Connecting a hydraulic accumulator to the water supply system: options and typical diagrams

An autonomous water supply system is a complex technical structure that requires the use of an impressive range of technical means.To automate the operation of pumping equipment and the supply of water to taps, you will need to install a hydraulic tank. Agree, not every homeowner knows how to install it, or indeed what kind of device it is.

We will tell you in detail how to connect a hydraulic accumulator to a water supply system. We will analyze in detail what is needed for its installation, in which independent water supply networks it is used, with what equipment and how it can be operated.

Installing a hydraulic tank according to our recommendations will prevent many potential problems: it will protect household appliances and minimize the effect of water hammer. To optimize perception, the information presented is supplemented with photographs, diagrams and videos.

The content of the article:

- Design and purpose of the hydraulic tank

- Operating principle of a hydraulic accumulator

- Role in the water supply network

- Options for membrane closed containers

- Hydraulic accumulator connection diagrams

- Selecting a membrane tank wisely

- Connecting the accumulator to the water supply circuit

- Correctly setting up a new device

- Optimal air pressure

- Conclusions and useful video on the topic

Design and purpose of the hydraulic tank

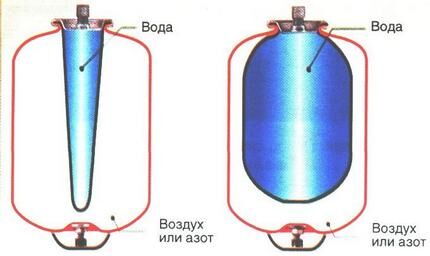

Hydraulic accumulator, which is otherwise called a hydraulic tank or membrane tank, is a sealed metal container in which a pear-shaped elastic membrane partially filled with water is placed. In fact, a membrane placed in the body of the hydraulic tank and attached to its body with a flange with a pipe divides its capacity into two parts: water and air.

As the volume of water in the hydraulic tank increases, the volume of air naturally decreases. As a result, the pressure in the water supply system increases. When the user-specified pressure parameters are reached, it fixed relay, which systematically gives the command to turn off the pump.

The tank body is made of metal, but the water does not come into contact with it: it is enclosed inside a membrane chamber, which is made from durable butyl rubber.

This bacteria-resistant material helps water not to lose the qualities required of it by sanitary and hygienic standards. Drinking water, when interacting with rubber, retains all its wonderful properties.

Water in membrane tank enters through a connecting pipe equipped with a threaded connection. The pressure pipe and the outlet of the connecting water pipe should ideally have the same diameters. This condition allows you to avoid additional hydraulic losses inside the system pipeline.

To regulate the pressure inside the device, a special pneumatic valve is provided in the air chamber. Air is pumped into the designated compartment through a regular car nipple. By the way, through it you can not only pump in air, but, if necessary, bleed off excess air.

Air is pumped inside the membrane tank using a compact car or simple bicycle pump for this purpose. When water enters the rubber bulb, compressed air resists its pressure, preventing the membrane from breaking through.The pressure inside the accumulator is also regulated using compressed air.

Operating principle of a hydraulic accumulator

If the system has just been installed, most of the internal volume of the accumulator is occupied by the chamber intended for air.

Entering the pear-shaped membrane through the pipe, water compresses the air. This continues until the specified pressure is reached. The relay then turns off the pump. The operation of the relay can be adjusted.

When we open the valve and use water for our needs, the system depressurizes. The air, pressing on the membrane, helps the water leave the container. This process will continue until the pressure in the system drops to the set minimum of -1.5 atm. At this moment, the pump should start, pumping water into the tank.

As you know, water also contains dissolved air. When it accumulates inside the membrane bag, the operation of the accumulator deteriorates, so it must be vented. Some models have a special valve for this purpose. If there is no valve, you need to carry out maintenance on the membrane tank every 1-3 months.

It is important to install correctly hydraulic accumulator in the water supply system. Then, if it breaks down or when carrying out maintenance work on it, the device can be easily disassembled so that you do not have to completely drain the water from the entire system.

Role in the water supply network

It would seem that the device simply passes water through itself. Could you do without it? In fact, it is with the help of a hydraulic tank that stable pressure is maintained in the water supply system.

The water pump, if present, does not turn on so often, which allows you to use its operational resource economically. In addition, the water extraction and transportation system is reliably protected from water hammer.

