Septic tank “Fast”: review of the model range, reviews, installation and operation rules

The American company Bio-Microbics sells the Fast septic tank on the Russian market, which in its technical characteristics is close to its domestic analogues Ekolos or Tver. Part of the model range is intended for the treatment of domestic wastewater in the private suburban sector.

You will learn everything about the principles of operation, advantages and disadvantages of VOCs of this brand from the article we have proposed. We will tell you whether American equipment is suitable for use in Russia. For independent home craftsmen, we provide detailed installation and connection technology.

The content of the article:

Brief description of the manufacturer

In order to have fewer questions about the operation and installation of treatment equipment, let’s get to know the manufacturer better and see how the American brand has proven itself in Russian conditions.

Production of equipment under the brands FAST® (domestic wastewater treatment) and BioSTORM™ (storm water treatment) takes place exclusively in the USA, in the state of Kansas, and is exported to more than 70 countries, including Russia. The abbreviation FAST stands for and translates as “Fixed Activated Sludge Treatment”.

In our country, the company began its activities more than 10 years ago, in 2004, and still successfully supplies models that have become popular. Among the popular equipment is a line of offers for country houses and cottage communities. The Russian official distributor is the company "TAKOM".

As a rule, the installation of VOCs on the territory of country houses requires permission from Rospotrebnadzor, but it is not needed for the installation of Fast systems.Since 2010, instead of concluding an SES, a “Declaration of Conformity” has been in force, a copy of which is posted on the official website of the Russian representative. If the inspection authorities require a sanitary certificate, it is enough to present the Declaration issued upon purchase.

The most difficult operating conditions for wastewater treatment plants are in the northern regions of the country, and not all Russian-made septic tanks function without problems in soils with low levels of freezing.

However, when installing the Fast system, an option is provided with the necessary recessing or additional insulation, which makes it possible to use the equipment continuously throughout the year.

Moreover, sewage treatment facilities can be installed even in permafrost conditions, when installation in the ground is not possible. The reservoir is placed inside a heated building or insulated container - for this purpose, the production of mobile blocks and prefabricated structures has been established.

Practice shows that FAST equipment has proven itself well in Russia, both among private clients and in servicing various enterprises and institutions (hotels, clubs, holiday homes, sports centers, hospitals), so when choosing a septic tank for your own cottage, it makes sense to get acquainted with household models from an American manufacturer.

Design and principle of operation of a septic tank

When mentioning FAST structures, the term “septic tank” is most often used, although in fact it is a deep biological wastewater treatment system that operates through the activity of aerobic bacteria. The cleaning efficiency is 98%, the output liquid is odorless and colorless.

According to representatives of the supplier company, the word “septic tank” is more understandable for customers. The system is a modular design with many installation and connection options. The RetroFAST and MicroFAST models differ in technical characteristics and installation capabilities.

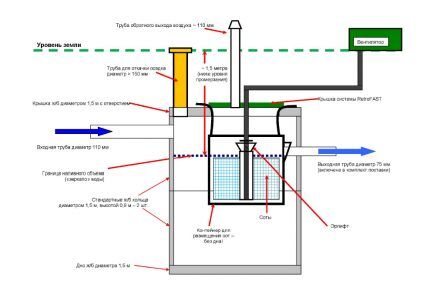

The RetroFAST station is suitable as a new wastewater treatment plant or a module for the reconstruction of an existing sewage treatment system. MicroFAST is installed in a container made of metal or concrete. When constructing a tank to house treatment equipment, construction rules are followed septic tank devices, belonging to the category of settling tanks.

