How to make a Buleryan oven with your own hands: step-by-step instructions for making

Externally, the Buleryan stove resembles a potbelly stove with a fancy design.But the efficiency of this device is much higher, and the scope of application is wider.

Industrial production models are quite popular, but by making a Buleryan stove with your own hands, you can provide heat for a garage, outbuilding, or even a small house. Agree, the idea is interesting, and the savings on purchasing a new unit are quite noticeable.

In the prepared article you will find all the necessary information for constructing a heating unit. We will tell you how the Buleryan stove works and works, describe what materials and tools will be needed during the work, and also provide step-by-step instructions for making a homemade product.

In addition, the article provides practical tips on arranging a chimney and maintaining a heating installation. By following our recommendations, you can organize efficient and safe heating of a small room.

The content of the article:

The operating principle of the Buleryan (Berneran) stove

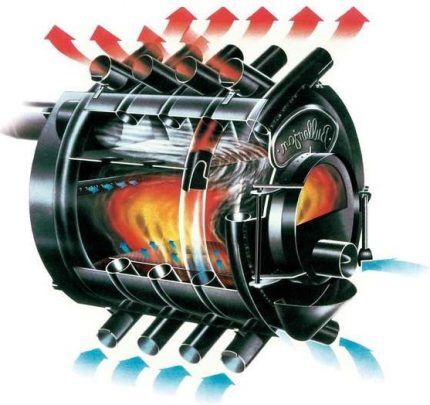

The operating principle of the Buleryan is ingenious in its own way. It combines the operating features of a long-burning furnace and convection of air masses through special tubes. These elements allow you to immediately visually distinguish the Buleryan stove from other devices of this type. The combustion chamber is designed in such a way that the fuel burns slowly.

Typically the load is designed for 12 hours of continuous operation. This allows for round-the-clock operation of the device with only two fuel loads: in the morning and in the evening.

The highlight of the design is the air tubes.They are integrated into the combustion chamber body and form part of it. The upper and lower sections of these tubes remain open.

Cold air enters the air ducts from below, heats up quickly enough and exits through the upper openings into the room. Convection is carried out constantly, so gradually all the air in the room warms up well and quickly to a comfortable level.

Using tubes as the body of the device has another undoubted advantage: constant air circulation does not allow the surface to heat up to a dangerous level. As a result, it is much more difficult to get burned by touching the Buleryan stove than by contact with the surface of a potbelly stove.

In this way, you can heat not only air, but also water. To do this, you will have to connect the Buleryan stove with a heat exchanger through which water heating circuit.

It is worth noting that to ensure the fuel combustion process in such a device, ignition is first performed, during which firewood is added gradually in small portions until the chamber is filled. After this, all that remains is to load firewood into the firebox every 12 hours.

The firebox carries out a process of slow combustion of wood, which takes place in two stages, as in other boilers of this type. At first, the fuel burns slowly with little oxygen.This process produces a flammable gas. It then connects with air.

The second stage is the combustion of this gas-air mixture, which releases a large amount of thermal energy.

Factory stoves and long burning boilers are characterized by high efficiency, since they allow you to obtain much more heat than with conventional wood combustion. The efficiency of the Buleryan furnace thanks to the implementation of this technology is about 80%.

The productivity of even small models can exceed five cubic meters of warm air per hour, which is quite enough even for spacious rooms.

Design and device features

The Buleryan stove consists of the following elements:

- a combustion chamber formed from bent tubes and strips of metal;

- secondary combustion chamber;

- back wall;

- front wall;

- fuel loading door;

- chimney pipe;

- ash pan;

- injector;

- chimney damper;

- power regulator;

- blower, etc.

The back wall is made of two sheets of metal separated by a small space. This protects part of the device body from heating up to high temperatures, and also increases the overall efficiency of the furnace. In the secondary combustion chamber, combustible gases formed during the smoldering of fuel in the primary section of the combustion chamber are burned.

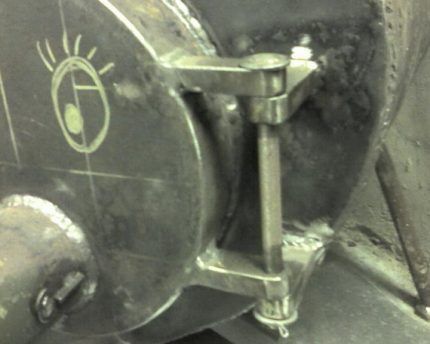

On the front wall, in addition to the door, there is a handle with which you can regulate the amount of air entering the chamber. The chimney damper performs similar functions. You can use only one of these elements to control the combustion process, or use them simultaneously.

