Do-it-yourself oven for the garage: a step-by-step design guide

In garages or workshops, in order to save money, they often install a working furnace instead of an expensive boiler: they process metal parts with their own hands, weld them and get a model that resembles a “potbelly stove.” However, when choosing a design for manufacturing, you may encounter difficulties. Do you agree?

We will tell you how to choose the optimal scheme and assemble an economical but very effective heating device yourself. The article we propose examines in detail popular options, the effects of which have been tested in practice. Advice is given on the construction and subsequent operation of the stove.

The content of the article:

What is oil waste?

Waste oil or used oil is the product that remains as a result of the operation of a car engine. Motor, transmission or other industrial oil accumulates in large quantities at service stations, in automobile workshops, as well as among ordinary car owners.

During use, the oil loses its beneficial qualities, accumulates salts, slags, resins, and tiny particles of metal, but people have found use for such an illiquid product.

In small quantities it is used for household needs:

- lubricate working tools (for example, chainsaws);

- impregnate wood (sleepers for railway lines);

- lubricate rubbing parts of light vehicles (scooters, bicycles);

- used as a fire starter;

- cover surfaces filled with bitumen.

As at the end of the last century, waste is used as fuel for furnaces installed in semi-residential premises - garages, utility rooms, workshops. If you build a stove yourself, then with constantly replenished supplies of used oil, heating the room will be practically free.

Other effective ways to organize economical garage heating presented in an article entirely devoted to this issue.

Why are waste oil furnaces popular?

The main reason for people's love for homemade stoves is the low (or zero) cost of the unit itself and the fuel for it. Some home-grown craftsmen make such heating devices as an experiment and at the same time a useful device.

With the advent of a homemade waste oil stove, the issue of “attaching” recyclable materials no longer exists.

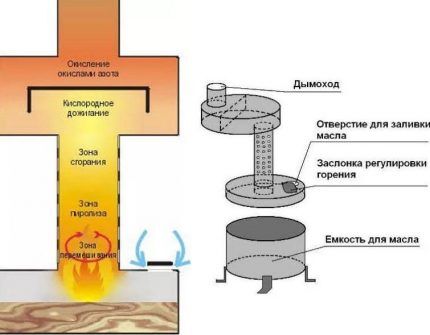

How does the unit operate during testing? The process consists of splitting heavy fuel with impurities, which has a rather complex composition. In another way, the process in which there is a lack of oxygen and the combustion of not the fuel itself, but its vapor, is called pyrolysis. Operating principle pyrolysis equipment described in our recommended article.

To start the process, it is necessary to evaporate the fuel, then heat the resulting vapor to a temperature of about +300-400 ºС, after which combustion will occur spontaneously. All you have to do is wait for the fuel to burn completely.

There are 2 schemes that are used when making stoves independently:

- filling the tank with oil and setting it on fire, as a result of which the vapors evaporate and begin to burn;

- the use of a burner in which three zones (pyrolysis, ignition and afterburning) are combined and make the combustion process more efficient, controllable and safe.

The second scheme is more complex, requiring serious modification of the fuel and manufacturing precision, so we will consider simpler models from the first group.

Advantages of using an oil-based garage stove:

- ease of design and maintenance of the device;

- fuel economy - about 1.5-2 liters per hour;

- absence of soot and soot;

- safety of storage of mining reserves;

- it is possible to connect an air or water heating circuit;

The compactness of the unit is also extremely important for small spaces.

There are also disadvantages:

- the need for regular cleaning of the stove and chimney;

- a mandatory element is a vertical chimney with a height of at least 4 m;

- for furnaces with nozzles, only purified oil should be used (the approximate cost of a filtered product is 8-12 rubles/l);

- One of the conditions for storing mining is above-zero temperature, that is, you need either a room heated in winter or a tank buried in the ground.

Before manufacturing/purchasing a finished stove or boiler in operation it is necessary to consider all the pros and cons of homemade devices, and then make a final decision.

DIY Projects

There are a great many options for manufacturing furnaces for mining. They are made from metal blanks or used containers (cylinders), with pyrolysis and turbo burners, with drip feed or blowing. We will focus on two popular models that are more suitable for independent design and assembly.

Sheet metal model

In garages and nearby areas you can often find unnecessary metal parts, cast iron plates, steel sheets, and pipes. Among them there will probably be several items suitable for welding a stove.

For example, to make a simple model you will need the following material:

- old steel sheet 3.5 mm thick;

- a piece of steel pipe with a wall thickness of 4.5 mm;

- tin pipe for chimney with a diameter of 110 mm.

In addition, you will need a tool that any garage owner usually has available: a welding machine with electrodes, a circular saw with cutting and grinding discs, a hammer, and pliers. A set of working protective clothing for welding work with goggles and gloves is required.

Before the welding process, we prepare some of the parts.

When some of the parts are prepared, we begin welding work, but we don’t put the circular saw far away - it can be useful for cutting out or cutting off individual fragments.

To prevent precipitation and debris from entering the chimney, we secure the cap at the end with self-tapping screws. The safe height of the chimney is about 4 m. Combustion products discharged above the roof will quickly dissipate in the atmosphere and will not harm people or plants.

After complete completion of the assembly and installation work, it is necessary to carry out testing and, if flaws are found in the work, try to correct them. We check the combustion quality in the following order.

