Do-it-yourself electrical panel wiring: current diagrams + detailed assembly instructions

Not only qualified electricians should have knowledge of the basics of installing electrical equipment.It is better for home owners to familiarize themselves with the basic provisions for assembling and operating an electric box that controls the supply of energy to all consumers in the apartment.

Knowing how and in what sequence the electrical panel is switched off, even the owner of an apartment or house who is far from electrical work will be able to quickly respond to a problem in the system - call an electrician or solve the problem on his own.

The content of the article:

Purpose of the electrical panel

Externally, products in which protective and accounting equipment are installed look different. This can be a compact plastic box with tinted glass installed in the hallway, or a large metal panel mounted into the wall on the landing.

We are talking about an electrical panel, which is necessarily present in residential buildings, office buildings, in production - wherever power lines are laid.

Possible installation locations are specified in the regulatory documentation, but largely depend on the purpose of the shield.For example, for private houses, one of the electrical panels, with an electric meter and an input device, is usually installed on the street, on a pole or facade.

Shield functions:

- receiving electricity from the central main line - a power line connected to the house;

- energy distribution among consumer groups or individual lines;

- protection of the electrical network from high loads and short circuits;

- accounting for quality and stabilization of electricity;

- protection of power grid users from electric shock.

Simply put, from proper assembly electrical panel the uninterrupted transmission of electricity to the house, the safety of all residents, as well as the safety of property will depend.

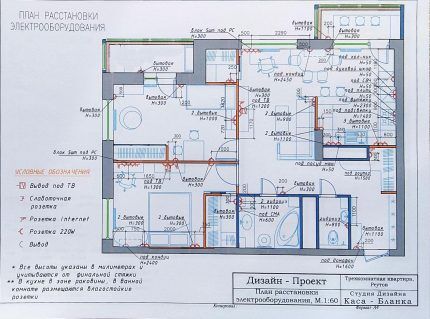

Drawing up a wiring diagram

Calculate the size of the apartment or street sign and you can decide on the choice of protective devices only after drawing up a schematic or installation diagram of the home’s energy supply.

The main thing is to indicate all electrical appliances, lighting equipment and electrical installation devices, as well as their power, voltage and current.

After preparing the wiring diagram, it is necessary to divide all the circuits into separate groups.

To do this, you need to follow the principles:

Now they are producing very powerful equipment, so you should not rely on universal advice; it is better to first study the installation requirements. For example, for some ovens the conductor cross-section must be at least 4 mm², and for water heaters - even 6 mm². Accordingly, machines with 20 or 32 A will be required.

Taking into account the above, a diagram for assembling the electrical panel is drawn up.

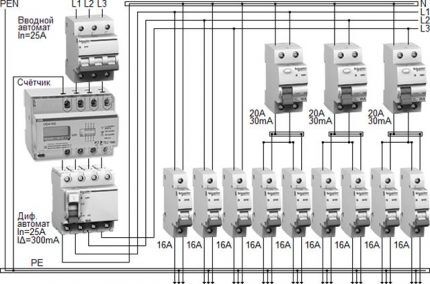

Installation RCD is required, since without it the protection of outlet lines is considered incomplete.The same can be said about dedicated power circuits for powerful equipment - each device requires its own disconnect device.

Equipment ratings: rated current - one step higher than that of the connected machine, differential operating current - 30 mA.

All circuits related to the bathroom or bathtub, connect the RCD with diff. current 10 mA. This may include separate lines for heated floors, washing machines, sockets, and shower stalls.

Selection of electrical installation equipment

Before starting installation, you need to buy the electrical panel itself and all the electrical installations and devices that will make up its contents. It should be taken into account that each item occupies a certain number of mounting spaces on a DIN rail - a metal strip 3.5 cm wide. One or several DIN rails can be located in one box.

One “mounting point” includes a section on the profile 1.75 cm long - a module. The passport of the electrical panel must indicate how many modules it is designed for.