Dimensions of the ash pan, i.e.The containers for collecting ash are small, and this is quite justified. If the Buleryan stove is started correctly, then during operation the wood will burn almost completely, so a minimal amount of ash will be produced or there will be no ash at all.

Several important elements are mounted into the front door. It is assembled separately and then hung using welded metal hinges. To increase the efficiency of the device, some manufacturers cover the Buleryan stove with a double casing. This is not a mandatory, but desirable element in the design.

If you have enough sheet metal available, once the basic assembly of the stove is complete, you can weld curved pieces on top of the tubes, which will hide the tubular “fins” and make the device safer.

DIY process

Considering the design of the device is not the simplest, it makes sense to draw up a drawing of the Buleryan stove in advance or find a ready-made project, for example, on the Internet.You will have to do a lot of cutting and welding of sheet metal, which requires a welding machine and skills to work with such equipment.

To successfully cut metal, experts recommend using patterns.

The main material for the manufacture of the Buleryan stove is sheet metal 5-6 mm thick and metal pipes with approximately the same wall thickness and an outer diameter of 50-60 mm.

To give the tubular elements the desired configuration, it is advisable to use hydraulic pipe bender. To check the position of individual elements relative to each other, use a construction hydraulic level.

For the normal flow of the work process, you will need a number of other devices and materials:

- electrodes for the welding machine;

- pipe cutter;

- roulette;

- marker;

- clamps;

- square;

- ruler;

- Grinder.

They usually start with cutting metal and cutting pipes. Then the remaining metal is removed, and the individual elements are welded together, gradually assembling the furnace.

You need to cut the required number of tubes (for example, eight pieces, depending on the specifics of the project) with a length of 120 cm. Using a pipe bender, they are bent to a radius of 225 mm. The elements of the rear and front walls, doors, regulators and strips for the housing are sequentially cut out of a sheet of metal.

The remaining metal is used for the manufacture of door elements, ash pan, pipes, etc. Blanks for the V-shaped chamber are made separately.The metal strips for the body are cut with a width slightly larger than the outer diameter of the tubes. Oval cuts are made at the ends so that they can be welded tightly to the tubes.

The inlet and outlet pipes can also be made from strips of sheet metal, bent into a ring. An alternative is to simply cut pieces of suitable length from the metal pipe. But its diameter must be larger than that of the structure used for the device body.

Assembly of the device begins with tubes. The correctly bent elements must be laid in a checkerboard pattern so that the back side of the structure is at the bottom and the front side is at the top.

To ensure that the pipes are in the correct position, wooden blocks with a thickness equal to the outer diameter of the metal elements are used.

If the pipes are cut and bent correctly, it will be possible to lay out such a “pyramid” on a level base without any problems. After this, the pipes should be welded to each other at the points of contact.

The resulting structure can now be turned over and a V-shaped pan can be welded in the space between the “ribs”. It will separate the primary combustion chamber from the secondary. An injector should be made in one of the front wall tubes to supply air to the secondary combustion chamber.

After this, you can continue to form the stove body by welding the previously cut strips of metal to the ribs. The optimal option is when approximately two-thirds of the pipe diameter is recessed into the body, and a third of these elements remains outside. You will have to tinker with the manufacture of the front wall of the stove.

In the blank for the door, first make a hole for the blower. A pipe is welded to it, in which a damper will be installed to regulate the flow of air entering the primary combustion chamber.

For the damper, you need to cut out a round part, the diameter of which exactly matches the dimensions of the pipe. A pin is welded to the damper. After this, a hole is made in the pipe along the axis into which this pin is inserted.

A hole is made in the blank for the front wall for the door. A narrow strip of metal is welded to it around the circumference.

You need to weld two such strips of metal to the door itself, one along the very edge, the other should be inside at some distance from the first. If everything is done in accordance with the drawings, then the “collar” on the front wall will fit exactly into the gap between the edges of the door.

It is recommended to lay asbestos rope in this space to ensure maximum tightness when closing the door. Now you need to weld its inner part to the door, as well as the hinges on one side and the eccentric latch on the other.

