Stove using waste oil from a pipe: how to make an effective stove using waste oil from scrap materials

For a motorist, drained oil is ordinary waste, but for a good owner it is an affordable and valuable fuel. For example, you can build a waste furnace from a pipe and use it to heat a garage or other utility room.

Agree, this solution is economically beneficial, since it results in double savings - on the purchase of fuel and a heating unit. Do you want to build a stove for testing, but you doubt that you will be able to implement your plans? We will help you in this matter.

The article describes the structure of the unit, and also provides a step-by-step work plan with a detailed description of each stage of assembly. By following the instructions, you can build and put into operation the stove yourself.

The content of the article:

Features of the stove device

The design of the furnace is not much more complicated an ordinary potbelly stove.

The device includes the following main elements:

- lower fuel chamber;

- perforated pipe;

- upper chamber;

- chimney.

You will also need auxiliary parts, such as a protective nozzle for the chimney, a device for safe refueling, a reinforcing belt, etc. Used oil is poured into the lower chamber and set on fire. Here it burns partially at a relatively low temperature.

Then the heated oil vapors and gases from its combustion rise up the perforated pipe. Here they are saturated with oxygen and enter the upper container.During afterburning, such fuel produces a lot of heat. Be sure to make a vertical chimney.

Work order

When figuring out how to make a waste oil stove from a metal pipe, you need to take into account the high combustion temperature of this specific fuel. You will need fairly thick metal. It is convenient to use pieces of metal pipe as a housing for combustion chambers. It's easier than making a square metal case.

But sheet metal will be needed for the manufacture of other structural elements. You can’t do without a welding machine and other tools. The metal parts should be quite thick, about four to six millimeters.

There are many ready-made drawings that can be used to make an effective furnace for mining. You don't have to follow them to the millimeter. It is enough to find a pipe with thick walls and an approximately suitable diameter.

But proportions must be respected. The combustion chambers are wide and low, and the pipe connecting them is narrow and long. The closer to the place of fuel combustion, the thicker the metal should be. A 100 mm pipe is suitable for connecting the chambers and the chimney pipe.

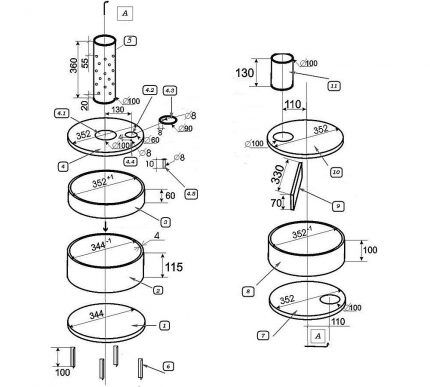

Step #1: Making a Fuel Tank

They usually start from the bottom container.This is perhaps the most difficult element of the design, since you need to make a lid for it.

The work is carried out as follows:

- Cut a piece 100-115 mm high from a wide pipe.

- Cut out two circles for the bottom and lid, the second one should be a little larger.

- The bottom is welded to the walls.

- A hole is made in the upper circle for a pipe with holes.

- A strip of metal is cut out, the width of which is 60 mm, and the length is equal to the circumference of the walls of the case.

- The strip is welded to the second metal circle, the lid is ready.

All welding work must be performed carefully, the seam must be smooth and completely sealed. To properly make the lid, it is better to first wrap a strip of metal around the bottom of the chamber and secure it with clamps. After this, a vertical weld is made.

The resulting ring is removed from the body. Now you can weld a metal circle with holes to it to form a lid.

Here you need to make another hole for filling fuel with a diameter of approximately 100 mm or slightly less.

You will need a sliding metal cap to add oil and regulate the flow of air needed for combustion.

Step #2: Installing Perforated Pipe

The optimal length of this element is 360 mm. They retreat about 20 mm from the bottom edge and begin to drill 9-10 mm holes. 8 holes are made in one row at equal distances. The next row is made with a shift so that the perforation is done in a checkerboard pattern.

It is enough to make six rows, but more can be done. About 50-60 mm of solid metal should be left near the top edge. It is better to chamfer the edges of this pipe, this will make it easier to weld.

The number of holes should not be too large, otherwise heat will escape through them, and the amount of air with which the oil vapor mixes will become too large. If there are not enough holes, it is not difficult to make additional ones.

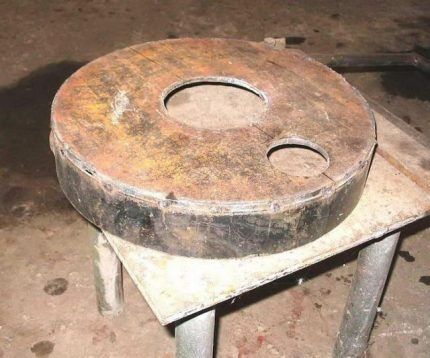

Step #3: installation of the upper combustion chamber

Now we need to make an afterburner. To do this, cut another piece about 110 mm high from a wide pipe. A 4 mm steel circle is made for the bottom, but six mm metal is placed on top. Then holes are made for connecting the perforated pipe and for the chimney.

Inside you need to place a small separator made of six-millimeter metal measuring approximately 60 by 7 mm. It is welded near the opening for the chimney. Such a barrier will slow down the movement of gases through the afterburning chamber in order to leave more thermal energy in the room.

