Installation of Baxi gas boilers: connection diagram and setup instructions

In the list of advantages of Baksi gas heating equipment, the leading positions are occupied by impeccable operation, reliability and an extremely high level of operating comfort. Boilers of this brand are deservedly recognized by global and domestic consumers. Practical wall-mounted models are in the most active demand.

A responsible manufacturer warns: installation of Baxi gas boilers must be carried out by representatives of gas supply companies. However, information about the specifics and stages of work is needed by all owners of units. It will not hurt to familiarize yourself with them to control the work of hired performers and further exploitation. Do you agree?

We will tell you how to install gas-processing heat generators from Baxi S.p.A. The article we presented shows the technological nuances and configuration features. Here you will find recommendations from experienced gas workers, following which will eliminate operational disruptions and dangerous situations.

The content of the article:

Specifics of equipping gas equipment from Baxi

In the range of trade offers offered to the buyer from Baxi S.p.A. There are floor and wall units. The first ones are purchased for autonomous heating in spacious country houses, industrial or commercial facilities. The latter are popular with owners of apartments, small dachas and small private houses.

Both wall-mounted and floor-standing models of this brand are produced with one or two heat exchangers. Each heat exchanger is designed to heat the medium of a separate circuit. Single-circuit boilers are designed to prepare coolant, double-circuit boilers serve the heating system and supply hot water to mixers.

The range of boilers from Baksi includes atmospheric and turbine units. Atmospheric models are equipped with an open combustion chamber, while turbine models are equipped with a closed one. The first ones are somewhat cheaper and easier to operate, the second ones are more expensive and more complex, but much safer, and therefore more popular among consumers.

Operation control and protection devices

Gas boilers in demand on the market are equipped with the following systems for regulating the operation of the heat generator and ensuring safety:

- Safety thermostat. A device with a sensor that responds to excessive water heating. If it detects a temperature above the set limit, the boiler is blocked. Disabling it is prohibited.

- Traction sensor. A device that records the temperature of gas processing products removed from the boiler. If they are above 90ºС, the electronic board shuts off the gas supply. It should not be disabled under any circumstances.

- Flame ionization sensor. An electrode that monitors the gas supply to the burner, detecting a violation in the supply of blue fuel or partial attenuation of the burner. If dangerous situations are detected, the system blocks the boiler.

- Pressure switch for medium flow. A system that allows the burner to be activated only if the pressure of the medium being processed exceeds 0.5 bar.

- Frost protection. A device that automatically starts the boiler when the temperature drops to +5ºС and makes it work until the coolant for delivery into the supply pipe heats up to +30ºС.

Protection against the formation of ice jams in a system filled with coolant or sanitary water is not turned off even when all other electrically dependent systems of the unit are disconnected from the power supply. A two-pole shut-off device allows you to leave it in working condition if the boiler is not used for some time.

In addition, the boilers are equipped with systems that provide post-circulation of the heated medium. Those. after the burner stops coolant will run along the heating circuit for another three minutes. There is a function that forces the circulation pump to periodically turn on for 10 minutes if the boiler is not used for more than a day, and many other useful innovations.

To read the ambient temperature background, the units are equipped with indoor and outdoor sensors.Using the thermostats to which they are connected, the owners of the premises being treated select the minimum and maximum temperature limits. In accordance with these data, the automation will start and stop heating the coolant.

Specialized systems of Baxi units

An excellent option, implemented technologically and structurally, is the ability to adjust the gas valve of boilers from Baxi. Using the screw available on the device, you can adjust the power, focusing on the CO content2 in the smoke exhaust duct.

To accurately calibrate the gas valve, the equipment manufacturer provides a table in the technical documentation for the product. It indicates the operating parameters of the unit with minimum and maximum power, as well as the corresponding fan speed. The adjuster simply needs to turn the screws until the desired value appears on the display.

The functionality also includes an extremely useful function - self-cleaning of chimney channels. It is produced when the device is operating at full power. Spontaneous removal of combustion products allows for less frequent chimney cleaning. In addition, it guarantees the stability of the system and the safety of users.

A degassing function is provided - removing air from the system, which inevitably occurs when the heating circuit is filled with water. They use it before the first start-up, as well as after stopping the boiler and draining the water for the warm period, when there is no need for heating.

In addition to a good set of functions, the ability to connect solar panels, sold in almost all models of this brand. The boiler included in the heating scheme can be supplemented remote boiler, for which pipes are provided, and an additional pump.

Installation subtleties and configuration nuances

We have already noted that the installation, connection, first start-up and adjustment of the operating parameters of the Baksi gas boiler should be carried out by a specialist from the organization with which an agreement has been concluded for the supply of blue fuel and for the maintenance of gas processing units. After applying your own efforts to implement the above steps, you will no longer be able to benefit from the warranty.

All steps of the installation cycle of work are documented. Boiler owners are given papers indicating who installed and connected what. If a malfunction is detected, the contractor will deal with it. If a manufacturing defect is detected, which is extremely rare, all replacement and repair problems are resolved by the gas service.

