have their eye on this group of heating devices.

Calculation of thermal power of batteries

The stage of preliminary selection of batteries is completed, you can proceed to calculating the thermal power required from them. The calculations are based on a relative power of 100 W for heating 1 m² of standard room.

The full formula includes many correction factors and looks like this:

Q = ( 100 x S ) x R x K x U x T x H x W x G x X x Y x Z,

Where:

S = area of the heated room, where:

R – additional parameter for rooms oriented to the east or north = 1.1;

K – correction for the presence of external walls in the room:

one = 1.0;

two = 1.2;

three = 1.3;

four = 1.4;

U – insulation coefficient of street walls:

low = 1.27 (without insulation);

average = 1.0 (plaster, surface thermal insulation);

high = 0.85 (insulation performed according to special calculations);

T – weather indicator of the period of lowest temperatures in ⁰С:

up to -10 = 0.7;

up to -15 = 0.9;

up to -20 = 1.0;

up to -25 = 1.1;

up to -35 = 1.3;

below -35 = 1.5;

H – ceiling height index in meters:

up to 2.7 = 1.0;

up to 3 = 1.05;

up to 3.5 = 1.1;

up to 4 = 1.15;

W – characteristics of the room located on the floor above:

unheated and uninsulated = 1.0 (cold attic);

unheated but insulated = 0.9 (attic with insulated roof);

heated = 0.8.

G – degree of window quality:

serial wooden frames = 1.27;

frames with single glazing = 1.0;

frames with double glazing = 0.85;

X – ratio of the area of window openings to the area of the room:

up to 0.1 = 0.8;

up to 0.2 = 0.9;

up to 0.3 = 1.0;

up to 0.4 = 1.1;

up to 0.5 = 1.2;

Y – battery surface openness value:

fully open = 0.9;

covered with window sill = 1.0;

obscured by a horizontal projection of the wall = 1.07;

covered with a window sill and front casing = 1.12;

blocked on all sides = 1.2;

Z – battery connection efficiency (1.0 ÷ 1.13; for more details, see the section below).

The calculated value must be multiplied by a conditional coefficient of 1.15. It will provide some heat reserve to enable more precise adjustment of devices to operate in low-temperature mode.

Effective ways to connect

Before you continue learning how to select, install and connect heating radiators and other heating devices, it is necessary to consider two main types of pipe layout of existing heating systems. They differ in the principles of organizing the supply of coolant to the batteries and its return to the system.

In practice, the pipe that supplies heat is called the “supply”. The pipe that returns the coolant is “return”. The vertical distribution pipe (supply or return) is called a “riser”.

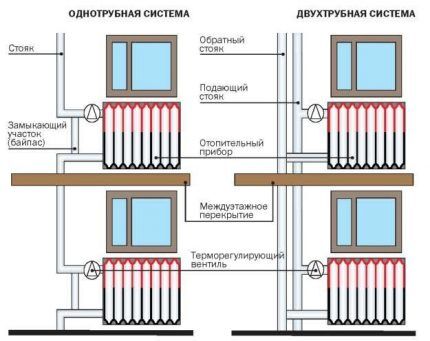

Traditional wiring options:

- Single-pipe. The wiring is arranged in such a way that one pipe plays the role of supply and return. The batteries “crash” into it sequentially.The coolant bypasses the heating devices in the order in which they are connected.

- Two-pipe. In a two-pipe distribution, one pipe is the supply, the other is the return. With this option, the battery heating devices are connected simultaneously to both pipes, parallel to each other. The coolant circulates through all batteries simultaneously.

The “Z” coefficient in the formula for calculating thermal power depends on the options for connecting heating devices.

The most widely used connection methods in practice:

Method number 1. Diagonally. Z = 1.0.

This connection procedure is the most effective, especially if the heating system is not working well. The coolant enters the battery from the top on one side, passes through the entire internal cavity and exits from the bottom on the other side.

Thermal energy is transferred to the entire surface of the heating device. For radiators with a length of more than 12 sections, this method is highly recommended.

Method number 2. From the side (top – entrance, bottom – exit). Z = 1.03.

Until recently, this was the most common method for connecting batteries. It is convenient for installation due to the short connection length.

For radiators of up to 12 sections, the heat transfer is almost equal to the diagonal connection method. But this is in well-functioning heating systems. If the systems are operating sluggishly, the hot coolant will not reach the final radiator compartments.

Method No. 3. Bottom on both sides. Z = 1.13.

Despite the least efficiency, this connection method quickly took root in new construction, thanks to plastic pipes. Heating system wiring is installed in the floor and does not overshadow the design of the premises.With properly configured heating systems, all parts of the batteries receive uniform heating.

The final stage of battery selection

The final stage of selection is based on the results obtained of the power required from the heating devices.