During the design and welding process, the following errors may be identified:

- too thin walls of chambers and pipes (rapid wear, inability to retain heat for a long time);

- the hole is not large enough to fill oil and adjust the combustion force;

- poorly chosen location for installing the stove;

- different diameters of the stove pipe and chimney (you will have to use an adapter for connection);

- inaccurately adjusted dimensions of parts for welding (the seams will be loose and will not last long);

- ignition with gasoline - an explosion is possible, it is better to use solvents (White spirit and the like).

If you weld the stove according to the rules, it will last a long time and easily heat a room of 20-30 m². With organization options heating during testing An article devoted to this difficult issue will introduce you.

How to make a stove from a gas cylinder?

The second option, which has become popular thanks to a successful assembly scheme, is a stove made from a regular gas cylinder, empty of contents.

First we draw up a diagram of the furnace.

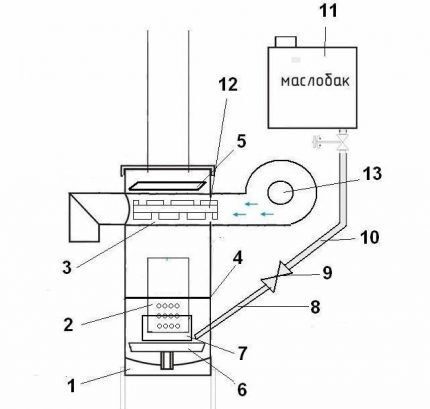

Cylinder volume – 50 l. The wall thickness of metal pipes is 4-5 mm, internal cross-section is 100 mm. To create a partition between the two chambers and make a visor, it is better to use pieces of metal sheet with a thickness of at least 4 mm. A brake disc is used as a reservoir for oil from which evaporation occurs.

The oil enters the evaporator through a ½ inch pipe. The part of the pipeline above the ball valve can be flexible to ensure ease of installation. A ball valve is installed so that it is always possible to shut off the fuel supply in an emergency. To manufacture the swirler, a pair of metal corners welded together was selected.

Next, we’ll look at how to make a compact waste oil stove for a utility room or garage.

In order for heated air to circulate throughout the room, it is necessary install a heat exchanger. This is a steel pipe with a diameter of 100 mm. The most suitable place is inside the housing, between the burner and the flue pipe. To hold the flame, we weld a metal platform cut from a 4 mm sheet to the top of the heat exchanger.

We organize forced air supply using a duct fan. It can be made automatic by using a thermal relay. To better preserve heat, we place a swirler inside the pipe - a structure of two welded metal corners, the shelves of which are cut and deployed in the form of blades.

It remains to make two doors, each of which has nuances. The upper mandatory part is a strong lock that ensures reliable closure while the oven is operating. We make a gap at the bottom of the second door so that air can freely flow inside the housing and support the combustion of the oil.

After manufacturing the furnace, we carry out testing. Pour a little oil into the pan, then place a small piece of sponge soaked in solvent there. Set fire to the sponge. The oil heats up, begins to evaporate, and a flame appears in the burner.

We gradually feed the oil into the evaporator through the tube. If it is necessary to stop the combustion, shut off the exhaust flow (close both valves). As soon as the residues in the pan are burned, the combustion process will stop.

Schemes and rules for making a stove for mining from a pipe are given here. We recommend that you read the useful information.

Rules of operation and safety

No matter how much they talk about the safety of homemade stoves, they remain devices, improper handling of which can lead to burns or fire of surrounding objects. As a result, there are a number of prohibitions.

The following actions cannot be performed:

- use other types of fuel instead of used oil;

- use faulty equipment;

- install a heating device in a room without well-established ventilation;

- light a fire if the stove is not equipped with a smoke exhaust duct;

- block the hole in the burner;

- leave the room with the stove running for a long time;

- place flammable liquids or objects near the heated body;

- Spray oil or water onto the hot surface.

Only adults have the right to use the stove; children or animals are not allowed near it while the unit is operating.

As an interesting and original example of a stove under development, we suggest considering potbelly stove manufacturing technology. This is also a very effective model, available for self-production.

Conclusions and useful video on the topic

The process of creating and launching a heating device is much easier if all safety measures are taken and the nuances of manufacturing and installation are taken into account. We offer videos with useful recommendations.

Video #1. How to start the oven correctly:

Video #2. Review of a working furnace. Tips for use:

Video #3. Hints on device and use:

The issue of waste disposal can be resolved quite easily by building a metal furnace in the garage. A homemade heating device that runs on cheap fuel functions no worse than expensive purchased models.

But if you are not confident in your abilities, it is better to seek help from experienced craftsmen who are closely familiar with the nuances of manufacturing and installing oil furnaces.

Those wishing to share their own experience in constructing a stove for mining are invited to leave comments in the block below. Perhaps you have information on a topic that would be useful to site visitors? Please write in the block below, ask questions, post thematic photographs.

An interesting idea, but I doubt the safety of this design: the sheets are old, the cylinder is not the first freshness. Sometimes with such advice you can do such a thing that it won’t take long for you to suffocate. People, trust the installation of such a system only to professionals. Don't spare a penny and pay for quality work by knowledgeable specialists.

Such a stove is also harmful to the environment.

Well, safety only depends on the straightness of your hands and the materials you choose. It’s not that difficult to make a reliable stove during mining. But even high-quality materials cannot get rid of its environmental friendliness. True, it’s all right for a garage, but you can’t put one like this in a dacha - it pollutes the groundwater and the garden. Just a minus. In my opinion, she still has more disadvantages than advantages.