Sewerage for a bathhouse with your own hands: diagram and step-by-step instructions on the device

A comfortable bathhouse on your own site is a dream that you can always turn into reality on your own.One of the key aspects of its construction is the solution to the problem of wastewater disposal.

Let’s take a closer look at how to install a sewer system for a bathhouse with your own hands and what points to consider when designing and installing the system.

The content of the article:

Type of sewer system

The installation of a well-designed waste water disposal system is prompted not only by aesthetic standards, but by current requirements aimed at maintaining environmental safety.

There can be many design solutions for autonomous sewers built during the construction of a bathhouse.

Based on the type of action, independent systems are divided into two types:

- Gravity system - involves the movement of wastewater through it by gravity. This effect is achieved due to the correctly maintained angle of inclination of the pipeline.

- Pressure system – provides for forced transportation of wastewater using pumping equipment.

A sewer system for a bathhouse building is constructed regardless of whether or not a water supply is connected to it. In any case, the very nature of the site implies a copious use of water, which must be disposed of.

When installing a gravity system line inclination angle determined by the diameter of the pipes.

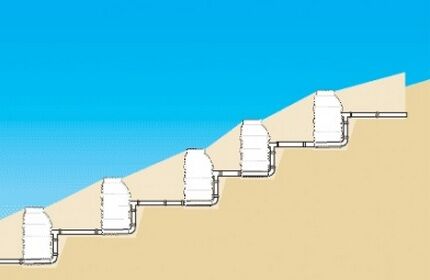

The gravity-flow system is energy-independent, but it is quite problematic to design it correctly in difficult terrain.

The pressure system is energy dependent and is more expensive than the non-pressure system. But she easily solves problems that gravity cannot handle. In order to be able to transport wastewater over long distances, when installing a pressure system, it is important to take care of the insulation of technical elements during the cold season.

The service life of a pressure sewer system is more than ten years, and the costs of its installation are more than recouped. The main thing is to use pumping equipment equipped chopper, which grinds solid particles entering the drain.

Connecting a pipeline to a centralized sewerage system is a less labor-intensive, but at the same time more troublesome method. Since only a few bathhouse owners can apply it in practice, we will not study its features in detail.

Regardless of the type of sewerage scheme chosen for a bathhouse, it is extremely important to maintain the straightness of the pipeline. If turning points are provided when laying a pipeline, then inspection wells will need to be built at the locations where they are installed.

Determination of terrain conditions and soil type

The first thing you need to do when installing a sewer system in a bathhouse is to determine the condition of the soil on the site.

At this stage it is important to identify:

- Groundwater level.

- The freezing point of the soil in winter.

The depth at which the pipes of the external sewage system should be laid and the septic tank should be installed directly depends on this.

You can get information about the depth of soil freezing from construction reference books, for example, from Construction Climatology, or by talking with neighbors who have already performed similar work.

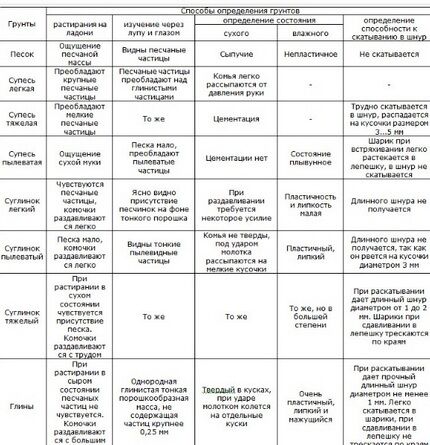

You can find out the type of soil by performing simple manipulations and checking the indicators with the data in the table below. To do this, in the place where you plan to lay the pipeline, you need to dig a hole 25-30 cm deep below the freezing mark.

A sample for research is taken from the bottom of a dug hole. The rock sample is first rubbed between the fingers and then rolled into a ball.

When dealing with loams and sandy loams, which are classified as heaving soils, when laying external sewerage, the bottom of the trenches will have to be equipped with a sand “cushion”.Acting as a damper, sand will prevent damage to the pipeline during spring earth movements.