Before choosing a shield, you should add up the number of all modules, and then add to the resulting sum several places that may be useful in the future. As an example, let’s calculate which box is needed for a 1-room apartment.

For 18-20 seats, an electrical panel with 24 modules is suitable.But if the apartment is large, and in the future you plan to purchase new equipment, installation of heated floors or repairs with replacement of wiring, it is better to purchase a box with 36 seats.

If you want to simplify further work, maximize network protection, and make the arrangement of modules convenient, try to choose a panel with a complete set, and this is:

- removable frame with DIN rails;

- entry holes and holders for fastening cables;

- two tires, working and protective zero - with stands and installation sites;

- set of fastenings for installation;

- organizers for wires.

Shields can be metal or plastic, built-in or mounted.

Let's look at how they differ fundamentally.

Experienced electricians recommend working with one shop. The advantages of purchasing from a large supplier are a large assortment of goods and a guarantee of receiving original products and not counterfeits. Therefore, it is better to purchase both the shield and the rest of the electrical installation products in one place.

In addition to the metering device and protective devices, you will need:

- combs for several poles with end caps - for connecting modules to each other, simplifying installation and saving space;

- 2-3 meters of PV1 wire with a cross-section similar to the input cable and color-coded insulation;

- zero busbars or cross-modules for group RCDs;

- clamps and ties for organizing conductors;

- limiters for DIN rails;

- plugs for masking empty spaces.

If financial capabilities allow, then it is better to select equipment from one trusted manufacturer - Hager, ABB, Legrand, Schneider Electric. Devices of the same brand are easier to install, and the shield will look much more aesthetically pleasing.

Step-by-step installation and assembly instructions

According to GOST and PUE standards, panels must be located in a well-lit, ventilated room, the humidity level in which is not higher than 60%. The installation height is not lower than 1.4 m, the distance to jambs and corners is not less than 15 cm. Gas pipes should not pass nearby.

Mounting a hanging panel is no more difficult than a bookshelf - the structure is supported by dowels driven into the wall. Therefore, we will consider the option of installing it in a concrete or brick wall.

Stage 1 - mounting the housing into the wall

Before installation, you should have the electric box in your hands so that you can clarify its dimensions and then use the case for fitting.

We start with markings - using a level, draw a straight line indicating the place where the bottom of the box will be located. Then we apply the body and trace it along the contour with a marker.

Next we use a hammer drill to knock out pieces of concrete (or brick) between the cuts. Carefully level the inner surface of the niche using a hand chisel.

We try to see if the housing fits into the niche, if everything is fine, we screw the mounting kit to it and insert it into place. We drill holes for the dowels and fasten them with dowels and nails.

There remains a gap between the panel body and the wall - we fill it with alabaster or an alternative building mixture, and then mask it with finishing along with the rest of the wall surface.

Stage 2 - cable entry and termination

Modern electrical boxes have holes for wires. They are located on different sides, but not all need to be used. The required holes are extruded along perforated lines. Their standard size is 16/20 mm, designed for input corrugated pipes, into which wires are placed for insulation.

Operating procedure:

- squeeze out the plates or remove the plugs;

- cut the corrugated pipe of the cables at the walls of the box;

- we insert the power supply cable inside the shield housing so that it is near the input machine mount, that is, in the upper left corner;

- attach the cable to the eyelet or other fastening element and secure it with a tie;

- We mark by insulation or heat shrink.

We repeat all the steps with the remaining cables leading to consumers.

As you know, all cables are protected by double insulation. The top layer is not required for switching wires inside the electrical panel, so it needs to be removed.

But you will need additional marking of each wire, since after intertwining the wires it will be difficult to guess which line leads where. For marking we use masking tape, which can be easily applied.

After cutting the cables, the shield is ready to install the already assembled frame. Typically, during the assembly process finishing work is carried out, during which it is better to cover the insides of the case.

To do this, use either a cardboard plug that comes with the shield, or a self-cut cover.