Ready-made one-piece designs of radiators, convectors or registers are selected at the time of purchase.

From the factory data sheets of the products, data on their thermal power is visible. When purchasing batteries, the specifics of the installation location (for example, the possible dimensions of the device) are taken into account.

Non-separable radiators and registers with individual parameters are manufactured by specialized organizations to order. Collapsible radiators should be considered based on the number of sections, based on their total thermal power.

Approximate individual powers of standard 500 mm sections made of different materials (Watt with a coolant of 70⁰C):

• Cast iron = 160;

• Tubular steel = 85;

• Aluminum = 200;

• Bimetallic = 180.

The power of collapsible radiators is regulated by attaching additional or disconnecting unnecessary sections.

When choosing batteries of different designs for one room, it is more correct to start their selection with non-separable products.

General tips for installing batteries of different groups

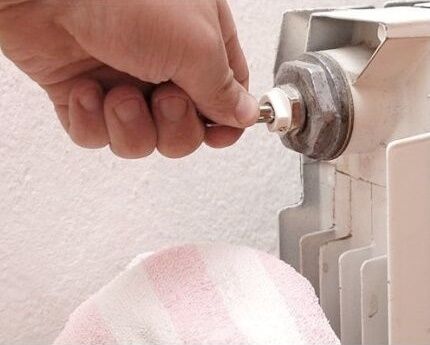

It is recommended to use heating appliances equipped with automatic and mechanical air vents. For other heater designs - the highest point on the side opposite the coolant inlet.

It is also suggested to install between the battery and the outer wall heat reflective screen. To make it, you can pay attention to modern heat-reflecting materials isospan, penofol, aluf.

When fixing heating devices in place, their deviation from the horizontal level is not allowed. It is allowed to raise the side with the air vent up to 1 cm for better collection and release of air.

When connecting heating devices to systems with risers, the centers of the battery inlets should not be higher than the centers of the outlets from the supply pipes. If, when connecting to risers, it is planned to equip heating units with taps or devices for adjusting the temperature, in single-pipe heating systems it is additionally necessary installation of bypasses in their absence.

Bypass is a jumper parallel to the battery connection. This element allows you to organize control of the operation of the heating device. It is a piece of pipe connecting the inlet and outlet of the battery. The diameter of the jumper pipe should be one size smaller than that of the riser pipe. In two-pipe heating systems, the installation of bypasses is not required.

Due to the vastly different expansion coefficients of materials, it is not recommended to connect batteries using plastic hoses to steel pipe wiring. Conversely, the main plastic wiring excludes the transition to steel connection parts.

Until the installation is completed, it is advisable not to remove the packaging shell from steel, aluminum and bimetallic batteries in order to avoid their mechanical damage.

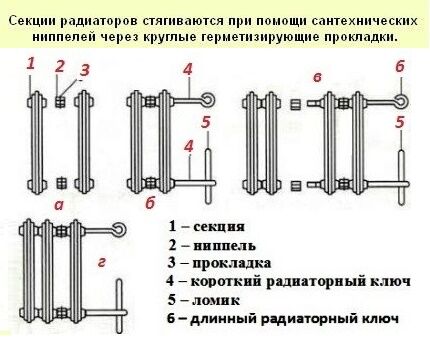

Preparing dismountable radiators for installation

If the purchased collapsible batteries do not have the calculated parameters, they should be modified by disconnecting excess sections or adding to the desired quantity. The radiator compartments are tightened together using plumbing nipples through round sealing gaskets.

The nipple is a short, thick-walled tube with an external thread. Half - right, half - left. Inside the tube along its entire length there are two opposite longitudinal technological protrusions.

The radiator wrench can be replaced with a chisel of a suitable length, with a tip width sufficient to confidently engage the nipple protrusions. The role of the wrench will be played by an adjustable pipe wrench.

The design of the collapsible radiator has a left-hand thread.

To correctly perceive the direction of rotation, it is recommended to unscrew or tighten the nipples by inserting a key or chisel into the holes of the sections where the threads are right-handed. To avoid distortions of parts, the holes need to be alternated after a revolution or two of the tool.

Securing dismountable radiators in place

Collapsible radiators are hung on special brackets. The most reliable are arc-shaped hooks mounted in the main walls of premises. In this case, the distances must be ensured:

• from the floor = 6-12 cm, sufficient for cleaning and heating the bottom of the wall,

• at least 7 cm to the window sill to ensure effective convection,

• from the heat-reflecting screen or from the wall = 3-5 cm.

The brackets are mounted in such a way as to fit into the intersection space of the radiators.According to the unwritten rule, when hanging batteries, the end caps with right-hand threads should be on the right, and those with left-hand threads on the left.

