Filling the heating system with coolant: how to fill with water or antifreeze

Every year, at the end of the heating season, the autonomous water circuits, which diligently supplied the owners with heat, are freed of water or the antifreeze that replaces it. With the onset of the first cool days, the heating system is again filled with the coolant necessary for its operation.

It is worth familiarizing yourself with the procedure for performing this difficult work and the necessary equipment in order to avoid mistakes. In this material we will talk about how to correctly fill the system with water and non-freezing coolant, the rules that should be followed during the work process, as well as how to correctly calculate the amount of coolant.

The content of the article:

How to fill the heating circuit with water?

Due to fluidity and high heat capacity, they are used to transfer heat from the boiler to consumers. coolants, among which water ranks first.

It is used to fill even the most capacious heating systems. It is publicly available and inexpensive, which determines the widest range of applications.

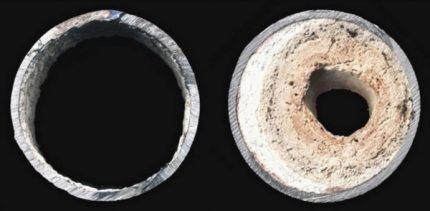

Both pumped from natural reservoirs or wells and tap water have many impurities and mineral inclusions. When boiling, impurities settle as scale on the walls of the boiler and form growths of similar composition on the pipes.

These deposits are extremely harmful to systems with the latest modifications of heating units. Therefore, the water must first be purified, boiled, or, if funds allow, purchase a distillate.

The second disadvantage of water is its ability to contain oxygen, which causes corrosion of metal.Due to high mineralization, coupled with oxygen released during heating, it is not recommended to change water in heating circuits more than once a year.

The significant advantages of water as a coolant are its optimal viscosity and heat capacity. It accumulates and releases heat better than antifreeze by 15-20%. It is inferior to them in fluidity, due to which it does not leak through the seals of detachable connections of the system, and in viscosity, due to which it moves more quickly through the pipes.

Calculation of coolant volume for filling

To correctly fill your own heating system with water, you need to determine how much water is needed in liters. You can calculate the volume of coolant yourself without any problems.

To do this you need to summarize:

Vsyst. heating = Vboiler + Vexpansion tank + Vradiat. + Vpipes

The useful volume of the boiler is usually indicated by the manufacturer in the technical documentation for the equipment it produces. The capacity of sectional radiators is the same. If such information cannot be found, then there are average indicators.

V of one radiator section depending on the housing material:

The total volume of the radiator is found by multiplying this figure by the number of sections.

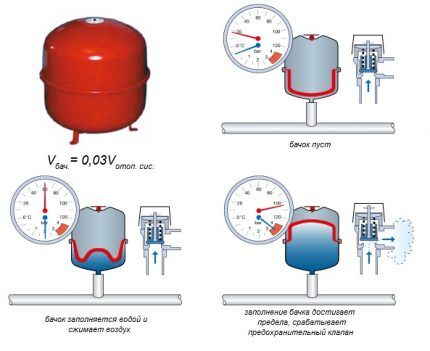

Vexpansion tank closed type is selected before purchase so that its useful volume is equal to or slightly exceeds the volume of water, taking into account thermal expansion. This means that this parameter must also be known.

For open type heating systems with an expansion tank freely communicating with the atmosphere, the volume is taken according to the actual dimensions.

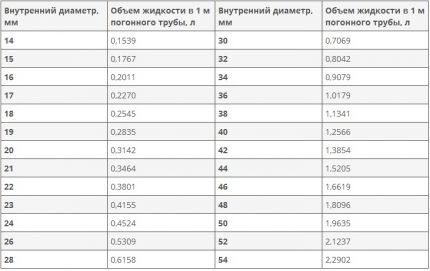

Volume in pipes:

V pipes = 0.786×D2×L

where D is the internal diameter of the pipes, L is the length of the pipes.

The volume of the system will then be equal to:

V system = V pipes + V boiler + V expansion tank + V consumers.

Where V consumers is the sum of volumes, boiler and other devices. Their volumes can be found from technical documentation or calculated. The calculated volume needs to be increased by 15-20 percent, i.e. multiplying by 1.15 or 1.20.

A more labor-intensive method is to fill the system with tap water and then drain it, measuring the volume with a meter or measuring containers.

Sometimes tap water is used, but this greatly reduces the heating operating time. By saving a ruble, we lose thousands. In this case, it is better to pass the water through special membrane or chemical cation filters.

To fill the heating, we also need adapter hoses and a pump for pumping liquid.

