Plastic sewer wells: varieties + installation features

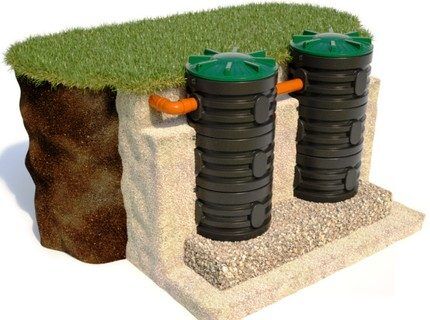

Sewerage installation involves installing wells to service the system.If previously this task was performed by reinforced concrete structures, today, due to the heaviness of the structures and the complexity of their installation, they have been replaced by polymer analogues.

How plastic sewer wells benefit from traditional hydraulic structures, and what installation features they require, we will consider in the article.

The content of the article:

Scope of application of plastic wells

In the post-Soviet space sewer wells were built mainly from reinforced concrete rings. To increase the tightness of the structure, the joints between them were sealed with cement mortar and sealed with industrial flax fibers.

But under the influence of temperature fluctuations and other environmental influences, the joint seal cracked over time, concrete rings shifted relative to each other, as a result, the shaft lost its tightness and partially collapsed.

Modern plastic wells do not face such trouble. The solidity of the product allows for tight connections.

Ready-made plastic sewer containers can be used both as independent structures and as an addition to ready-made shafts made of concrete rings.

In the second option, they act as a reliable waterproofing sewer wells. A plastic sealed insert into a well made of concrete or brick reliably protects the soil from seepage of wastewater.

The main purpose of polymer wells is to connect sewer lines to each other.

But thanks to the design features, in addition to the main function, their use allows solving several problems at once:

- provide conditions for monitoring the technical condition of the pipeline at the junction, change of direction or diameter of the pipe;

- create conditions for laying sewer pipeline branches at different levels;

- reduce/increase the wastewater flow rate;

- guarantee access to the sewer section enclosed in the well for inspection and maintenance.

In large-sized collector sewer wells, shut-off and adjustable equipment and pumps are placed if there is a technical need to stimulate the movement of flows.

Such hydraulic structures are used both for industrial sewer structures and for laying utility, storm, drainage networks.

Design features and production standards

Regardless of the type of material used, the design of sewer wells is the same. The structure is a cylindrical shaft sunk into the ground, at the bottom of which there is a kineta - a tray for two or three pipes with wastewater.

The length of the structure can be adjusted using extensions and retractable shafts. To gain the required length of the structure, they are joined together, creating a strong and hermetically sealed connection.

Often, sliding extension models are used to expand the structure. Acting as connecting elements, in parallel with this they serve as a continuation of the wall of the structure.

The upper part of the well is equipped with a ceiling with a hatch. When installing plastic wells, it is a logical choice polymer hatches, thanks to which it is possible to ensure equally greater durability of the entire structure.

The dimensions of the plastic models correspond to the dimensions of their cast iron counterparts. When choosing a hatch, they are guided by its functionality.

Depending on the degree of load withstand, all types of sewer manholes divided into 4 categories:

- Standard "A15" used for installation on green areas and pedestrian paths. It can withstand up to one and a half tons.

- "B125" installed on sidewalks and in park areas and parking lots where the load weight does not exceed 12.5 tons.

- "S250" used in the construction of sewers, which are laid under city roads. The products can withstand loads of up to 25 tons.

- "D400" the most durable structures, capable of supporting up to 40 tons, are designed for highways.

Hatches of the “A15” standard can be installed directly on the well shaft, and their analogues of the “B125”, “C250” and “D400” categories can be installed on a discharge ring or a retractable telescopic pipe.

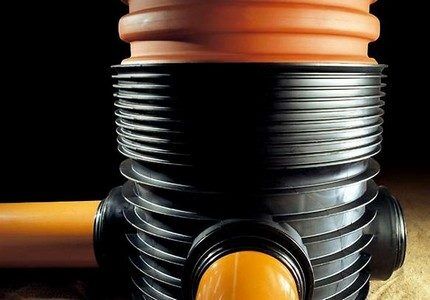

The neck is a transitional element between the shaft and the hatch. Its main purpose is to accept and compensate for external loads that can damage the mine and the pipes leading to it. For this reason, it is a corrugated or telescopic structure.

