Septic tank made of concrete rings: device, diagrams + step-by-step installation process

A good-quality septic tank made of concrete rings allows you to organize wastewater treatment up to 70%, but the percentage of treatment in it is lower than in high-tech biological stations (98%). Although such a system is several times cheaper, and its design is simpler. Why not use it to install a sewer system in your country house, right?

Do you want to build a septic tank on your own and don’t know where to start? We will help you understand in detail all the intricacies of this issue. The article examines in detail the structure of a concrete storage tank and detailed diagrams of its construction. As well as a step-by-step installation process, starting with the preparation of materials and ending with putting the system into operation.

The article is supplemented with visual photos and videos, which examine the nuances of the functioning of a septic tank and the process of constructing a two-chamber treatment plant.

The content of the article:

How to place a septic tank on the site?

Concrete rings are a good material for making sewer systems in private households. If the territory does not belong to environmental protection zones, then you can save on sewerage, since the cost of such a septic tank is half the price of purchasing a treatment station.

Before starting work, it is necessary to determine the type of soil on the site.The choice of filtration system depends on its characteristics, since the design of a septic tank made of concrete rings involves several containers. According to sanitary standards, water must be allowed to settle for three days or more before being discharged into the ground.

The type of soil can be determined by digging a hole, interviewing neighbors who own a well or well, or requesting information from an organization conducting construction or drilling near the site.

The filtration coefficient is slightly higher for loams, slightly higher for sandy loams. However, their filtration properties are still not enough to install groundwater wastewater treatment systems on the listed clay soils.

In addition, almost all clay soils are characterized by heaving - the ability to increase in size during freezing and decrease during thawing. These soil movements can easily push concrete containers out, completely destroy them, or simply squeeze them until cracks appear.

Sand, gravel, pebble and crushed sedimentary rocks have good absorption properties. They freely allow water to pass through their thickness and do not interfere with its movement into the underlying layers.

True, coarse sediments, such as gravel and pebbles, occur mainly in river floodplains, and crushed stone is at the foot of mountain formations.

On river and mountain slopes, filter structures are not suitable, because Part of the drainage liquid will not be able to undergo a post-treatment cycle sufficient for disposal into the ground.

Therefore, sandy soils of all degrees of coarseness and density, except for dusty ones, are considered normal conditions for constructing filtration fields, absorption wells and installing infiltrators.

In addition to geological conditions, it is necessary to comply with the norms of its location from residential buildings and water sources.

If sanitary standards are neglected, biological contamination of water may occur. Dangerous pathogens of infectious diseases develop in sewage. These include E. coli, which causes severe poisoning. It easily reaches the source of drinking water through groundwater.

Nuances of calculating the required volume of capacity

To organize a septic tank from concrete rings it is necessary to calculate the volume based on daily water consumption. According to the standards, one permanent resident receives 200 cubic liters of water per day.

The first container for settling wastewater should have a volume of at least three times the consumption (200 l) for each person. The second container with a bottom for settling should have a volume equal to 1/3 of the size of the first.

The rules for constructing a two-chamber treatment plant can be found in our other article.

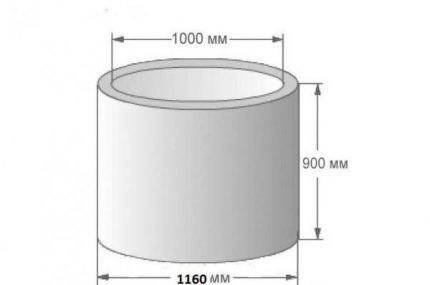

The number of rings can be determined by dividing the volume of the container by the volume of the ring. Their sizes come in small, medium and large.

For a family of two:

Volume of the first container = (200*2)*3= 1,200 liters.

Volume of the second and third containers = 1,200/3 = 400 liters.

Number of rings for two containers = (1200+400)/700= 4

Number of rings for three containers = (1200+400+400)/700= 5

Bottom line: 2 rings for the sump, 2 for the sedimentation tank and one for the drainage well.

For a family of three:

Volume of the first container = (200*3)*3= 1,800 liters.

Volume of the second and third containers = 1,800/3 = 600 liters.

Number of rings for two containers =(1,800+600)/700=4

Number of rings for three containers =(1 800+1200)/700= 6

Result: 2 rings for the sump, 2 for the sedimentation tank and two for the drainage well.