Dependence of filling technique on the cause

Filling principles influence the sequence of work. If this is a new system, then we check it visually and carry out tests, pressure testing with excess pressure, pumping air or liquid of approximately 2-2.5 atmospheres (the norm is 1.25 part of the working pressure, but not less than 2 atmospheres). Using the pressure gauge, we check that there is no pressure drop.

To fill small heating circuits, you can use a car pump instead of a compressor. Sometimes pressure testing is carried out directly with liquid using a centrifugal pump, having previously connected expansion tank to the system. For small volumes, a hand pump with a liquid compartment can be used.

If we periodically clean the system and replace the water, we must first drain the liquid and prepare a place or container for it. After waiting for the coolant to cool, we relieve excess pressure by unscrewing the nipple.

At the top point open the valve or Mayevsky valve to communicate with the atmosphere. At the lowest point, gradually open the drain valve. When opened abruptly, water hammer occurs, leading to damage. You need to be careful here.

After draining the coolant, we fill the system with flushing liquid and use a pump to ensure its circulation.

Then they are washed with clean water with additives and a neutralizer designed to neutralize the additives of the first wash.

After these operations, as in the first case, pressure testing of the heating is carried out. Identified leaks and weak spots usually occur in areas of welding and threaded connections.

Cast iron batteries are equipped with connecting gaskets, which dry out over time, become rough and leak when cooled. They should be replaced and the batteries should be additionally tightened.After the repair work, pressure testing is performed again and if the result is positive, we move on to the next stage.

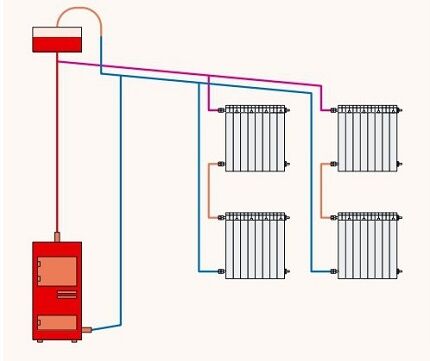

The heating system is filled with water through the lower point with the upper one open. Having connected the electric pump, we pump water into the system through the tap. Moreover, the tap is opened halfway or less to exclude water hammer. Gradually the system fills, which is confirmed by the noise from the movement of water and a slight gurgle. We finish when water starts flowing from the top point.

Then we begin to bleed air from connected consumer appliances, the boiler, boilers, expansion tank with membrane and batteries using existing taps and valves. Next, we connect a transparent hose to the top point of the system, which we lower into a container with coolant.

Having turned on the pump, we additionally fill the heating until water flows from the transparent hose into the container without air bubbles.

If possible, you can then loop the pumping system with a hose and circulate the coolant several times. This will provide additional degassing. And finally, they pump air behind the expander membrane, providing the necessary pressure for the operation of the heating circulation pump, which we turn on for running without heating.

To fully check the quality of filling the system, it is necessary to turn on the heating on a trial basis and, based on heating, determine the absence air jams and heating uniformity using a thermal imager or infrared temperature meter.

At the same time, using taps or modern thermostats, the temperature in the rooms is set and adjusted. The effectiveness of thermal insulation is also assessed. It is necessary to provide a supply of purified water and a means of adding it to the system to eliminate losses due to evaporation. All these actions are designed to ensure trouble-free heating operation in the winter.

Rules for heating make-up

Recently, individual heating has begun to be installed not only in private houses, but also in apartments. Usually installed double-circuit boilers, having a recharge module.

And it’s easier to learn how to recharge yourself than to call a specialist, for this:

- Open the tap at the bottom of the boiler, then at the top point of the system there is an air release valve and when water appears, close it and the make-up tap.

- Turn on the boiler and if you hear bubbling and gurgling in the pump, then remove the outer casing from the boiler and find it.

- Weaken, but don't unscrew the screws a screwdriver to bleed air out of it until moisture appears. The pump has a cover for this purpose, screwed on with screws. Although the instructions say that these boilers have automatic air release devices, they cannot remove all of it.

Especially when starting heating for the first time, it is necessary to gradually, smoothly heat the coolant to avoid damage from water hammer. You cannot immediately turn on the boiler at full power. When stopping heating, it is also important to slowly lower the temperature.

This is especially important for long heating networks that have significant deformation and thermal expansion.From this expansion or compression, held by fasteners or forms, stresses are formed, which are discharged abruptly, transmitting the shock to the liquid.

The liquid, depending on the flow sections, can increase the impact force and cause destruction in another place, usually at bends. And if resonance occurs, then the loads increase significantly and the pipes even break off their fastenings. They begin to “play” and “dance.”

