How to make a two-chamber septic tank from concrete rings: construction instructions

Issues of waste disposal in suburban areas concern both summer residents and owners of private houses.Most dacha areas and many small settlements in the country are not provided with the ability to connect to centralized networks. It’s hard to come to terms with this situation, isn’t it?

A two-chamber septic tank made of concrete rings, the construction of which will require a minimum of money and effort, will allow you to get rid of problems. You can build such a system with your own hands without any problems. However, even if you plan to attract workers, it is simply necessary to know the rules and features of the device. After all, the structure must operate without failure.

We suggest that you familiarize yourself with reliable information about the construction of concrete septic tanks, the basics of designing an autonomous treatment plant and its organization. In addition to valuable information, we have selected photos, diagrams and video tutorials.

The content of the article:

Two-chamber design device

A septic tank, consisting of two chambers, is a practical treatment facility capable of processing organic waste.

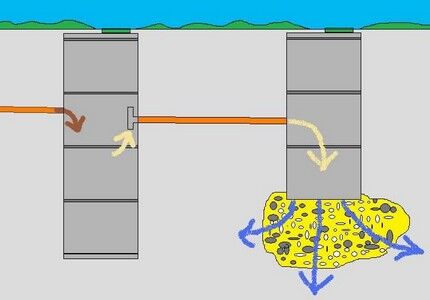

The cleaning mechanism is based on the operation of two communicating compartments, inside of which the liquid component and the insoluble solid component are separated by settling.

Each compartment of the two-chamber structure is responsible for specific tasks:

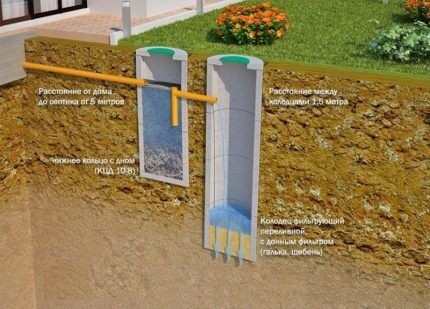

- First camera. Receives waste from the inlet sewer pipe coming from the house. Inside the chamber, the wastewater settles, as a result of which the solid fractions sink to the bottom, and the clarified waste flows through the overflow pipe into the second compartment. The sludge that accumulates at the bottom must be pumped out periodically.

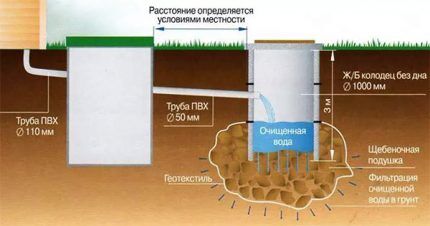

- Second camera. Responsible for the final disposal of clarified, settled wastewater. Passing through a ground filter with a thickness of 1 m, the wastewater is purified to a degree that allows it to freely enter the environment without the threat of disturbing the natural balance.

Additional cleaning inside the second chamber is achieved using a crushed stone or gravel filter. It prevents the penetration of insoluble inclusions into soil layers.

The clarified wastewater that has undergone such treatment significantly reduces the total volume of sewage mass, due to which it is possible to call sewer trucks to empty autonomous sewage facilities much less frequently.

Often instead filtration wells place filter fields. They consist of several trenches laid in parallel, the bottom of which is covered with crushed stone and sand.

Pipes with perforated walls are laid on top of the filtration bed. The entire structure is covered with crushed stone and sand and covered with soil.

The use of concrete rings: pros and cons

The main thing that “bribes” septic tanks made of concrete rings – affordable cost with high performance parameters. After all, reinforced concrete is rightfully considered one of the most durable materials.

Among the undeniable advantages of concrete septic tanks, consisting of two compartments, it is worth highlighting:

- Resistance to ground movements, sudden volley discharges of sewage and aggressive effects of the sewer environment.

- Ability to process cubic meters of wastewater. During the multi-stage treatment process, the bulk of the wastewater is discharged in the form of clarified liquid outside the structure. Only a small part of the sludge settles at the bottom, formed as a result of the processing of the organic component by bacteria, always present in sewage masses.