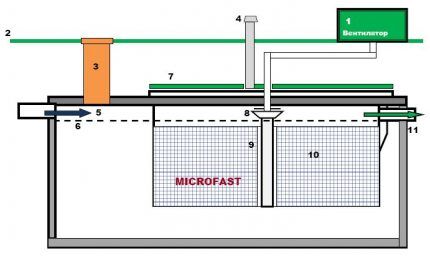

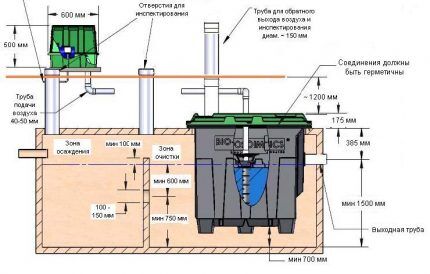

Let's consider the design of the Fast septic tank and its location relative to the surface of the earth:

As you can see, the tank is completely in the ground; only a fan for forcing air and a pipe for its outlet come to the surface.

The body of the FAST working container is made of high-strength plastic, which is resistant to rapid wear and corrosion and is designed for a service life of up to 50 years. All station parts are manufactured in the USA, except for the engines, which are imported from Italy or Taiwan.

The operating principle is as follows. Dirty sewage flows through pipes from residential and utility rooms into a reservoir divided into 2 working areas.

In the first zone, primary settling occurs, in the second, aerobic purification occurs directly. There is no need to specially purchase and add microorganisms into the container; they enter the septic tank along with the wastewater.

Habitat aerobic bacteria become honeycombs - a plastic load that does not need to be changed or rinsed throughout the life of the VOC.

When sewage is first supplied to the system, colonies of aerobes settle on the cellular surface of plastic honeycomb modules. Their vital activity and self-regulation of the population is supported by a constant supply of oxygen and the replenishment of a new portion of wastewater.

One of the airlift parts is a system of air diffusers that saturate the aquatic environment with oxygen and ensure circulation of sediment. As a result of the gradual movement of the medium and its processing by bacteria, the liquid becomes lighter, and the already clarified liquid enters the outlet.Drainage occurs simultaneously with the arrival of a new portion of sewage.

The only energy-dependent element of the station is the air compressor, which has a dual purpose:

- ensures the circulation of liquid necessary for cleaning;

- supplies air to support the vital activity of aerobic microorganisms.

The optimal compressor operating mode is interval: half an hour in an active state, half an hour resting.

Advantages and disadvantages of VOC "Fast"

Fast is not the only station that performs deep cleaning using aerobic bacteria. However, it has advantages that distinguish it from most other models.

Among the main advantages are the following:

- volumetric peak loads not available to other brands (easily withstands a Jacuzzi discharge of 800 liters);

- combined cleaning principle - in addition to aerobic bacteria growing on the surface, anaerobic bacteria living inside the load also function;

- self-regulation of the system - if there is a lack of aerobic bacteria, it quickly replenishes their number with anaerobic ones;

- no moving parts (all elements associated with the cleaning function are static), therefore, frequent maintenance and repairs are not required;

- compact design that occupies a minimum of usable space;

- the highest possible cleaning efficiency is 98-99%.

There are a number of nuances that make servicing the station more comfortable. For example, when leaving for the city for the winter, there is no need to carry out conservation, and in the spring, put the system back into operation. Compare with standard rules winter septic tank maintenance You can by reading the material dedicated to this issue.

It is enough to turn off the power supply and then turn it on again. Another nice plus is the ability to flush household cleaning products containing chlorine and other chemicals into the toilet.

To understand the level of comfort provided by the Fast station, let’s compare it with the Topas brand, well-known in Russia. Septic tanks "Topas" They also produce biological aerobic treatment, but they require constant removal (or transfer to a settling tank) of activated sludge and regular removal of solid sediment.

It is prohibited to dump chemicals (solvents, household detergents) into Topas.According to reviews, various modifications of septic tanks actually work smoothly, without requiring repairs or regular pumping of sludge. However, shortcomings were still found. The first is the energy dependence of the station.

The second disadvantage is the relatively high cost. For example, a household model RetroFAST 0.375 with a capacity of 1500 l/day costs 159 thousand rubles. For comparison, a Topas septic tank of similar performance costs 127 thousand rubles. With features septic tank maintenance Topas The article we recommend will familiarize you with it.

