How to make a sewer well: do-it-yourself installation and installation

Owners of private houses most often have to independently install local treatment facilities on their site.It is cheaper and easier to install sewer wells in the form of a regular cesspool or a sealed storage tank. A well-designed treatment or storage point will do the job perfectly. Do you agree?

Here you will learn what materials are used in the construction of treatment facilities and storage tanks for independent sewerage. We have described in detail the technologies for constructing typical sewer wells. Taking into account our recommendations, it will be easier for you to decide on the best option in terms of price and effort.

The content of the article:

Place of the waste well in the sewer system

Often, there is simply no centralized sewer system in the private sector with low-rise buildings. And it is necessary to get rid of household waste, but not to pour it on the ground. For this purpose, an autonomous sewage system is constructed, including an internal and external part.

The in-house sewer system collects wastewater from plumbing fixtures, and its outer part is intended for its disposal or accumulation for subsequent pumping by sewer trucks. Receiver of waste storage well on the street is the end point of the local removal system.

Fecal wastewater in the sewer well is clarified, resulting in the formation of partially purified water and suspended matter. In the case of a cesspool, the first one drains into the ground, and the second one is decomposed by microorganisms to the state of sludge that is safe from a biological point of view.

If the option with a storage tank is chosen, then the sewage is simply collected in a sealed container, and as it fills, it is pumped out using a sewer truck.

Of course you can install full septic tank with several cleaning chambers, but it costs a lot. For a small cottage or dacha, where a family of three or four people lives, a storage tank or cesspool with a volume of several hundred liters is quite sufficient. There is not much wastewater, such a disposal system will cope with sewage without problems.

Fermentation and clarification of wastewater can be carried out in one or several tanks connected in series. However, in the second case, the installation of sewer wells becomes much more complicated.

It is easier to equip one well structure, and to speed up the purification process, add chemical or biological reagents to it.

Most often, the owners of private houses make a cesspool on their own in their own area. But if the groundwater level is high, then the cesspool option is not suitable; you have to install a storage tank. Moreover, its volume is selected large enough to reduce the number of calls for vacuum cleaners.

The decomposition of the biological component of sewage in the cesspool occurs due to anaerobic microbes. They do not require oxygen supply to function, so there is no need to install additional aerobic units in the well. The entire cleaning system is energy-independent and does not require connection to the electrical network.

All rotting processes inside a sewer well occur naturally, thanks to bacteria living in the soil. In this matter they are quite successful, but anaerobes “work” quite slowly. Therefore, in order to speed up the processes, occasionally enter the pit add bioactivators.

Requirements for the construction of such structures

All sewage systems must be installed according to a pre-developed plan, which indicates the layout of all elements of the system and the building materials used. Its outer part in the case under consideration consists of a pipe leading away from the house and a sewage treatment plant.

The design and installation of sewer wells is regulated in the following regulatory documents:

- SP 55.13330.2016 “Single-apartment residential houses...”;

- SP 32.13330.2012 “Sewerage. External networks...".

If you do not comply with the requirements specified in them, then the sewerage system after assembly may simply be inoperable.

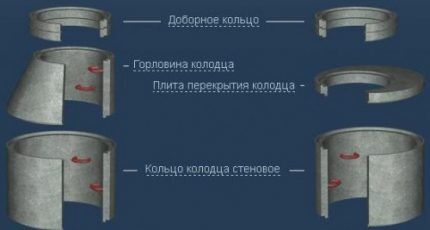

Structurally, the sewer well consists of:

- necks with a lid or hatch;

- shafts in the middle part (working chamber);

- bottom (draining or sealed depending on the installation option chosen).

Even similar elements of this design can vary greatly in size and shape. Here, a lot depends on the material of manufacture and design features of the treatment plant, as well as the volume of the tank.

What can a sewer well be built from?

A well structure can be made from a variety of building materials.

When choosing the best option, you need to consider:

- Climatic conditions of the area (maximum possible and average temperatures, total amounts of rainwater and snow).

- Soil characteristics (freezing depth, composition and groundwater level).

- Features of the site's relief.

If the soils are very heaving, then the sewer well should be made of the most durable building materials. And for wet soils you will have to select the most moisture-resistant option.

You can easily make a sewer well with your own hands from:

- brick and stone;

- monolithic concrete;

- reinforced concrete rings;

- ready-made plastic structures

- old car tires.

It will cost the least if you install it yourself brick drain pit or a septic tank assembled from factory-made or home-made concrete rings.