All that remains is to attach the circles to the walls of the combustion chamber. It is more convenient to weld the upper part first, it is heavier, then install a rectangular jumper, then the lower part.

Step #4: final assembly of the unit

When all the elements are ready, it's time to assemble the device. First, a perforated pipe is welded to the bottom of the afterburner. The pipe must stand strictly vertically; its position should be verified using a level.

Then the pipe is grabbed to fix the correct position. After this, the weld can be made. Then the chimney pipe is welded to the corresponding hole in the same way.

The technology for assembling a chimney for a stove on the return line is similar to the procedure for arranging a chimney pipe for a potbelly stove; more details in this article.

Now the fuel chamber cover is attached to the structure. Legs should be made at the bottom; they can be cut off from the corner. After this, the stove can be considered ready.

How to improve the design?

The efficiency of such a device can be significantly improved by adding some elements. To make the fuel chamber as airtight as possible, you need to weld a “belt” of round rod to its lower part.

It is placed where the vertical edge of the lid ends. As a result, even a small gap between the container and the lid will be closed.

An issue that you need to think about in advance is adding fuel. If such a furnace has already been lit, then you cannot add used oil directly into the chamber through the hole. You need to wait until the existing portion of oil burns out.

This is not always convenient, so it makes sense to create an additional fuel tank. This is a small container of any shape that is attached next to the lower chamber of the stove. From below, you can weld two corners to the bottom of the fuel chamber and the additional tank.

In addition, you will need a small tube.Holes are made on the bottom panel of both containers for this pipe, and then it is welded.

So the fuel chamber and the additional tank turn into communicating vessels. You need to attach a removable lid to the top of the tank. This will allow you to determine the fuel level in the main tank and safely add oil when necessary.

The perforated pipe is not centered on the bottom container, which makes the structure a little unstable. To strengthen it, you can simply weld a parallel metal rod to the upper and lower chambers.

Such ovens are usually used for garage heating and other similar premises, therefore they are not expected to have a particularly aesthetic appearance. But it still makes sense to clean the surface and coat it with heat-resistant metal paint. This will reduce the impact of corrosion processes and extend the life of the device.

A useful addition is a protective screen that is installed between the main and additional tanks. This will allow you to avoid overheating of the fuel while the stove is operating, especially if it is intended to be used for a long time.

Another good tip does not relate to the stove, but to the condition of the room in which it is intended to be used. You should take care of insulation.

Although used oil is almost free fuel, the less it is used to heat the object, the easier it is to use the stove. Of course, it is better to carry out insulation from the outside of the garage; it is well suited for these purposes extruded polystyrene foam.

Installation and test ignition

The location for installing the stove should be chosen as far as possible from objects and materials that are sensitive to heat. The device gets really hot. If not handled carefully, it can damage property and even cause a serious fire.

There must be a non-combustible base underneath the device. You should not install such a device in areas of active air flow. Under the influence of a draft, the flame can be blown out, and this is dangerous. The finished oven and installed in a suitable place is connected to a vertical chimney pipe.

Then perform a test ignition. To do this, pour oil into the fuel container, and add about 100 ml of fireplace liquid or other similar composition on top. At first this liquid will burn, but soon the oil will boil and the device will begin to make noise. This means that the stove is made correctly and can be used for its intended purpose.

Before pouring the oil into the tank, you need to let it sit for some time so that unnecessary impurities settle down and do not get inside. The container should be filled only two-thirds, then the primary combustion process will be more efficient and safe.

From time to time it is necessary to clean the inside of the fuel tank from accumulated contaminants. Remove the cover and simply drain the remaining oil, remove deposits, etc. From time to time you need to tap the perforated pipe and chimney to remove accumulated soot and soot.

Conclusions and useful video on the topic

An interesting option made entirely from a narrow pipe:

The working stove is a simple and quite effective device.When making it, you need to adhere to the basic proportions, and during use, do not forget about safety.

Do you have experience making a stove using waste oil? Please tell readers about your method of assembling a heating device. Comment on the post, participate in discussions and add photos of your homemade products. The feedback block is located below.

And what is the efficiency of this miracle unit? I would really like to have one of these in my garage, but my hands are growing in the wrong place. Has anyone come across similar devices for sale?

Of course, there are such stoves on sale. There are a lot of homemade products of fairly good quality on Avito and similar sites, and factory ones are also available for sale in stores. Brands Multeat, Polarus, Borzo, maybe there are some others. But you need to understand that store-bought ones will cost significantly more than home-made ones, and the main advantage of such a furnace for testing is its low price. Efficiency varies depending on the design, but is generally high.

Hello. As correctly noted in the comments above, such stoves are available for sale. But if you want to save money, you can purchase a stove from a private owner. Sometimes they sell products that were not needed and have not been used or are homemade. With a used one, of course, you should be careful; the safety of the elements should be checked carefully, just like with homemade ones. Of course, there will most likely not be a warranty period, but the price is half as much. It's up to you to decide. In our city there is a craftsman who makes stoves from cylinders and sells them, he already has a proven reputation, people buy without fear.

The efficiency of such furnaces is usually from 75%, depending on the design, but it should be noted that efficiency is more of an abstract concept. The heating power also depends on factors such as the area of the room, its insulation, and so on. That is, a stove can create steam in one room, but be completely useless in another, just to warm your hands. The choice is based on these factors; do not forget to consult with the seller and check the device when purchasing.