Which septic tank to choose: rating of the best wastewater treatment stations

Installing a septic tank is a practical way to solve the problem of wastewater disposal when arranging a local sewage system.But, you must admit, it is sometimes not easy to make a choice among the variety of ready-made designs.

To simplify the task, we suggest that you familiarize yourself with an overview of the main types of treatment facilities and popular models from leading manufacturers. We will tell you which septic tank to choose based on the characteristics of its operation, and outline the main parameters of the device that must be taken into account when purchasing.

For a better understanding of the issue, we have supplemented the information with photographs of various models of waste disposal units, as well as diagrams for their installation.

The content of the article:

Recycler models and their features

A septic tank is a waterproof structure consisting of one or more sections or divided into two or three compartments or chambers. But any sewage treatment plant has its own characteristics.

Therefore, in order to choose a recycler correctly, it is necessary to analyze the types of equipment available on the market, understand installation of septic tanks, the principle of their operation and determine for yourself the feasibility of using a particular model.

Types of materials used

Septic tanks, which are the main element of local sewerage, are classified according to different criteria.

The correct choice of a septic tank is largely determined by the material of its manufacture, each of which has its own pros and cons:

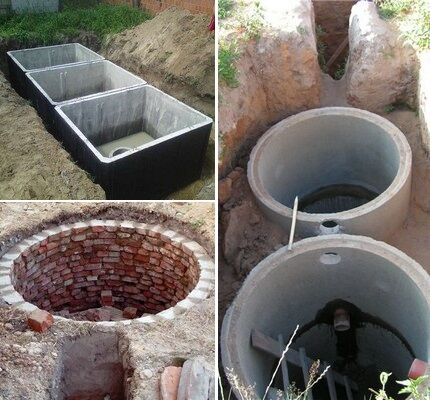

- Reinforced concrete rings – finished structures are highly reliable and resistant to corrosion. But their installation is problematic to perform without the use of special equipment.

- Monolithic concrete structures, for filling the walls and bottom of which formwork is constructed.

- Brick and foam block structures, erected from the bottom of a pit, the bottom and walls of which are abundantly sealed with clay or modern coating compounds.

- Steel tanks – are famous for their affordable price and high mechanical strength. But steel alloys are susceptible to corrosion processes, and therefore structures made from them require waterproofing.

- Polymer containers – They are distinguished by their low weight and relative cheapness. But the polymer is susceptible to cracking when exposed to low temperatures, and is also vulnerable to damage by rodents.

- Fiberglass – durable and lightweight material is famous for its chemical neutrality, and therefore containers made of fiberglass are the most practical and durable.

Regardless of the type of material chosen, the main thing is that it is strong enough and sealed enough to prevent untreated waste from leaking into the surrounding soil.

Complex of implemented functions

If you focus on the complex of implemented functions, the septic tanks offered for sale come in three versions:

- Cumulative type. A durable sealed tank may include one chamber or two connected sealed wells. Such structures require regular, timely pumping.

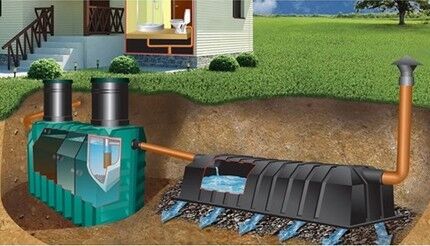

- Septic tanks. They are equipped with ground treatment systems, because are able to cleanse only 70-75%. They are a structure of one or more sections. The process of processing wastewater in them is carried out by separating the liquid and solid components, accompanied by fermentation with the help of anaerobes.

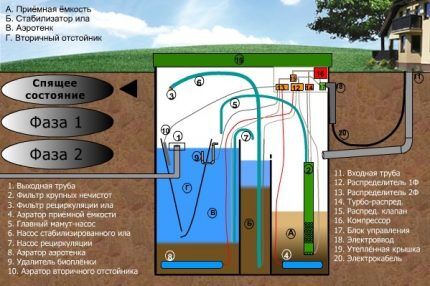

- Deep biological treatment stations. A treatment structure that includes several sections or chambers. It is designed in such a way that the waste that gets inside it decomposes in stages using chemical, biological and mechanical methods. Residual organic matter from such treatment tanks can be discharged directly into a body of water or soil.

