Compressor for a septic tank: principle of operation, how to choose + operating rules

When choosing between a homemade autonomous sewer system and an expensive local treatment station, the owner of a private home may ask the question: is a compressor really necessary for a septic tank?

This device is used in many industrial VOC models, but they are not used very often in simple sewer applications. In this article, we tried to present as clearly as possible information about the design and operating features of a compressor for a septic tank.

The content of the article:

Features of the functioning of homemade septic tanks

Two types of bacteria are involved in wastewater processing produced by local treatment plants: aerobic and anaerobic.

The first species can live and act only in an environment saturated with oxygen, the second exists excellently and performs vital functions in an oxygen-free space.

To protect the soil from contamination by unprocessed sewage, the septic tank compartments are made airtight. Their walls not only prevent the penetration of bacteria and impurities into the ground, but also block the access of oxygen into the system.

In such conditions, only anaerobes can exist, and aerobes need to ensure the supply of vital gas.

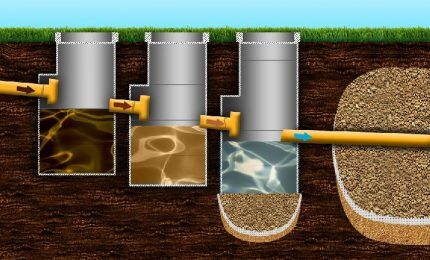

A septic tank for the needs of a small family consists of two or three sections. In the first section, wastewater is settled, fermented by anaerobes, and mechanical filtration of the settled mass is carried out.

In the following compartments the process is repeated, but the result of multi-stage separation in rare cases reaches 65 - 70%. Therefore, the sewer system with settling tanks is supplemented with ground treatment devices - infiltrators, absorption wells, filter fields.

To increase the degree of processing and ensure the possibility of free discharge of water from the septic tank onto the terrain, anaerobic microorganisms and their ability to digest organic matter are needed, purifying wastewater by 95-97%. And aerobic organisms require a regular supply of O2. Read more about bacteria for septic tanks Further.

Why do you need a compressor?

This device is necessary to form and move a flow of compressed air in the desired direction. Compressors are used in a variety of areas, but specifically in a septic tank it is necessary to oxygenate wastewater that has undergone oxidation and fermentation with the help of anaerobes.

As already noted, an autonomous sewage system is a sealed device. Naturally, almost no oxygen contained in the air gets here.

The presence of a compressor in a septic tank eliminates the problem of lack of oxygen2. Providing oxygen allows aerobic microorganisms to be included in the wastewater treatment process.The degree of purification, clarification and disinfection of wastewater increases significantly.

The resulting water can not only be disposed of in the ground, but also used for irrigation or other technical needs, although it is, of course, not suitable for cooking. If a compressor is installed in a homemade septic tank and a compartment is made for storing purified water, it is better to check its quality in the laboratory before using this liquid.

With a high degree of purification, you can use not only water on the farm, but also activated sludge accumulated in the septic tank. This substance is a good fertilizer. Self-made sewer structures cannot guarantee the same degree of cleanliness as certified ones. industrial production models.

The risk of infection is low, but it is better to exercise caution. In addition to supplying oxygen, the compressor performs another useful function. The compressed air flow enters the wastewater in such a way as to exert an active mechanical effect on it.

As a result, the wastewater is mixed, which causes grinding of solid inclusions and increases the speed of their processing.

Thus, the presence of a compressor in a septic tank increases the efficiency of its operation and the degree of wastewater treatment. But at the same time, one should take into account the need to supply power to the septic tank. As a result, the main advantage of homemade septic tanks is lost - energy independence.

But problems due to power outages are unlikely to arise, especially if such situations occur rarely. If the compressor is turned off for some time, the sewage system will operate as before, and the device is usually not in danger of overflowing. Although during long power outages, the level of wastewater in wastewater treatment plants should be monitored.

Device installation procedure

It is not difficult to supplement the design of a septic tank with a compressor, but you will still have to work hard. If two-chamber septic tank, then it is better to add a third compartment to it, designed for aeration of wastewater and called an aeration tank. It is here that the wastewater will be saturated with air and purified using aerobic microorganisms.