When the pipes are quickly filled with liquids, due to air pockets, pressure increases are also formed, which are discharged by water hammer. This is where the recommendation comes from to drain and fill the heating slowly, opening the tap a quarter or half way.

Resonance phenomena vary depending on size, weight, fastenings, deposit thickness and other factors. This imposes additional restrictions. You need to take your time and be careful.

That is why the design of heating networks for enterprises and apartment buildings is done by specialists who take into account many factors. Heating of individual houses is done according to standard designs.

Technological progress and cheaper smart home equipment make it possible to control and change heating parameters remotely using a smartphone.

The main thing is to be within the coverage area of cellular communications and the Internet. This further expands the possibilities of using water, because timely measures can be taken to prevent its defrosting.

Other amenities, such as raising the room temperature before arrival and saving mode during departure, are included.

The choice of water for heating is advisable if a backup heating system is provided. If heating is used periodically in winter or there is a possibility of equipment shutdown and defrosting, then it is better to use non-freezing liquids. For example, at a dacha with short-term visits typical of winter dacha life.

Refilling with non-freezing coolant

Before figuring out how to fill various heating systems with antifreeze liquids or antifreeze, you should understand their types.

For normal operation of heating systems, antifreeze (anti - against, freeze - freeze) must be:

- non-toxic, excluding the possibility of the slightest threat to people;

- non-flammable, and their pairs are explosion-proof;

- inert to the materials from which the heating system is made;

- have a heat capacity not less than its calculated value;

- be fluid.

In their “pure” form, antifreeze is aggressive and can destroy pipelines, boilers and heating devices. To reduce or completely eliminate the negative properties of antifreeze liquids, they are diluted with water in the proportions specified by the manufacturer of the compositions.

Additives are also used: anti-corrosion, stabilizing, cleaning, anti-foam and others. The less water, the lower the freezing point and the higher the cost. When diluting antifreeze, you usually need to add the additives that come with the kit.Additives work at a certain concentration.

The compositions cannot be used without a complex of additives, as they provide the specified parameters. For the same reason, it is not recommended to mix different coolants, especially with different bases. Their service life is sharply reduced. Antifreezes have high viscosity and cannot be used in heating with natural circulation.

The average shelf life of organic coolants is 3–5 years, after which the additives lose their properties and the liquid becomes aggressive. When replacing, old antifreeze must be pumped out and taken for disposal, which further increases costs.

Cars once used water for cooling, but this is now rare. Now in the world, more than 70 percent of heating systems operate on water, but the percentage is decreasing all the time. The reason holding back the widespread use of antifreeze is both their high cost and increased requirements for equipment, toxicity and the need for their disposal.

For more complete removal, antifreeze that has spent its life is drained in a state heated to 45 degrees.

Now the main equipment is designed for water and manufacturers, who value their reputation, often indicate that they do not guarantee operation with antifreeze. Or indicate the permitted type of antifreeze under certain conditions. Experimenting on your own is dangerous.

Antifreeze compounds are critical to overheating. They begin to decompose and form gases and solid deposits. Air locks, burnt marks in boilers and equipment failure occur.

At temperatures of 80 degrees and above, steam formation begins, so modern boilers have heating up to 75 degrees, supported by automation.If exceeded, an emergency shutdown of the boiler occurs. With organic coolants, the temperature is reduced to 70 degrees.

For safe operation of the heating circuit with antifreeze, an automatic system is needed that turns off the heating unit when the temperature is exceeded. If there is no such device in the heating system circuit, antifreeze should not be used as a coolant.

Typically, the technical documentation for boilers and equipment indicates the type of coolant. The use of another coolant removes responsibility from the manufacturer and terminates its warranty service.

To refill heating systems, coolants are produced based on ethylene glycol, propylene glycol and glycerin.

Cheapest ethylene glycol

The disadvantage is toxicity; a dose of 100–250 grams is lethal to humans. Has the third hazard class according to GOST. The fumes are also toxic. The permissible MPC norm is 5 milligrams/cubic meter. meter. Therefore, it cannot be used in open heating systems. Also prohibited for double-circuit boilers, because it is possible for the product to leak into the hot water supply line.

To eliminate this, craftsmen make the water supply pressure higher than the heating pressure. But this does not provide a complete guarantee and can cause, if damaged, the boiler to fail. The use of ethylene glycol is only permitted for closed heating systems.

