Review of the septic tank “Tver”: design, principle of operation, advantages and disadvantages

In areas with private buildings, the absence of a central sewerage system is not uncommon.Waste disposal is becoming a problem for home owners, and they are increasingly choosing to install their own treatment system. One such solution could be a Tver septic tank, which performs a full cycle of wastewater treatment.

But you must admit, before you decide to purchase a treatment plant, you need to study the design of the unit, understand the principle of its operation, and become familiar with the operational advantages and disadvantages. All these points are described in detail in the article.

The content of the article:

How the Tver treatment station works

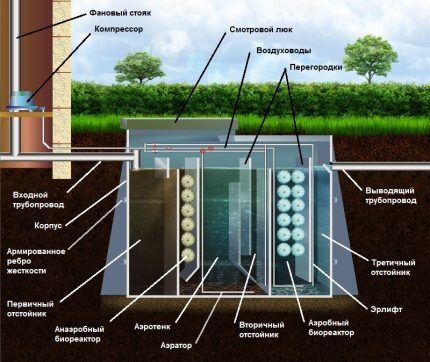

The Tver septic tank is a local station for the complete treatment of household wastewater. The internal volume of the septic tank is divided into working chambers in which settling, mechanical separation and biodegradation of the liquid occur.

Main components of the system:

- frame;

- a system of dividing and semi-submersible partitions with holes and cutouts, thanks to which water flows from section to section;

- compressor;

- air pipelines with appropriate shut-off valves;

- aerators;

- airlifts;

- inspection hatches with insulation;

- inlet and outlet pipelines;

- ventilation (fan) riser.

There is practically nothing to break in the installation.The only energy-dependent unit that ensures the operation of the installation is compressor - installed in the house. The system elements are made of polymers, therefore they are not subject to corrosion and decomposition by microorganisms, and are resistant to aggressive environments.

In the system, wastewater passes alternately through six zones:

- Septic chamber, or primary settling tank;

- Anaerobic bioreactor;

- Aerotank;

- Secondary settling tank;

- Aerobic bioreactor (second stage aeration tank);

- Tertiary settling tank.

Bioreactors are filled with brush nozzles. Aerators are installed in the bottom part of the chambers of the aeration tank and aerobic bioreactor.

Airlifts are located in the secondary and tertiary settling tanks and are connected by a sludge pipeline to the septic chamber.

What is a hull?

The septic tank body is a sealed container made of durable polypropylene. This construction material is not subject to corrosion or any type of erosion, and does not react chemically with substances contained in soil and wastewater.

On the sides of the body there are horizontal reinforced ribs, which, combined with the elasticity of polypropylene, allow the tank to easily withstand soil pressure.

If installed correctly with a dense sand cushion around the pit, even frost heaving and uneven extrusion of individual layers of soil will not cause harm to the body of the septic tank.

The special shape of the tank - trapezoidal with a rounded smooth bottom - is convenient for maintenance. There are no dead zones inside the tank, and you can even clean the septic tank from sludge yourself using nets. The working sections of the station are arranged alternately in the horizontal direction, so the tank is elongated and has a relatively small height.

This feature allows the septic tank to be located in the upper layers of the soil, which reduces labor costs for earthworks and makes it possible to use the structure even in very high aquifer.

In the upper part of the tank there are one or two inspection hatches, depending on the design. Thanks to their large size, the Tver septic tank is one of the most easily maintained structures among deep cleaning stations on the market.

Bioreactor design

Since a lot of work in cleaning wastewater from contaminants is performed by microorganisms, it is necessary to provide optimal conditions for their growth and reproduction in the septic tank. This is exactly the function that both bioreactors perform in the Tver septic tank.

The physical opportunity for biofilm formation is provided by bioloading. Its main function is to create as large a free area as possible for the settlement of bacterial colonies, with its own minimum dimensions.

In the bioreactors of the Tver treatment plant, brush loading is used.The nozzles are shaped like a regular household brush, which is why they got their name.

The shape of the loading elements promotes the growth of activated sludge and the uniform distribution of microflora. At the same time, they do not clog like porous bioloads.

The specific surface of brush nozzles is 50–60 m2/m3. The chemically stable polymer materials from which they are made are absolutely safe for microorganisms and the environment.

They settle in an anaerobic bioreactor bacterial coloniesthat live and reproduce without access to air. For their vital functions, a sufficient supply of organic matter is sufficient.

