Do-it-yourself potbelly stove: diagram of a homemade potbelly stove for a summer house and garage

Often homeowners prefer to assemble simple and useful homemade products from scrap and unnecessary materials, instead of buying ready-made ones.And a potbelly stove is one of these useful devices.

The main feature of a potbelly stove is that it heats up as quickly as it cools down. Therefore, the scope of its use is narrowed mainly to those rooms where it is necessary to provide rapid heating, while the appearance of the device is often completely unimportant for the user.

You can make a potbelly stove with your own hands, and, if desired, modernize it to achieve more efficient heat transfer.

Are you also thinking about assembling such a homemade product and don’t know where to start? We will help you in implementing the task - the article discusses the procedure for assembling various versions of a homemade stove, drawings and diagrams are provided.

Also discussed in detail are ways to improve a homemade potbelly stove, as a result of which the efficiency of the stove will become noticeably higher.

The content of the article:

How to make a potbelly stove: device and diagrams

The choice of furnace design depends on what material is used as fuel. Each user himself determines the degree of its availability and economic feasibility.

It is the combustible material, which has different temperatures and combustion patterns, that dictates the principles for creating different modifications of the device.

The shape of a potbelly stove can be different, often depending on the availability of suitable material.This could be an old can, a gas cylinder, a metal container - whatever is at hand. The main thing when choosing it is the thickness of the metal and the shape, which requires a minimum of alterations.

Waste oil stove

Used engine oil is a multi-component, slightly flammable substance that, in order to be burned, must first be broken down into simple components. For this purpose, the method of pyrolysis or flame separation is used, in which fuel is heated and evaporated.

To do this, light a fire using a rag soaked in gasoline or kerosene. Fuel, when heated, splits into simpler, flammable substances. Then the pyrolysis combustion process supports itself.

Step-by-step description of work

The manufacture of a potbelly stove using waste oil is carried out in the following sequence:

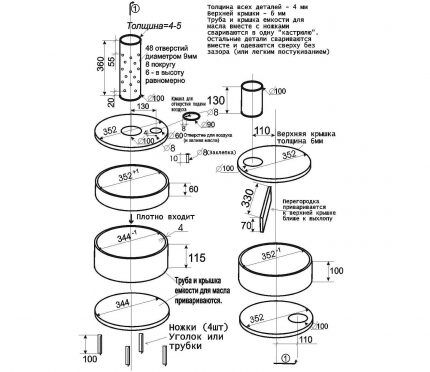

- Take two pieces of pipe with a height of 100 and 115 mm, a diameter of 350 mm - they will serve as the basis for creating two chambers.

- A bottom and a cover with holes are welded to the ring with a higher height: the first with a diameter of about 100 mm for the pipe; the second is small in size for air intake. For the blower, a damper is made from a circle of slightly larger diameter.

- In the pipe, which is fixed on top of the fuel compartment, holes are drilled evenly along the entire length.

- A second chamber is made with holes for the chimney and secondary combustion pipe. A partition is made from a rectangular sheet of metal inside it.

- A chimney pipe is installed on top, and legs are welded to the base.

The design of a cylindrical two-volume boiler during exhaust operation ensures high temperature and complete combustion of fuel. Instead of cylindrical ones, rectangular chambers can be used.

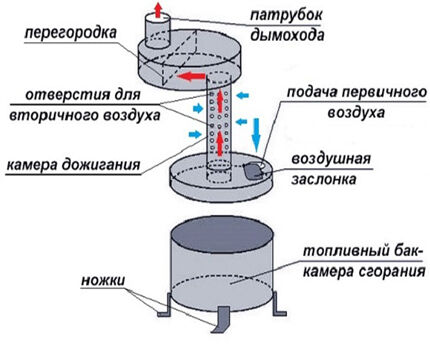

Operating principle of the furnace

Fuel is poured into the lower reservoir of the potbelly stove through a small hole. At the same time it serves as an evaporator and a primary combustion chamber.A small hole on the lid is also intended for ignition, air supply and regulation of air flow (using a damper).

A pipe with holes installed in the first compartment serves as a secondary afterburning chamber - pyrolysis decomposition of the fuel occurs in it, which evaporates due to heating in the first chamber.

The next cylindrical container is equipped with an internal partition to reduce the speed of movement of combustion products, ensuring an increase in the degree of oxidation of nitrogen compounds. At the same time, it serves as both an infrared and convection heater.

It is in potbelly stoves for garages that waste is most often used as fuel. Of all heating devices, it is one of the most dangerous.

If someone decides to violate fire safety rules and make a stove on their own, it is better to allocate a separate room for the boiler room or fence it off with a brick wall.