If for any reason the voltage in the electrical network is lost, a small “emergency” supply of water in the tank will help solve priority economic problems.

Let us clarify the list of advantages that this fairly simple device provides:

- Premature pump wear. There is a certain supply of water in the membrane tank. It satisfies the primary needs of cottage owners. And only when the supply runs out will the pump turn on. It should be noted that all pumps have a turn-on rate of an hour. If there is a hydraulic accumulator, this figure will not be exceeded, and the unit will last longer.

- Stabilization of pressure in the system. If you turn on two taps at the same time, for example in the bathroom and in the kitchen, pressure changes can affect the water temperature. This is very unpleasant, especially for those household members who are taking a shower at this moment. Thanks to the hydraulic accumulator, such misunderstandings can be avoided.

- Water hammer. These phenomena, which can damage the pipeline, can occur when the pump is turned on.With a hydraulic tank, the risk of water hammer is virtually eliminated.

- Water supply. In a country house, the problem of water supply is especially acute. If there is a sudden power outage and the pump cannot perform its functions, then it is no longer necessary to store a supply of water in a bucket or other container to solve urgent problems. It is available in the hydraulic accumulator tank and is regularly updated.

Obviously, the presence of this device in a water supply system independent of centralized networks is not accidental. It is necessary and useful.

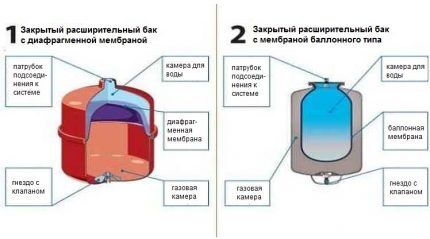

Options for membrane closed containers

Membrane tanks are used as part of pipelines installed for various purposes, including:

- Cold water supply. The tank is used to accumulate and supply cold water and protects various household appliances from water hammer when the pressure in the system changes. Extends the life of pumps by reducing the number of pump starts.

- Providing hot water. The device used in this case must operate successfully in high-temperature conditions.

- Heating systems. Such tanks are called expansion tanks. They function as part of closed heating systems and are their important components.

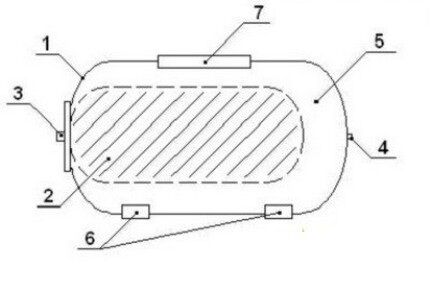

Depending on the configuration, hydraulic tanks can be horizontal or vertical. However, the principle of their operation does not depend on the configuration.

A special feature is the presence of a special valve for bleeding air in the upper part of vertical models, the volume of which exceeds 50 liters. This air, as mentioned above, accumulates in the upper part of the chamber as the device operates. Therefore, the presence of a bleed valve in this place is a completely justified measure.

If it is necessary to bleed air masses when operating horizontal models, then a drain or a separate tap located behind the membrane tank is used for this purpose. To remove air from small devices, you will have to completely drain the water from it.

Since vertical and horizontal models are equally effective and functional, you should choose a suitable device based on the dimensions of the room in which it will be located. Whichever model fits best into the room is the one they take.

Hydraulic accumulator connection diagrams

This device can be connected to the water supply system in different ways. The choice of connection diagram for a hydraulic accumulator depends on the quality in which it will be used and what functions are expected to be assigned to it. Let's look at the connection diagrams that are most popular.

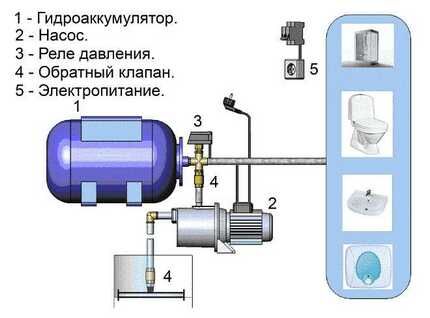

Standard version with surface pump

The most common option for autonomous water supply with a hydraulic accumulator is a tandem with a surface pump.In this case, the hydraulic tank may be part complex pumping equipment, assembled by the manufacturer in the factory, or a separate component placed next to the pump in a caisson or in a heated utility room.