According to the type of organization of sewerage, bath sewer systems are divided into organized and unorganized:

Choosing a location for a treatment plant

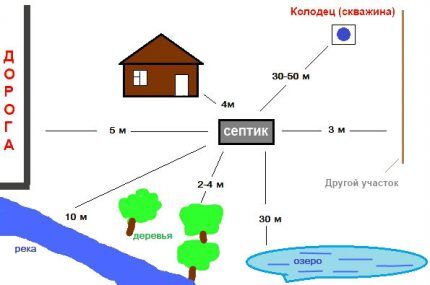

To prevent unpleasant odors from bothering the owners and guests of the site, it is important to correctly calculate the location of the structure.

The distance from the waste collection point should be:

- to the foundation of the bathhouse - 4-7 m;

- to the water intake point - from 10 m;

- to green spaces - from 2 meters;

- to the road – 5 m.

IN SNiP 2.04.03-85 The minimum permissible distance that should be maintained from the septic tank to the border with the neighboring plot is also specified point by point. It should leave at least 3 meters.

To process wastewater transported from the bathhouse, various types of treatment stations are used:

Design of a sewerage scheme

The design and installation of an autonomous sewer system includes two mandatory parts:

- internal – includes communications laid indoors;

- external – connects communications beyond the boundaries of the building.

If desired, the sewer system installation project can be completed on your own.

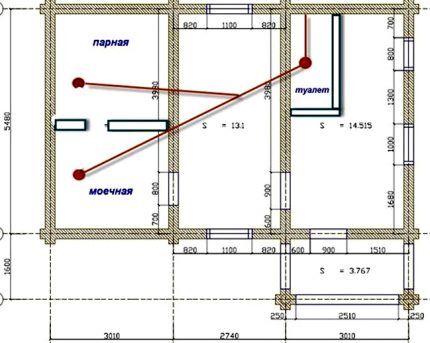

To simplify calculations on the plan, you must indicate:

- Places for installation of plumbing fixtures.

- Dimensions of rooms and distances from drain points to partitions.

- Main line outlet location.

- Installation fan pipe (if a toilet is provided).

In the drawn up plan, plumbing fixtures are connected to the main pipe along the shortest and at the same time convenient path. The main task is to minimize the number of turns on the highway.

After this, sum up the length of the communications, not forgetting to add an allowance for the thickness of the outer wall, and begin drawing up a drawing of the external wiring.

Basic rules to consider when designing external wiring:

- An inspection hatch is installed at the junction of the internal and external sewers.

- At the turning points of the pipeline and places where the side branches of the pipeline branch, inspection wells are constructed.

- The first inspection well is placed no closer than 3 meters from the bathhouse and no further than 12 meters.

According to the prescribed SNiP standards, when laying external sewerage with pipes D 100-150 mm, inspection wells must be built every 15-30 meters of a straight line.

When dealing with a relatively flat area, when laying an external network along its entire length, to ensure uninterrupted operation of the system, you only need to maintain an inclination angle of 10-15 mm per meter.

Options for arranging a water seal

The spread of a foul odor where there is a sewer is not a rare occurrence. Installing a water seal helps get rid of it. The design is an improvised water plug, which is always located in the cavity of the pipe, even during periods when the bathhouse is temporarily not in use.

The main purpose of the device is to separate two adjacent gas environments, cutting off unpleasant odors coming from the septic tank.

The simple design has one drawback - if the system is rarely used, the liquid evaporates over time.

For such rarely used systems, it is better to install a “dry” water seal.

This design is convenient in that when liquid enters the system under the influence of the created pressure, the valve lowers, opening the path for the flow, and after it passes, it returns to its original position.

In the absence of the opportunity to purchase a finished product, you can build a similar structure on your own.

To make a water seal, the wide edge of the adapter is cut at an angle of 30°. A circle D 110 mm is cut out of dense rubber and fixed to the cut site. The finished structure is placed at the outlet of the pipe from the septic tank.

Selection of required materials

Before you make a reliable sewer system for a bathhouse, you need to select high-quality pipeline elements.

There are several types of pipes on the modern market for laying internal and external networks.

The main ones are:

- Cast iron – such pipes durable, but at the same time heavy, and therefore extremely inconvenient to install. The price for them is quite high.

- Asbestos-cement – inexpensive products whose performance parameters are inferior to plastic and cast iron analogues. Due to the fact that they have a rough inner surface with many tiny depressions, they should not be used when constructing a free-flow system.