An aerobic bioreactor provides conditions for microorganisms that live only in the presence of oxygen. To do this, install an aerator in the container.

What is an aerator?

An aerator is a device that saturates the contents of a septic tank with the active component of air - oxygen. In its simplest form, it is simply a perforated tube, on one side of which air is supplied under pressure, and on the other side a plug is installed.

The gas is squeezed out through the holes and, in accordance with physical laws, rises. Since the aerator is installed at the very bottom, the entire volume of the section is filled with air bubbles. Oxygen dissolves in water and allows aerobic bacteria to exist.

However, if the air supply stops, liquid will begin to flow into the aerator pipe, which is unacceptable. Therefore, a special film is put on the pipe.The air from inside calmly passes through the micropores, forming tiny bubbles that saturate the water well with oxygen. Water does not leak in the opposite direction.

How does this sewer system work?

The process is organized in a flow mode - the liquid goes through all stages of purification by gravity. Therefore, a power outage does not become a disaster - the compartments do not overflow and the station continues to function and perform high-quality cleaning for at least a day.

Such design features make it possible to effectively use the Tver septic tank both for a dacha with seasonal or periodic use, and for a house with permanent residence.

In the tank, the wastewater undergoes four stages of fine biological treatment.

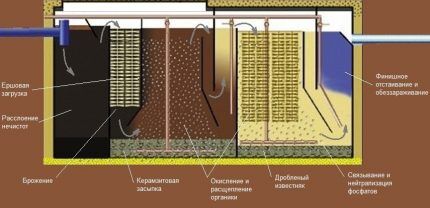

Primary settling and anaerobic fermentation

Through sewer pipes, sewage enters the primary settling tank, where sedimentation, mechanical separation occurs, and treatment with microorganisms begins. Hydrobionts enter here along with wastewater from the anaerobic bioreactor, as well as with activated sludge from the secondary and tertiary settling tanks.

Under the influence of bacteria, large heavy structures are broken down, and wastewater is separated according to specific gravity. Heavy, poorly soluble particles settle to the bottom, light fatty fractions rise to the surface.

Sludge and fat film are also gradually processed, but this takes longer. As a result, only solid sediment remains, which must be pumped out.

The next section is an anaerobic bioreactor, where colonies of anaerobic bacteria are concentrated. Relatively clean water from the middle layer of the septic chamber enters here.

Due to the content of a large amount of organic matter, fermentation and sedimentation of sludge on the fibers occurs in the loading space. Hydrobionts break down difficult-to-oxidize and complex organic compounds into simple ones.

Oxidation and aerobic decomposition of organic matter

Water with simple suspensions enters the next section - the aeration tank, where constant aeration is carried out. In an oxygenated and nutritious environment, aerobic bacteria begin to work. They use simple organic matter as food to maintain their metabolism. As a result, the water is saturated with active suspensions.

A layer of gravel is poured onto the bottom of the aeration tank. The remains of bacterial activity (metabolites), as well as some organic matter, settle on it. Due to this, an environment for the reproduction and growth of anaerobes is formed and activated sludge is formed.

Together with air bubbles, it rises again, and the bacteria continue to work throughout the entire volume of the chamber. Next, this “agitated” liquid enters the secondary settling tank. The process subsides, the particles settle.

The secondary settling tank and the aeration tank are connected sections, so the activated sludge, settling, returns to the aeration tank chamber. The clarified water flows further through the upper overflows into the aerobic bioreactor.

In the bioreactor chamber, conditions have been created for the growth and reproduction of huge colonies of aerobes.Water saturated with oxygen and organic residues passes through a brush bioload, in which the same processes occur as in the aeration tank. Only much more active.

The lion's share of activated sludge settles on the fibers of the ruffs and is processed by bacteria until complete decomposition.

Neutralization of toxic compounds

In addition to organic matter and insoluble heavy suspended matter, household wastewater contains toxic substances. Detergents and cleaning products used for bathing, laundry, dishwashing or cleaning contain phosphates and nitrogen compounds.

They dissolve in water and do not settle or decompose by bacteria. It is prohibited to drain water containing toxic compounds into the ground - this threatens environmental damage.

To neutralize them, a layer of limestone is placed in the bottom area of the bioreactor section. It reacts with phosphates and nitrogen compounds and forms insoluble salts, which precipitate.

