Sawdust briquettes: how to make “Euro firewood” for fuel units with your own hands

Firewood that would burn for a long time, provide a lot of heat and little ash, and would not emit sparks or soot—the dream of the owner of a country house with stove heating or a fireplace.These are the properties that sawdust briquettes have, which you can not only purchase, but also make with your own hands. It is worth familiarizing yourself with the process of their manufacture. It is so?

We will tell you how to make fuel briquettes for use in heating a country house or cottage. The article we have proposed describes in detail the technology for producing logs from pressed sawdust. Do-it-yourselfers will find brief instructions on how to assemble a pressing machine.

The content of the article:

Benefits of sawdust logs

The following arguments can be given in favor of briquettes pressed from sawdust:

- Long burning time - 4 hours.

- Minimal smoke generation.

- Environmental friendliness. The starting materials are natural materials, so you can fertilize the beds with ash.

- High energy output. It far exceeds the energy capabilities of firewood and is comparable only to high-quality coal.

- Constant combustion temperature.

- Economical. The cost of 1 ton of such fuel will be cheaper than the corresponding amount of firewood or coal.

- Possibility of self-production.

There are also disadvantages. The main one is the fear of moisture. They cannot be stored in the open air, because... they will quickly absorb moisture and therefore will burn poorly. Therefore, it is necessary to allocate a dry room for storage.

Any significant mechanical impact on sawdust briquettes is contraindicated.If you buy special equipment for their production, the cost will be high and not always justified.

It is profitable to set up handicraft production if the sawdust is free, and you can use existing equipment for installation.

Types of fuel briquettes

Briquettes are divided into types depending on their shape. The main types you can find on the market are:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from natural wood sawdust with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading container, and then fed through a screw for pressing. Dispensers distribute the mass into molds under pressure.

- Pini kay. In shape they are polyhedra with the number of faces from 4 to 6. During the production process they are subjected to processing at high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

Chemical composition and heat transfer of all these species pressed sawdust are the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. Its high density and low hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

If you have the necessary raw materials to form briquettes, you can make them yourself.

Equipment for the production of briquettes

In industrial conditions, the grinding of wood waste is carried out using special mechanisms - crushers. Such an important part of the technological process as drying is performed using drying machines, which come in two types - drum and aerodynamic.

The molding of products is carried out on hydraulic press. With a force of at least 30 MPa, it compacts the mass. At the same time, there is no need to add any substances to the raw material for bonding, because under these conditions, due to compression and high temperature, wood glue - lignin - is released.

Briquettes of any shape can be produced using a mechanical impact press, but their density is not very high.

There is another method for producing “eurowood” - extrusion. It is based on the fact that with a force of about 40 MPa, the mass is pushed through calibrated holes by means of a screw, thereby forming products in the form of cylinders or hexagons. At the exit they are cut with special knives.

The productivity of screw extruders is higher than that of mechanical or hydraulic presses.

It is irrational to buy such installations for making your own and preparing fuel briquettes; there are other options for this.

Independent production of briquettes

The main supplier of sawdust is the sawmill. It doesn’t matter what type of wood it is, the main criterion is moisture content. It should not go beyond 12%. In the total mass, the amount of spoiled wood should not exceed 5%.

Description of the technological process

This process is not very complicated and generally consists of five stages:

- Purification of raw materials. It is necessary to remove dirt and excess impurities.

- Grinding. The size of the sawdust matters - a maximum of 0.6 cm.

- Pressing.

- Drying.

- Warehousing.

After the first preparatory stage, the mass is mixed with dry, powdered clay, proportion 10: 1. Next, adding a little water, begin mixing. Please note that the thickness of the mixture should be medium. The ability of it to hold its shape, the drying time and the finishing density of the products depend on this indicator.

The next step is loading the resulting mixture into the bunker of the briquetting equipment. Then the actual pressing in molds. After all, all that remains is to dry the finished briquettes well. Cardboard soaked in water is sometimes added to the clay mixture. In this case, the flammability of the fuel increases.

Homemade pressing plants

At home, you can make equipment in three versions:

- with hydraulic drive;

- with manual drive;

- with jacks.

The manual device is the simplest. It can be attached to the wall. The frame for it is made of a steel pipe or angle by welding.

It is impossible to create a full-fledged technological line for the production of briquettes at home, because it is very expensive and requires large areas. Craftsmen at home use homemade machines of various designs

One cannot miss the point that when the sawdust is large, it must be crushed before pressing. A simple cutter is suitable for this, but it is better to mechanize this process. It’s good if you have a machine for grinding grass at home, it will also cope with crushing sawdust.

Some craftsmen adapt outdated washing machines for this purpose. For this purpose, the activator is supplemented with knives.

Manual machine

A press for the production of briquettes from sawdust at home is fixed on the wall with dowels. A stationary form is attached to the lower part of the structure.

Its geometry can be any. To control the mechanism, a lever is needed, so a hinge is mounted on the top crossbar, through which a piece of pipe or a long metal pin is attached.

The mold, installed motionless, will serve as a matrix, and the punch is attached to the lever. It is important to correctly calculate the length of the pipe so that the punch fits freely into the matrix.

The second option for a manual press is a floor mechanism. Its design is identical to the wall fixture, the only difference is that the welded frame to which the main parts are attached is installed on a flat horizontal surface.

