Review of the Eurobion Yubas septic tank: design, advantages and disadvantages, comparison with competitors

A deep cleaning station allows you to recycle household waste and save space on your garden plot.The Eurobion Yubas septic tank supplied to the markets of Russia and neighboring countries is in reasonable demand due to the ease of installation and good quality of treatment of household wastewater.

The article we propose describes in detail the operating principle of a sewerage treatment plant of the specified brand. The design features and specifics of wastewater treatment are given. We will introduce you to the model range and the specifics of choosing the optimal model.

The content of the article:

The evolution of Eurobion septic tanks

Some of the developments were improved experimentally during the release of the first models. The modifications were made based on the problems that arose during operation by end users. The first models had a number of design flaws.

They did not have an anchoring system, and when the groundwater level rose, the tank floated up. This led to deformation of pipes, and in some cases to failure of the sewer system.

Buyers en masse turned to the company, which came out and on-site modernized the body of the Eurobion septic tank. The cost of removing the container was paid at the rate of 50% of its cost.

After identifying this shortcoming, ground hooks were added to all models. This allowed us to solve the problem with ascent. Special hooks were mounted at the corners of the installation, which at that time had a rectangular shape. It wasn't a good decision either.

Since the container had an elongated rectangular body, cases of depressurization occurred due to excess pressure on the walls of the tank. This was due to the presence of a large number of welding seams.

The number of joints was reduced by making the body cylindrical. Additionally, it was reinforced with stiffening ribs on four sides.

Subsequently, this problem was partially solved. In areas where the temperature drops below 25 degrees in winter, the top of the container needs to be insulated. This is necessary to maintain the optimal temperature for the growth of active sludge in it, which purifies wastewater.

The manufacturer has actively improved the cleaning system and for older models it is possible to purchase a modernization kit that solves the problem of excessive removal of active biological mass during a volley discharge of water.

This made it possible to improve the quality of household wastewater treatment. The last modernization took place in 2015. It affected those station models that are designed to receive household wastewater in households where 12-15 people live.

Expected quality of cleaning

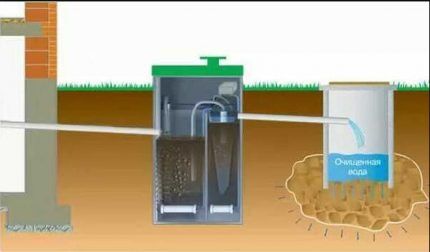

The quality of wastewater treatment directly depends on the state of the microflora. Immediately after connecting the septic system, the water coming out has a cloudy appearance. The installation needs to be operated for several weeks to reach full capacity. During this period, the percentage of purification does not exceed 70%.

To prevent environmental pollution, the active microbiological mass can be colonized immediately after installation. The system does not provide for the use of aeration fields, so the final quality of the effluent can be checked by taking a sample from the tertiary settling tank.

If the number of people living is less than the septic system is designed for, reaching full capacity will take much longer. The process can last from 6 to 12 months.

Sometimes this is a consequence of a clogged one of the system pipes. After the installation reaches full capacity, the water should not contain fine suspended matter.

But even clear drains contain large amounts of phosphates and other surfactants found in detergents. The design of a standard septic system does not provide a mechanism for neutralizing chemical impurities.

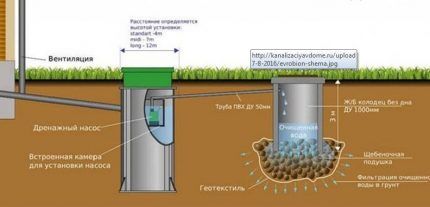

Treated domestic wastewater does not have an unpleasant odor and can be discharged into a drain or swamp.Discharge into rivers or other bodies of water is prohibited, as this leads to phosphate poisoning of local biological flora and fauna.

The company allows you to separately purchase a dispenser for wastewater disinfection, but it cannot be installed in the device’s container itself. Since the water in the station constantly circulates between the compartments. For this you need a drainage well.

An alternative method of purification is the installation of ultraviolet radiation. The plastic from which the body is made is resistant to UV rays. If the station is installed in an environmental zone, then it needs additional modernization. The equipment can be ordered on the manufacturer's website.

Design and operating principle

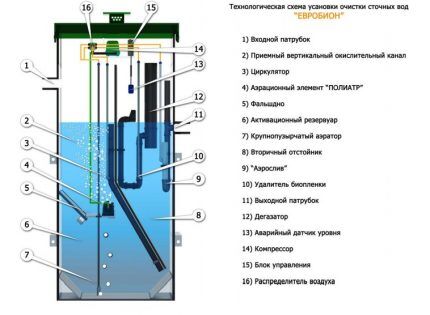

Water purification includes two or three stages. Accordingly, the container itself has three compartments. It has reduced the number of airlifts to one. It has an internal diameter of 28 mm. There is one compressor and one aerator. The diagram shows a detailed design of a biological treatment plant, which involves aerobic and anaerobic bacteria.

The step-by-step cleaning process is as follows:

- Through the inlet pipe, water enters the receiving vertical oxidation channel.

- There, solid fractions are broken up by a coarse-bubble aerator.

- The suspension obtained after oxygen breakdown settles on a false bottom, which has a slope and an overflow hole.

- Through the hole, a fine suspension settles at the bottom of the activation tank.

- Activated sludge forms at the bottom.

- Water that does not contain suspended matter moves through the airlift into a secondary settling tank.

The water then circulates through the system until its level rises to transport it out of the system. As the mass of activated sludge increases, the quality of the purified water also increases.

Sludge aeration occurs continuously, which over time makes it necessary to clean the device. Russian-made aeration elements are installed in the station. Their cost is lower than their foreign analogues.