Final settling and disinfection

The last stage of purification is the settling of water in a tertiary settling tank. The remaining metabolites and neutral salts formed by the combination of phosphates and limestone settle here. As a result of passing through all chambers, the wastewater is completely cleared of contaminants - the degree of purification is 98%.

In a tertiary settling tank, practically pure water is disinfected. To do this, chlorine-containing tablets are placed in a special float.

Purified water can be discharged onto the terrain and into a natural body of water. However, resource saving trends are increasingly spreading not only in Europe, but also here.

Therefore, more and more economical owners are using treated wastewater again - for irrigation, for technical or economic needs.

Disposal of excess activated sludge

With a sufficient amount of nutrients, the increase in the biomass of aerobic bacteria occurs very intensively. In this case, a lot of activated sludge is formed.To dispose of its excess, airlifts are installed in the secondary and tertiary settling tanks.

An airlift is a jet pump that lifts liquid using compressed air. The design is very simple - it consists of two tubes and a compressor. One of the pipes carries air under pressure. It is connected to the bottom of the second pipe, lowered into the water.

An air-water emulsion is formed - a liquid filled with air bubbles. Its specific gravity is less than the specific gravity of the water surrounding the pipe.

Due to this, it rises up the pipe - denser water simply pushes out the lighter air-water mixture. The suspended matter contained in the water also becomes part of the emulsion and rises successfully.

Two airlifts installed in the Tver septic tank, together with the liquid, lift excess activated sludge from the aeration tank and tertiary settling tank sections. The sludge line pumps the mixture into the septic tank. The cycle is completed.

Advantages and disadvantages of the treatment system

Septic tanks Tver have advantages and disadvantages, like any technical device. However, the number of advantages significantly outweighs, due to which these treatment plants are widely and successfully used.

Design advantages:

- Complete water purification occurs in one tank - no additional filtration devices are required.

- A septic tank with properly selected capacity cleans wastewater by 98% - such water can be discharged onto the terrain, into a reservoir, and used for household needs.

- The septic tank body is made of high-strength polymer material that is not subject to corrosion and erosion, which ensures a long service life of the device.

- There is no need to constantly use bioactivators - the bacteria in the septic tank are restored independently and actively multiply.

- Provides for purification from toxic phosphates and nitrogen compounds.

- Solid sludge is pumped out once a year or less.

- The Tver septic tank can be used even with intermittent operation - thanks to the combined cleaning method, the intermittent cycle does not create a large load on the activated sludge and, in the absence of power supply, the septic tank goes into sleep mode.

- In a septic tank, liquid does not move through pipes or hoses, so there is no danger of clogging the system.

- The design easily withstands volley discharges of wastewater without loss of treatment quality.

- Large inspection hatches make it easy to carry out preventive inspections of the system, maintenance and pumping out solid sludge.

- The compressor is located indoors - this is convenient for maintenance and significantly extends the life of the unit.

- Compact overall dimensions and light weight allow for septic tank installation Tver on your own, without the use of special equipment.

Flaws:

- Volatility of the system;

- High price of the complex.

However, the considerable cost of the septic tank pays off already during installation - no need build absorption wells or spend money on arrangement of the filtration field.

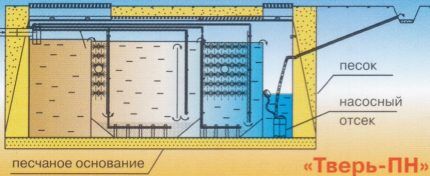

Modifications of treatment facilities "Tver"

Designs of Tver septic tanks are classified depending on their productivity - the amount of wastewater that the installation can process within a day. Select the required volume of the tank taking into account the number of people permanently residing in the house.

The productivity of Tver station modifications on the market starts from 0.35 cubic meters. m per day - this is suitable for 1-2 people. Next comes the performances. Tver-0.5P And Tver-0.75P – for 2-3 residents, Tver-0.85P – for 3-5 residents, Tver-1P – for 4-6 residents, etc.

The letter “P” in the designation means that the septic tank is made in a plastic casing.

The modification has the maximum daily processing volume for a septic tank with a plastic body Tver-3P. This design can serve up to 18 people.

Septic tanks with greater productivity belong to the professional class; their body is made of steel. The productivity of such structures is from 4.5 to 500 cubic meters. m per day.