On our website there are other materials on the manufacture of waste oil stoves:

- Stove using waste oil from a pipe: how to make an effective stove using waste oil from scrap materials

- How to make a potbelly stove using waste oil with your own hands: options and examples of making a stove

- Do-it-yourself garage oven: the best examples of making homemade products

- Do-it-yourself oven for the garage: a step-by-step design guide

Installation of a stove for solid fuel

Firewood, brick, coal are by far the most accessible and economical fuel materials. Its use is the least safe, which means that a stove running on this fuel is the easiest to make.

There are extremely many options for various modifications of potbelly stoves made by yourself. Let's look at the most common models.

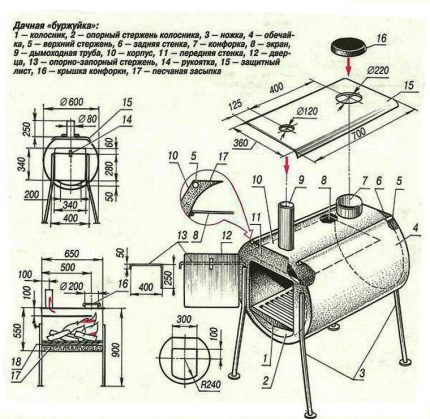

Potbelly stove made from a cylinder and a barrel

An old gas cylinder made of thick-walled metal is suitable for any type of fuel, including coal. A simple design will cope with the task of quickly warming up the room, but as soon as the supply of fuel stops, it will quickly cool down.

A homemade cylinder stove is compact and has a neat appearance. This type of potbelly stove is used for a summer house, temporary shed, or garage.

To make a stove from a gas cylinder, you need to cut holes in the body for the door and for the chimney. The cut out sections of metal will serve as doors after the curtains and locking mechanism are welded to them. To allow air to enter the firebox, the door at the bottom is drilled through.

We reviewed a detailed description of the process of making a homemade chimney for a potbelly stove. in another article.

A grate made of grate (it can be welded from reinforcement) is placed at the bottom of the chamber, under which ash will accumulate. You can also organize a hob. It is easier to do this on a horizontally located cylinder by welding corners on it on both sides.

A potbelly stove made from a gas cylinder can also be used as a basis for the further construction of a hot water column, as it is also called “Titan”. To do this, a stainless container is installed on top of the stove, through which the chimney pipe passes.

The water in a wood-burning boiler heats up quickly, and little firewood is used - in the summer, one load into a small firebox is enough.

A metal container with walls at least 3 mm thick is also suitable for a potbelly stove. The open top of the container is closed with a circle of metal sheet and brewed.

A hole is cut out in the lid or wall for the chimney. Its diameter should be at least 100-150 mm. The top of such a potbelly stove will heat up so much that you can cook food and heat water on it.

We also have more detailed instructions on our website with diagrams and drawings for manufacturing potbelly stoves from a gas cylinder.

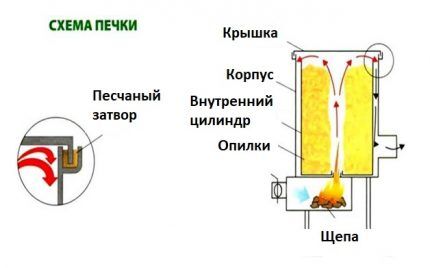

Features of a sawdust stove

If there is no shortage of sawdust on the farm, then this type of fuel will fully justify its use. Such a potbelly stove does not require frequent loading - the compacted sawdust inside does not burn, it smolders slowly, releasing thermal energy gradually and providing heat for a long time.

We recommend that you look at the information on how make briquettes from sawdust with your own hands.

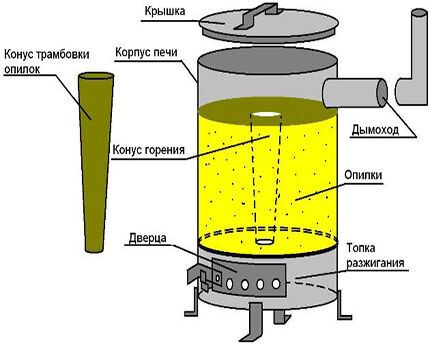

The basis of the furnace can be a metal barrel with an open top (if the container is sealed, the top is cut off) or a pipe with a diameter of 300 to 600 mm.

Then a metal circle is cut out of a sheet three or more millimeters thick, which should be smaller than the inner diameter of the barrel. In its middle, a hole with a diameter of 100 mm is cut under a cone for compacting sawdust.

The workpiece is welded to the walls of the barrel. Using this circle, the ash pit is fenced off - in it, with the help of shavings or wood chips, ignition will be carried out. The height of the ash pan should be 100-200 mm.