To do this, you will have to go through all the stages of creating a septic tank: dig a pit, install a sealed plastic container, concrete or other suitable material, connect it to the sewer pipe leading from the house, connect it with an overflow to other sections of the septic tank, install a lid, etc.

It is better to mount the compressor in the upper part of the container, rather than outside, so that the device is reliably protected from bad weather. To do this, a special shelf is made inside, right next to the lid, on which the compressor is subsequently placed.

It would be even safer to make a more insulated compartment to protect the device from accidental wetness and other damage.

It is necessary to provide a hole in the cover for the compressor electrical wire. You will also need another hole through which air will flow into the compressor.

You need to install a plastic pipe inside the aeration tank. Its lower end should be hermetically sealed, and the walls should be perforated. Usually it is enough to make about three hundred holes or a little less.

It is better to do this with a drill with a two-millimeter drill bit. Through these holes, compressed air will enter the thickness of the wastewater, saturating it with oxygen and crushing large solid waste. The holes should be approximately equal distance apart so that the air is distributed evenly. The upper part of the pipe is connected to the compressor using a hose.

When all the elements are prepared, the following steps should be followed:

- Lower the aerator into the aeration tank.

- Install the compressor in the designated place.

- Connect the aerator with a hose to the compressor outlet.

- Connect the device to power supply.

- Turn on the compressor.

- Close the septic tank lid.

Now all that remains is to regularly inspect the device and periodically, approximately twice a year, clean the air filter. This operation is not difficult to perform. The location of the filter is indicated on the device diagram in the manufacturer's instructions.

You need to unscrew the protective cover; it is usually held in place by mounting bolts. Then carefully remove the filter, rinse it and dry it.After this, the cartridge is placed in its original place and closed with a lid.

If, upon inspection of the septic tank, it is discovered that the operating compressor is noisier than usual or the presence of some extraneous noise is detected, this is a cause for concern. If you leave everything as is, the compressor will soon break down.

Sometimes standard air filter cleaning helps. But if the noise does not decrease, you should invite a specialist to diagnose the problem or apply for warranty service.

If the septic tank is located in a country house or in a country house where the sewage system is not used all year round, it is necessary to carry out septic tank conservation, with mandatory shutdown and removal of the compressor.

How to choose the right model?

The requirements for a compressor designed to work in a septic tank are not that great. The quality of the outlet air can be almost anything, the main thing is that it contains the oxygen necessary for bacteria. Therefore, expensive models equipped with filters and complex automation may not even be considered.

Considering the conditions in which the compressor will have to operate, high demands are placed on such characteristics as:

- reliability;

- ability to tolerate negative external influences;

- corrosion resistance;

- ease of operation;

- reasonable price;

- maintainability;

- low noise level, etc.

In addition, it is necessary to take into account the performance of the compressor, its design features and operating principle, as well as the outlet pressure or compression ratio.

The fact is that the air flow coming from the compressor to the aerator experiences resistance from the column of water that is located inside.

If the compression ratio is low, the air simply cannot overcome the resistance of the water, i.e. the wastewater will not be aerated at all, or the process will not be intense enough.

The deeper the septic tank, the higher the resistance the compressor will have to overcome. Calculating the resistance is simple; for each meter of tank depth you need an outlet pressure of one atmosphere.

The depth of the septic tank rarely exceeds two meters, so you can safely choose a compressor with a compression ratio of about two atmospheres. Compressor performance is an indicator that reflects how much air the device can move per unit of time.

The higher this indicator, the more powerful the motor used in the device and the more electricity it consumes.

Although usually the energy consumption for such devices is relatively small. So far, no one has gone broke servicing a septic tank. A compressor with low performance is not suitable for a septic tank. If the air flow speed is low, the wastewater will not be sufficiently saturated with oxygen.

As a result, the environment inside the septic tank will be unsuitable for aerobic bacteria; microorganisms will not be able to process waste and will die over time.You should not buy a compressor with excessively high performance. Such devices are more expensive and can complicate the operation of treatment facilities.

If air is pumped into a sealed aeration tank too quickly, excess pressure will build up inside. This environment can also be detrimental to aerobic bacteria. If you do have to use a high-performance compressor, it should be used for short periods, constantly switching on and off.