Septic system diagrams

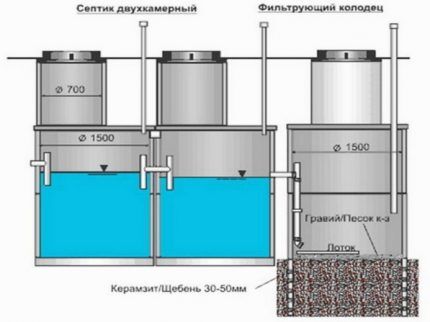

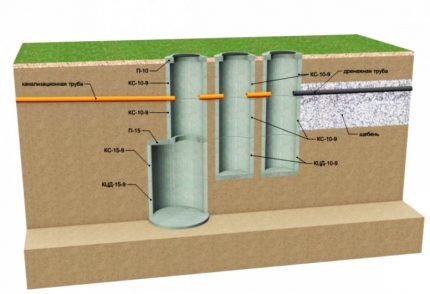

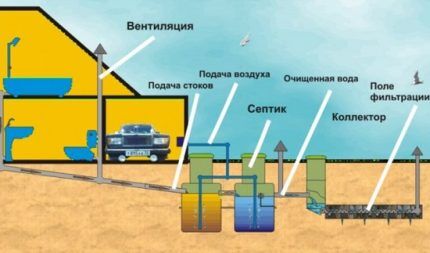

Septic tank designs made from concrete rings assume the presence of one, two or three chambers where wastewater settles and is biologically processed.

In fact, a single-chamber septic tank is a regular storage tank, the wastewater from which is pumped out by sewer trucks.

The first and second containers must have a bottom. This is followed by the third compartment, where ground cleaning is also carried out. The next stage of purification is the removal of clarified wastewater settled in the chambers into the ground through the bottom filter well.

All chambers are arranged with a monolithic bottom, cleaning is carried out by settling. The settled liquid is discharged into an infiltrator or filtration field for subsequent disposal into the ground.

Depending on the absorption capacity of the soil, you can choose several filtration options for constructing a septic tank made of concrete rings:

- Septic system with filter field.

- Septic system with absorption well.

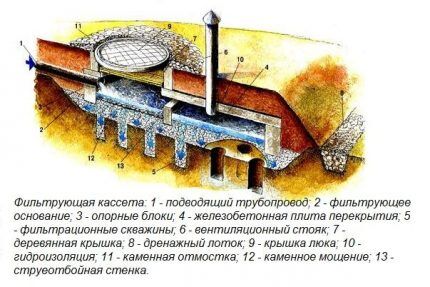

- Septic system with filter cassette (infiltrator).

The most common filtration option is a drainage well. It is used when the soil has good absorption properties.

Between the level of the conventional bottom of the absorption well and the highest level of groundwater in the autumn/spring rainy period there is no meter required by the standards, a filtration field is established. There must be enough space on the site for its construction.

This is the optimal solution for areas where the groundwater level does not exceed 2.5 meters. It should be remembered that between the lower edge of the filtration field drains and the roof of the water-saturated layer there must also be a soil thickness of at least a meter thick.

This design is not widespread in the CIS countries.

You need to decide on a filtration system before installation of a septic tank made of concrete rings, as this will allow you to prepare a pit of the required size and depth in advance.

Installing filtration systems after installation can damage pipes and tanks.Therefore, the space that borders the wall of the second sedimentation tank will have to be excavated manually, without the use of special equipment.

Installation of a septic tank with two sedimentation tanks

Before starting work, it is necessary to check the groundwater level. This can be done if the house has a cellar or basement without a concrete bottom. It is necessary to measure the height from the ceiling to the surface layer of soil. This is the depth to which you can dig.

To find out how deep the groundwater lies, you can dig a hole that is small in diameter but deep. Groundwater begins when clearly damp soil appears. This is a sure sign; there is no need to dig further.

Once the approximate water level has become known, you can begin excavation work. It is necessary to outline the location where the septic tank will be located. To do this, you need to outline the pits. To do this, you need to take a construction thread or any strong thread, measure 80 cm. Tie two pegs to both ends.

Insert one end into the middle of the place where you plan to place the first settling tank. Draw a circle. This is the approximate diameter of the desired hole. Next, you need to retreat a meter and draw boundaries for the second container. Next, you need to outline the boundaries of the filtration structure.

