How to make a heating register with your own hands: assembly and installation instructions

Heating radiators are elements of engineering plumbing systems that are functionally designed to heat the air in a room.According to SNiP (2.03.01-84), radiators that comply with heat balance calculations should be used in any room. They are quite sufficient to maintain normal temperatures inside buildings.

However, for a garage or small workshop it is better to make a heating register yourself. In terms of dimensions and heat transfer, this device goes beyond the parameters of classical designs, but is much more suitable for these premises. The article we presented describes in detail the technology of its manufacture.

The content of the article:

Homemade heating registers

By increasing the heat exchange area and the volumetric component of the coolant, of course, it is easier to achieve the desired temperature in the room. Therefore, quite a lot of property owners, taking advantage of the lack of control over heat extraction at each specific point, increase heat removal by manufacturing radiators of non-standard designs.

In fact, this is prohibited, as it is seen as an irrational approach to energy consumption. In practice, they think less about resources than about their own well-being. Will introduce you to options for economical garage heating next article, the contents of which we advise you to familiarize yourself with. However, closer to the point.

Making a heating register with your own hands is a relatively simple task, especially if you have welding skills and have a welding machine at hand. All that remains is to purchase the required quantity of pipes of suitable diameter and sheet metal.

How to calculate heat transfer?

The required amount of material can be calculated based on the temperature parameters that need to be obtained in the room. At the household level, this step is usually skipped - they make heating registers with their own hands “by eye” according to the principle “the more, the better.”

But it is better to make simple calculations of heat transfer, for which you do not need to be a mathematician. All you need is:

- Calculate the area of the room.

- Learn about the heat transfer properties of steel.

- Select the optimal pipe diameter.

The area of a room is calculated by multiplying its length by its width (S = L*W). However, for more accurate calculations, it is recommended to calculate the volumetric parameter by adding the height (H) value to the calculations.

So, the final calculation formula takes the form:

V = L*W*H

For example, you need to calculate V of a room where the length is 5 m, width is 3 m, height is 2.15 m. The volume of the room is obtained: V = 5*3*2.15 = 30.25 m3. Based on this basic value, further calculations should be made to determine the amount of heat, the size and number of heating registers to make with your own hands.

First of all, the required amount of heat per calculated volume of the room is calculated to achieve the required internal temperature (W):

Qп.т = V * k (Tin – Tout),

where V is the volume of the room; k – heat transfer coefficient of the building walls; Tin – temperature inside; Tout – outside temperature.

The amount of heat generated by one register can be calculated using the formula:

Qр = q * L * (1-n),

where: q – heat flow from each horizontal and vertical pipe of the register (approximately 20-30 W/m); L – length of vertical and horizontal pipes of the register (m); n – coefficient of unaccounted heat flows (for metal pipes – 0.1).

The category of unaccounted heat losses also includes hood in the garage. If the mechanical type is installed, the coefficient n must be increased to at least 0.2.

The number of registers, accordingly, is determined by the formula:

Nр = Qп.т. / Qр

Such a calculation method will most likely be assessed by design specialists as a simplified and crude form. However, this approach still seems to be a more rational action than calculation and production of registers with your own hands by eye, without any calculations.

Selecting a heating device configuration

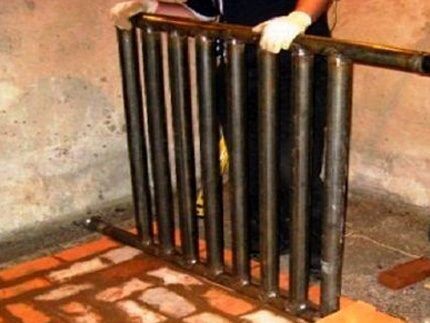

Homemade radiator designs are mainly made on the basis of metal pipes with a diameter of 80 - 150 mm.

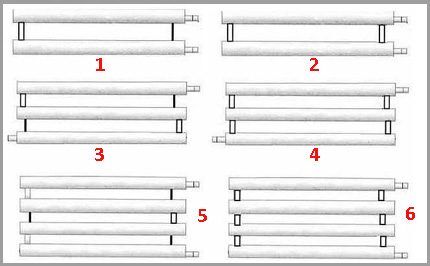

Design features are limited to two versions:

- Lattice.

- Snake.

The lattice design of the heating battery differs from the “snake” in a slightly different circuit design, and, depending on the variations in such batteries, the distribution of the coolant may be different.

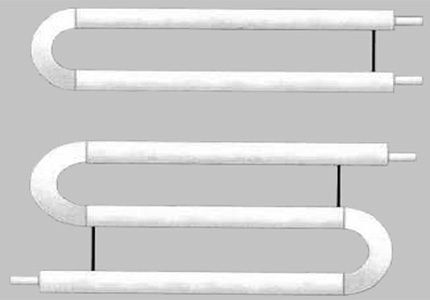

Coil structures actually have a monotonous design, implying strictly sequential movement of the coolant.

Lattice registers are constructed according to different schematics:

- with one or two jumpers and one-way power supply;

- with one or two jumpers and versatile power supply;

- parallel connection of pipes;

- sequential connection of pipes.

The number of pipes in one assembly can range from two to four or more. Rarely, there is also the practice of making single-pipe registers.

A coil assembly usually contains at least two pipes connected on one side by a blind jumper and on the other by a through jumper, which are made from two pipe bends (2x45º). It should be noted that the design of heating registers in the form of a coil is used much less frequently than “grid” designs.

Both manufacturing options - lattice and coil - can be made not only on the basis of classic round pipes, but also on the basis of profile pipes.

Profile pipes seem to be a somewhat specific material, since they require a slightly different approach when assembling heating radiators. However, registers made from a profile pipe are more compact and take up less usable space, and this factor is also important.