Stage 3 - assembly of modules on the frame

For work you will need slotted and Phillips screwdrivers, stripper, round nose pliers, pliers, wire cutters, hacksaw, construction knife, screwdriver, tester.

The modules are arranged according to a linear or group scheme:

- linear – first they install RCDs and automatic devices, then AB devices;

- group – first the RCD/difavtomatic device, then the machines connected to it, again the RCD, etc.

Will familiarize you with the differences in the design and principles of operation of RCDs and difavtomats next article, covering this difficult issue in detail.

The first option is easier to install, and the second is more convenient when you need to find a problem on the network. It should be remembered that the wires enter from the top and exit from the bottom. The cross-section of the conductors inside and outside the box must be the same. It is advisable to connect devices with single pieces of wires, and not combined from different sections.

Assembly instructions:

The frame is assembled, all that remains is to install it in the electrical panel housing and connect it to the power cable and consumer wires.

Stage 4 - connecting circuits and testing

The frame, completely ready for use, must be inserted into a wall-mounted or wall-mounted housing. This stage is carried out only after the mortar has dried, or better yet, after all finishing work has been completed.

Then we proceed according to plan:

- We turn off the power to the panel, let others know so that they don’t accidentally connect it (in words or using a sign).

- We remove the protective cover and any debris that has gotten inside the case, bend the wires inserted into the box upward.

- We insert the assembled frame and secure it with self-tapping screws.

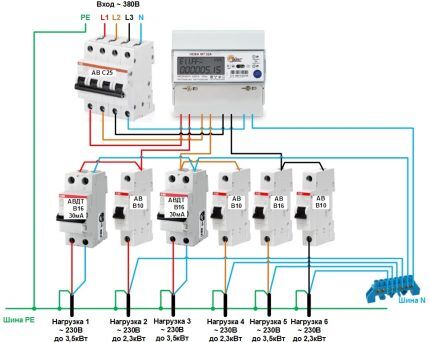

- We mount two buses - N and PE, and it is better to fix the second one where the wires go, for example, from below.

- We distribute the wires according to their intended purpose (separately phase, neutral and ground), and fasten the groups with ties.

- We direct the yellow-green ground wires to the PE bus, leave a small margin, mark and connect.

- We direct groups of blue wires of the working zero to the buses of group RCDs, mark them and connect them.

- We connect the remaining blue wires and the neutral of the input cable to the common bus, mark them and connect them.

- We direct the phase wires to the modular devices, trying to lead them on the other side opposite the neutral cables. Label, connect to contacts circuit breakers AB and difavtomatov.

- We connect the input cable to the upper terminals of the input machine and connect it.

Connection to the buses is relevant if it has not previously been made directly in the frame. After connecting all conductors to the corresponding terminals of buses or modular devices, we check and tighten the fasteners.

All devices on the electrical panel must be turned off before commissioning. At the same time, all electrical installations in the apartment - lighting fixtures, household appliances, sockets - must be brought into operation mode.

We do it one by one connection of automatic machines and RCDs, we test using a special button and turn it on again after disconnecting. Let's move on to the machines, check if there is voltage at the input terminals. Then we turn them on and check the voltage at the output.

Lastly, we check the operation of dedicated lines for powerful equipment.We turn on the oven, washing machine, air conditioner one by one, and monitor the functioning of the appliances. If you are satisfied with the result, hang the door and lock the electrical panel.

Conclusions and useful video on the topic

Video #1. Electrical panel assembly option:

Video #2. Assembly instructions and recommendations for a 72-module panel:

You can assemble the electrical panel yourself, but checking the installation and connection by a qualified electrician is mandatory.. Without an appropriate conclusion, the organization supplying the house with electricity will simply block the line.

Would you like to talk about your own experience in electrical installation work? Do you have useful information that could be useful to independent novice electricians? Please write comments in the block below, post photos and ask questions about the topic of the article.