Models with pump compartments are available. The section with the pump may be the last one along the flow of liquid through the septic tank. Such modifications have the letter “H” at the end of the designation code - for example, Tver-1.5PN.

Pumping units are used for forced removal of purified water onto the terrain or into a well when the level of the discharge pipe is higher than that exiting the septic tank.

There are models with a pump compartment, which is located in front of the receiving chamber - the primary settling tank.The sewer pump pumps sewage into the septic chamber when the main line leaving the house is located low enough underground - below 60 cm from the surface level.

Septic tanks with a pump are marked with the letter “H” at the beginning of the designation code - Tver-1NP.

There are also combined installations - their designation has the code NPN. For example, execution Tver-2NPN.

If the issue of choosing a septic tank is still relevant, we suggest that you read the article - Which septic tank is best for a home: comparison of popular treatment plants

Conclusions and useful video on the topic

Design and principle of operation of a septic tank Tver:

Design and operation of the Tver septic tank, its advantages in comparison with other systems. Tips for preserving for the winter:

The Tver septic tank, due to its versatility, is used for private houses and summer cottages located on areas with any type of soil. More productive versions are suitable for recycling wastewater from small production sites and warehouses remote from central communications.

Share with readers your experience of using a septic tank Tver. Please tell us about the features of its maintenance and operation. Participate in discussions and ask questions that interest you - the comment box is located below.

It's amazing how some companies operate! I called several companies looking for a septic tank for my dacha.Often managers don’t even know their product! And recently I talked with engineers - the consultations were competent. They found me a horizontal septic tank Tver, reliable and practical. No complicated electronics. Reinforced, with anchors against ascent. Interested.

I googled it, thought about it, weighed everything and decided to take it. They installed it at the dacha quickly and completed it in a day. By the way, we go there on short visits; we didn’t want to hassle with the sewer system. Therefore, we simply turn off Tver and that’s it. Even in winter. Convenient, practical, reliable. I recommend.

“Tver” is thought out in everything at first glance, and I consider it a priority for acquisition. But I still have some doubts about the fact that the installation is completely dependent on bioreactors. It turns out that there is an option to accidentally destroy the necessary bacteria with some household chemicals?! And second: is it really possible to go on vacation and leave the installation unattended?!

Good afternoon, Anatoly. A small amount of household chemicals can be discharged into the septic tank. Naturally, if you only dump chemicals, the concentration will reach dangerous levels for bacteria.

It is strictly forbidden to dispose of the following in a septic tank:

- bones;

- seeds from fruits and berries;

— fabric materials;

- alcohols and acids.

Turn off the compressor and safely leave. Aerobic bacteria are found in organic impurities. After arriving, turning on the compressor and dumping organic waste, they will immediately begin to multiply.

It is still recommended to add live bacteria and the operation of the septic tank will be immediately restored. If this is not possible, then you can try replacing it with regular kefir. Kefir will do two things:

1. Contains live bacteria.

2.Acts as a stimulating nutrition for living bacteria.

“Tver” is one of the easiest septic tanks to operate and therefore one of the most reliable.

Good afternoon. There is a house in the village in which from 1 to 5 people live in the summer and visit (3-5 times) during the winter. Those. The house remains unheated and without power for almost the entire winter.

Which septic tank option is best suited for such conditions? The soil is clayey and the groundwater periodically overflows - the well flows over the edge in the spring. I look at Tver, but I doubt that he will survive 4-6 months without anything at all.

In the summer, a pump from a well with a storage tank on the roof is turned on and everything is drained into a bucket. And the toilet is just bio. I would like to modernize it, because... elderly people live. It’s hard for them to walk with buckets. But with the expectation of only summer operation and periodic (2-3 days) power outages. Or are there only bio and buckets for such conditions?

In this case, you need a completely sealed septic tank, which should be located below the freezing depth of the soil. IN this article you can find useful information on preparing your septic tank for winter. I also advise you to read the comments where a person has a similar question. It is recommended to use extruded foam as insulation.

If you plan to turn off the electricity upon departure, then septic tanks such as “Tver” or “Topas” will not be suitable, since they require a power supply for full operation. In your case, if you are considering ready-made options, I recommend a septic tank of the “BARS” type, domestically produced. The principle of its operation is such that it can function properly without electricity even in winter.

If you have a limited budget, it is better to install the septic tank yourself from concrete rings and insulate it with extruded foam.