Winter water supply from a well: review of the best options and arrangement schemes

Do you need your own stationary water supply system that can provide water to a private home all year round? Agree that it will be very disappointing to be left without water with the onset of cold weather, especially if there is a well in a suburban area that serves as a source of water intake.

Have you decided to make a winter water supply from a well on your own that will be suitable for use in any weather, but you don’t know the subtleties and nuances of this process?

We will help you understand all the features - the article provides the best methods and outlines the layout of an autonomous water supply system for year-round operation. The material is supplied with visual photographs.

The process of preparing the water supply system for winter is discussed step by step, including insulation of all important components. Useful video recommendations from experienced plumbers are provided.

The content of the article:

Features of winter water supply installation

Winter plumbing is necessary if you plan to use a well water system throughout the year.

Such an autonomous system has many advantages:

- well water, when properly arranged at the source, has excellent quality characteristics and taste;

- Well care can be carried out independently, without the involvement of highly paid specialists;

- the water supply system from the well is completely autonomous and even in the event of a power outage, it will be possible to extract water manually;

- can be used to improve operating efficiency submersible pump required power.

If the arrangement of the well was carried out according to all the rules, the source and the water supply system connected to it will last for many years.

The installation of winter water supply has a number of its own features, including:

- Availability of an insulated well or borehole, not subject to freezing throughout the year.

- The need to comply with the slope to prevent water stagnation and ensure gravity drainage during conservation.

- Availability of a preservation system, implying the possibility of completely draining water into the well, turning off the pumping equipment and closing the well.

In addition, it is necessary that the pipeline layout takes into account local climatic conditions.

If the system is to be used during frosty periods, the pipeline must be reliably protected from freezing.

Methods for installing winter water supply

To install a water supply system that will perform its main function - supplying water all year round, you must choose one of two options:

- Lay the water supply system so that the pipes run below the freezing depth of the soil.

- Lay pipes above the freezing horizon, but at the same time insulate them.

Both methods have their advantages and disadvantages. Let's look at them in more detail.

Method No. 1 - below the freezing depth

This method is advisable to use in cases where the freezing depth is no more than 150 cm. In this case, the value of the freezing depth is determined based on data for the last 10 years.

It is also worth considering that very cold winters periodically occur when the ground freezes below.Based on this, it becomes clear that pipes should be laid to a depth equal to the depth of soil freezing in the region plus 20 - 30 cm.

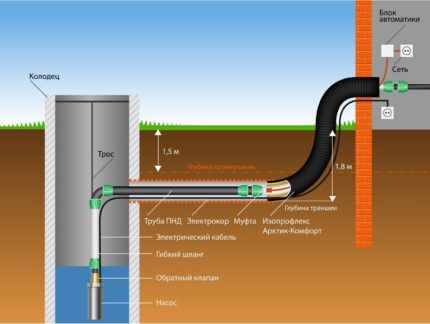

The installation of a water supply system begins with digging a trench of the required depth from the well to the point of entry of the water supply system into the house.

A 10 cm layer of sand is poured into the bottom of the trench and water pipes are laid. The trench is filled with earth, the soil at the backfill site is compacted.

Despite the fact that this is the simplest and most inexpensive way to create a winter water supply from a well, a problem arises with the choice of pipes: polyethylene pipes are not suitable here, because... will not withstand the mass of soil pressing from above, and metal pipes (steel) will corrode.

The problem can be solved by treating the pipes with an anti-corrosion compound before installation.

In addition to the problem with choosing pipes, this method of installing winter water supply has several other disadvantages:

- when carrying out repair work, there is a need for a large volume of excavation work;

- difficulty in finding a damaged section of the pipeline;

- the likelihood of freezing and rupture of pipes in the water supply system in case of insufficient depth of the water supply system.

To reduce the number of accidents in the water supply to a minimum, it is recommended to make as few pipe joints as possible, because It is at the joints that leaks most often occur.

Also, when installing a winter water supply system below the seasonal freezing level, it is necessary to especially carefully monitor the tightness at the junction of the water supply pipes and the well.

Method No. 2 - insulating the water supply

With this method, the water supply is buried to a depth of 40-60 cm, but the pipes are laid insulated in the trench.

For northern regions, it would be advisable to line the trench with bricks or cellular concrete blocks to increase heat retention.

Of course, this will significantly increase the cost of building a winter water supply system, but it provides a 100% guarantee against freezing.

From above, such a trench is covered with concrete slabs and filled with soil. Pipes for installing insulated water supply systems usually use the most common ones: low-pressure polymer pipes of suitable diameter.

