Where is a threaded plug used - what you need to know when choosing and installing

A threaded plug, also known as a plug, belongs to the category of pipe shut-off valves.Its purpose is to plug (clog, close) the holes in the pipeline on which the threads are cut. Installation of the plug is simple; it is screwed onto the pipe thread using a regular adjustable wrench, gas wrench or wrench.

The content of the article:

Where is it used?

The scope of application of this type of shut-off valves (but there are also other types of plugs) wide:

- pipelines for various purposes (water, gas, sewer, material pipelines), through which various liquids and gases move;

- pipes of tanks, boilers, vessels operating under high pressure.

Therefore, there is a wide range of products on the market. Not only the material from which the plug is made differs, but also the characteristics:

- temperature range: from -70°С to +600°С;

- pressure – up to 16 MPa;

- diameter: 32-1020 mm.

Production technology of threaded plugs for pipes:

- stamping;

- casting;

- gas cutting from metal sheets with subsequent welding of parts.

Main types

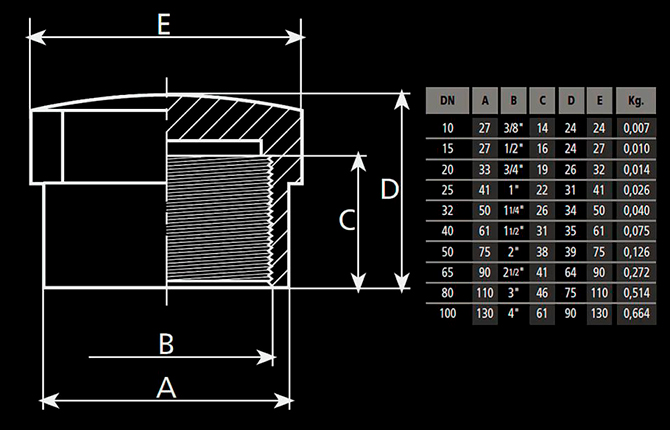

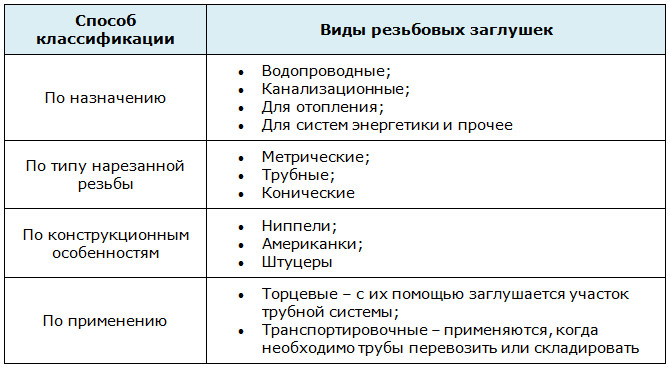

The classification of screw plugs is quite wide. For example, at the location of thread cutting. There are two positions here - with external thread or with internal thread. Other types are presented in the table.

End options have higher characteristics than transport ones. Hence their quality is higher, and therefore their price.

What materials is it made from?

The classification is based on the material of manufacture.There are two groups here - plastic and metal. The latter are more widespread. They are represented by four groups:

- steel;

- made of stainless steel;

- cast iron;

- brass.

Steel

Threaded steel plug is the most popular version of this type of shut-off valve. More often they use a product with a diameter of up to 65 mm. Apply a plug:

- in plumbing systems;

- gas pipelines;

- oil pipelines;

- chemical and food industries;

- mechanical engineering.

Steel is a material that has increased resistance to chemically active substances. Especially those that have high oxidative characteristics. Therefore, a steel plug can be installed on material pipelines through which various acids move.

Stainless steel

In terms of its characteristics, this type of shut-off valve is not inferior to the previous one. But it also has its advantages - stainless steel does not corrode in an aquatic environment, which is important in water supply and plumbing networks.

More often, stainless steel plugs are made from AISI 304 or AISI 316 steel. This is the most versatile type in terms of size range. The diameter of the proposed plugs varies in the range of 6-100 mm. Therefore, they are often used in the automotive industry, where it is necessary to plug engine cooling radiators.

Cast iron

This kind of screw plugs was mainly used in water supply, sewer and heating systems, which were assembled from cast iron pipes. Today, due to the fact that cast iron has been completely replaced by plastic, the need for them has disappeared. But they are still used in heating.

