Sewer wells: complete classification and examples of arrangement

One of the main elements of a modern drainage system is a sewer well. We often come across the hatches of these structures, even if we are just walking along the city streets.But the autonomous sewer system, which a private owner installs on his property, also uses wells.

We suggest that you familiarize yourself with the classification of wells for sewage systems presented by us. They were divided into types according to their functional purpose and the material used in their manufacture. The article will help you understand the varieties and choose the appropriate option.

The detailed information we offer about the types and operational features of wells, which are an essential component of the sewer system, is supplemented with diagrams, videos and photos for visual perception.

The content of the article:

Why are sewer wells needed at all?

Sewage is one of the essential attributes of civilized life. And it doesn’t matter whether we are talking about the life of a large industrial city or a separate family living in a country cottage. Through this communication, waste is drained, the disposal of which in its absence would be a big problem.

Sewage systems, like any other structures, require maintenance. Their condition must be monitored: maintain operational functions by periodically performing routine repairs.

If the system becomes clogged, emergency intervention may be necessary. To ensure all these processes, we need sewer wells.

If it seems to you that the hatches, by which we determine the presence of a well on the street, are located chaotically, then this is not so. There is SNiP “Sewerage. External networks and structures”, which defines standards regarding the number and location of wells, their types, construction technology, as well as requirements for the maintenance of sewer systems.

Classification of wells for sewerage

Structures related, according to technical terminology, to sewer wells are divided into several types.

The division is made depending on what classifying features we will use. For example, you can divide wells by material of manufacture, by purpose or by the method of their construction.

The following classification characteristics and the corresponding types of modern sewer wells are distinguished. The first is produced by the medium, which is transported by the sewer system.

The drainage networks on which sewer wells are installed are designed to move wastewater of different composition and degree of aggressiveness, these are:

- Household. These include waters that have changed their composition as a result of mixing with waste and garbage. Depending on the contaminants they contain, they are divided into household and fecal.

- Industrial. These include waters that have changed their mechanical and chemical composition as a result of contamination with industrial waste.

- Atmospheric. These include water formed as a result of the active melting of winter precipitation, flood and rain water.

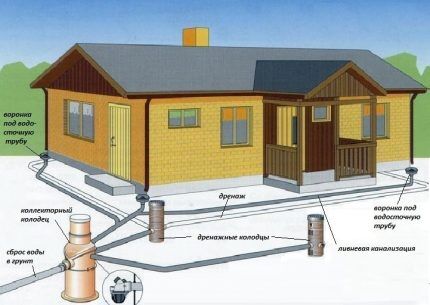

In addition to the listed types of wastewater, the sewerage system receives flows collected by the drainage system, the task of which is to drain the territory or drain groundwater from underground building structures.

Wells of sewer systems are divided according to the material of manufacture into:

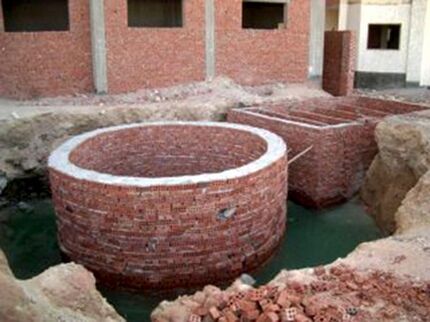

- Brick. Brick was once a commonly used material for making wells, but over time there are fewer and fewer brick structures.

- Concrete. Concrete structures are today the traditional material option for a sewer well.

- Plastic. It is obvious that compositions with a polymer base are the material of the future; it will one day replace both brick and concrete.

Plastic or composite ready-made well structures are attractive because they are lightweight and easy to install. They are pleased with their resistance to chemical influences during prolonged contact with aggressive environments. They tolerate sharp and smooth temperature fluctuations well and do not allow or absorb water at all.

Sewage systems are divided into floating and export. The former move wastewater to treatment plants, facilities or discharge fields. The latter only collect wastewater for subsequent pumping and removal. The wells included in both types of systems perform both identical and different functions.