The simplest drives among the listed models. The principle of operation of such structures is that the wastewater collected in a container naturally stratifies: heavy particles settle, and the lighter liquid rises.

IN septic tanks the insoluble sediment naturally separates from the water during the settling process. Sedimentation tanks are complemented by infiltrators designed to dispose of clarified wastewater into the ground.

Infiltrators, which are chambers without a bottom, serve as aeration platforms. The wastewater entering them undergoes additional purification, passing through a soil filter before being discharged into the environment.

Deep treatment facilities use several methods aimed at ensuring that waste decomposes in stages: primary sedimentation of solid fractions, subsequent bioprocessing of organic matter, chemical treatment of the contents, filtration of purified water.

With the help of deep treatment stations, 95-98% purified, clarified and disinfected wastewater becomes neutral and suitable for discharge into sewers.

Subtleties of choosing the optimal septic tank

On selection of treatment plant, primarily influenced by the conditions at a particular facility and the needs of residents.

The cost of any model consists of the following parameters:

- body material;

- volume and number of connected containers;

- technology used for waste processing;

- availability of additional equipment.

Depending on the type of design, the models may include: compressors and drainage pumps, filters and float level gauges, automatic control systems.

Compressors are used in biological treatment plants to supply wastewater-oxidizing oxygen, which is also needed for the life of aerobes.

Drainage pumps are required if there is a need to stimulate the movement of wastewater within the septic tank or to discharge treated water if the septic tank is located below the discharge point.

Advantages of a factory product over a homemade one

Homemade tanks made from tires, bricks or concrete rings, will cost less. But their construction will require a lot of time and effort.

Depending on the operating mode, you can independently build from available building materials either a simple storage-type structure or an installation of series-connected settling tanks that provide stepwise clarification of water.

By choosing a ready-made structure, you receive a guarantee that it complies with building and environmental regulations.

Type of soil and depth of groundwater

When determining how best to install a septic tank on your site, focus on the geological conditions of the area.

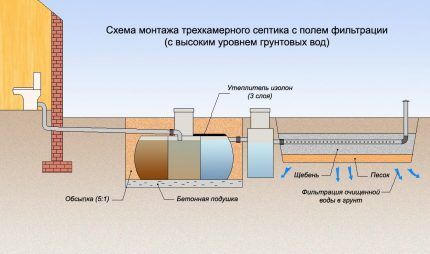

When choosing a treatment plant based on a septic tank with an infiltrator or absorption well, keep in mind that groundwater must lie at least 1 m below the conditional bottom of the groundwater treatment system.

Please note that the discharge of purified water into the ground is possible if sand, gravel and pebble soils, and sandy plastic sandy loams lie below the post-treatment system.

In addition to infiltrators and absorption wells, filtration fields are used for wastewater treatment. This is a drainage system assembled from perforated pipes, drains, with a shell of filter gravel and geotextiles.

If the filtration field is located above the treatment structure, then pumps are used to move wastewater through drains.

On clay soils, installing post-treatment systems is pointless, because... clays, loams and hard sandy loams do not allow or absorb water. This means that disposal into the ground will not be carried out, as a result the septic tank will flood and stop working.

In such situations, discharge is carried out through sealed pipelines into drains or into centralized sewer networks.

The high level of groundwater or its significant rise during floods creates certain problems in the operation of autonomous wastewater treatment plants.

For such areas, acceptable options include:

- sealed storage containersinvolving pumping and removal of wastewater;

- VOCs, the design of which provides for the forced removal of the purified liquid.

The most affordable option for areas with a high groundwater horizon is the use of polymer tanks that involve bioremediation with subsequent discharge to a storage tank.

