Turnkey gas tank: how to install a gas tank and install equipment

Turnkey projects involve fully completed construction, production or installation of objects that can be used immediately.Owners of private property often choose this method of installing new gas equipment.

Ordering a turnkey gas tank from one organization is much easier than concluding contracts with several companies. In any case, installation is carried out strictly in accordance with the requirements and standards.

In this material we will understand the stages of installation of a turnkey gas tank.

The content of the article:

Advantages of completing a turnkey project

Owners of private housing, wanting to save money, sometimes try to do some of the work themselves. And this is advisable if you have experience in installation or connection and there are no legal barriers.

However, just in the case of organizing an independent gas supply, there are practically no “loopholes” left for independent intervention:

- all installation work, equipping with additional equipment, connection, commissioning must be carried out by an organization that has a special license;

- The development of specifications and the preparation of the project are also carried out by companies with permission;

- Before concluding an agreement with the installers, the owner collects a package of documents (specifications for gasification of the house, title documents for the land, site plan, approvals from many authorities, etc.), which takes a lot of time.

If a home owner is faced with the design and installation of an autonomous gas system for the first time and is a busy person, it is better to immediately contact a private company that has long been successfully engaged in the installation of turnkey gas tanks and maintenance of gas systems.

Representatives of a private company, as a rule, have the necessary connections in various related authorities, so the process of approving documentation will go much faster.

The advantages of the “full package” also include prompt installation of a gas tank, including excavation work, transportation and installation, connection and pressure testing.

If errors occur during the installation process, they are corrected free of charge. Concluding a service agreement (prevention, gas injection) with the company installing the gas tank facilitates repair or replacement of equipment. You can read more about the cost of installing a gas tank in a private house in this material.

Requirements for installation of a gas tank

An autonomous gas storage facility, like a gas pipeline, is a structure with a high degree of danger, therefore there are a number of requirements for the installation and connection of gas equipment.

They are set out in regulatory documents: for example, in PB 03-576-03 you can learn about the installation conditions of pressure vessels, and in SP 62.13330.201 – on the general provisions for the construction of gas distribution systems.

Similar requirements apply to the gas pipeline through which fuel is supplied from the tank to the building:

- the depth of trenches for polyethylene (steel is used extremely rarely) pipes is at least 1.7 m;

- mandatory installation of a condensate collector;

- the slope of the pipe to the condensate collector is 1 cm per 1 m;

- pipes are connected in a permanent way;

- the distance to parallel pipelines is at least 1 m.

When filling trenches, the gas pipeline laying area is marked with a wide signal tape, which is stretched along the entire length of the pipe and covered with soil.

Options for a contract with a contractor

If a home owner is interested in installing a turnkey gas tank, he will have to choose from several options that differ in nuances. To expand the circle of customers, companies offer 3-4 solutions. They are usually called “Economy”, “Standard”, “Optima”, “Premium”, “Lux” and similar names.

The good thing about the choice is that you can choose the optimal package, saving on the same excavation work or concluding a gas supply agreement with another organization.

The main stages of installing a turnkey gas tank

Turnkey installation implies the execution of all stages of autonomous gasification by the company with which the contract is concluded. However, some control on the part of home owners over the activities of installers will not hurt.

Design and selection of a tank

Project documentation is drawn up only after a specialist has visited the site. The choice of gas holder and installation nuances depend on the size of the plot, the location of the house and highways, the composition of the underlying rocks, and the groundwater level.

It is decided on site what tank volume is optimal. This parameter is tied to the area of the house, so even professionals often use correspondence tables.

Having experience in installation work, representatives of the performing company can advise on the choice of a gas equipment manufacturer. However, in practice they are usually distributors of one or more gas tank companies and will therefore recommend their products.

It is logical to assume that it is not profitable for them to offer low-quality tanks, because they bear full responsibility for the safety of the facility.

Read more about the types of gas tanks Further.

Options for gas tanks for cottages:

After inspecting the territory and selecting the equipment, a detailed action plan is drawn up and an estimate is drawn up, taking into account what exactly is included in the concept of “turnkey”.

If any work must be paid additionally, this will be discussed before the work begins. Design documentation is provided along with documents from the customer to obtain permission to install an autonomous gas system.

Preparing the pit and trench

Some companies offering services for autonomous gasification of village houses and country cottages do not include earthworks in a comprehensive turnkey service or include them only in “Lux” packages, that is, the most expensive ones.

Consequently, at the stage of digging a pit and trench, you can save 15-20 thousand rubles. and carry out the land work yourself.

What you need to do for this:

Backfilling is carried out after installation of the gas tank and fittings, connection and testing. River sand is used for backfilling, and only the top layer (20% of the entire backfill) is allowed to use native soil.

Installation of a gas tank in a pit

Transportation of the gas tank is carried out using special equipment. Mini-tanks can be delivered using your own transport, but for cottages, as a rule, large tanks of 2000 liters are used. If there is access to the pit, then the best option is a truck with a manipulator.

Installation is carried out by an organization licensed to work with gas equipment. Independently installing a gas container, connecting a gas pipeline and other equipment to it is strictly prohibited.