The eccentric lock ensures a tight fit of the door to the front wall of the stove for maximum tightness, which is important during long-term burning of wood.

It is better for an inexperienced craftsman to order this element from a professional turner. Hinges and a metal pin for the latch are also mounted on the oven body.

Now a double back wall with a hole for the chimney pipe is welded. This element is first applied to the finished structure to make sure that its contours exactly match the outlines of the pipes fastened together.

At this stage, you can cut off the excess without any problems. This also applies to other elements - before welding, they are checked for consistency and adjusted if necessary. Now the oven is almost ready. Four legs need to be welded to the body. They can be made from bent pieces of thick wire.

The legs are welded to the front and rear walls of the housing. The finished device is installed on a flat and durable base, covered with fire-resistant materials: asbestos, smooth slate, ceramic tiles, etc.

It would also be a good idea to protect the walls around the stove from exposure to high temperatures.

Now a pipe is attached to the chimney pipe and secured with a coupling connection. In this case, the pipes are installed in a position opposite the direction of gas movement, although the manufacturer recommends doing otherwise. It is recommended to insulate the chimney, for example, with mineral wool.

Helpful operating tips

“Wrong” installation chimney pipes due to the need to protect the structure from resin, which is formed as a result of wood combustion. If this moment is not provided for, then the resin will flow out of the stove, and with such an installation it will remain in the chimney and gradually burn out.

Clogging with resin for the Buleryan stove is almost inevitable. Over time, resinous layers accumulate and clog the device.This is expressed in a noticeable reduction in the efficiency of its operation, a decrease in traction, and problems with the free movement of the gate. So it's time to start cleaning the oven.

A lightweight version of this cleaning is to heat the device with aspen firewood. Unfortunately, the practical benefits of such a measure are small and short-lived.

The best way to eliminate resin contamination is by burning. To do this, the stove is heated strongly with the ash pan open, essentially calcining all the channels. As a result, the resinous deposits burn out.

Based on the Buleryan stove, you can organize an autonomous heating system:

Some craftsmen use oxygen to burn the furnace, bringing the nozzle of the cylinder to the opening of the ash pan. This is an extremely dangerous operation that violates fire safety regulations. Careless handling of an oxygen cylinder near an open flame may cause an explosion.

As fuel for the Buleryan stove, you can use not only firewood, but also wood waste (shavings) or special briquettes. An important condition is low fuel moisture. The less moisture, the less resin is formed inside the stove, and the less often it will have to be cleaned.

During operation of the furnace, you need to select an operating mode in order to obtain maximum heat with minimal resin formation. If the best option is found, cleaning will only need to be done a couple of times during the heating season.

Conclusions and useful video on the topic

Real experience in making a Buleryan stove from scrap materials can be seen here:

Making such a device yourself is not the easiest task. But the result is a high-performance and convenient heating device. Experts note that with proper installation and compliance with operating conditions, the service life of the Buleryan stove is practically unlimited.

Share with readers your experience of making and using the Buleryan stove. Please leave comments on the article, ask questions that interest you, participate in discussions and attach photos of your homemade products. The feedback form is located below.

An interesting design, built on a well-known principle. I’ve been planning to put something like this together in a gardening house for a long time (I don’t see the point in installing a full-fledged stove in a room of 15 sq.m.). But I noticed one flaw in the article - it states that the stove is assembled from metal sheets.

I would like to understand what kind of metal it should be. From personal experience I know that not every tin can withstand prolonged high temperatures and simply burns out.And it is not yet entirely clear whether it is possible to install some kind of protection against excess odors formed during fuel combustion and entering the pipes (I think that such entry cannot be avoided). Maybe something like a catalyst on the exhaust pipes? Thank you.

Regarding the thickness of the metal from which the stove will be made, you will need sheet metal with a thickness of at least 3 mm. But it doesn’t make sense to use more than 5 mm for a stove with a heating capacity of 15 square meters.

As for odors, here you need to carefully weld all the seams in the bulleryan pipes, ensure normal draft, and work on the firebox door mechanism. Taken together, these measures should minimize odors that appear from combustion products of solid fuels.

As for bulleryan pipes, they are not always used in Cossack chimneys, they can be deaf. Through them, the air in the room simply warms up faster, but there are also solutions where the side pipes are used as chimneys.