Step #1 - selection of consumables and tools

Before you begin, you need to collect all the necessary materials and tools.

To work you will need:

- hammer drill and large concrete drill;

- mixer attachment for the hammer drill;

- shovels and bayonet shovels;

- ladder;

- level:

- buckets;

- container for mixing the solution;

- durable nylon rope;

- hose;

Materials for installing a septic tank made of concrete rings:

- cement;

- sand;

- gravel;

- bitumen or liquid glass;

- metal staples;

- mineral wool or polystyrene foam;

After the equipment for all stages of work has been selected and prepared, you can begin digging a hole.

Step #2 - digging a pit for a septic tank

If you think that it is difficult to excavate such volumes of soil manually, you can use the services of organizations with special equipment.

It is necessary to pour sand at the bottom of the pit, where the lower rings of the containers will be installed. The thickness of the sand cushion is 20-25 cm. The base must be leveled. Next, the sand needs to be shed with water for shrinkage to occur. After compacting the sand base, you can proceed to installing the rings.

Step #3 - installation of sedimentation tanks

To install pre-delivered concrete rings for the septic tank, you need to build a foundation. To do this, wooden formwork is installed around the perimeter of the bottom of the pit. The height of the formwork walls should be 30-40 cm.

After constructing the formwork, you need to lay the reinforcing mesh and dilute the cement mortar. To do this, you need to take 1 part cement to three parts ASG (a mixture of sand and gravel).

You can mix the solution using a construction mixer. You can add two tablespoons of liquid soap to the solution as a plasticizer.This will make the concrete more resistant to pressure and moisture.

After pouring the base, you need to wait 10 - 14 days until the solution hardens and acquires the necessary strength. The formwork does not need to be removed. If rented equipment is used, it is more advisable to purchase ready-made concrete slabs as a base.

Once the base is ready, you can mount the rings. The weight of concrete structures is impressive, so it is necessary to use a crane. Installation of containers occurs in stages.

The first ring is immersed on the concrete base. Following it, the second one is lowered and installed. The ring must be moved smoothly, avoiding bumps or slipping. After installation, bracketing is done.

At the next stage, while the lid is not lowered, it is necessary to seal the seams between the rings. After installing the ceiling, it will become dark in the container and there is a risk of leaving untreated joints. For this, cement mortar is used.

You may also find useful information about waterproofing a septic tank made of concrete rings, in detail disassembled here.

For ease of movement, running brackets are mounted inside the container. They are necessary for servicing the septic tank in case of blockages or depressurization.

The adjacent sedimentation tank is installed in the same manner. In both containers you need to make holes for sewer pipes and install them. The inlet for sewage should be located higher than the overflow pipe between the containers.

Next, you need to install ceilings with openings sufficient for a person to climb down through them.

This completes the installation of a septic tank made of concrete rings, and the installation of a ventilation system follows.

Step #4 - installation of the ventilation system

Ventilation is necessary to allow air to enter the system, which ensures the normal functioning of microorganisms. They process household wastewater and remove the organic component. To ensure constant air circulation, two ventilation pipes are required.

In this case, you will have to lay an electrical cable to warm the pipe, since when warm and cold air collide, condensation forms in it, which blocks the access of oxygen.

It must be secured with fasteners or clamps. The length of the vertical background riser must be no less than the height of the house wall.

Ventilation also gets rid of unpleasant odors that periodically appear from containers and can spread throughout the house. This often happens when there is a long absence of residents and the liquid in the siphon dries out.

The second pipe is installed in the ceiling of the sedimentation tank. To do this, using a perforator, a hole is punched in the ceiling that matches the diameter of the ventilation pipe.

The air duct should rise 70-100 cm above the ground surface.The position of this pipe will be fixed by the weight of the soil and does not require additional fastening.

Another option for solving the problem of unpleasant odor is to install check valve for sewerage, which is installed at the point where the sewer system exits the house.

Step #5 - installation of the filtration system

Next, we will consider step-by-step instructions for arranging an aeration field and a filter well.

Option #1 - arrangement of a filtration field

A pipe emerges from the second concrete tank into a distribution well. For the well, you can use a polyethylene barrel, in which you can cut holes suitable for aeration pipes.

You can purchase a ready-made distribution well.