What insulation should I use? There are two options here:

- hard heat-saving shells made of polystyrene foam or extruded polystyrene foam (“shell”);

- soft thermal insulation materials (foamed polyethylene options, mineral and basalt wool with external water-repellent protection).

When choosing a thermal insulation material for pipes, you need to pay attention not only to its cost and ease of use, but also to its physical properties.

For example, mineral wool is an inexpensive and easy-to-install insulation material, but it has high water-absorbing properties, which means it must be used with a mandatory vapor barrier layer.

Basalt wool based on sedimentary rocks is a fairly heavy insulation material that cannot be used for small-diameter pipes.

To backfill a trench with insulated pipes, it is best to use crushed stone or expanded clay rather than excavated soil.

These materials have a lower thermal conductivity coefficient than soil, and therefore will provide longer heat retention.

Organization of winter water supply

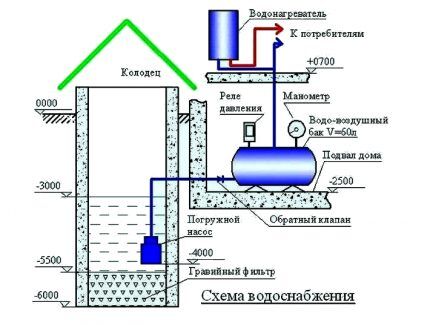

The winter water supply system in its composition is not much different from summer water supply. It also includes the following elements: pump, water pipes, storage tank or accumulator, drain valve.

At the same time, the installation of a winter system requires compliance with certain rules.

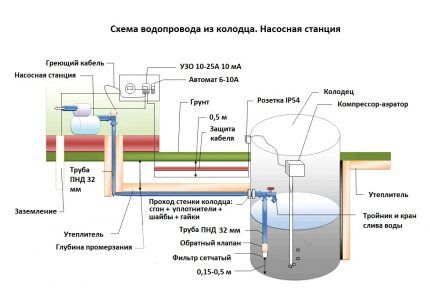

Step #1 - insulate the water supply pump

The pump and the cable feeding it need insulation. To thermally insulate a pumping station, you can use ready-made thermal insulation systems or build a casing yourself using mineral wool, polystyrene foam or other insulation materials.

The junction of the pump and water pipes (sump) also requires insulation. Typically the dimensions of the pit are 0.5 x 0.5 x 1.0 m. The walls of the pit are lined with brick, and the floor is covered with a layer of crushed stone or concrete screed.

Read how to choose a pumping station In this article.

Step #2 - thermally insulate the hydraulic accumulator

Storage tank or hydraulic accumulator must also be insulated. The tank acts as a storage tank, allowing the water supply system to operate uninterruptedly.

In the absence of a storage tank, the system will periodically shut down, which will lead to wear and tear of all its elements.

To insulate a hydraulic accumulator, you can use the following types of insulation:

- polystyrene foam or polystyrene foam;

- mineral and basalt wool;

- polyurethane foam and polyethylene foam;

- rolled fine-cell insulation with a foil layer.

The insulation process consists of installing the outer lining of the hydraulic accumulator, followed by finishing with the final material, if necessary.

Step #3 - take care of water pipes

For an insulated winter water supply with a laying depth of 40-60 cm, the best option would be to choose low-pressure polyethylene pipes.

Compared to metal ones, they have the following advantages:

- not subject to corrosion;

- low specific gravity;

- easy to install;

- much cheaper in cost.

The diameter of the pipes is calculated based on the planned water consumption at the design stage of the water supply system.

Water consumption depends on the number of people living in the house, the presence of water-consuming devices, the volume of water used for watering and caring for animals and other factors.

For example, a pipe with a diameter of 25 mm has a throughput capacity of 30 l/min, 32 mm - 50 ml/min, 38 mm - 75 l/min. Most often, HDPE pipes with a diameter of 32 mm are used for country and country houses with an area of up to 200 m².

Read more about how to choose insulation for water pipes Further.

Step #4 - install the drain valve and pressure switch

The drain valve is necessary to preserve the system; thanks to it, water can be drained into the well. If the water pipe is short, the drain valve can be replaced with a bypass drain pipe.

The relay performs the function of maintaining pressure in the water supply system, ensuring its uninterrupted operation and preventing ruptures and stagnation of water. When the maximum pipe fill level is reached pressure switch will turn off the pump.

Small installation tricks

Construction work begins with drawing up a water supply scheme (project). The diagram clearly shows the path that water takes from the point of water intake to the point of distribution of the water supply system in the house.

Wiring in the house can be done in two ways:

- consistentwhen the pipe is laid along the entire house and several water consumers depart from it;

- collector, in which a separate pipe is laid to each water consumer.