- Ease of operation and maintenance. It is only necessary to involve vacuum cleaners to clean the walls of a capacious structure from deposits once every two to three years.

- Long service life. The operational period of concrete rings can reach more than half a century, and with proper care - even longer.

Treatment facilities made of concrete rings will not “float” to the surface under the influence of frost heaving of soil, as often happens with lightweight tanks.

But this design also has its drawbacks:

- The need to attract construction equipment for installation. It is almost impossible to deliver heavy rings to the site and load them into the pit without the use of construction equipment.

- Allocation of a large area for development, which is not always possible in small areas.

Tanks made of concrete rings may lose their tightness during operation. The reason for the depressurization of the structure may be the appearance of cracks and leaks at the junctions of the elements.

Among the “disadvantages” of the structure, some users highlight the fact that even with proper installation, an unpleasant odor emanates from the contents in the area where the septic tank is located.

But this defect can be easily eliminated by using biological products that contain bacteria that process organic matter. They easily fix the problem, but do not cause damage to the concrete surface and sewer pipeline.

Calculation of tank volume

One of the key conditions for the uninterrupted operation of a treatment plant is the correct calculation of its volume.

To correctly calculate the volume of a septic tank, you need to focus on three parameters:

- The number of people who live in the house permanently.

- Total daily volume of sewage waste per person.

- The period of time during which organic substances have time to be completely processed.

When calculating, it is taken as a basis that the average daily volume of wastewater per household is 200 liters.On average, it takes up to three days to process organic substances inside a treatment plant.

Knowing that one person consumes an average of 200-250 liters of water per day, it is easy to calculate that the three-day volume of waste per household member will be about 600 liters. The resulting value can only be multiplied by the number of family members permanently residing in the house.

When making calculations, it is also worth taking an additional margin of 15-20%. It will allow you to avoid overfilling the norm in case of a temporary increase in the number of household members and guests staying in the house for several days.

So for a family of four people, a structure with a capacity of 200 liters x 3 days will be required. x 4 people = 2.4 cu. m. We round the value and find that for a family of 4 people you need a septic tank with a capacity of 2.5-3 liters.

If the area where the mini-sewage treatment plant is located has a high level of groundwater, which can cause a slowdown in the water drainage process and even flooding of the structure, consider installing a septic tank that discharges wastewater to drainage fields.

Choosing a location for a treatment plant

When designing a treatment plant, the sanitary zone is placed at a distance from significant objects on the site so that organic waste does not accidentally enter the source of drinking water.

When choosing a location for a structure, they are guided by two standards: SNiP 2.-4.03.85 and SanPiN 2.2.1/2.1.1200-03. They spell out the rules for the construction of external sewerage structures and list the requirements for the arrangement of areas that may pose an environmental hazard to the environment.

If there are bodies of water with running water nearby, the distance to them should be maintained at least 20 m. If there are plantings on the site, then the distance to trees should be about 3 m, and to shrubs - no more than 1 m.

When planning the arrangement of a sanitary zone, it is worth clarifying the location of the underground gas pipeline in order to maintain a distance of 5 m to it.

It is important to provide free space for access and maneuvering of construction and sewage equipment. At the same time, keep in mind that it cannot be placed directly above the place where the septic tank is buried, since a heavy machine can destroy the walls of the treatment plant.

Septic tank installation technology

When installing a two-chamber septic tank made of concrete rings, be prepared for the fact that this is quite difficult and painstaking work. To make your task easier, use the services of special equipment or hire two or three assistants to carry out the work.

It will be difficult for even several workers to lift a heavy ring. Well, installing it exactly in place is even more difficult.

Purchase of materials and components

Concrete rings are available in the market in different sizes. The height of the products is always the same and is 90 cm, but the diameter can vary from 70 to 200 cm.

The volume of a ring directly depends on its diameter. Thus, a reinforced concrete ring with a cross-section of 70 cm has a volume of 0.35 cubic meters. m. And the construction of tanks with a volume of 2.5 cubic meters will require 7-8 such rings.

If you use rings measuring 100 cm, each of which has a volume of 0.7 cubic meters. m, the construction of tanks of the same capacity will require only 4 such rings.