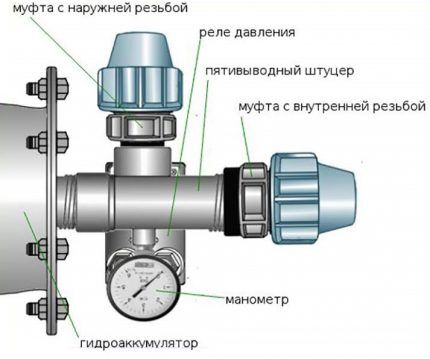

A check valve is placed in front of the hydraulic accumulator to prevent a change in the direction of flow, after it there is a pressure switch that responds to changes in pressure, and a pressure gauge to monitor operating parameters.

For normal connection to the water supply circuit, the hydraulic tank is usually equipped with an elbow pipe, which is connected to the flange:

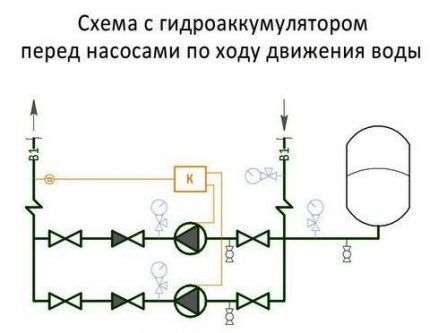

Use with booster pump station

A booster pump unit is used to constantly maintain and regulate pressure in pipelines with active water consumption. Typically, such stations have a pump that operates in constant mode.

If there is a need to connect additional pumps, the hydraulic accumulator helps compensate for pressure surges that occur in the system.

The same scheme is used if the power supply to the booster pumps in the system is unstable, but the water supply, however, must be uninterrupted. During a power outage, the water supply contained inside the accumulator is used. In fact, the membrane tank plays the role of a backup source of water supply during this period.

The more powerful the pumping station, the larger the tasks assigned to it. She must support more pressure, the volume of its hydraulic accumulator should also be large.

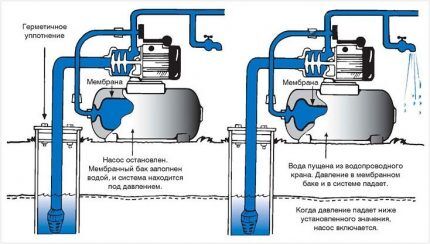

Application in circuits with a submersible pump

In order to maximize the service life of the submersible pumping unit, the number of its starts per hour must correspond to the declared technical characteristics of the device. Typically this figure is about 5-20 times.

If the pressure in the water supply network drops, when it reaches a minimum value, a relay is activated, turning on the pump that supplies water. At maximum pressure values, the relay turns off and the water supply stops.

If the water supply system is autonomous and small, even a small amount of water consumption can start the pump. In this case, the operation of the pump will be ineffective. And the device itself will not last as long as its owner would like.

The supply of water contained in the membrane tank will save the situation. In addition, it will not allow a pressure surge at the moment when the submersible pump starts operating.

To choose a hydraulic tank of a suitable volume, you need to know the following characteristics: the power and frequency of pump activation, the expected water flow per hour and the installation height of the device.

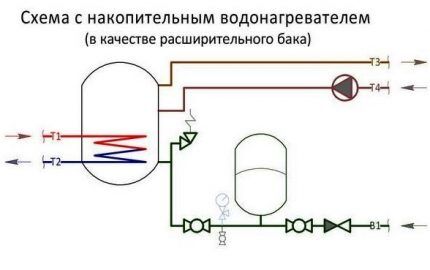

If the connection diagram shows storage water heater, then the hydraulic accumulator acts as an expansion tank in it. If water is heated, its volume increases. It will expand. For a confined space, such as a water supply system, such a process could lead to devastating consequences if it were not for the hydraulic tank.

To be included in this scheme, it is necessary to select a hydraulic accumulator, taking into account its following characteristics: the maximum temperature of the heated water and the maximum permissible pressure in the water supply system.

Selecting a membrane tank wisely

A hydraulic tank is a container whose main working body is a membrane. Its quality determines how long the device will last from the moment of connection to the first repair.