The variety, which is called a radiator plug, is still very popular today.It is made by casting with subsequent finishing - cutting right or left threads.

Products of this type are made from gray cast iron, so they have good technical and operational characteristics:

- high strength;

- affordable price;

- high anti-corrosion resistance;

- resistance to aggressive environments;

- long service life.

Brass

Threaded brass plugs are manufactured using hot stamping technology. Therefore, the material is always homogeneous, and the product has precise dimensional parameters, which reduces the cost. The absence of large additional operations associated with modification makes it possible to reduce the price.

Brass is a ductile material. This makes it possible to use plugs on pipelines through which media with high or low temperatures move. They easily tolerate temperature changes.

Other advantages:

- high strength;

- low magnetic conductivity;

- good anti-corrosion properties.

There is only one drawback - a short service life when in contact with aggressive environments.

Plastic screw plugs

Plastic, as a material cheaper than metal, today has begun to replace the latter almost everywhere. Plastic threaded plugs have replaced all other analogues, wherever possible. And the point here is not only in price, but in practicality. Plastic plugs:

- Do not corrode.

- They easily tolerate changes in temperature and pressure.

- Easily cope with some aggressive environments.

- They have a low specific gravity with high strength and reliability of the product.

- They are distinguished by a wide range of standard sizes.

- They are characterized by 100% environmental friendliness.

In addition, the technology for the production of plastic products makes it possible to produce them:

- different colors;

- with a logo;

- different configurations;

- different thickness.

It is also possible to take into account other customer wishes.

At the same time, during installation, plastic plugs do not require winding FUM tape onto the pipe threads, as should be done with metal analogues. To seal and seal the joint, additional gaskets and cuffs made of a softer polymer are used.

Rubber screw plugs

Separate from the above-mentioned plugs there are rubber ones. They are rarely used in engineering systems. More often, such plugs are installed on pipes that are being prepared for transportation.

They are often installed in a pipe system that is being prepared for pressure testing. Rubber products are used in the furniture industry - medical and school furniture, exercise equipment.

Choosing a high-quality plug for a profile pipe - the main characteristics of this type of plug in the article link.

Installation in a pressurized system

The plug is simply screwed onto the thread of the pipe pipe. The main thing is to choose the right sealing material.

For example, if you need to plug a steel pipe operating under low pressure (domestic gas, water supply):

- FUM tape is used for steel cork;

- for cast iron, tow is better;

- for plastic – gasket.

The tape and tow must be screwed onto the end of the pipe in the direction of the cut thread. The thickness of the sealing layer should not be large so that the plug can be easily twisted, but sealing must be ensured one hundred percent.

Today, silicone sealant is increasingly used to install threaded plugs. It is applied to the thread, no matter whether it is a pipe or a plug, and the plug is screwed onto the pipe.

Threaded water plugs make it possible, without any complex tools, to permanently or temporarily close a pipe installed in the pipeline. This is a removable connection. The product can be dismantled without reducing its quality and another section of the pipeline can be attached to the pipe.

If you have any questions, each of you will receive a comprehensive answer from our specialists in the comments. If you liked the article, repost it on social networks and save it in your bookmarks.

We also recommend watching selected videos on our topic.

Threaded stainless steel plug.

Are polypropylene threaded plugs durable or not?

Sources:

- https://trubtraid.ru/dopolnitelnye-jelementy/zaglushki/zaglushki-rezbovye-metallicheskie-chugunnye.html

- https://santehstandart.com/poleznye-materialy/zaglushka-rezbovaya

- https://spark-welding.ru/montazh-i-remont/pravila-ustanovki-zaglushek.html

A threaded plug is the easiest way to plug a pipe. No welding for you, no additional operations for you. Tighten it by hand, tighten it with a wrench - and you're done. Reliable and long lasting

Twist it, but don’t twist it. If you press it a little, you will get a cut or crumpled thread that will leak. It’s good if it’s on the plug, but if the thread is cut off on the pipe, you’ll have to replace the pipe with a new one.

Plugs (brass) can be used to plug the output under the “towel”, if it is missing. How often will they need to be changed? They say that in the absence of water circulation, the connection will become unusable over time.

Good evening.

The plug in the heated towel rail is installed at the bottom.It is there that a kind of dirt collector is formed, that is, a zone with an aggressive environment. Hence the low service life of the plug. Corrodes quickly. The best option is a stainless steel plug. Brass will work too. But you will have to change it often - once every two or three years.