According to their functional responsibilities they are divided into:

- Cumulative. They are used to accumulate wastewater for subsequent extraction and removal. Naturally, they are constructed in sewerage systems.

- Collector. Designed to collect wastewater from several sewer branches and to direct it to a storage tank, treatment plant or discharge fields. They are installed in both floating and export branched networks.

- Filtering. They are used to dispose of the liquid fraction of wastewater naturally. They play the role of compact treatment facilities that transport pollutant-free media into the ground or into water bodies. They accompany exclusively the floatable type of sewerage.

- Observations. They are constructed on collector sections longer than 50 m, as well as at all turning points and junction points of highways. Necessary for monitoring the operation of the sewer system, for periodic cleaning and repair activities. They are installed in both types of sewers.

- Variable. They are located in areas with sharp changes in altitude. The reasons for the construction include ensuring buried discharge into the reservoir and the need to slow down flows on sections of the pipeline with a large slope. They may be present in both exhaust and floating sewers.

The classification of manholes is much more complex. We'll talk about this a little below, but now we'll look at different types of wells in more detail.

Storage and filter type

A storage well is a large sewer well into which all sewage from a private home flows.The required size of this structure is determined by the number of people living in the house and the volume of water they use.

Typically, a storage well is placed in the lowest part of the site. This ensures the required angle of inclination, allowing the drains to move spontaneously under the influence of gravity along sewer pipeline.

This structure is often made of plastered reinforced concrete rings. For the same purpose, you can use a factory-made plastic container.

The plastic well is convenient both in installation and in operation. Of course, when installing it, you also need to have some knowledge and skills, but still its installation is simpler than working with its concrete counterpart. A concrete structure should not have gaps or cracks, otherwise liquid waste may seep through unsealed joints, spreading an unpleasant odor.

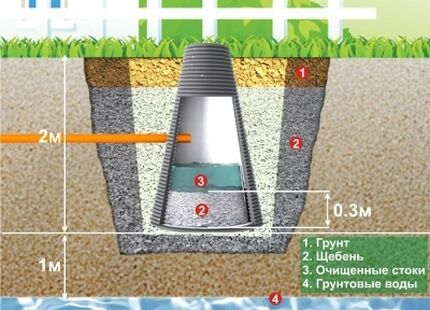

Another point for receiving and partially recycling wastewater is filter well. Effluent also flows into it by gravity, but it does not linger in a sealed tank until removal, but moves to the underlying soil, undergoing a kind of filtration along the way.

Filtration wells are constructed without a bottom in the usual sense. At its base there is a multi-layer, multi-stage natural filter made of sand and gravel of various fractions.

For the manufacture of filter structures, brickwork or concrete rings are also most often used, but their diameter is usually smaller. The design of this well is different in that it does not have a bottom. The structure itself is filled with either coarse sand or crushed stone.

Functions and features of inspection wells

In order to monitor the condition of the sewer system and promptly eliminate problems that arise in it, it is necessary sewer inspection wells. That’s why they are placed in places where system failure is most likely.

They should be present in the following places:

- where the slope of the pipeline or its diameter changes, which determines the speed of movement of wastewater and the width of the flow;

- where the flow changes its direction;

- where side branches are connected to the main pipeline;

- where it is necessary to monitor, despite the fact that there are no special preconditions for breakdowns.

Inspection structures are usually placed in a straight line, maintaining a distance of 15 meters between wells. If we are talking about a private house, then the first inspection well should be located at a distance of no less than 3 m, but no further than 12 meters from the house.

The main function of these wells is not to eliminate the blockage that has arisen, but to prevent it. When the sewer becomes clogged, backflow may occur.To prevent this from happening, experts recommend installing a check valve in the first inspection structure, which will close the outlet pipe in case of clogging.

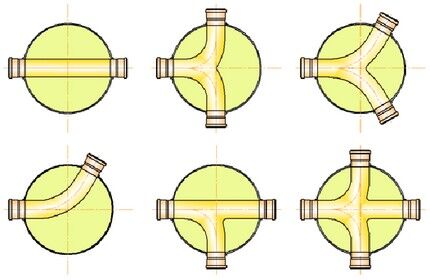

Inspection wells are also divided into several subtypes.