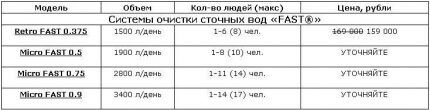

Review of popular models

Residents of cottage and holiday villages are often interested in septic tanks designed to serve one or several houses, so we will focus on models with minimal productivity. The main technical characteristics are presented in the table:

The cost of MicroFAST systems can be clarified online on the official website of the TAKOM company or by contact phone number.

RetroFAST 0.375 for a country house or cottage

The compact biological treatment system for country houses is designed to serve from 1 to 6 people (maximum 8 people). Productivity – 1.5 m³/day, with increased load – up to 1.8 m³/day. without loss of efficiency.

A special feature of the equipment is its installation - the system is suitable for installation in a new or old tank of suitable dimensions. Most often this plastic container or a well of 2-3 concrete rings.

Fan power – 0.2 kW/h, air supply speed – 0.14-0.48 m³/min.

When installing the fan, the following requirements must be taken into account:

- concrete base;

- location – no more than 30 from the station;

- installation in a non-flooded area;

- power supply – 115/230 W, 60/50 Hz.

The fan and cable should be insulated from moisture. To protect the cable, it is recommended to use a corrugated polymer sleeve.

MicroFAST 0.5 for cottage

The MicroFAST 0.5 modular system, like the entire line, works on the principle of aerobic-anaerobic deep cleaning. Unlike the previous model, it is designed to serve a large cottage inhabited by a family or group of 8-10 people.

It can simultaneously treat sewage water from several sources - cottage, bathhouse, guest house. The exception is drainage from the pool, which should be done not into a septic tank, but into a drainage system.

The model’s productivity is 1.9 m³/day, with increased load – up to 2.3 m³/day. Withstands uneven discharge of wastewater. This means that it works without loss of efficiency even with sewage volumes of 0.1 m³/day and at maximum load. Self-repairs in a short period of time if solvents or chemical detergents get into the sewer.

MicroFAST 0.75 for a large cottage or group of houses

Like the previous model, the MicroFAST 0.75 station is used to service one large cottage or a group of buildings located nearby.

In order for the system to operate smoothly and the quality of cleaning to correspond to the declared indicators, it is recommended to connect no more than 2-3 cottages to one structure.

Productivity is 2.8 m³/day.

Maintenance of more powerful systems does not differ from the operation of models with lower productivity: sediment is removed no more than once every 5 years, washing of the polymer load or preservation during departure is not required.

MicroFAST 0.9 for a cottage community

The MicroFAST 0.9 modular system is not installed on a standard summer cottage, for which a less productive station is sufficient.

It is designed to serve large estates with several houses, small hotels, and sports facilities located far from centralized communications.

To install powerful structures, in order to eliminate technical problems, it is recommended to use the services of a supplier.

Installation and installation technology

The choice of model and technical aspects of installation of treatment equipment depend entirely on whether there is an already installed structure on the site. For example, purchasing a RetroFAST system requires pre-installed capacity.

If you have a sealed well made of concrete rings (at least 2 pieces) with a diameter of at least 1.5 m, then the system can be installed directly into it.Additional requirements: strong bottom and lid.

If a septic tank is being installed for the first time, you need to choose a location. The low noise level and absence of odor allow the equipment to be located close to the house. The manufacturer recommends maintaining a distance of 1-100 m from the house, and at least 7 m from the well. However, if the area of the site allows, it is better to comply with SNIP standards: 5 m and 25 m, respectively.

To muffle the noise of the compressor, it is necessary to use insulation in the compartment in which the engine is located. A self-adhesive membrane is suitable as a sound-absorbing material - sound insulation for cars.