The price of the product depends on its size. Therefore, in order not to make a mistake, before buying rings Always calculate the total volume and required quantity.

When calculating the capacity of a treatment plant and choosing rings for its construction, keep in mind that the actual volume of the tank must be higher than the calculated one. This is explained by the fact that as the liquid is filled, it will not be able to rise above the level of the overflow holes, which are placed 20-25 cm below the top edge of the column.

When choosing rings of the required diameter, it is necessary to take into account the groundwater level. The higher the groundwater is located, the larger the rings you should choose. Indeed, as the diameter increases, their number decreases, and, consequently, the installation depth of the entire treatment plant decreases.

Materials you will also need:

- pipes D110-120 mm;

- tees for overflows;

- crushed limestone of three different fractions;

- river sand.

The soil filter in the second chamber is formed from three layers of gravel or crushed stone, the size of the fraction of each underlying layer should be smaller than the fraction of the previous one.

In addition, you will need to stock up on liquid glass, cement for preparing the solution on the site, and polyurethane foam for sealing the joints.

Tools required for work:

- bayonet and shovel;

- building level;

- perforator;

- ladder;

- bucket with rope;

- mixing container;

- narrow spatula;

- wide brush.

For laying sewerage to a septic tank and creating overflows, it is permissible to use different types of pipes. More often a polypropylene or asbestos-cement pipeline is installed.

Technology construction of a septic tank made of concrete rings includes a number of standard steps:

Carrying out excavation work

The optimal period for starting excavation work is in the hottest weather or after the first frost, when the groundwater level is at its lowest.

To install a two-chamber purifier, it is better to dig a common pit for two wells at once. Although some experts are of the opinion that it is better to create two independent pits for each tank of the structure.

The dimensions of the pit are determined by the diameter of the selected rings.

When calculating the dimensions of the pit, the following points should be taken into account:

- Pit depth should be 30-40 cm lower than the height of the rings used. This is necessary in order to arrange a fill at the bottom or pour a concrete screed.

- Pit length and width should be such that the distance from the walls of the pit to the rings is at least 50-70 cm.This is necessary in order to simplify installation and be able to waterproof the outer walls of the structure.

You can also dig a pit manually with a shovel, removing the soil with a bucket. But it is much easier to use special equipment for this, with the help of which it will not be difficult to dig a hole in just a few hours.

In conditions of limited space, it is most convenient to use a small excavator. It is better to immediately remove the soil removed from the pit outside the site, using for these purposes the same machine that brought the rings.

When creating a common pit for two tanks, the result should be a two-level pit so that the first compartment is half a meter deeper than the first.

At the same stage they lay trenches for sewer pipes. They are laid below the freezing level of soil layers, which for mid-latitude regions is about 1.2-1.5 m.

The bottom of the trenches is leveled, guided by the building level, and compacted. The leveled base is covered with a layer of crushed stone or sand, on top of which supply pipes are subsequently laid.

Pouring the foundation and erecting walls

The bottom of the dug pit is carefully leveled and compacted. The leveled base is covered with a layer of sand, forming a “cushion” 15-20 cm thick. The formed backfill is well compacted, creating a smooth surface free of changes.

To create a concrete foundation for the storage tank, the bottom of the pit is filled with cement mortar.

The size of the concrete screed should be 20-30 cm larger than the diameter of the rings used. It may take four or more weeks for the cement mortar to harden, depending on temperature and weather conditions. Only after this they begin to install the first ring.

To bypass the stage of pouring a concrete base and make your work easier, it is better to use ready-made sewer well bottoms. They, like rings, are produced by concrete factories.

Using a crane, install the first ring so that its walls are positioned strictly vertically. This is necessary in order to ensure the stability and strength of the structure. A second one is placed on top of it. And so on.

To enhance the strength of fixation at the joining points, metal brackets are mounted on the outside of the rings. The “entry” points are covered with a layer of concrete and sealed.

Measures to ensure waterproofing

To reduce the harmful effects of groundwater on concrete, while protecting the structure from leakage, all joints between the bottom and the walls from the inside should be sealed with cement mortar. Both the inner and outer walls of the tank are subject to treatment.