Please note that these gas heat generators can be installed in heating circuits with any heating appliances. They are no exception warm floor, but for them to work, the boiler power should be set to 65ºC at the inlet to the supply pipe. They are suitable for both one- and two-pipe heating circuits, for tee and radial options.

Steps to connect the boiler to communications

Let us list step by step what gas workers must do during the installation and connection of a Baksi gas boiler.

Conventionally, the entire cycle of work can be divided into three main parts, these are:

- Preparation of building structures and communications. Strengthening structures as needed. Laying lines for connection, if necessary.

- Hanging the boiler on the wall and connecting to communications. Purely mechanical work that requires strict adherence to the diagram and recommendations of the unit manufacturer.

- Performing the first launch and setting up operating parameters. The first launch is the responsibility of representatives of the gas company. The user can set the settings himself.

All actions are carried out in a thoroughly thought-out and clearly worked out manner by the boiler manufacturer.

The preparatory period includes:

- Inspection of the premises to confirm the possibility of installing equipment using gas.

- Drawing up a contract for the work, attaching a connection diagram for a gas boiler with the Baksi logo and an accurately calculated estimate. It should indicate the prices for the work and the cost of materials purchased by the company for the installation of the thermal energy generator.

- Cleaning used heating and hot water systems from mineral deposits and contaminants deposited on the walls of pipelines and devices during operation. Produced by any available chemical.

- Laying communications to the boiler installation site. Only heating and gas supply lines are connected to single-circuit ones, and heating, gas and water supply lines are connected to double-circuit ones.

- Installation of shut-off valves on each communication line. They are needed to shut down the unit in case of repair, accident, or replacement.

- Installation of a dirt filter on the return pipe of the heating system. It is required to collect mineral deposits that may remain after cleaning and will form when the water heats up.

- Connection of a separate power supply line.It is used to ensure that other electrical equipment is not connected in parallel with the device, which creates the risk of a short circuit with fire hazardous consequences.

Connection of communication systems is carried out with the mandatory use of seals. All work must be carried out in accordance with plumbing standards.

The optimal location of the electrical outlet relative to the gas boiler is 30-50 cm from the body. Its installation and laying of the power supply branch is carried out in accordance with the PUE. In addition, equipment is needed be sure to groundusing a three-core cable with a ground wire.

The list of measures for installing the boiler includes:

- Boiler mounting. It is made on a wall with sufficient load-bearing capacity. Fix the unit with anchor bolts; if necessary, cover the wall with non-combustible finishing if it is made of flammable materials.

- Connecting pipelines to the boiler. It is carried out in accordance with the diagram attached to the technical passport by the manufacturer.

- Chimney assembly. The connection of chimneys to Baksi boilers is made only with fasteners supplied by the manufacturer of the unit.

For turbocharged models equipped with a closed combustion chamber, connect either coaxial pipe, or a regular pipe coupled with an air supply pipe to a closed burner. The first option is simpler, but more expensive in terms of purchasing a coaxial system.However, it is not a fact that installing two channels for air supply and smoke removal will ultimately cost less.

A conventional chimney is connected to atmospheric models with an open combustion chamber. The products of blue fuel processing are discharged either through a wall into the street space or into the collective chimney of an apartment building.

Chimney elbows allow this channel to be brought out in any direction through the wall. Let us note that exits through the walls are mainly in high-rise buildings, the number of storeys of which does not exceed five levels. In private houses, it is preferable to build vertical smoke channels.

Upon completion of the installation work, they proceed to the first launch and configuration.

Launch and commissioning activities

For the first start-up, the gas boiler and the circuits it processes are filled with the medium transported through them. Unlike most wall-mounted models, which can only heat water as a coolant, Baksi units can be filled with antifreeze - an aqueous solution of propylene glycol with antifreeze additives.

Process filling with coolant connection of the boiler and heating circuit is carried out through a pipe located in the lower part of the unit. After filling, bleed off the air, then, if necessary, replenish the coolant volume in the same way.

The commissioning activities are preceded by the following actions:

- Checking the pressure in the system. It should correspond to the recommended values of 1-1.5 bar.

- Connecting the boiler to the power supply.

- Supplying gas to the combustion chamber, for which you need to open the yellow tap at the inlet of the gas pipe in front of the boiler.

It happens that when you turn it on for the first time, the unit is blocked due to the presence of air pockets in the pipes. In the case of Baksi boilers, there is no need to manually bleed the plugs; the system will remove them itself. You just need to press the start button again and hold it for 2 seconds until the burner is activated.

Operating parameters are set using an electronic panel located on the front side of the boiler. To select the heating operating mode there is a button with a stylized battery, for hot water there is a button with a tap.

The operation of the Baxi gas boiler is configured in accordance with a single algorithm:

- Select the button responsible for heating or preparing sanitary water.