Heating leaks and breakouts are very likely. If the system is filled with an inexpensive but toxic ethylene glycol-based product, leaks can pose a health hazard to home owners. The relatively low price is the reason for its application. You can't buy health like you can buy antifreeze. Therefore, the choice is yours.

Ethylene glycol has 1.5-3 times greater penetrating ability and aggressiveness towards seals.

Automotive antifreezes and antifreezes should absolutely not be used as they contain more toxic additives.

For glycol coolants:

- The maximum temperature should be no more than 70 degrees, which further increases the size of the batteries.

- Viscosity is 40-60% higher and pumping requires 1.5 - 2 times more motor power and minimization of bends, bends and increased pipe size.

- Volumetric expansion during heating is 140-150% greater; an increased volume of the expansion tank is required by the same amount.

- Density is 15–20% higher, strength characteristics increase.

The construction of a new system designed for the use of synthetic coolants costs 1.3–1.5 times more than the construction of a water analogue. The considerable cost of the non-freezing liquid itself should also not be forgotten.

Reworking the water fluid is also not used, since the service life is reduced and, as a result, it is more expensive. Glycol mixtures are also aggressive to zinc, causing peeling and sludge that completely clogs the pipes. In older structures, galvanized pipes are common.

However, taking into account the above disadvantages, ethylene glycol is still used. It is necessary to fill the systems only after all heating system equipment is adapted for filling with antifreeze.

A special feature is the need to locate the refueling equipment on impermeable surfaces to prevent glycol from entering living spaces and careful control of the connections of the adapter hoses. Although neat craftsmen do this when filling with any antifreeze.

Specifics of using propylene glycol

Recently, it has been actively replacing other types of coolants, although its physical and technical parameters are almost no different from ethylene glycol and require almost the same changes in heating system equipment.

According to GOST, it belongs to the second hazard class and also requires disposal. Vapor MPC – 7 milligrams/cubic. meter.

The advantages of this non-freezing coolant:

- relatively environmentally friendly and harmless to people. This is the main reason why many manufacturers now recommend it for single-circuit and double-circuit boilers;

- has lubricating properties, which facilitates the operation of pumps;

- does not freeze when water completely evaporates, maintaining fluidity;

- very low corrosion activity, and with additives it improves even more;

- When spilled, just rinse with water and wipe.

Polypropylene glycol liquid has disadvantages. This

its cost, which is 1.5 - 2 times higher than ethylene glycol, because it is produced mainly abroad. The liquid is aggressive towards metal pipes and is not compatible with pipelines constructed from galvanized pipes, because upon contact with zinc, the additives in the composition lose their properties.

At temperatures above the permissible level, decomposition begins with the formation of gases, foam and solid insoluble sediment.

Despite all these disadvantages, it is considered one of the best coolants.

Features of glycerin coolants

As harmless as propylene glycol at acceptable temperatures. Historically, they were the first to be used for these purposes, obtaining glycerol from fat. The strait is not dangerous. The advantage is the price, which is lower than that of propylene, remaining higher than ethylene glycol. Therefore, it is used by counterfeiters to dilute polypropylene glycol.

Even some European manufacturers add it up to about 10%, so you need to be careful and read the composition. On the other hand, in the European Union, glycerin is not used as the main coolant component.

Glycerin has wider temperature limits - up to 105 degrees. Hazard class two.

Flaws:

- When maximum temperatures are exceeded, decomposition releases toxic gas with an unpleasant odor.

- When evaporated, it becomes gel-like, burning and decomposition begin, you need to regularly compensate for evaporation by adding distillate.

- They have increased viscosity and require larger diameter pipes.

- It foams easily, which is partially eliminated by additives.

- It has increased penetrating ability and requires the use of paronite and Teflon gaskets.

It is highly corrosive and has long been rejected by automakers. Due to modern additives, this is reduced and eliminated. Yes, even with proper use.

Glycerin coolants, however, are recommended to a greater extent than ethylene glycol ones for their harmlessness and, with a complex of additives, they work satisfactorily in heating networks. The trouble is that in pursuit of money, they produce products without a full range of additives or without them at all. You need to be careful when purchasing.

A special type includes heating systems with electrode boilers, in which the coolant is also a heating element. Heating occurs when current flows through the solution during its ionization.

The solution, in addition to the above, must have a calculated electrical resistivity of the order of 3.5 - 4 KOhm×cm. To do this, use an aqueous solution or a solution of propylene glycol with additives, which create the necessary electrical characteristics.

Conclusions and useful video on the topic

The video will clearly present the process of filling the heating circuit and setting the expansion tank:

Common to all coolants is gradualness when starting the system. The temperature must be increased slowly, step by step, not only because of the coolant, but also because of the additives, which also change their properties with temperature.