But in the first case you will have to tinker with the masonry, and in the second you will need lifting equipment. It is not recommended to lower heavy concrete products into the pit manually; if they fall off or receive a strong impact, they may collapse.

The concrete monolithic option will require arrangement of formwork and preparation of mortar. If the latter is ordered already mixed in a concrete mixer, this will lead to a serious increase in the cost of work.

Structures made of plastic (polyethylene or PVC), fiberglass and polymer sand are quite expensive. But they are durable and extremely easy to install yourself. Such products weigh little, a couple of people are enough to install them.

Used tires will make a very cheap sewer well. They cost pennies at a tire shop, but you can collect tires at a landfill for free. But here the problem is the same as in the case of brick.

It is extremely problematic to make such a structure airtight, and it is almost impossible to repair it. Absorption well You can make them out of them, but you can’t create a storage device.

You will learn everything about choosing a container for installing a storage sewer well for independent sewerage from the article we presented.

Selecting the location and volume of the tank

When installing a sewer well, a number of sanitary and construction requirements must be observed. Failure to do this increases the risk of biological contamination. The situation can lead to an outbreak of infections, which threatens the owner of the cottage with serious problems.

The installation of a sewer well should be done away from:

- fruit-bearing trees and beds 3 m;

- foundations of buildings on a personal plot of 4–5 m;

- roads and underground utilities (gas, water, electrical networks) 5 m;

- wells for drinking water and reservoirs 30 m.

A slight deviation from these figures is possible only when installing a sealed storage tank or when constructing a cesspool with thick concrete walls with reliable external waterproofing.

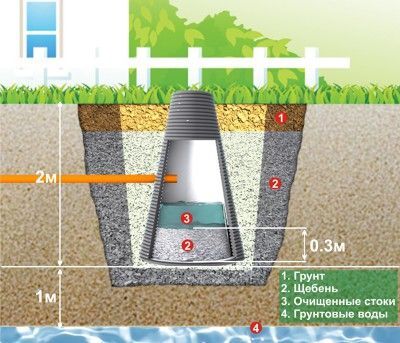

In the case of an absorption well, water that has passed through a multi-layer filter of sand and gravel must enter the underlying layers of soil away from buildings, communications, drinking wells, all types of reservoirs and private pools.

Distances should be maintained so as not to change the composition of groundwater for the worse, not to pollute water bodies due to insufficient cleaning, and not to wash out the underlying base from under building structures and utility networks.

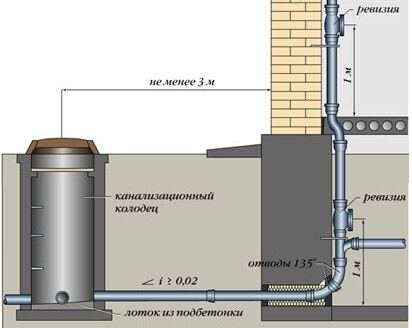

However, if the well structure for sewage drains is removed too far from the house, then the pipeline between them will have to be inspection (inspection) wells every 10–15 meters, which will lead to significant additional expenses. But this will have to be done, otherwise if the pipe is clogged, you will have to open up the soil in order to simply clean it.

SNiPs recommend that the volume of the drainage sewer well be selected at the rate of 600 liters for each person permanently residing in the house (200 daily liters of wastewater multiplied by three days). With such a capacity, the cesspool will have time to clarify the water, and the soil will receive purified water.

With storage capacity the situation is somewhat different. It should be large enough so that there is a gap of a couple of months between calls for a sewer truck. However, it is also not worth installing an excessively capacious tank.

The optimal option would be slightly larger than 3.5 or 5 cubic meters. Effluent from such a container completely fills the barrel of the sewage disposal machine.You have to pay for the call, not the cubic capacity.

Installation and assembly rules

When constructing a well structure for external sewerage, you must:

- Dig a pit with dimensions 30–40 cm wider than the selected structure.

- Compact a sand and gravel cushion of 15–20 cm at the bottom of the pit.

- Install the well elements.

- Lay and connect the waste pipeline from the house.

- Check the tightness of the joints.

- Install a ventilation riser.

- Backfill and insulate.

Outdoor sewage pipe can be plastic, cast iron, ceramic or asbestos-cement. It should be laid at a slight slope to the well. Drains should flow into it freely by gravity. And the fewer bends the pipeline has in the horizontal plane, the better.

Pipe products made of cast iron and asbestos cement have rough walls; their slope must be slightly increased. In general, only a highly competent engineer can correctly calculate the required diameter and slope of laid pipelines.