- Use the +/- buttons to select the appropriate mode.

- Press the Power button so that the electronic control remembers the set parameter.

If the performance task procedure is completed successfully, the display shows “MEM”. This means that the boiler will operate according to these exact settings until the user decides to make changes.

The reluctance to remember the newly selected parameter must be confirmed by pressing the “i” button.The system that has perceived a refusal to change will report this with the message “ESC” on the display.

In order to select and set the boiler operating characteristics, the buttons are held for 6 seconds. To display current information about the operation of the unit, you need to press the “i” button for 5 seconds. If the “INFO” function is activated, the display displays “A00”, instead of which the temperature at the outlet of the heated coolant from the boiler appears.

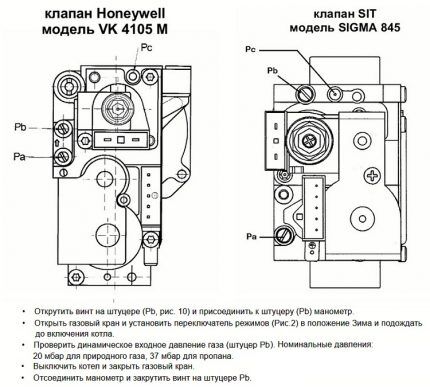

Then you need to check the dynamic value of the gas pressure at the inlet to the gas burner. When consuming main fuel, it should be 20 mbar. When using a cylinder mixture with a predominance of propane, the dynamic pressure value should be 37 mbar. Measurements are carried out by connecting a pressure gauge to the gas valve fitting.

Next, adjust the maximum and minimum pressure values using the regulator. In this case, again, a gas valve is used, to the fitting of which a sensitive pressure gauge is connected, recording changes in mbar. The values are selected according to the data given in the table by the manufacturer. They depend on the model and the type of gas that the boiler will process.

The gas coolant and hot water heaters offered to consumers from Baksi are initially configured to process main gas. If the boiler is to “work” in an autonomous system with a group of cylinders or a gas holder, then before performing all the listed settings, the nozzles are replaced. And then they change the voltage on the modulator by selecting parameter F02.

Recommendations for reducing operating costs

If all operational settings are made in accordance with the tabular data given by the manufacturer, then the equipment will consume energy very economically, generating the necessary heat in the volume required by the owners.

To do this you should:

- For systems with radiators or thermosiphons, select the temperature of the coolant at the boiler outlet +60ºС. It is worth increasing it only if, during operation of the unit, comfortable heat in the room was not obtained.

- Adjust temperature conditions in accordance with the manufacturer’s instructions and the purpose of the room. To heat bedrooms and other rarely visited rooms, the heating temperature can be set below average.

- Do not exceed the temperature background recommended by the manufacturers of the heating devices included in the circuit.

- Use indoor and outdoor temperature sensors that record temperature increases/decrease. The thermostat connected to them will independently start/stop the boiler as needed.

- Adjust the temperature of the coolant by the hour using a timer. At night, for example, it can be lowered by 3-5 ºС.

It should be remembered that by increasing the temperature in the room being treated by just 1º, we immediately increase costs by approximately 6%.

In order not to constantly change the coolant temperature settings during the difficult autumn-spring period, it is better to install an outdoor temperature sensor. If you don’t find a suitable model or don’t have the funds to buy the original, you can build a homemade device like this:

In case of prolonged absence, it is better to disconnect the boiler from the power supply, but you should not turn off the frost protection system. It is turned off only for the summer period, during which the heating function is abandoned, completely turning off the single-circuit model and switching to the dual-circuit version for the supply of hot water.

In order to save on heating, you should not cover radiators with screens and heavy curtains. They will disrupt normal air circulation and force the boiler to work at full capacity for no apparent reason.

Also, the equipment manufacturer does not recommend micro-ventilation in rooms, keeping the transoms constantly ajar. It is better to open the window wide and ventilate in one gulp than to artificially lower the readings of the room temperature sensor for a long time. It has been proven in practice that it is more economical.

When using the water preparation function, it is better to initially select a temperature that is comfortable for use, without counting on mixing heated and cold water in the mixer. Believe me, thanks to this solution, the thermal energy generated by the generator will not be wasted. In addition, limescale will not settle on the inner walls.

Conclusions and useful video on the topic

The following video will clearly demonstrate the installation, connection and configuration stages of the Baxi boiler:

Information about the installation process of the Baksi wall-mounted boiler and the rules for connecting it is needed to control invited performers. Unfortunately, not all of them please with a conscientious attitude to work and knowledge of all the nuances.If the owner of a gas-using unit cares about his own safety and the normal operation of the device, the information we present will not be superfluous.

Would you like to tell us how you installed and set up a boiler with the Baksi logo in your home or country house? Do you have useful information on the topic that will be useful to future owners of the unit? Please leave comments in the block form below, post photos related to the topic of the article, and ask questions.

Installing a stabilizer and thermostat on Baxi Eco4 24F