Another type of manually operated equipment is a screw press. It is very easy to use. The lower part is a perforated molding container located under the bed.

When tightening the screw, the pressure necessary for pressing is created. The performance of such a device is very low.A lot of time is spent on loading, tightening the screw, and removing finished products. Lever models have more potential.

Improved homemade version

Manual equipment can be improved by adding a jack or hydraulic press. The shape is made square or round. The base is welded from channel. Racks - corner 100 x 100.

Round shapes are made from thick-walled pipes. The matrix is perforated so that the water released during compression escapes. To remove finished products, the bottom is made removable.

For this purpose, you can install a spring inside the matrix, attaching it to the bottom, but then it must be tightly welded. A disk is attached to the spring. When the product is formed, it contracts, and when the rod reverses, it straightens and pushes the finished briquette out of the mold with a disk.

The rod is made from a pipe with a diameter of about 3 cm. A punch is attached to one end by welding, which fits into the matrix with a small gap. The opposite end of the rod is fixed to a hydraulic jack or press.

Before loading the raw material, it must be mixed well. This requires a special container. They make it from sheet steel or adapt a drum from an old washing machine and install it on racks. You can mix it with a mixer or in a concrete mixer.

From the drum, the wood pulp is supplied for pressing into molds along a tray made of sheet steel. It is best to dry briquettes in an oven, but you can also dry them in the sun. The main thing is that the humidity is minimal.Only a dry type of fuel will give off such an amount of thermal energy that is enough to heat the premises.

Stationary briquetting press

To make such a press, you will need a 2.5 kW motor if you are working on a 220 V network. If three-phase voltage is supplied, a 9 kW motor will do. In addition, you need a gearbox, shaft, bearing, auger, heating elements, and a relay for temperature control.

The engine, gearbox and other components are mounted on a welded frame from an angle. It is installed on racks made of pipes. The auger in this design consists of two parts. One of the bottoms transforms sawdust into a loading container, the second acts as a punch. The role of the matrix is played by the pipe.

Before starting the press, the pipe is heated using heating elements to 260⁰. Heating is regulated using a relay. The compaction of the briquettes is controlled by a square welded to the pipe. As a design flaw, large heat losses into the environment can be noted. But at the same time, the quality of the briquettes increases significantly.

How to calculate the need for fuel briquettes?

Having decided to switch the heating of your home to sawdust briquettes, it is better to immediately calculate how many of them will be needed to last for the entire period. Here you need to take into account the temperature that needs to be maintained, the area of the room, the thickness of the walls and other factors.

The quality of eco-fuel also plays an important role. The heat output of 1 kg of high-quality briquettes can reach up to 4.4 kW. From products made at home for use in brick kilns or metal bath units, such a result will not happen.

Let's say a house with an area of 100 m² is well insulated, the heating period lasts 190 days, the boiler operating coefficient is 0.7. Then 100 x 190 x 24 x 0.7 x 70 = 22,344 kW. If we take into account that the efficiency of the furnace is 86%, the heat transfer will decrease to 3.9 kW. Investigator, you need a supply of briquettes of 22,344: 3.9 = 5.7 tons.

Conclusions and useful video on the topic

Video #1. An interesting version of a homemade machine for the production of briquettes from sawdust:

Video #2. Preparation of working mixture for briquettes:

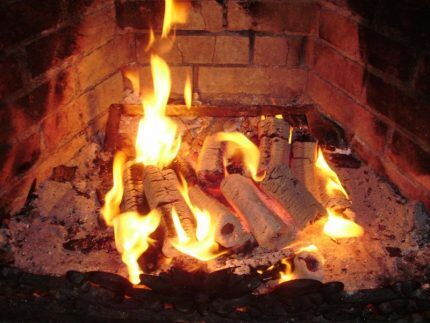

Video #3. Combustion of fuel briquettes in a boiler:

Anyone can make their own briquettes. This requires both physical and material costs, plus time. It is also necessary to take into account the fact that it is unlikely that it will be possible to achieve high quality at home at the level of European firewood.

Still, if raw materials are available, briquettes can be made, at least not for a full heating cycle, but for igniting firewood.

Tell us about how you made sawdust briquettes with your own hands. Share useful technological nuances that will be useful to site visitors. Please leave comments, ask questions, post photos related to the topic of the article in the block below.

I use 8-10 tons of briquettes per season. The year before last they almost doubled in price, it became very expensive to buy them, and we have few manufacturers.

The last time I bought briquettes made from seed husks out of poverty, I really liked the way they burned (except for the fact that the chimney quickly becomes clogged with smoke). Now I’m thinking that I could make them myself for my own needs, nothing too complicated. I made cinder blocks for a fence, and this is something similar.Plus the oil shop is nearby, they always have husks. And I have plenty of available materials for making a press. In the summer you can harvest and the savings will be serious.

And I have somewhere to store them, I have a dry shed, and you can wrap them in film, they will be like branded ones!

Sawdust briquettes are quite convenient fuel. It is easier to store due to its neat and roughly uniform shape and size. When burned, they produce more heat than regular firewood. Plus they burn almost twice as long. However, the cost of Euro firewood exceeds the cost of regular firewood, so if you have the opportunity to make it yourself, then that’s great. The main problem is the raw material - sawdust. You can still find them for one batch, but it’s problematic on a regular basis.