Below the welded circle, a window is cut out, which will serve as a blower. Curtains are welded to the cut piece of metal, making a door for the same hole.

An exit to the chimney is made in the lid of the container. The lid must fit tightly onto the potbelly stove and be made of a fairly thick sheet, otherwise it will quickly burn out.

The same model can be improved by adding an additional cylinder. In this option, the sawdust will be in the inner chamber, and the space between the two compartments will serve to burn gases and increase the heating area. In this option, the outlet of smoky gases is arranged in the lower part of the stove.

How can you improve your potbelly stove?

An ordinary potbelly stove has a lot of positive qualities, but also has many significant disadvantages.It is unable to accumulate heat and heats the room while the fire is burning. Requires continuous fuel supply, on average every 30-40 minutes.

In addition, a large amount of heat escapes through the chimney into the atmosphere, bringing no benefit. That is why work on improving the potbelly stove is ongoing.

The standard design of a potbelly stove has many modernized designs that allow:

- save fuel;

- increase the efficiency of the stove;

- increase heat capacity;

- reduce the frequency of fuel filling.

The most common methods for increasing the efficiency of a potbelly stove are creating a slow burning mode, a gas afterburning system, and installing heat-resistant lining of the internal walls.

You can also improve the quality performance of the stove by increasing the heat transfer area using welded pipes and an installed fan that will drive air flows through them.

The industrial model of such a potbelly stove is called “Buleryan”, but besides it, there are many different designs made by handicraft. We recommend watching a detailed master class on homemade production "Buleryan" stoves.

You can increase the heat transfer time if you line the stove with brickwork. Such a potbelly stove will heat up more slowly, but will also give off heat longer, maintaining the temperature in the room for some time after the fire has died down.

Are you interested in brickwork? We have a detailed guide on our website. furnace masonry with your own hands with diagrams and drawings.

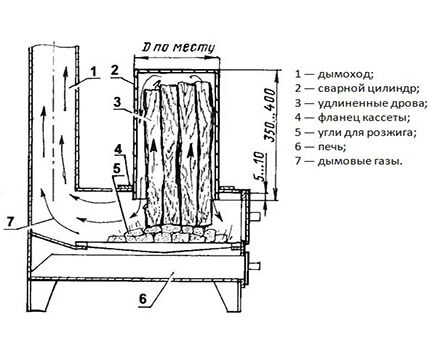

Option #1 - stove with increased fuel load

This model is designed to increase efficiency and continuous burning time.The basis is taken as a horizontal rectangular potbelly stove on massive, stable legs and complemented with a cassette made of a blind sealed cylinder. Such design additions significantly increase its efficiency.

A flange is welded to a cassette cylinder about 400 mm high. After installing the cylinder in the burner hole, its edge should fall 5-10 mm below the stove plate. To make it easy to install and remove the cylinder, handles are welded to its body.

How does a potbelly stove work:

- The lower part of the firewood, falling on the coals of the preparatory ignition, flares up. In this case, the upper part, located in the cassette, will not burn due to lack of oxygen, but will dry under the influence of hot smoke.

- Under the weight of its own mass and as it burns, the firewood gradually falls into the firebox.

- The hot gas, which is in the cylinder for some time, gives off heat to it, thereby increasing the heat transfer area in the room. In this case, the cylinder cover can serve as a cooking surface.

- At the same time, the temperature of the exhaust smoke decreases, which means the heat capacity and efficiency of the potbelly stove increases.

As a result of this modernization, the time interval between laying firewood increases and the efficiency of using the stove increases.

Option #2 - long-burning potbelly stove "Bubafonya"

The low efficiency of a conventional potbelly stove is a fact that has long been known and verified by many users.

One of the methods to increase it is to slow down the combustion process by limiting the flow of air into the combustion chamber.This improvement can be found in such stoves as “Bubafonya” and “Filipina”.

This model of potbelly stove is used in non-residential premises - workshops, greenhouses, and other outbuildings. To work for 9-12 hours, one stack of small firewood, chips, and sawdust is enough. Coarsely chopped and damp firewood cannot be used in this heating device model.

A potbelly stove can be created from any metal tank. Most often they use a barrel of fuel and lubricants or an old cylinder.

Manufacturing is carried out in the following sequence:

- A combustion chamber is prepared from an accessible cylindrical container, in the upper part of which a hole is cut for the chimney.

- A circle is cut out of metal (at least 10 mm thick), slightly smaller than the inner diameter of the barrel.

- A hole with a diameter of 100-150 mm is made in the center of the circle (the exact size depends on the diameter of the rod pipe used).