The first method is recommended to be used if the house does not have powerful sources of water consumers and there are 1-3 people living in it.

If you have a washing machine, watering hoses, automatic watering and irrigation systems, and if there are more than 3 people living in the house, it is recommended to install a collector water supply system to provide sufficient pressure for comfortable water use.

The technology for installing a winter water supply system will be as follows:

- Development of a water supply scheme. Selection of pipe materials and laying depth.

- Digging trenches for pipes.

- Installation of pumping equipment, hydraulic accumulator.

- Connection of pipes with pumping equipment and hydraulic accumulator.

- Inserting an intake pipe into a well.

- Installation of insulated pipes from the well to the house.

- Wiring the water supply system inside the house.

Installation of pipes from the well to the house is carried out using special pipes - short pipes with threads at the ends. The squeegee is pressed against the pipe using flanges or fitting adapters.

Both structures must be carefully sealed to avoid leaks. HDPE pipes are connected to each other using soldering or fittings.

The joints must be treated with silicone sealant. Treatment with bitumen and mastic is prohibited!

The depth of immersion in the well of the surface pump intake pipe should be slightly below the water level or at least 50 cm from its bottom. When lowering to the bottom, the elements of the bottom filter will be sucked in.

Before installing the intake pipe, water is pumped out of the well to ensure a tight connection with the elbow of the outlet pipe from the well.

It is advisable to equip the elbow with a tap to be able to shut off the water supply during repair work.

Pipes from the well are laid with a slope towards the well to ensure drainage of water from the water supply system during conservation work.

You can control the slope using a building level. To ensure gravity drainage, it is enough to maintain a slope of 2 degrees.

Another way to create winter water supply is the method of heating pipes. For this, a heating cable or plates are used, which are mounted along the pipes or wound in a spiral.

The installation of such a cable is advisable if the area is uninterruptedly supplied with electricity.

If the power supply is turned off, the uninsulated pipe will immediately freeze and the water supply system will fail.

The best option can be considered a combined method, in which insulated pipes are heated heating cable. In this case, the cable will consume a minimum amount of electrical energy.

An innovative way to install water supply

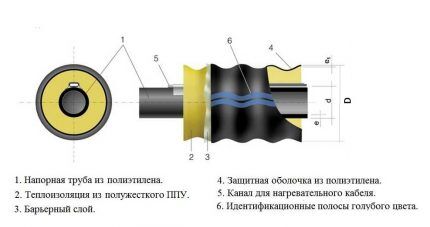

More recently, a new method of creating a winter water supply system has been developed, based on the use of flexible polymer pipes insulated industrially.

There is a layer of waterproofing on top of the thermal insulation shell of such pipes, and a special channel is made along the surface of the pipe for laying a heating cable, which greatly simplifies installation and reduces the time required to lay the water supply system.

The pipes are flexible and supplied in coils, which allows the number of joints to be minimized, which means reducing the risk of leaks and the need for repairs to zero.

Conclusions and useful video on the topic

Installation of finished thermal insulation elements on pipes before laying them in a trench:

Winter water supply in a private house:

Installation of heating cable:

Installing a winter water supply system is a simple process that allows you to uninterruptedly receive water throughout the year. The basic principle of creating a winter water supply system is to prevent pipes and system elements from freezing.

This can be done by installing an insulation system using thermal insulation materials or by laying pipes below the freezing level of the soil. The choice of method depends on the climatic conditions of the area, landscape and hydrogeological features of the site, as well as on the personal preferences of the owner.

If you have the necessary knowledge or skills for arranging winter water supply from a well, please leave your comments in the block below. There you can ask questions about the topic of the article.

When installing the water supply system, the builders we hired laid the water supply system above the freezing level - our winters are warm, and it turned out to be more economical. In addition, the area where the system enters the basement of the house was poorly insulated. As a result, in winter we sat practically without water, tried to warm up the pipes with a soldering iron - the first frost turned into ice plugs in the pipes, in the spring they redid everything. We didn’t dare save any more money.

To do this, it is necessary that the pipeline from the well to the house is sufficiently protected from frost. Again, take into account the climatic conditions: either it is Siberia or the South of Russia.It is necessary to maintain a slope so that water can be freely drained from the system before it is preserved. The pipes are laid deeper than the freezing level of the soil; it is possible, of course, higher, but then the external water supply branch will have to be completely insulated. When we were setting up our system, we dug a trench to a depth of 1 meter, which is 20 cm more than the freezing depth, and laid pipes. Only the area was insulated before the water supply was introduced into the house. Pumping station in a heated utility room.

In Siberian conditions, I won’t be able to bury it below the freezing depth; I’ll have to insulate it with something. I'm thinking about the heating cable.