Model range "Eurobion Yubas"

The company produces several configurations of Eurobion septic tanks. They differ in size and the presence of some additional functions.

The model line is represented by the following devices:

- Eurobion-5R ART

- Eurobion -5R ART Midi

- Eurobion -8R ART

- Eurobion -8R ART Midi

- Eurobion -8R ART long

The number in the abbreviation means the number of people for which the installation is designed. Midi and Long models are designed for areas with high groundwater levels. This is far from a complete lineup.

Characteristics of Eurobion-5R ART

Installations of this type have a capacity of up to 900 cubic meters. liters per day. Designed for year-round use in private households inhabited by 1 to 6 people.

They have a volume of 2.38 to 2.80 cubic liters.The hole for the waste pipe leaving the house is set at a level of 60 -80 cm. The maximum salvo discharge does not exceed 390 cubic liters.

Characteristics of Eurobion-8R ART

These models have a capacity of up to 700 cc. liters per day. Designed for year-round use in private households inhabited by 6 to 9 people.

They have a volume from 4.35 to 6.12 cubic liters. The hole for the waste pipe leaving the house is set at 60 -120 cm. The maximum discharge of wastewater is limited to a volume of 700 cubic liters.

Rules and frequency of care

Since the primary settling tank has a small volume, it must be pumped out using a pump or every 6 months.

Next, it is mixed with vegetation residues and other substances suitable for producing fertilizers. To reduce the frequency of pumping, you can additionally install an overflow well. Then the wastewater will flow into it, and only then into the installation. This will prevent non-degradable debris from entering the septic tank and possible breakdowns.

The use of an overflow well in the sewerage system will also reduce the washout of activated sludge with large volumes of simultaneous water entering the installation.

Membranes need to be changed every two or three years. compressor. If a timer is set, then the membranes may need to be replaced sooner.

In addition, it is necessary to reduce the amount of chlorine-containing household chemicals that destroy activated sludge. Remains of rotten vegetables and other food products should not be allowed to enter the septic tank. This has a negative effect on microorganisms.

Pros and cons of these septic tanks

By analogy with all septic tanks for biotreatment, Eurobion Yubas have advantages and are not without disadvantages. The advantages of the station include the shape of the container, which has a small number of welding seams and is reinforced with stiffeners. Another advantage is the presence of one airlift and minimal presence of electronics.

All electrical appliances are collected in a separate compartment and are available for maintenance. The presented models of septic tanks are lightweight and compact in size. This simplifies the transport and installation of stations.

The shortcomings include insufficient treatment of household wastewater from phosphates. In addition, the station needs constant monitoring. Needs maintenance every 6 months. The aerator works continuously, which reduces its service life.

The chamber intended for the primary discharge of wastewater has a small volume, which leads to the washing out of activated sludge from the station. The septic tank runs on electricity, so this increases the cost of its maintenance. The drawback is the location of the ventilation hole on the lid.

In some cases, moisture ingress is caused by melted snow. This happens when it hits the station cover. Damage caused by moisture getting into the electronics is not covered under warranty. Repairs are carried out at the owner's expense.

Will familiarize you with the rules for maintaining a septic tank in winter next article, the contents of which we recommend that you familiarize yourself with.

Comparison of septic tanks with main competitors

The closest competitors of Eurobion Ubas treatment stations are "Topas" And "Aster". Their design has a lot in common, but each brand has design features.

In terms of the degree of cleaning, Topas can be ahead of Eurobion if the basic Topas package is supplemented with a UFO system. It is offered optionally by the manufacturer.

Astra also does not have this disinfection mechanism. The bodies of the Topas and Astra tanks are rectangular in shape with a large number of welding seams. This makes containers more susceptible to deformation and depressurization.

Eurobion has a cylindrical body, which distinguishes it from its closest competitors. Since there is one seam on the container. This makes its body more resistant to compression and deformation.

The number of airlifts at the Topas and Astra biological treatment stations is three. In this case, the width of the tubes is approximately the same. Eurobion has only one airlift with a large pipe diameter. This sets it apart, since blockages in the system are minimized.

Another advantageous feature of Eurobion Yubas septic systems is the lower content of electronics.

The Topas models have two compressors, and the Astra septic systems have two aerators. At Eurobion, these devices are present in a single copy. This reduces the cost of plant maintenance. In addition, the control unit in the Topas and Astra systems is controlled by a float switch sensor.

Conclusions and useful video on the topic

The video explains how to pump out excess sludge and maintain the station:

The video shows the step-by-step process of replacing membranes:

Review of design differences between septic systems of similar configuration:

The advantages and disadvantages of Eurobion Yubas septic tanks are typical for all low-power treatment stations. This is due to low cost, which is achieved by reducing the size of installations.

The volume of the chambers where cleaning occurs is reduced, which necessitates repeated circulation of water, and also increases energy consumption. The advantage of such systems is their compactness.

Please write comments in the block form below, intended for feedback. Tell us about which septic tank you chose for installing a sewer system in a suburban area. Ask questions, share useful information and photos on the topic of the article.

From the text: “In terms of the degree of purification, Topas is superior to Eurobion.” Since the basic configuration of “Topas” has a UFO system.” Where did you see the UFO in the basic configuration??? This is NOT even on the manufacturer's website.

Hello. Yes, you are right, Andrey. There is no UV in the basic configuration; it is offered by the manufacturer as an option. The author has slightly exaggerated the colors, convincing the reader of the advantages of the installation.

At the customer's request, a disinfection system using UV irradiation is built in and supplemented with a circulating flow dispenser and ozone-bubble post-treatment.

A significant advantage of the device is the regeneration function of the quartz flask in which the emitter is located, which greatly facilitates the care and maintenance of the system.