Organization of basement entry into the house

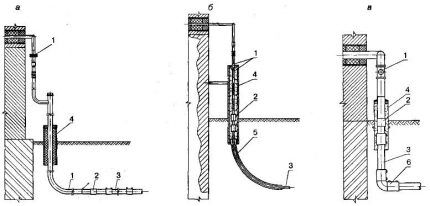

Low-pressure gas is introduced into the building using a special technology called “basement input”.At its core, this is the transition of a polyethylene pipe that goes from a gas tank to a steel pipe that goes inside the house.

For installation of the input, the shortest path is usually chosen. During the installation process, make sure that gas pipes do not intersect with other communications.

Plinth bends are produced in a factory manner according to SNiP 42-103-2003. Dimensions of parts may vary depending on installation conditions.

Do not confuse the two types of base inlet - for liquefied and wet or dried gas. If they are not used for their intended purpose, the fuel supply may be disrupted during frosts.

We also recommend reading the article about at what distance to install a gas tank. More details - go to link.

Connecting gas equipment

After installing the tank on the stove, install the devices without which gas cannot be supplied:

- electrochemical protection against corrosion (anodic-cathodic);

- bellows compensator to ensure linear expansion and compression during ground movements;

- condensate collector to prevent ice jams in frosty times (mounted at the lowest point of the gas pipeline);

- grounding loop and lightning protection system.

On the neck panel that protrudes above the ground, all valves and valves must be in good condition. This applies to the safety and filling valve, pressure gauge with tap, adjusting gear, percentage taps, etc.

A gas pipeline made of HDPE is laid from the reservoir to the basement water. Low-density polyethylene was not chosen as a material for pipes in vain: it is durable, elastic, does not react chemically with fuel, easily withstands soil pressure, and has a long service life.

Unlike the external gas pipeline, the internal one is assembled from steel pipes.They are connected to each other by detachable connections and left open in order to be able to repair or connect additional equipment.

When installing a turnkey gas holder, the internal connection of stoves or boilers is most often not taken into account, except in the most expensive service package. This issue is discussed separately.

Commissioning and backfilling

Commissioning is carried out before backfilling in order to correct possible errors, tighten connections, and provide additional protection for the gas pipeline at the joints.

First, the tank and pipes are pressure tested and purged using pneumatic equipment under a pressure of 50 kg/h, after which leakage is monitored. If everything is normal, the container is filled with gas and all connections are checked again to detect leaks.

All data is entered into the commissioning log, gas sensors are installed (optional), and a thermal shut-off valve is installed. And only after the commissioning work has been completed, the tank is filled with sand.

If the connection package includes installation of internal equipment, you can immediately check the operation of the gas boiler, stove, fireplace, etc. Installation work, like all devices, is guaranteed.

Gas supply system maintenance agreement

Maintenance and refueling of an autonomous gas station are mandatory items, so an agreement for further servicing is concluded either with the organization that installed the gas holder, or with another company (for example, which is located closer or offers lower prices for refueling).

Payment for gas is made in cash at the time of service (according to the meter installed on the gas carrier) or by bank transfer.

System maintenance is divided into planned, unscheduled (repair) and emergency (emergency). The planned one includes inspection of the equipment, checking the functioning of all devices, determining the gas pressure, and, if necessary, setting it up.

The safety valve is being replaced according to schedule. The reservoir is checked for integrity every 4-5 years.

If you have any doubts about whether it is worth installing a gas tank on your site, we suggest reading the article where we compared the installation of a gas tank and main gas. Read more Here.

Conclusions and useful video on the topic

You can learn how gas tanks look and work, how they are installed and refueled, from the following videos filmed by professional installers.

On the nuances of using liquefied gas and autonomous gasification:

Intelligible about installation and fittings:

An example of incorrect installation of a gas tank:

The use of gas in domestic conditions makes life outside the city comfortable, but subject to absolute safety.Professional installation of equipment by a company that has a license and extensive experience is the only option for the correct and legal connection of a gas tank. Turnkey installation in this case looks practical and expedient.

If you have experience installing a turnkey gas tank, share it with our readers. Leave comments in the block below the article. There you can ask questions about the topic of the article.

We want to install a gas tank at our dacha, but I can’t make up my mind yet. But I’m interested in the following question: how safe is the gas tank and, most often, what problems can you encounter? It is clear that only specialists should install it. There are concerns: after all, the gas is under high pressure; could it explode due to a drop or from internal pressure? Is there a possibility of a gas leak?

If the gas holder is installed by specialists and then properly operated, you don’t have to worry too much about safety. Use the services of trusted companies (including for maintenance and refueling); during installation, be sure to request a certificate for the gas tank.

The gas tank must be new, do not settle for a used one, no matter how good it looks. In general, if you follow simple rules, you don’t have to worry about safety. A gas holder is much safer than the same household gas cylinder.

You're starting off on the wrong foot; security is fine with them. But have you looked at the prices for the installation and maintenance of these gas tanks? And you need to get a lot of permits. A gas holder is definitely not an option for a summer residence.