Changing the direction of flow:

- Nodal. They are installed above the node, that is, in the place where the side branches are connected to the main pipeline. In this case, the structure tray cannot have more than one incoming and three outgoing pipes.

- Rotary. Such structures are located above the place where the pipeline turns. There is a rule that the rotation angle should not be less than 90 degrees.

The turn should be performed with a smooth rounding, the radius of which can be from one to five diameters of the incoming pipe.

Direct-flow structures in places where there is no change in flow direction and branches:

- Tests. These wells are installed in places where treated water is discharged into the sewer system. With their help, the quality of the cleaning performed is monitored.

- Flushing. They are placed at the beginning of the network to wash it.

- Linear. Used for periodic preventive inspection of networks and for their cleaning.

Sometimes, with the help of one structure, not one, but several problems can be solved at once. Despite the abundance of functions assigned to these structures, all inspection wells are designed approximately the same.

They have manhole cover, inlet neck, well shaft, its working chamber and bottom - the outgoing and incoming pipelines are specially connected here to facilitate the diagnostic procedure.

The material for making manholes is usually reinforced concrete, but recently plastic containers have become increasingly in demand. Installation of such structures is carried out in the ground. They become the connecting parts of the sewer pipeline.

If this inspection structure is made at dachas, then some craftsmen adapt sewer pipes with a large diameter for such purposes. Typically, such a design copes well with the tasks for which it was built.

To maintain drainage and storm sewer systems, inspection wells are also installed, the types and installation features of which you can read in another popular article our site.

Features of differential varieties

The main function of differential type sewer wells is to change the height and regulate the flow speed. These structures can have a fairly diverse design.

Sewer drop wells are installed there:

- where the depth of the incoming pipeline decreases;

- where there is a risk of a sharp change in the speed of flow;

- where there is a highway crossing underground structures;

- where this well is the last along the path of movement of wastewater before discharging it into the reservoir; Such a structure may have a flooded outlet.

Considering the various tasks that are assigned to these structures, the internal structure of these sewer wells may have different design solutions.

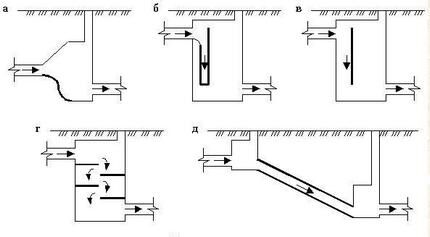

Based on the type of differences, structures are divided into:

- tubular, which must have a vertical pipe at its base;

- cascade - multi-stage shaft-type structures to reduce flow speed;

- with a practical profile, having a water outlet in the downstream;

- equipped with a water trench and drain wall;

- high-flow pipelines are short sections of pipeline that are installed at a significant slope.

The last of the listed wells can also be used in autonomous sewers, in cases where the volumes of drainage are not large enough to ensure cleaning of sewer pipes.

There is another type of differential wells, which are installed in those sections of the sewer network into which flammable or explosive substances can enter or form.

Such wells are equipped with water seals. The specificity of such structures is that the flow level here changes in the opposite direction: instead of decreasing, it rises.

This effect is created using a special chamber in which preliminary accumulation of wastewater occurs. In case of an emergency, the water valve will prevent the fire from spreading.

What are these wells made of?

The majority of our fellow citizens are confident that everything sewer wells made of concrete. And they're almost right.

Typically, reinforced concrete rings are used to construct wells located on the lines of the central city sewer system.Only occasionally are cubes or slabs of the same concrete used for the same purposes.

Modern commodity producers are actively mastering the production of polymer products, which are superior to their reinforced concrete counterparts in all respects. Gradually, although not as quickly as we would like, they are conquering the Russian market. But while polymer structures are limited in their use, concrete structures will retain their leading positions for some time.

Reinforced concrete serviced wells

When the standards and rules were created, which to this day regulate the creation of sewer networks, no one had heard of high-strength polymers.

Until now, sewer cleaning can be done manually. One worker goes down into the well to push the wire towards the blockage, while his assistants at the top rotate its other end.