In this case, from the storage tank, the purified component of the wastewater is either pumped to centralized networks or pumped out by sewer trucks, but much less frequently than from a conventional storage tank.

For comparison: 1 m2 sand can absorb up to 90 liters of water during the day, sandy loam - up to 50 liters, loam - 25 liters, and clay - only 5 liters.

Volume and dimensions of the septic tank

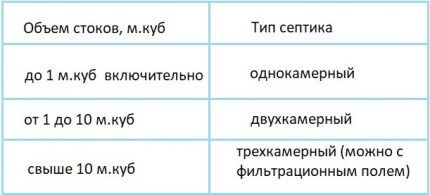

The volume of the receiving tank or section is calculated based on the average daily rate of wastewater per household.

It is taken as a basis that daily consumption when using a standard set of plumbing fixtures is about 200 liters per person.

According to accepted standards, the sewer storage tank must accommodate a volume of wastewater from each of the residents equal to the three-day norm.

So, for a family of four people, the volume of the septic tank should be: 4 people. x 200 l x 3 days. = 2.4 cubes. If the house is often visited by guests, when calculating the tank, an additional reserve of volume is made by another 20-30%.

In factory-made models, manufacturers indicate the number of people for whom they are designed and the performance of the structures.

The optimal tank depth varies from 1.5 to 3 meters. When choosing models of greater depth, keep in mind that this may make it difficult to pump out the contents using sewer equipment.

Wastewater treatment plant performance

To ensure trouble-free operation of the system and prevent overcrowding of the tank, it is necessary to focus on the type of housing and the performance of the model.

No. 1 - models for seasonal homes

If you plan to visit your country house only on weekends or live in it only during the warm season, it is not rational to install a multi-chamber production complex.

Thrifty dacha owners for landscaping their plots, if the average daily volume of wastewater does not exceed one cubic meter, mainly choose single-chamber, low-performance storage tanks.

Compact mini-septic tanks, due to their low weight, are convenient to transport and bury in a pit, using your own resources and without resorting to the services of special equipment.

No. 2 - septic tanks for year-round homes

For areas where year-round use is expected, it is advisable to install a treatment plant that uses all methods of wastewater treatment.

An alternative can be septic tanks with groundwater treatment systems if the groundwater horizon is low in the area of the sewerage system.

In order for an autonomous sewage system to function more efficiently, aerobic and anaerobic bacteria are often used when starting it.

To do this, bacteria are placed inside the tanks, which “eat” the organic matter. Biological decomposition of waste makes it possible to reduce household wastewater to the state of industrial water.

Deep cleaning units are ideal for developing areas located in close proximity to a natural body of water.

After all, purified wastewater that has passed through stations with a high percentage of filtration can be discharged into any body of water.

Rating of domestic offers

The production of treatment facilities for local sewage systems on the Russian market began only a few decades ago. But over the years, many manufacturers have emerged specializing in this area.

The models of some of them are only copies of leading European brands, but still the majority are truly unique structures and structures.

Based on the results of a survey of consumers who actively use wastewater purifiers on their property, we have compiled a rating of septic tanks:

- Eurobion. The stations are the result of many years of work by specialists from the Yubas production association. Thanks to the use of innovative membrane technology and a rhythmic aeration tank, the stations can be operated even during long periods of downtime of the sewer system.

- Poplar. The products of the Eco-Grand company are famous for their high degree of purification, reaching 99%. By using a non-standard design in production, in which access to the primary chamber is open, the manufacturer has simplified the maintenance of the sections: large debris that impedes the operation of the sewer system can be removed from them independently.

- Aster. Septic tanks-settlers of the Unilos brand guarantee the removal of harmful components up to 75%. There are several modifications on sale depending on the number of consumers. The station, supplemented by a compressor, performs cleaning in several stages, due to which the wastewater that passes through it is permitted by sanitary standards to be discharged into a ditch.

- Tank. Products manufactured by the Triton-plastic company. The model range includes compact tanks with a capacity of 600 l/day, and high-performance structures designed for 1200 l/day. Their parameters are identical to classic treatment plants with multi-stage wastewater treatment.