This creates an increased risk of device breakdown, and is simply inconvenient. You can use a high-performance compressor only as a temporary option; in the future, it must be replaced with a more suitable unit. To determine the performance of the compressor, it is necessary to take into account the volume of the aeration tank chamber.

You can focus on the following indicators:

- For an aeration tank of 2-3 cubic meters, you need a compressor with a capacity of 60 l/min or less;

- For an aeration tank of 4-5 cubic meters, you need a compressor with a capacity of 80 l/min;

- For an aeration tank of 6 cubic meters or more, you need a compressor with a capacity of at least 120 l/min.

If the compressor is selected correctly, it will need to be turned on for a long time. Before purchasing, you should make sure that the selected model is designed for this particular operating mode. Depending on the principle of operation, piston, centrifugal, membrane and screw compressors are distinguished.

Piston devices move air using a piston moving inside the housing. This is a simple device that is not too demanding in terms of operating conditions. But piston units quickly overheat, have low efficiency and are too noisy. Not the best choice for a septic tank.

Centrifugal compressors demonstrate excellent characteristics and would be quite suitable for autonomous sewers, if not for their large size. Compact devices of this type are rare and expensive, so this option is almost never considered. Screw compressors are much better suited for such purposes.

The working element here is two helical rotors that effectively move air flows inside a special chamber. They are characterized by a high degree of air compression and excellent efficiency. They are reliable and profitable, and can work around the clock. But despite all their advantages, screw compressors come at a high price.

In membrane devices, air is moved by a membrane or diaphragm controlled by an electromagnet. This is another great option for a septic tank. The device is cheaper than screw analogues. Their compression ratio is low, but it will fully meet the needs of the septic tank.

These compressors are easy to operate, withstand external factors well, have suitable performance, and are compact in size. For homemade septic tanks, membrane compressors are most often used.

The most popular compressors on the market are Japanese-made Hiblow compressors. They are widely used in local industrial cleaning stations and are suitable for homemade aeration tanks.

These devices are highly reliable, their productivity can reach 200 l/min, but there are also less powerful models that are suitable for conventional septic tanks.

German Thomas compressors are traditionally reliable and durable. Their advantages include an increased level of waterproofing, as well as reduced energy consumption.Less expensive options include AirMac products made in Korea. In terms of quality, they are not inferior to expensive analogues; VOC manufacturers willingly equip their devices with them.

Common breakdowns and repairs

Compressor failure can be caused by a number of reasons:

- Frequent and sudden changes in voltage in the electrical network.

- Septic tank overflowing or flooding.

- Natural wear and tear of individual elements.

Often devices become unusable due to mechanical damage: careless removal from the septic tank before storing the system for the winter, falls, etc.

Eliminating the negative impact of voltage surges in the electrical network is relatively simple. To do this, just install a stabilizer.

Owners of membrane compressors are forced to replace the membrane approximately once every five years, which fails due to natural wear and tear.

It is quite possible to carry out such repairs yourself by following these steps:

- Disconnect the compressor from the power supply and from the aerator.

- Unscrew the mounting bolts and remove the device housing cover.

- Remove the soundproof cover.

- Remove elements blocking access to the membrane.

- Unscrew the fasteners holding the membrane cover.

- Remove the cover.

- Unscrew the central nut.

- Remove the membrane block and disassemble it.

- Replace worn membranes with new elements.

- Assemble the membrane block and install it in its original place.

- Reassemble the compressor in reverse order.

Detailed repair recommendations and descriptions of nuances can be found in the instructions and technical data sheet of the product.For many models, special repair kits containing a set of new membranes are sold. As a tool for replacing the membrane, a regular or Phillips screwdriver is usually sufficient.

Conclusions and useful video on the topic

An overview of one of the Нiblow compressor models can be found here:

This video presents an experience comparing different compressor models:

How to replace the membrane in a Нiblow compressor yourself:

A compressor is a great way to upgrade a regular two- or three-chamber septic tank. A correctly chosen model will significantly improve the operation of autonomous sewage systems and improve the quality of wastewater treatment. But you need to take into account that additional work on creating an aeration tank can take a lot of time and effort.