- Ribs up to 50 mm high are welded onto one of the planes of the circle.

- A pipe is welded to the center of the circle. Its length is calculated so that the piston, when lowered, rises above the reservoir lid by approximately 100 mm. If you leave the pipe longer than necessary, draft will arise in it and it will begin to smoke.

- Next, they build a lid that will fit tightly on the barrel and cut a hole in it that fits the piston pipe

You can further increase the efficiency of this model by organizing the supply of air from the street into the firebox. Thus, heated air from the room will not fly out into the chimney.

Option #3 - furnace with secondary combustion “Filipina”

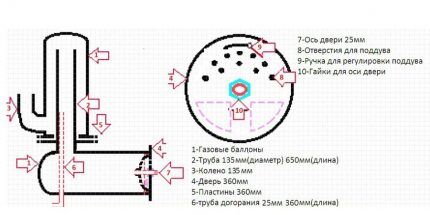

The furnace uses two methods to increase its efficiency, based on the principles of long-term combustion and pyrolysis. To make it, you will need two gas cylinders, which will serve as chambers for primary and secondary combustion.

The sequence of actions for making a potbelly stove is as follows:

- The cylinders are prepared for use by releasing the remaining gas from them and filling them with water. Without this procedure, it is absolutely impossible to cut them, otherwise the sparks that are formed during the operation of the angle grinder can provoke a gas explosion, a certain amount of which always remains in the cylinder.

- In the first cylinder, which will serve as a chamber for the firebox and ash pan, remove the tap and cut off the top (it is used to make the door), and cut out a hole for installing a chimney.

- Opposite the hole for the chimney, a pipe is welded, the other end of which should not rest against the lid of the second chamber, leaving free space for smoke to escape.

- At the outlet of the pipe from the first cylinder, a metal ring is welded; it will serve as a support for installing the upper cylinder. Holes are drilled in it.

- A metal ring is also welded to the second cylinder where the top is cut, in which the locations for the holes are marked, focusing on the holes already made in the first ring.

- Before finally installing the second cylinder, an air supply pipe is inserted into it.

- Place the upper chamber on the pipe, aligning the holes, wind a heat-resistant rope between the rings, and secure the connection with screws.

- The chimney exit is made from the bottom of the secondary combustion chamber.

To obtain a stable structure, reliable legs are welded to the lower chamber.Install the door on the awnings. It can be further improved by adding the ability to regulate the air entering the firebox.

In the first chamber of the potbelly stove, wood burns, releasing flammable gas. Hot flue gases, entering the second chamber and mixing with air, ignite and burn completely.

With the help of a blower, the draft is regulated, which, after the firewood has ignited well, can be reduced to a minimum in order to reduce the speed of gas movement and heat loss.

Conclusions and useful video on the topic

How to maximize the potential of a potbelly stove using used machine oil:

An improved potbelly stove made from a gas cylinder with a secondary combustion chamber:

Design and rules for using the Bubafonya long-burning stove:

When making a homemade potbelly stove, you should not forget about safety precautions. Its design should provide maximum protection against the spread of fire.

Neglect of fire safety rules can play a cruel joke on those who want to save money on purchasing an industrial model.

Have you been using a homemade potbelly stove for several years now? Tell us what scheme you used and what was the most difficult thing when assembling the stove.

Perhaps you have improved your potbelly stove using one of the methods discussed in the article? Share your experience and pictures of your homemade stove in the comments to this article - your successes will inspire other users to experiment.

Using a potbelly stove under normal conditions is indeed not entirely advisable.But I would recommend connecting the furnace to a water circuit. It is thanks to this combination that it will be possible to warm up the rooms much better. Moreover, the heat will be distributed more evenly throughout the house. As a result, the efficiency of your stove will increase significantly. Plus, it’s better to use solid fuel - it’s usually easier to get.

Homemade potbelly stoves are the lot of garages and small garden and country houses. They occupy their niche and are quite appropriate in it. Their heat output is quite enough to heat compact rooms even without additional gadgets, in the form of a water circuit, etc. Here, improvements will likely be in demand that will save fuel and reduce the frequency of its loading.

After reading it, it seems that making a stove with your own hands is a simple matter. In reality, everything is not quite like that. There are a lot of different nuances, failure to comply with which will not allow the wood to burn properly and will not create the correct draft. It is useless to talk about them; everything can only be learned through experience. So, if you have a desire with possibilities, then be patient and experiment in creating your own furnace monster. If you don’t have enough patience, then it’s better to go to the store - you’ll save both time and nerves.

Have you seen the prices for potbelly stoves? It feels like they are selling a solid fuel boiler.