- Triton. Another popular product from this company. The model range of septic tanks of this brand includes several types, differing in configuration and cleaning method.Products of the “micro” and “mini” classes are designed for volumes of 450 and 750 liters, and storage tanks of the type with the letter designation “H” and “T” are designed for volumes of 10 thousand liters and above.

- Tver. The products of the trading house "Engineering Equipment" carry out wastewater treatment not only mechanically, but also biologically. The stations are equipped with a four-level wastewater clarification system and are designed to process waste from 750 to 1.5 thousand cubic meters per day.

- Topas. Products manufactured under this brand are characterized by low energy consumption. Four-chamber aerobic devices have a cleaning rate of up to 98%.

A distinctive feature of the products manufactured by the Triton-Plastik company is the large thickness of the walls and the presence of stiffeners, thanks to which they can easily withstand large external loads.

They also do not float up even under the influence of floods, if their presence was not taken into account when choosing the design.

Cleaning facilities of manufacturing enterprises are also no less popular. "Leader". Polypropylene tanks of this brand carry out three stages of cleaning: mechanical, aerobic and biofiltration.

Septic tanks have also proven themselves well "Rostock", produced by the company "EkoProm". The manufacturer specializes in the production of anaerobic treatment devices.

But, since the percentage of cleaning inside the chambers reaches only 65-70%, for the full operation of the structures it is necessary to install drainage tunnels.

The presence of designs with various parameters in the model lines of the listed manufacturers allows any consumer to make a rational choice, based on the optimal price/quality ratio.

Conclusions and useful video on the topic

The video talks about the operating principles of different septic tanks and lists practical tips on choosing the optimal unit for domestic use:

Advantages and disadvantages of various cleaners:

Which option is suitable for organizing an autonomous sewer system is up to you to decide. The main thing is to remember that only a correctly selected and properly installed septic tank can become an effective means of recycling and cleaning household waste.

Are you looking for a septic tank for a private home? Or do you have experience using such installations? Please leave comments on the article, ask questions and share your opinion about the operation of septic tanks.

They also forgot to mention the autonomous sewage system of Kolo Vesi. Modern Finnish technology that allows high-quality wastewater purification by 98%. Such wastewater can be discharged onto the terrain, into the ground, or used for irrigation without additional treatment. The device has a simple and reliable design, perfect for installation in summer cottages, near a house or cottage. Kolo Vesi is included in the class of biological treatment plants. Can be installed in any soil, the model is volatile. Suitable for both temporary and permanent residence.

Dear Tamara, let's not fantasize. Kolo Vesi has nothing to do with Finland or Finnish technologies. This is just a marketing gimmick.And the Kolo Vesi station cannot in any way be classified as a deep biological treatment station, such as the Topas, Astra, BioDeka, Genesis installations. Kolo Vesi can rather be classified as a station of the previous generation - the septic tank category.

Well, the cost of septic tanks is generally impressive... Especially new biological stations. Although for Moscow this may not be much...

So, of all the above, KoloVesi is the most expensive. In Novosibirsk, no one buys them at all.

Oh yes, choosing a septic tank is very difficult. It’s good that my husband did this; he’s at least a little technically savvy. In the end, they installed Alta Bio 5 for us - they installed everything turnkey and told us how to use it. Everything has been working well for a little over a year now. In general, I read that the correct operation of the septic tank and, in general, its service life are directly related to proper installation. The neighbors in SNT initially installed everything somehow incorrectly, and there were some problems with the operation of the septic tank, then they reinstalled it again, and everything seemed to be fine. So, pay attention to who you order the installation from.

Why pay for a station if there are more reliable solutions, without hemorrhoids and costly maintenance? We installed a regular septic tank BIO 3.0. Installs in 7-8 hours. We installed it ourselves - 2 people - me and my father-in-law. No tractor needed. You can place a septic tank in a small area if you use an infiltrator.