To improve the water resistance of the composition and to accelerate its hardening, liquid glass is added to the solution.The main thing is to maintain a ratio of 25% when adding liquid glass to cement.

If this indicator is exceeded, the glue can worsen the properties of the cement, increasing the risk of the solution hardening directly in the container being mixed.

To increase the waterproof properties of the structure, craftsmen recommend using 2-3 types of waterproofing materials.

For processing the walls of concrete elements, the following is used:

- deep penetration impregnation;

- bitumen waterproofing mastic.

The only condition is not to use toxic compounds that can destroy the beneficial bacteria of the sump. To insulate from the outside, the surface is covered with bitumen mastic or roll material with a similar composition of derivatives.

An alternative and fairly reliable option is plastic insert in septic tank from rings.

A concrete cover with a hole is installed on top of the well, inside which a cast-iron hatch with a removable cover is mounted. To prevent the system from freezing, the upper part of the tanks is insulated with pieces of expanded polystyrene.

Features of creating a filtration compartment

The second well of the structure is constructed according to the same scheme. The only difference is the creation of a filter layer. It is laid at the bottom and along the walls of the tank.

To do this, the bottom of the dug pit is covered with:

- the first layer of sand is 10-15 cm thick;

- the second layer of fine-grained crushed stone is 15-20 cm thick.

When forming the fill, it must be thoroughly compacted. To do this, tamping the “pillow” alternates with filling it with water.

If lateral discharge of treated wastewater is expected, the walls of the absorption well are made of special perforated rings, the hole size of which is 30-50 cm.

A neck with holes for a sewer hatch and a ventilation riser is installed in the upper part of the tank. The ventilation pipe should be 70-80 cm above ground level.

To install the overflow pipe, a trench is dug between the tanks. The overflow is constructed in such a way that the height difference between the entrance to the first compartment and the exit to the second tank is 15-20 cm.

The inlet and overflow pipes between the chambers must be equipped with tees.

The easiest way to make a hole in the tank wall for an overflow is to use a hammer drill. Bringing the edge of the pipe into the wall of the storage tank, fix it by blowing it with foam. The cured foam will do double duty: act as a damper pad and retain moisture.

Having made sure that the structure is tight, they begin to backfill it. To do this, the voids between the outer surface of the well and the pit are filled with earth, previously mixed with sand. To create additional waterproofing, clay is used when backfilling.

Conclusions and useful video on the topic

Review of one of the options for installing a two-chamber septic tank:

Secrets of proper installation:

How to build a septic tank at minimal cost:

In general, installing a two-chamber septic tank made of concrete rings, although troublesome, is a completely feasible task.

The main thing is to take a responsible approach to choosing a place for its arrangement and strictly adhere to installation technology. And then, the treatment plant will serve regularly for decades, making country life more comfortable.

Do you have experience constructing a septic tank from concrete rings? Please share information with our readers, tell us about the features of the arrangement and operation of an autonomous sewer system. You can leave comments in the form below.

According to your scheme, no wastewater treatment occurs in the second chamber, and over time, harmful substances will accumulate around the chamber, which will poison everything around the filtration perimeter from the second well. After all, the so-called “clarified waste” contains many harmful organic and inorganic substances.And no filtration field will remove these substances from the wastewater! This option is suitable for those who save on the environment.

An interesting option for organizing a sewage treatment structure, but it is not new. There are many articles about this method. After all, autonomous systems with biotreatment are quite expensive, and in order to maintain them in impeccable working condition, you need to constantly live in a house that is served by a volatile septic tank. Not everyone can afford this option. The main thing when determining what you need is to take into account not only your convenience, but the specifics of the area.

Which rings to choose - with or without a lock? With a lock of course! The pros outweigh the cons. Easy to install and they actually leak less water. A good ring lock won't let you through! Depends on the manufacturer! The downside is the price, they are a little more expensive. I know what I’m saying, I’m the director of the Septiconos company!!!

In the table of characteristics of concrete rings, the volume is indicated incorrectly. Remember your school math and recalculate!