After reading the material, questions arose about how to choose or repair a compressor for a septic tank? Please write them in the comments to this article, and we will try to answer them promptly.

Good afternoon There is a three-chamber septic tank made of concrete rings, each chamber has 6 rings. A compressor and aerator are installed in the first chamber, on the overflow from the 2nd chamber to the 3rd biofilter.

Question for the experts: is an aerator needed in the 2nd chamber? And at what depth is it correct to install the aerator?

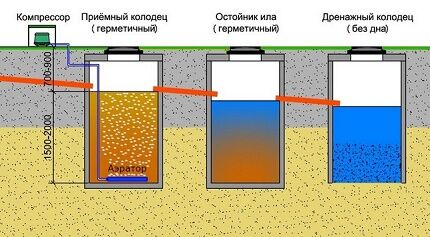

First of all, I’ll attach a diagram of three septic tanks with detailed instructions to make it more visual and understandable. It is possible that in the future someone will have a similar question.

Now the actual explanations from the diagram:

1. Outlet pipe for waste water;

2.Tee for HDPE pipes;

3. Primary settling tank;

4. Aerotank;

5. Drainage well;

6. HDPE pipe of the required diameter;

7. Gravel and crushed stone.

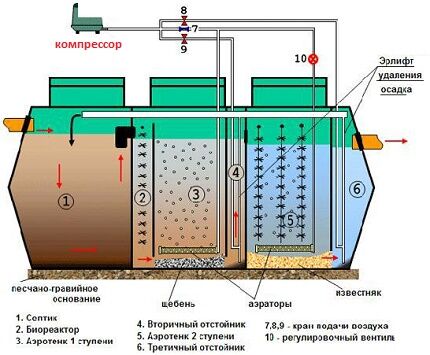

I also attach a diagram for the aeration system:

1. Compressor;

2. Silicone tubes;

3. Membrane diffuser.

Membrane diffusers must be located a meter from the bottom of the aeration tank; taking into account the performance of the system, their number can reach up to three pieces. I recommend membrane diffusers that are used in fish farm basins.

Good afternoon Tell me, which is better, a compressor or a pump for air pollution?

Good day, Natalia.

A compressor cannot be better or worse than a pump and vice versa. They have different purposes:

1. The compressor is designed to pump oxygen into the wastewater bioprocessing section. Necessary for aerobic microorganisms, which in turn provide deep cleaning up to 98%. More details can be found in the article “Bacteria for septic tanks«.

2. The pump in septic tanks is used to pump already treated wastewater into a ditch or filter well provided there is a counter-slope towards unloading.

The second application option is as an emergency pumping for a large one-time discharge, in order to protect electrical equipment from short-circuiting if it is installed directly in a septic tank.

The types and features of sewage pumps can be found in the article about sewage pumps, guidelines for their selection and operating features.

Good afternoon I want to make a septic tank from three or four plastic barrels with a capacity of 240 liters each. You will get a three or four chamber septic tank. Aerate. From the last barrel, water is removed by a pump into a ditch. Questions:

Will a septic tank work with such a capacity?

Which compressor and aerator to choose?

Permanent residence for 3 people.

Suitable for one person. For three, multiply by 3. 200 liters per person. Aeromicrobes are said to be processed in 24 hours, and the device is much more difficult not only to insert a hose with air. It won't work!

A small adjustment in pressure when choosing a compressor - 1m depth is ~0.1 atm,

Good afternoon. Is it appropriate to use a compressor and aerator if there is a cesspool (reinforced concrete rings of 8 rings) to remove odors?

Have you tried adding microorganisms once a month? With aeration, microbes must live on the load, and that’s just ventilation)

Hello. I have a septic tank made of concrete rings, the first section is 4 rings. Can I install such an aerator if it says “recommended depth 1.5 m?”

Manufacturer: Matala

Model: MDB11

Diameter: 225

Material: Silicon rubber

Compressors: 60 l/m, 80 l/m

Recommended depth: up to 1.5 m.

The pressure in water is 1 atm. at 10 meters depth, i.e. at 1 meter the pump should create a pressure of not 1 but 0.1 atm. The author, please correct the article, otherwise it’s 2 atmospheres, it’s too cool - it’s almost like a car wheel.