The telescopic part of the shaft can be extended, taking the most convenient position for inspecting the condition of the wall surface and providing access during repair work. The relief ring is threaded at both ends, making the connection as tight as possible.

There are holes in the walls of the structure for connecting the inlet and outlet pipes.

Depending on the size of the structure, wells are of two types:

- Diameter up to 1 m with an unattended shaft. Compact inspection structures are installed at shallow depths.

- Diameter over 1 m. The design allows for easy maintenance of the equipment and, if necessary, repair of the structure.

The well itself is made of the same material that is used in the production of ordinary sewer pipes. It can be structured or two-layer polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP).

Models made of corrugated plastic are no less popular. This solution simplifies the task of adjusting the height of the tank and makes it possible to partially compensate for the load on the bottom, thereby significantly extending the service life of the structure.

Both types of wells are available with both single and double walls. To resist soil compression from the outside, the products are equipped with stiffeners.

Advantages and disadvantages of plastic models

Structures made from composites with a polymer base are in no way inferior to traditional reinforced concrete ring-shaped modules. And in some respects, polyethylene and polyvinyl chloride wells are even superior.

Among the undeniable advantages of plastic wells for arranging a sewage system, it is worth highlighting:

- Affordable price. The price, depending on the dimensions of the structure, types of plastic and the number of pipes, varies from 5 to 50 thousand rubles.

- Lightweight design. The weight of a product, even with a diameter of more than one meter, does not exceed 100 kg.

- High compressive strength. The walls of the structure are able to withstand high pressure created both inside and outside.

- Easy to transport and install. Installation of the structure can be completed without the involvement of additional labor and the use of small-scale mechanization.

- Low thermal conductivity. Polymer formations are resistant to high temperatures. The tray part of the structure is also characterized by increased wear resistance. The only exception is silting and overgrowing of elements.

- Resistant to corrosion and frost. A plastic well or polymer liner manufactured according to standards can withstand down to -60°C without loss of practical qualities.

With proper use, polymer products can last over half a century.

Not so long ago, products made from polyvinyl chloride were considered not strong enough and frost-resistant in comparison with concrete structures. But modern compositions can easily withstand frosts down to -70°C, so they can be used in any climate zone.

The only drawback of plastic structures is that, although they have thick walls and additional stiffening ribs, their installation should be carried out extremely carefully, since there is a risk of deforming the container.

In addition, in most cases they can be repaired. Any chip or crack on the wall leads to the disposal of the product. For this reason, it is extremely important to choose only high-quality and durable products.

Types of sewer wells

According to their purpose, polymer sewer wells are divided into three types: inspection, absorption and water intake.

Viewing models with kinets

Inspection models are mounted on potentially dangerous sections of the pipeline. Their main purpose is to provide access for monitoring the condition of the system, placement of special equipment and the need for maintenance of the structure. Not a single sewer pipeline can do without them.

They must be installed in the following places:

- turning the highway;

- branch connections;

- changing the slope and diameter of pipes.

One inspection well can combine up to three or four traffic flows.

When installing a sewer system, plastic inspection wells are placed at a distance from each other, regulated by regulatory documentation. The larger the diameters of the installed hydraulic structures, the greater the normatively permissible distance between them.

Additional information on different types of sewer inspection wells is presented in this article.

Absorption drainage structures

Structures of this type are installed where it is not possible to easily drain wastewater. They are cylindrical plastic shafts two meters deep and one and a half meters in diameter.

Unlike inspection wells, absorption-type models do not require the installation of showers. Instead, the bottom of the tanks is equipped with a mesh or lined with materials that have a drainage effect: gravel, crushed stone or crushed brick.

The same material is also used as coating for the outer walls of the well.

The minimum height for inserting drainage pipes into the walls of a plastic well is 40 cm. Thanks to this solution, the bottom of the tank, in addition to its main task, acts as a sand trap, which catches settling sand particles and other inclusions present in the water.