To do this, you need to purchase pipes based on the size of the field. For a family of four, an area of 20 square meters (10×2) is sufficient. To do this, you will need three pipes 10 m long. In addition, you will need three corner pipes where the ventilation pipes will be mounted.

The field is pre-filled with sand and gravel to improve the absorption capacity of the soil.

Perforated pipes connected to the distribution well are laid on the prepared drainage. Corner pipes are installed at the ends of the aeration pipes, into which a background riser is installed, one for each pipe.

After this, the pipes are covered with geotextiles and filled with a mixture of gravel and sand, then leveled. As silting occurs, the filtration field must be moved or cleaned, changing the drainage.

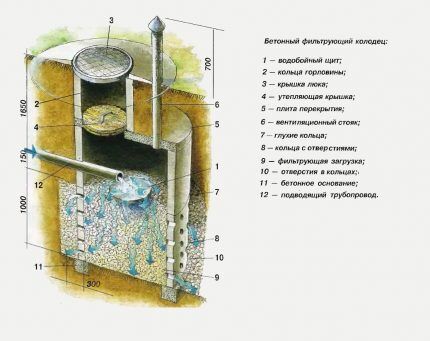

Option #2 - installation of a filter well

A filter well has a number of advantages over an aeration field. It takes up less usable space on the site.

But the quality of purified water will be higher near the aeration field, since before it enters groundwater, the wastewater will be filtered by soil, and its layer under the aeration field is much larger than that of a well with drainage. The well area cannot cope with the amount of wastewater that the aeration section receives.

The well should be installed according to the same principles as sedimentation tanks, excluding concreting the bottom of the tank. In addition to the sand cushion, you need to place crushed stone, gravel, or another filtering compound at the bottom of the well. The standard capacity of a soil filter in an absorption well is 1 m or more.

To increase its throughput, you can supplement the filtration well with side drainage. To install it, the lower concrete ring of the septic tank must be perforated.

This process is best done on the surface, before the ring is lowered into the pit. You also need to make a hole for the overflow of water from the sedimentation tank; it should be located slightly lower than the previous overflow.

The walls and joints of the filter well must be fastened with staples, but there is no need to seal them.By connecting the overflows, you can bury the structure. The first ring must be sprinkled from the outside with crushed stone, up to the junction with the second segment. The rest of the volume can be filled with soil from the plot.

Step #6 - pre-launch preparation process

If the temperature in winter drops below 30 degrees, it is necessary to prepare insulation for the interior manhole covers. Since the container itself is located below the freezing level, it does not require additional insulation.

To insulate the lid, you need to take foam plastic and cut out a circle that fits the diameter of the inner small concrete ring.

Next you need to cut out the lid itself. For this purpose, ordinary plywood of sufficient strength is suitable. You can screw a door handle to it to make it convenient to open. Similarly, it is worth insulating the internal covers of the second sedimentation tank and drainage well.

Before using the septic tank, the first sedimentation tank must be filled with water to 1⁄4 of its volume. Into a filled container add a biological product, which will help the septic tank reach full capacity faster.

After these steps, it is necessary to close the hatches.

Conclusions and useful video on the topic

The video shows the installation process of a two-chamber septic tank step by step:

How a septic system works:

If the construction of a septic system from concrete rings is carried out in compliance with the rules, it will last for 20 years.

We must not forget about the operating rules and carry out maintenance in a timely manner. The pipes are made of plastic, so they are easy to damage. It is strictly prohibited to place equipment or a car in the place where the tanks are located.

Are you building a septic tank on your property? Did you have any questions during the work process? Ask them in the comments to this article - we will try to help you find the right solution in the current situation.

Unfortunately, no one makes a septic tank from concrete rings using the technologies described here. Usually they dig a hole, the bottom is not concreted, a concrete ring is placed, then the next one is placed, and so on until the end. It is done for the natural outflow of liquid sewage and its absorption into the ground; as the well silts up, solid sediment is pumped out.

The service life is also at least 20 years, but this causes soil settlement, erosion of the foundation, and contamination of soil layers and water. When such a sewer becomes silted, when even water cannot drain, the well will have to be moved and the entire sewer system rebuilt.

Thanks for the article, good material. I have a question: is there a strong smell from the settling (first) containers in the summer, when the temperature is up to 40*? And at a summer cottage, provided that the sedimentation tanks fill slowly?