- Plastic - a universal option suitable for installing any type of sewer system. They are inexpensive, easy to install and durable in use.In addition, there are many options on the market - all you have to do is choose the right one, and read how to do this in this material.

When laying autonomous sewer systems in suburban areas, plastic pipes are most common.

They are available with and without bells. To simplify the installation of long products, fittings and other shaped elements are produced for them.

For laying a horizontal pipeline in the walls of a building, gray pipes D110 cm are chosen, for vertical branches when installing receivers - pipes D50 mm and D110 cm.

When laying an external pipeline - yellow-red PVC pipes of the same size. To connect elements of different diameters, adapters are used.

Internal system design

It is best to install the sewer system at the stage of building the bathhouse. But there are situations when it is necessary to improve existing buildings that are already in use. The volume of work performed and their sequence will be different in each case.

Installation of the system during the construction phase

After the foundation is erected, connection points for drains, sinks and other plumbing elements are determined.

The depth of laying pipes from the ground surface to the top point of the laid pipe should be:

- for southern regions – 70 cm;

- for the middle zone – from 90 to 120 cm;

- for northern regions – from 150 to 180 cm.

If the height of the base reaches 30-40 cm, then the depth of the trenches to be laid should be about 80-100 cm relative to the top point of the constructed base.

Laying the pipeline in accordance with the sewerage diagram should begin with the installation of the main pipe, remembering to maintain the slope. Large nodal elements and side branches will extend from it, made of elements of the same or smaller diameter. In the final form, all drains provided for by the steam room design must be connected into a single pipeline.

A hole is dug at the end of the outlet pipe to provide water drainage. To check the correct slope of the pipes, do a test drain. To do this, small portions of water are poured into all drain holes one by one.

The same volume of liquid that was poured into the holes should be poured into a bucket placed at the end of the outlet pipe.

The height of vertical layers is made with a margin. After pouring the floor and installing the ladders, they will be easy to trim. At the same stage, a ventilation riser is installed.

If the installation of a sewage system in a bathhouse is carried out in an area that is located in a region with a cold climate, it is worth taking care of insulating the pipes.

For insulation you can use:

- foam half-cylinders;

- fibrous materials;

- rolls of foamed polyethylene.

We also recommend reading about how to choose insulation for sewer pipes. To reduce the volume of sounds created by a functioning system, the pipes can be additionally wrapped in noise-absorbing material.

The flooring in the bathhouse can be organized in two ways: by creating a leaky floor, which involves laying boards with a gap of 5 mm, or by creating an inclined surface.

When choosing the second method, it is important to ensure that when laying the finishing coating, a slope towards the ladder is maintained so that the used water does not accumulate, but immediately flows into the drain.

Laying sewerage in an already completed building

The waste water drainage system can also be installed in premises that have already been put into operation. To do this, you will also need to draw up a wiring diagram, indicating the connection points. In places where the pipeline is laid, the floor will have to be opened.

When installing drains in a steam room and washing room, it is important to comply with three basic requirements:

- Drainage drains in the steam room and bathhouse are located flush with the floor.

- The gaps of the system are treated with moisture-resistant grouting compounds.

- The tiles are laid only after the installation of the ladder is completed.

To connect the toilet and provide ventilation, a tee is installed in the toilet.

To reduce the risk of deposits forming on the walls of the pipeline, which leads to clogging of the bore diameter and clogging of the drainage well, install a filter grid in the shower and on the drain hatches in the bathhouse. It will catch bath leaves and small debris.

Laying external sewerage

The key element of the external wastewater disposal system is the septic tank.It can be a structure in the form of a drainage well or two-chamber treatment structure.

Photo guide for installing a sewerage station

If a deep treatment station is selected to treat wastewater before disposal, in addition to connecting to the sewer system, you will also need electrical wiring.

Otherwise, the stages of work on the arrangement of all types of treatment points of autonomous sewer systems are carried out in a similar order.

Construction of a treatment plant

If the bathhouse is designed for a family of 2-3 people, its arrangement does not include a toilet and it is not used so often, you can limit yourself to the construction of a primitive outlet. To do this, maintaining the distance specified by sanitary standards, dig drainage well.

But it can only be installed on soils characterized by a high level of moisture permeability. These include sandy, fine-clastic and coarse-clastic soils.

The construction of the treatment plant is carried out in the following sequence:

- In the marked area, a pit is dug, the depth of which is 1-1.5 meters higher than the freezing mark of the soil.