A simple drainage well can be built with your own hands, more details in the article - How to make a drainage well with your own hands and connect pipes to it

Water receiving storage tanks

The main function of water intake wells is to accumulate wastewater until it is pumped out, removed and transferred to treatment facilities. The “final destination” option depends on the degree of water contamination.

Since storage tanks are designed to hold tons of liquid, they are quite impressive in size.

Water receiving plastic tanks have completely sealed walls and bottom.One of the prerequisites for installing water intake wells is that the lid is sealed.

This is necessary in order to prevent sewer overflow after heavy rainfall.

Criteria for choosing wisely

The price of polymer wells consists of three main parameters:

- Quality of material and wall thickness.

- Dimensions of the structure (internal diameter and height).

- Number of pipes.

Monolithic and prefabricated models are found on sale. The price of monolithic products is an order of magnitude lower than their prefabricated counterparts.

Wells with a monolithic body are used in cases where it is necessary to ensure high compressive strength of the walls of the structure.

Due to the static internal volume of the structure, when choosing wells with a monolithic body, it is important to correctly assess the volume of water that will flow into it.

Please note that there are models in which the inlet pipes are already built-in. But there are also options where you need to insert the inlet and outlet pipes yourself.

Prefabricated structures allow you to create wells of any height. They consist of component parts, each of which is equipped with an O-ring that ensures the tightness of the structure.

When purchasing a plastic well for draining technical waste, pay attention to the type of material used.It must be resistant to aggressive environments, since during operation it will be exposed to the organic solvents present in it.

Models made of polyvinyl chloride are famous for their non-flammability and high resistance to chemicals. If you need high tightness and resistance to temperature changes, you should choose models made of polyethylene. They perfectly compensate for soil pressure in the cold season.

On soft soils, where there is a high probability of loading on the walls of a hydraulic structure, it is recommended to install wells made of polypropylene. They have high wear resistance and ductility. They can be welded.

You shouldn’t try to cut down on expenses by refusing to purchase a kineta. The damage to such “savings” is many times greater than the direct financial benefit.

The absence of a wastewater tray makes it difficult to remove wastewater from the well. This in most cases leads to frequent contamination of the system with coarse waste, which results in great resistance to the flow of wastewater, and as a result, the structure quickly wears out and fails.

Polyethylene wells of standard dimensions can be purchased at hardware stores. A shaft of specified dimensions can also be ordered according to an individual project.

Basic installation rules

The technology for installing polymer wells is not much different from the process of installing similar sewer structures made from other materials.

The work is carried out in several stages:

- Digging a pit. Having measured the dimensions of the structure being installed, dig a pit 10-20 cm wider.

- Preparing the base. When constructing a storage structure, the bottom of the pit is lined with a 20-centimeter layer of pebbles and then cemented. To construct a drainage structure, the bottom is concreted only around the perimeter, and the inside is lined with a 40-centimeter layer of gravel or crushed stone.

- Well installation. Using a tripod, ropes and cables, the container is lowered to the bottom of the pit. To prevent displacement and increase the reliability of fixation, it is secured in a given position with metal chains or belts.

- Connecting sewer pipes. To seal connections and give them strength when connecting pipe outlets, sealing collars are used.

- Perform backfilling. Before filling, if the container is not protected by anything from the outside, in order to avoid deformation due to pressure changes, it is recommended to fill the tank with water.

- Hatch installation. First, a support ring is installed, in which there are technological holes, and then the cover is placed in the ring so that it aligns with the corresponding grooves.

Information support during the work should be the current SNiP for work on installation of sewerage systems.

Conclusions and useful video on the topic

Step-by-step installation technology is clearly presented in the video:

Technology for creating plastic sewer wells:

The use of plastic wells for sewer construction significantly facilitates and reduces the cost of work. This is a worthy alternative to conventional reinforced concrete structures. Heat-resistant, sealed and easy-to-install elements are easy to assemble, quick to install and require virtually no maintenance.

Are you looking for a suitable sewer well model? Or do you have experience using such installations? Please leave comments on the article, ask questions and share your well installation skills.