Markings for hooks are carried out in the following order:

- Draw a vertical line of the axial center of the radiator (when installing the battery under a window, most often this is its center) with a length no less than the height of the battery.

- The distance between the spaces of the first-second section of the radiator and the last-penultimate one is measured.

- A horizontal line is drawn corresponding to the center of the upper radiator manifold, with a length no less than the measured distance (taking into account the general tips outlined above).

- The distance itself is plotted left and right on a drawn horizontal line symmetrically relative to the line of the axial center. The resulting two points are the places for the upper hooks. They will support the weight of the structure.

- From the point of intersection of the horizontal lines and the axial center, a distance equal to the center-to-center distance of the collectors (standardly 500 mm) is laid down vertically.

- A horizontal line is drawn through the intended point, corresponding to the center of the lower radiator manifold.

- The distance measured in point 2 is plotted left and right on a drawn horizontal line symmetrically relative to the axial center line. The resulting two points are the places for the lower hooks. They will ensure the immobility of the structure.

- At the designated points, holes are drilled for dowels, into which threaded brackets are screwed or hooks with smooth rods are hammered.

The drilling process is described for cast iron and bimetallic heating devices with no more than 10 sections, and aluminum radiators with no more than 12 sections.For larger batteries, a hook should be added in the center area at the top and bottom.

Fastening in place non-demountable types

Brackets for installing non-separable radiators are usually included in the product kit. The sequence of marking the mounting points of the brackets for hanging these batteries is described in the attached installation diagram. The procedure is similar to that described for dismountable radiators.

The choice of brackets for securing convectors is varied. It is determined by the location of the heating device.

By analogy with collapsible radiators heating registers hung on arc-shaped hooks, immovably embedded in the walls. The total number of brackets is standard four (two hold the upper pipe, two hold the lower pipe). For light registers, it is possible to use holders for pipes of the appropriate diameter with clamps.

Connecting batteries to heating systems

It is advisable to use a torque tool for connection work. The required tightening forces are specified in the passports of the purchased heating devices. To create a tight seal for threaded connections, you will need fluoroplastic sealing material, briefly called “FUM tape,” and plumbing flax.

If the connections of the batteries with the wiring of the heating system are made with plastic liners, you will additionally need:

- Welding machine for polypropylene parts.

- Or a crimping device for metal-plastic pipes.

When deciding to control the heating of batteries, taps or temperature control devices are purchased. Some ready-made designs are immediately equipped with built-in thermostats.

The required number of pipes for the supply line and the set of connecting parts (fittings) depend on the options for connecting to the heating system and are determined after the batteries are secured in place. Connection methods “diagonally”, “from the side” or “from below on both sides” are determined at the stage of calculating the thermal power of the installed heating devices.

One of the options for assembling and installing a non-separable radiator. The preliminary stage is the purchase of the device itself and shut-off valves.

When everything is prepared, first we attach the fittings, install the adapters, and then hang the radiators from the wall under the window according to the following scheme:

Having figured out how to correctly install a heating radiator, you can safely begin responsible work.Before installing devices, their locations must be repaired and plastered.

You can learn how to replace heating appliances from another popular article our site.

Conclusions and useful video on the topic

The video clearly demonstrates the connection options:

Video tutorial on installing radiators:

Specifics of tying batteries with polypropylene:

It is deeply believed that the knowledge gained from the article will make the installation of any design of a heating radiator, convector or register with your own hands accessible to every owner. The main thing in the upcoming work is exceptional care and responsibility at every step of the task.

Write about how you or plumbers installed batteries in your house/apartment. Share whether you are satisfied with the performance of the devices. Please comment in the block below. Here you can ask questions and provide useful information.

I can tell you from my own experience, if you don’t understand this, then don’t bother. This is what happened in my life. I read the articles, I seemed to have decided on everything and what to do correctly, I consulted with a friend who is involved in this and he told me, don’t get involved in this without me. But it seemed to me that everything was simple. The pipes in the house are old and I didn’t think to clean them properly, after installation I sealed the “riser” with plaster, and in winter we all froze. Never terminate batteries.

Hello. Drywall has fairly low thermal conductivity and, of course, should not be used to seal radiators. Especially for puttying and finishing.And if you really want to cover the engineering systems with something, then it is better if they are lattice structures or removable and always with technological hatches in order to get to the components in time and be able to control them.

The choice of radiator size directly depends on the dimensions of the heated room. When repairing a heating network, it is also important to replace old radiators, since during operation dirt accumulates in the devices and rust settles on the walls. Contaminants impede the flow of water, which can ultimately disrupt the operation and reduce the efficiency of the heating system. I purchased radiators of the same brand so that there would be no problems. The air vent is also a very useful thing. If you used to wait for neighbors on the top floor to bleed air from the system, now you can do it yourself.