Products made from food-grade (isobutane) rubber are considered the best. The metal of the product body is important only for expansion tanks.Where water is contained in the pear, the characteristics of the metal are not decisive.

When choosing a device, special attention should be focused on the flange, which is usually made of galvanized metal. The thickness of this metal is very important. With a thickness of only 1 mm, the service life of the product will be no more than 1.5 years, since a hole will certainly form in the metal of the flange, which will damage the entire device.

Moreover, the warranty on the tank is only a year with a stated service life of 10-15 years. So the hole will appear just after the warranty period expires. And it will be impossible to solder or weld thin metal. You can, of course, try to find a new flange, but most likely you will need a new tank.

To avoid such misfortunes, you should look for a tank whose flange is made of stainless steel or thick galvanized steel.

Connecting the accumulator to the water supply circuit

As it became clear from everything written above, a membrane tank is not just a container with water. This is a special device involved in a continuous work process. Therefore, the installation procedure is not at all as simple as it might seem. It should be secured very carefully, taking into account vibration and noise factors.

It is attached to the floor using rubber gaskets, and to the pipeline using rubber adapters. And it should also be taken into account that the diameter of the line cannot decrease at the outlet of the hydraulic system.

The new tank should be handled with particular care, filling it with water under low pressure. The membrane could have caked due to long-term storage. A sharp jet of water can damage it and even completely disable it. It is better to remove all the air from the membrane bulb before you start filling it with water. The location for installing the accumulator must be selected taking into account its accessibility.

The process of connecting the hydraulic accumulator is carried out in the standard sequence:

Correctly setting up a new device

The new hydraulic tank should be checked to see what its internal pressure level is. It is assumed that it should be 1.5 atm. But during transportation of the product from the place of production to the warehouse and during storage, a leak could occur, which reduced this important indicator at the time of sale. You can check the pressure by removing the cap on the spool and taking measurements.

To measure pressure, you can use different types of pressure gauges:

- Electronic. These are expensive devices. Their performance may be affected by temperature and battery charge.

- Mechanical. They are produced in a metal case, otherwise called automobile ones. If this device has successfully passed the test, then you couldn’t find it better. To get the most accurate value, since you will only need to measure 1-2 atm, it is better to buy a device with a large number of divisions on the measuring scale.

Inexpensive pumping stations and automatic pumps are most often equipped with pressure gauges in a plastic case. The error in the readings of such Chinese models is too great.

If there is less air in the tank than needed, water will take its place. This will affect the water pressure in the water supply. At high pressure, the pressure will always be high. Higher pressure will provide less water in the membrane bulb, so the pump will have to turn on more often. If there is no light, the water supply may not be enough for all needs.

That's why sometimes it makes more sense to sacrifice pressure to achieve other important goals. However, it is better not to reduce the pressure below the recommended values, nor to exceed the maximum characteristics. Lack of pressure can lead to contact of the bulb surface with the tank body, which is undesirable.

Optimal air pressure

For household appliances to work normally, the pressure in the hydraulic tank must be in the range of 1.4-2.8 atm. For better preservation of the membrane, it is necessary that the pressure in the water supply system be 0.1-0.2 atm. exceeded the pressure in the tank. For example, if the pressure inside the membrane tank is 1.5 atm, then in the system it should be 1.6 atm.

This is the value that should be set to water pressure switch, which works in conjunction with a hydraulic accumulator. For a one-story country house, this setting is considered optimal. If we are talking about a two-story cottage, the pressure will have to be increased. To calculate its optimal value, use the following formula:

Vatm.=(Hmax+6)/10

In this formula V atm. is the optimal pressure, and Hmax is the height of the highest water intake point. As a rule, we are talking about the soul.To get the required value, you should calculate the height of the shower head relative to the accumulator. The obtained data is entered into the formula. As a result of the calculation, the optimal pressure value that should be in the tank will be obtained.

Please note that the obtained value should not exceed the maximum permissible characteristics for other household and plumbing appliances, otherwise they will simply fail.

If speak about independent water supply system at home simplified, its constituent elements are:

- pump,

- hydraulic accumulator,

- pressure switch,

- check valve,

- pressure gauge

The last element is used to quickly control the pressure. Its constant presence in the water supply system is not necessary. It can only be connected at the moment when test measurements are being made.