Easy maintenance. No electrical connection. It is enough to carry out pumping once every 2 years. No winter preservation required. The service life is more than 50 years - this is what the manufacturer claims. But they gave a 10-year guarantee - this is longer than others. Fiberglass septic tanks do not decompose like plastic ones.They remain sealed - it is impossible to break them.

I don’t advertise anyone, I chose from 3 - Flotenk, Septobak and Baikal. I can write a treatise about each one. I finally chose it after visiting the production facility. Don’t be lazy, watch everything live - and there will be no questions.

Good day, Andrey. Do not mislead people.

I’ll tell you why people pay money:

1. Energy-dependent stations purify wastewater up to 98%, which, according to sanitary standards, allows it to be discharged into an open ditch;

2. Maintenance of septic tanks comes down to cleaning the sludge chamber, and it is possible to do it yourself. Frequency once a year or once every two years. Pumping/calling by a sewer truck is not performed as such.

3. An excavator is required when installing large septic tanks designed to accommodate 12 people in a house. Running models for 6-8 people are installed without the use of equipment.

4. Plastic does not decompose in the same way as fiberglass, and the strength of the container in both versions depends on the number of seams, but not on the material.

Disadvantages of the BIO 3.0 septic tank and similar models without an electrical connection:

1. Maximum cleaning level 60%. Sewage with this level of purification is prohibited from being thrown into a ditch, so a filtration well must be installed on the site.

2. Installation in a small area with a well is impossible, there is a high risk of bactericidal water contamination.

3. Requires pumping out sewage and calling a sewer truck at least once a year. In the autumn/spring period, the frequency of calls depends on the height of groundwater in the area. If tall and filter well cannot cope with the daily discharged volume, then calling expensive specialists is possible once a month.

If you choose a biorefinery station, then there is little that can compare with Topas Automatics. They installed it at home, and then their neighbors also installed it. Very pleased! When there is no possibility of connecting to a central sewer, this is the ideal solution.

I am now in doubt about which septic tank to choose, there are 5 of us, we will live seasonally (in the house according to the plan there are 2 sou (shower + toilet, dishwasher), plot of 10 acres, centralized water supply) I wanted without a constant connection to electricity, but then you can’t dump it into a ditch water(((

Thanks for the analysis, but our main problem is that they often cut out electricity in the village.

When I built the house, I was immediately puzzled by the sewerage system. There is so much choice, but the reviews are contradictory. Family of 4 people, the house has a shower, washing machine, toilet, sink, in general everything is as it should be. I walked around the neighbors and asked around. Well, based on advice, I decided to install Alta Bio 5 LOW, it’s just right for up to 5 people and is suitable for high groundwater, like mine. The guys installed it in two days and provided an extended warranty of 5 years. The station works great, there is a pump instead of a compressor, and it doesn’t get clogged with garbage or toilets. And most importantly, after a power outage it starts up without any problems. In general, we use it to the fullest and don’t think twice about it.

I looked at a lot of sites, and here it’s the same as everywhere else.

Guys, you write about various stations, but not a single site cited the VOC technology of similar manufacturers as an example.

In my opinion, the Crystal septic tank is the simplest and best, but this is deliberately kept silent.

I myself have been working on septic tanks for several years at the BIOLEV company. I installed Topas and Asters and Tanks... 3 years ago I started looking at a septic tank for my dacha and settled on Eurolos. Yes, now many will say - ADVERTISING)) No, I’m not praising Eurolos specifically. There were many offers on the market and at a good price; at first I looked at Topas. But I dismissed it, because... I just chose a simple aeration barrel for my dacha and Eurolos is not that cheap, if you look at it that way. At the exit, Narzan does not flow out, which you can drink, BUT there were not a single complaint from the neighbors about the stench or anything else. Clear, odorless water flows out. I clean the septic tank myself, once a year and have no problems. The compressor has been running for 3 years, I only clean the filter. Shit recycles and is fine. So contact me, I’ll help you with installation or maintenance, no problem!