Installation steps for models with a plastic tank:

- preparation of a pit (if necessary, deepening up to 12 m below ground level is possible);

- installation of container;

- sewer pipe installation;

- fixation of loading, airlift and compressor parts;

- connection.

Installation can be done in several ways: independently (according to instructions), installation under the technical supervision of a company employee, online installation, installation of equipment by a master in a prepared tank (concrete, plastic, metal, stone), turnkey installation supervision.

The warranty is 10 years (3 years for the electric motor), but a lifetime warranty can be purchased for an additional fee.

Equipment operating rules

Service and operating conditions distinguish Fast equipment from similar brands. The systems are energy dependent, therefore, you will have to pay extra for electricity.

The consumption of the most popular model RetroFAST 0.375 is 250 W/h, in energy saving mode it is 2 times less (saving mode is 12 working hours per day).

There is no need to constantly turn on/off the compressor, just program the timer to the 30/30 mode - it works for half an hour and rests for half an hour.

The only thing you have to do regarding the compressor is to clean the air filter once every 5 years. To control the start or shutdown function, an ordinary key is used, which can be installed in a comfortable place, for example, in the house.

The station’s operating condition must be maintained only in case of permanent residence; when leaving, it is enough to simply turn it off. There is no need to preserve it, nor do you need to fill in various technical solutions such as antifreeze. The next time you turn it on, the system will work as usual without additional preparation.

Electricity costs can be considered the only ones, since regular cleaning, sludge removal or pumping out of solid sediment is not required. It is recommended to remove compacted sludge sediment once every 5-7 years, otherwise it will harden and grow to the walls of the container.

Pumping is carried out using sewer equipment. The hose length can reach 100 m, meaning no access roads are required.

The equipment manufacturer does not offer service because it is not necessary.There is no need to wash the polymer honeycombs - their condition is regulated by the system itself, replacement is also not necessary - the service life of the load is equal to the service life of all equipment (50 years).

In order for the system to function smoothly, there is no need to dump solid, water-insoluble objects, such as cat litter, into the toilet (and other entry points). But toilet paper, household cleaning products, and solutions containing chlorine are ok.

Conclusions and useful video on the topic

With the help of videos filmed by representatives of the TAKOM company, you can get an idea of the operation of FAST septic tanks.

Video #1. General information about Bio-Microbics products:

Video #2. How the MicroFAST 4.5 model looks and functions:

Video #3. Degree of purification of liquid taken from the drainage well:

Video #4. Engine noise level:

Video #5. Installing the RetroFAST system in a concrete tank:

If you need high quality wastewater treatment and are not experiencing financial difficulties, pay attention to VOC "FAST". You can choose the most suitable model yourself, after first consulting with a representative of the TAKOM company, but it is still better to entrust the installation to specialists.

What treatment plant did you use to organize an autonomous sewage system for your site? Tell us what are the advantages of the option you have chosen, and why you preferred it. Please write comments in the block below, post photos related to the topic of the article, and ask questions.

When it is not possible to connect to the central sewer, septic tanks are a very good solution. I’m also thinking about installing something like this for my grandmother in the village.There are those here who bought “Fast”, I have a couple of questions. You really don't need any special permission to install? Have you done any insulation? After all, severe frosts in winter are not uncommon? Can I do everything myself or is it better to turn to professionals?

Good afternoon, Anatoly. Installation permits are not required if the recommendations of SNiP and regulatory documents are observed. Unless you are going to dump treated wastewater into a natural reservoir. You can find the basic rules in this article.

When installing a septic tank at a depth below freezing of the soil, insulation is not necessary. Bacterial activity occurs inside the septic tank, during which heat is generated. The temperature stays around 400C.

Self-installation is possible if you have certain skills and experience. If you feel strong, then there won’t be any special difficulties. The main thing is to provide for the nuances at the preparatory stage.

When you decide to turn to professionals, be sure to sign an agreement. In cases of conflict situations after installation, it will be much easier to resolve controversial issues.