Wells for all types of sewerage vary in depth and dimensions. According to these characteristics, they are divided into serviceable and inspection types. The first require immersion within the operating personnel. The performance and technical condition of the latter can be monitored from the surface.

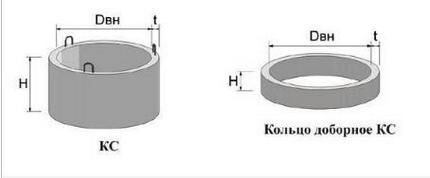

The standard sizes of serviced wells were calculated in such a way that a person could not only fit in it, but also work. The structure size of 700 mm is the minimum.The series of standard sizes continues with 1000, 1250, 1500 and 2000 mm. These standards have been preserved in our time.

Taking into account these standard dimensions, round slabs are also produced, which are used as a base or top floor with a hole for a hatch with a diameter of 700 mm. Thus, the components of a standard reinforced concrete well are:

- base or bottom in the form of a circle or rectangle;

- rings making up the shaft;

- upper ceiling with a round hole for a hatch;

- polymer or cast iron manhole cover.

The round shape is explained by the fact that a structure with this particular geometry best offers resistance to the surrounding soil.

The manufacturer does not know in advance where and how they will be used. reinforced concrete elements, therefore, they are manufactured in a standardized, even form, and are supplied only with embedded parts - hinges, which are supposed to be used during the installation process.

To insert a pipeline into the well, you need to punch a hole in the lower reinforced concrete ring, and mount a tray of the desired shape on the bottom plate. This design forms the basis of inspection wells and even differential wells, in which the device can be somewhat modernized taking into account the design features of a particular model.

The height of the well depends on the number of standard and additional rings that are used during its construction. In order for the next ring to be installed as tightly as possible to the previous one, it is necessary to remove excess mounting loops. All cracks in the structure should be sealed with cement.

Since such measures are still unable to provide a normal level of waterproofing, wastewater from a reinforced concrete well pollutes the soil, while groundwater, on the contrary, penetrates the well and contributes to its overflow.

Polymer products for inspection

Manholes made from advanced polymers have given sewer designers a whole new level of freedom.

The technical revolution arrived very timely, thanks to which mobile complexes arose. With their help, sewer pipelines can be maintained without the participation of people descending into wells.

This means that the dimensions of the wells may not be adjusted to the parameters of an adult man. You can replace a bulky structure with a compact device up to 300 mm in diameter. Another advantage of polymer products is their low weight. The size of such a well can be precisely adjusted to the needs of a specific sewer network.

Modern polymer wells can be classified according to different criteria.Well shafts may differ in the material from which they are made. They can be smooth, corrugated and combined.

In turn, smooth and corrugated shafts can be single-walled or double-walled. Moreover, the design of the well itself can be telescopic, that is, retractable.

Initially, polymer models were made of two parts: a neck and a tray. The tray part was equipped with a pipeline layout corresponding to the purpose of the well. Currently, trayless models are also available for direct-flow structures.

A huge advantage of polymer products is the complete waterproofing of their shaft. This gives such structures an unconditional advantage, which over time will provide them with priority in the construction products market.

Conclusions and useful video on the topic

This video material clearly presents the advantages of models made from modern polymers over reinforced concrete products.

Modern plastic wells not only look more attractive than their reinforced concrete counterparts, they weigh less and are better waterproofed. The future is definitely theirs.

Without a sewer system it is impossible to imagine the life of a civilized society. And without wells of various types, not a single sewer system can carry out its work. Now you have an idea of what these structures are like, how they are designed and what materials they are made from.

Do you have any questions while reading the material we offer? Do you have useful information that you want to share with site visitors and us? Please write in the block below.

Modern materials make it easy and quick to install sewer wells. Whether it is private or city-wide sewerage. I believe that polymers are the future, even though most existing wells are made of concrete. For example, in the city sewer system everything is thought out to the smallest detail, the wells are located where they should be according to SNiP, otherwise the sewer system will not be able to function normally.

What concrete is best to use for constructing a company in storm sewer wells?