Instructions for making a radiator

To make a heating register yourself, it is recommended to initially carry out the necessary calculations (methodology above in the text).And the point here is not to save resources, but to make batteries that are really useful in all respects.

Surviving the winter with the windows open - this option is suitable for “walruses”. Everyone else who is not part of the hardened group runs the risk of getting a serious cold. And powerful radiators are just as bad as too weak ones.

So, the calculation is done, you can start choosing the material.

An economical and quite suitable choice for a homemade design can be considered steel pipes and manufactured for steel pipe fittings to them:

- bends (suitable for pipe diameter);

- corners (reinforcement);

- steel sheet (thickness equal to the thickness of the pipe wall);

- pipes (small diameter pipes).

Gates may also be required, which are often not installed directly on the registers. Production skills and knowledge would be useful gas welding technologies, if the future performer has them.

Pipe preparation and welding

According to the calculated length parameters, the pipes of the future radiator are cut to size. A convenient tool for cutting is a circular saw. Then plugs for the ends of the pipes are cut out of a metal sheet. The round-shaped plugs are convenient to cut with an oxygen cutter.

First of all, circles of the required diameter are marked on the surface of the metal sheet with chalk and then carefully cut. Some of the sliced pancakes (the quantity is calculated) are made with holes for the coolant inlet and outlet pipes.

It is also immediately recommended to cut holes (one or two, depending on the assembly project) in the wall of each pipe, with a distance of 100 - 150 mm from the end edge. These holes are intended for through-connection of pipes during battery assembly.

After cutting the holes, it is recommended to clean the inside of each pipe from slag and scale. Next, place pancakes at the ends of the pipes and carefully scald them in a circle. One pancake with a hole is welded on the first and last pipe.

Heating battery assembly

Finished pipes must be combined into a battery. To do this, determine the configuration of the radiator (if it is decided to make a lattice structure). Based on the accepted choice of configuration, jumpers are prepared - through and blind.

The material for jumpers is usually small diameter pipes. For example, d = 25 mm or d = 32 mm. Tubes for the supply/return pipes are also prepared (length 150 - 200 mm, diameter 25 - 32 mm).

The pipes prepared for the heating register (2 – 3 – 4) are laid out on a flat surface and aligned along the end edges. The first (upper) and last (lower) are laid out with end edges with holes, according to the selected connection diagram: one-sided (input and output on one side) or double-sided (input and output on opposite sides).

All that remains is to carefully weld the through and blind jumpers between the pipes, the inlet and outlet pipes, after which the heating register is ready for installation in the system. Before starting work, a novice master will need to study electric welding rules, described in detail in the article devoted to this issue.

Features of the “snake” design

The coil register is assembled a little differently. Here, instead of vertical jumpers, metal bends are used, with the help of which the end parts of individual pipes are connected.

To assemble a register with a snake you need:

- Lay the pipes on a flat surface.

- Weld 45º arc bends from paired bends.

- Connect the paired register pipes on each side with arc bends.

- Close the initial and end ends of the first and last pipes with plugs with branch pipes.

Coil heating registers are large in size due to the limited possibility of adjusting the interpipe distance. In this regard, “snakes” are superior in parameters to lattice structures. However, from the point of view of the efficiency of coolant flow, the “snake” looks like a more preferable option.

There are practically no air pockets formed inside such registers, which is typical for products of the “grid” type. In addition, thanks to large-diameter arc bends, coil structures have less hydraulic resistance. However, it is quite rare to make such registers with your own hands.

Difference between profile registers

An interesting design compared to those described above is a register made from a profile pipe. More compact, but no less efficient batteries are assembled using almost the same technology.

The only peculiarities of the assembly can be noted in the preparation and adjustment of inter-pipe jumpers. As a rule, welding is not used here. It is enough to have a good metal-cutting tool.

The ends of the interpipe jumpers and the register pipes themselves are cut at an angle of 45º, achieving an exact match along the edges on the connection line. If a “grid” type register is being assembled, the interpipe jumper is made with angular cuts at the ends and straight cuts at the points of supply of the central pipes.

After preparation, the jumpers are placed in place and carefully scalded. On the “snakes”, blind reinforcing jumpers are additionally installed parallel to the passages.

Homemade registers were widely used for domestic needs in the recent past. Now this type of heating devices is used less frequently.

An alternative to registers, especially if the garage is not connected to a centralized heating system, would be miracle diesel stove. Our proposed article will introduce you to the method of its manufacture.

Conclusions and useful video on the topic

You can learn about the sequence of manufacturing a heating register from a profile pipe and the secrets of welding from the video:

Homemade heating equipment continues to be actively made and used in rural areas or in private industries for heating office technical premises. But many refuse to use such irrational structures, especially where metering and monitoring devices for coolant consumption are being introduced.

Would you like to tell us how you assembled a register for your garage or cottage with your own hands? Do you have information that could be useful for DIYers? Please write comments in the block below, share useful information and photos on the topic of the article, and ask questions.

We also made a register for the bathroom, ours is large, more than 15 square meters. In order not to install two batteries, we decided to simply install one large register, which we welded ourselves. In general, there is nothing complicated there, the main thing is to know how to do it. So, before cooking, we read detailed instructions on the Internet. By the way, it turned out quite well, it heats up perfectly, and no air lock has ever formed.

Registers, of course, are a good thing, especially if there is material for them. I found sheet copper in my father's attic and made this small register. A coil made of copper pipe with copper fins, like a radiator in an air conditioner, only the diameter is larger.

Heat dissipation is super. True, you yourself understand that his look is from the “handmade, made with an ax” series. I put it in the bathhouse, it fit fine there, the most important thing is that it’s warm, and I didn’t spend money on material.