The process of filling systems with both water and antifreeze is similar, but the requirements for the quality of work and safety when filling with antifreeze are increasing. Antifreezes that have expired require disposable containers and removal for disposal.

If you have questions about the topic of the article or already have experience in filling heating systems with coolant, please share it with our readers. Leave your comments at the bottom of the article.

I don’t understand why antifreeze is used in heating systems? Its only property that suits us is its low freezing point. We are forced to practically fight with all its other parameters, since they harm the heating system and us. Well, why the extra trouble? Water, if filtered and softened, is the best coolant without any internal or external aggressiveness.

Hello. In my opinion, you are absolutely right. The technical properties of antifreeze do not match those of classic coolant and can actually harm the heating system. Even manufacturers of heating devices write about the inappropriateness of using antifreeze, but, unfortunately, in Russian climatic conditions people prefer to ignore these recommendations.

I somehow never thought about draining the water from the system. In summer, of course, heating is not needed. And by the fall, I simply added the evaporated water, and that’s it.Or is it not possible to do this? Do I need to drain the coolant every year and fill in a new one? I’m also afraid that an air lock might arise somewhere if I try to change the water myself. The owner, I’m still young and don’t know how to do everything, but I’d really like to learn.

Hello. You need to drain the coolant:

1. When eliminating leaks.

2. Replacing radiators.

3. Cleaning the system.

4. Changing the coolant.

Completely draining the water after the heating season is not necessary and even harmful.

When filling or adding coolant into the system, do I need to turn off the circulation pump? Thank you.

My husband and I decided to add antifreeze to the heating system, because... there were freezing and damage due to power outages. Please tell me, my husband wants to fill it himself, maybe it’s better to call a specialist? As I understand it, if we change it ourselves, the boiler may not work correctly.

Hello. It is best to invite a specialist to fill antifreeze. This is a labor-intensive process and there are a lot of technical nuances. But in general, most boiler manufacturers do not recommend using antifreeze.

There are many reasons for this - for example, the technical characteristics of water and antifreeze are different in terms of heat capacity, expansion, temperature endurance, substances formed as a result of thermal sediment that harm the system, their fluidity, permeability, toxicity, and so on. It is much easier to install a UPS or choose an electrically independent boiler.

We have a Lemax boiler.The coupon says that the manufacturer’s warranty for the boiler will be valid when refilling with Thermagent antifreeze, Thermagent - 30 has already been purchased from us. The water was freezing, there was damage, so we decided to try antifreeze. Can you tell me what to pay special attention to when servicing the system?

Hello. Most importantly, pay attention to the fact that the thermal agent is more fluid than water, so before pouring, carefully double-check all joints for high-quality sealing. And, of course, read the operating instructions more carefully.

Also note that this antifreeze cannot be used in systems with galvanized pipes; it cannot be brought to a boiling point; it is advisable to install an expansion tank of at least 15% of the system volume and choose the right circulation pump, as well as other manufacturer’s recommendations indicated on the product packaging.

“The coupon says that the manufacturer’s warranty for the boiler will be valid when refilling Termagent antifreeze” - could you take a photo of the warranty card and remove personal data in the editor and send it to us, because the manufacturer, when calling the hotline, replied that the use of antifreeze propylene glycol based is allowed, but not required. Although this point needs to be clarified with the technician, who is not there until Monday. It would be interesting to look at this point in your document and check with the manufacturing company after the weekend for answers to other users. And if possible, indicate the specific model of Lemax boiler that you purchased.

Yes, by the way, please note that it was stated above that it is undesirable to use antifreeze and this is indeed true if you have the opportunity to use a natural coolant suitable for its physical properties without freezing. But, let’s make a footnote - again, in some cases the systems freeze due to the climate or you have to leave home for a long time. Therefore, look at the boiler manufacturer's recommendations (whether you can use antifreeze or not) and note that ethylene glycol is strictly not recommended in most cases. If you use a coolant, then let it be safer propylene glycol. You should also be careful about the heating system so that it is suitable for this type of coolant.

All coolant is either harmful, or over time corrodes the gaskets and the radiators begin to leak. I diluted distilled water with alcohol, making it 30 degrees, so the system will not freeze in frosts of 30 degrees. At the dacha there are 20 sections of radiators, only 4 liters of alcohol and 11 liters of distillate were used. Cost - 500 rubles.

It's fun to check the volume of the system, fill it, then drain it and measure it. Wouldn't it be easier to just use a water meter?