- The bottom of the pit is laid out with a 10-centimeter layer of clay.

- Expanded clay or crushed stone-sand filling is laid on top, forming a layer 40-50 cm high. This will serve as drainage.

- To prevent the earthen walls of the pit from collapsing, they are lined with bricks, laying out rows in a checkerboard pattern, or with ready-made concrete rings.

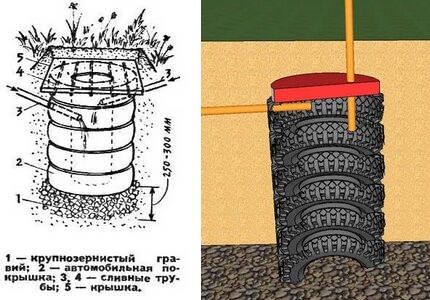

If desired, the walls of the drainage well can be lined with tires. To do this, dig a pit, the diameter of which allows you to accommodate 4-5 used tires laid out on top of each other.

To prevent the tires from moving after laying the first tier, it is advisable to drive four guide stakes around the circumference. To increase the strength of the structure, the junction areas of the tires can be treated with bitumen. When laying each tier, to prevent silting and improve drainage, crushed stone and pieces of broken brick are poured onto the sides of each tire.

To find out how to properly set up a septic tank from tires, go to link.

If the soil of the area where the bathhouse is located does not allow water to pass through well, you should think about installing a ready-made polymer septic tank or purchasing a deep cleaning station.

The main advantage of such systems is environmental safety. The accumulated wastewater will not be able to seep through the walls made of waterproof materials, and therefore will definitely not harm rocks and groundwater.

Thanks to the activity of aerobic or anaerobic bacteria, solid waste decomposes into simple elements, due to which it decreases in volume tens of times. As accumulation occurs, you only need to periodically pump out the contents of the septic tank, resorting to the services of sewer trucks.

Digging a trench and laying a pipeline

To lay the main line, a trench is dug, giving it a U-shape. Its depth should be below the freezing point of the soil. The bottom of the trench is thoroughly compacted and leveled, not forgetting to maintain the slope towards the drainage system.

A crushed stone “cushion” is laid on top of the compacted bottom at the same angle and pipes are laid.

At the turning points of the highway, inspection wells are installed - holes with a concreted bottom and reinforced walls.

To enhance the effect, the inner walls of the inspection well are lined with heat-insulating material, and the outer walls are covered with sawdust and earth.

The pipe is brought to the drainage hole at an angle, having previously made a hole in the wall for it. If the drainage well is made of tires, then the drain pipe is removed between the first and second tires or through a hole made in the upper tier.

The cover for the septic tank can be made from a wooden panel or a piece of sheet metal. To ensure the flow of oxygen, a hole is made in the lid for installing a pipe.

At the final stage, all that remains is to do a test drain in order to check the correct slope of the sewer pipes and compact the area around the walls of the upper part of the treatment plant.

Conclusions and useful video on the topic

The material presented in the videos will help you apply theoretical foundations in practice and avoid mistakes when installing sewer systems.

How to lay sewer pipes:

How to build a septic tank from tires:

In the future, in order to ensure the stability of the sauna sewer system, it is important to regularly clean the walls of the storage facility. This will reduce the risk of soil filters clogging with silt and silt deposits clogging drainage paths.

If you have personal experience in arranging a sewer system for a bathhouse, please share valuable tips or subtleties that you know with visitors to our site. This can be done in the block below. There you can ask questions about the topic of the article.

In my bathhouse for several years now, the waste water has been drained by gravity. I achieved this due to correctly laid pipes on a slope. And here it is important not to make a mistake with the slope angle; you also need to take into account the relief. The main thing is to calculate everything and do not yet make a cesspool next to the foundation or next to the well. Ideally, the pipes need to be insulated, then no frost is scary.

Igor, that’s why I didn’t read your comment earlier?!! They also made a gravity sewer system, but they installed a drainage barrel just a meter from the foundation so as not to dig a long trench, which they later regretted. The barrel has holes, through which water goes into the ground. Over the years, this water began to erode and grab the ground from under the foundation. As a result, the corner of the bathhouse next to the barrel began to sag after 3 years. Don't repeat this mistake!