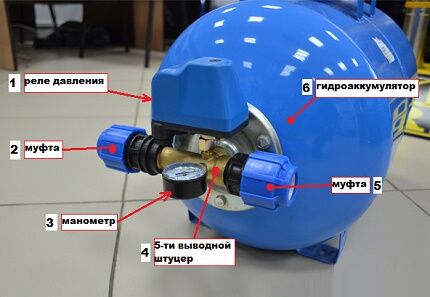

When a surface pump is involved in the circuit, the hydraulic tank is mounted next to it. The check valve is installed on the suction pipeline, and the remaining elements form a single bundle, connecting to each other using a five-pin fitting.

The five-pin device is ideal for this purpose, since it has leads of different diameters. The incoming and outgoing pipelines and some other elements of the connection can be connected to the fitting using American connectors to facilitate preventive and repair work on individual sections of the water supply system.

However, this fitting can be replaced with a bunch of connecting elements. But why?

So, the accumulator is connected to the pump as follows:

- one inch lead connects the fitting itself to the hydraulic tank pipe;

- a pressure gauge and pressure switch are connected to the quarter-inch terminals;

- There are two free inch outlets left, to which the pipe from the pump is mounted, as well as the wiring going to the water consumers.

If a surface pump operates in the circuit, then it is better to connect the hydraulic accumulator to it using a flexible hose with a metal winding.

The hydraulic accumulator is connected to the submersible pump in exactly the same way. A feature of this circuit is the location of the check valve, which has nothing to do with the issues we are considering today.

Conclusions and useful video on the topic

If, after reading the text, it is still not clear to you exactly how to connect the accumulator, watch this video, which briefly but very clearly displays all the nuances of this procedure.

The hydraulic tank is an important component of the plumbing system. With its help, a whole range of problems can be solved. And, as it turns out, it’s not at all difficult to properly connect the hydraulic accumulator with your own hands. But the benefits of its use are undeniable.

Did you have any questions while reading the information provided? Do you have useful information or personal experience that you would like to share with us and site visitors? Please leave comments in the block located below the article.

My house in the village is far from the water tower. Therefore, in summer during the watering season, and in winter during severe frosts, there is practically no water in the house. The question wasn’t even about swimming; sometimes there was no water to drink.

I installed an expansion tank at the water inlet to the house, on the drains and on the valve. That is, when there is water in the pipeline, I don’t use the tank, there is no water, I take it from the storage tank. It helped, now it doesn’t matter what time of year, there is always water.

The only thing is that you need to carefully choose a tank for your tasks, take a large one, you will overpay, take a small one, its volume will not be enough. Therefore, calculate your consumption per day, add 50 liters to it, and take such a tank.

Six years ago, a hydraulic tank and a pressure switch were installed at the dacha to automatically turn on the pump. The hydraulic accumulator was taken at 24 liters. But the pump still failed in the first year; they thought it was defective. Since the pump could not be repaired, we bought a new one. But he, too, quickly burned out. We began to look for the cause, and a pump specialist advised replacing the hydraulic accumulator with a larger one. After replacement, the system has been working flawlessly for three years.

We bought AquaLiv BNU-50 Favorite for a private home. Considering the presence of a well, we connected it with a submersible pump BCP Aquarius. The household pumping unit has shown itself well; for the third year now there have been no problems. Just be sure to check the pressure in the air tank once a month so that it is about 2 bar.

I have some problem with the water pressure at the outlet. When the pump is connected, 1.5 bar, when turned off, 3.0 bar. What can be wrong? Leaky membrane?

How to properly position the accumulator on the wall? Should the water supply come from above or below? Or does it not matter?

I want to install a surface pump (with an external ejector) with a hydraulic accumulator. What is the maximum distance that can be made between the pump and the accumulator?

Hello. Very useful article!

Please tell me where to put the tank if you use a submersible pump in a well under a hill, and you need to supply water to a house on a hill. The height difference from the pump to the distribution is 15 meters. Should the tank be placed at the well or in the house? (Below or upstairs?)

what's the difference? I have a hydroac. It's located 25 meters from the well. It's just in the house

connected 3 hydraulic accumulators of 50 liters each

everything works clearly - there is no difference, whether it is on the wall, attic or in the basement - the pressure will squeeze out the water itself... turn on the logic