It is necessary to take into account the material of the pipes, the volume of waste and the speed of their movement. It is best to entrust the development of the entire sewer system project to a professional, and then you can do the installation yourself.

The installation of the sewer well should be carried out in such a way that its cover rises 15–30 cm above the ground. During rains and floods, under no circumstances should water from the outside enter the tank. This will instantly lead to its overflow and failure.

For insulation in warm regions, half a meter thick soil on top of the main body of the well and a small layer of thermal insulation on the lid are enough. In the northern regions this will not be enough; the entire engineering structure will have to be covered with foam plastic. It is not afraid of moisture and frost.

Option #1: construction of concrete rings

Sewage well from reinforced concrete rings easy to install and unpretentious to use. You just need to carefully seal the seams between the rings using concrete mortar, and also cover the outside walls of the housing with bitumen-based coating.

The main thing during installation is to align the rings exactly on top of each other without displacement. Otherwise, gaps will form in the walls, which will no longer be able to be sealed hermetically. The cesspool hole can be dug to its full depth at once and then the rings can be lowered into it.

A possible option is to first install one of the concrete products and gradually dig under it, while being inside the resulting shaft.

When constructing an absorption well, gravel is poured inside in a layer of about half a meter of crushed granite to form a drainage layer. You can use limestone (dolomite), but it will last no more than 20 years and can lead to soil salinization. The crushed stone should be of medium size, several centimeters. Smaller fractions are simply compressed, ceasing to drain water.

Option #2: tire drain pit

Car tires made of rubber are not subject to corrosion, do not crack in the cold and do not break when soil heaves. They make an excellent cesspool. But before make a sewage well out of tires It's worth serious thought.

If even one of the tires leaks, the entire well structure will have to be dug up and rebuilt. It cannot be replaced or repaired in any way.

Plus, it is impossible to ensure the tightness of the seams between the tires. Various sealants can be used, but due to thermal expansion, the rubber will still “breathe” slightly throughout the year, destroying the sealing layer.

A similar well design is suitable as a sewer for a small house for one or two people or a summer house with irregular visits.But if you need to purify wastewater produced by a larger family, then it is worth choosing a structure that is more productive and has a larger volume.

Option #3: plastic construction

The easiest way to install factory-made plastic containers. Their price is higher than their reinforced concrete counterpart. But how much time and effort can be saved by installing such a sewer well with your own hands? Due to the low weight of the structure, a crane is not required; two people can lower it into the pit.

Plastic sewer wells are available in various sizes and heights. You can always find an option for the required volume. It is better to choose a body with stiffening ribs and reliable fastenings for a concrete “anchor” under it.

If plastic well If it is not secured securely at the bottom of the pit on a concrete foundation, then it can be squeezed out of the ground during heaving and floods. The lightness of the design makes installation easier, but leads to problems with “floating up”.

If a sealed version is installed, then there are zero problems. All you need to do is pour a 15–20 cm thick concrete slab at the bottom of the pit, placing iron hooks in the solution to secure the body.

But when installing a well with drainage in place of the bottom, you will have to tinker. It will be necessary to make a reliable heavy foundation that would not block the access of drained water to the ground. You will have to install an additional concrete ring down or pour something similar with your own hands.

Conclusions and useful video on the topic

Video #1. How to make a tire cesspool yourself:

Video #2.Stages of constructing a sewer well from concrete rings:

Video #3. How to properly fasten concrete well rings:

You can make a sewer well yourself from various building materials with a minimum of effort and money spent. There are no difficulties here, the main thing is to correctly design the entire sewerage system and correctly select a place on the site for its external component.

From above, the waste tank can be disguised with a removable flowerbed or an artificial boulder.

Tell us how you installed a sewer well on your own summer cottage. Please write comments in the block below. Share your impressions, step-by-step photos of the construction process, ask questions.

I saw enough of my neighbor's sewer system being done by hired workers. After them, he had to redo everything himself and write a statement to the authorities (an agreement was concluded). I decided to do it myself. At first I considered a septic tank, but the price is just wow, it’s not worth it. It’s good that our area is not swampy; within a month, of course, with the help of friends, I made sewer wells out of brick and stone and laid pipes. For me, it turned out great.

I had an idea to make a sewer well myself. But now I realized that a person without training and experience cannot do this. Especially alone, you need to connect friends. Our land is also swampy, which creates additional difficulties both during digging and when installing drainage. Better to hire people. And to avoid problems later, you need to find craftsmen through friends, then there is a guarantee that everything will be done well.