Building an eco-house with your own hands: technological principles and diagrams

Autonomous ecological housing, fully equipped with effective support systems, is able to “maintain” itself.And without causing harm to the environment. But it’s quite possible to build it and equip it with smart technology.

We will tell you how to build an eco-house with your own hands, using exclusively natural building materials - clay, sand, straw, wood. For you, we have collected, studied and presented information about the most promising options. They described in detail the technology for constructing environmentally friendly housing.

The recommendations we provide will provide effective assistance to beginning builders. To facilitate the understanding of a difficult topic, photo selections, informative diagrams, and video instructions are attached to the text.

The content of the article:

Construction of an eco-house: dream or reality

Interest in the construction of eco-houses is growing every day - projects that previously seemed fantastic are being brought to life and showing amazing results. Some principles of eco-friendly housing are familiar to anyone who has lived or vacationed in a village.

To this day, outside the city, houses are built from rounded logs, timber, bricks - that is, natural materials that do not contain harmful artificial impurities.

Advanced villagers and summer residents have long installed septic tanks and biological stations - compact modern waste processing systems. Household plums decompose naturally, then the solid sediment is used as fertilizer, and the liquid is purified (up to 98%) and put into secondary use - for watering the garden or vegetable garden, and maintaining the territory.

Of course, with heating system everything is different: as before, the main source of heat is either an electric (gas, gasoline, coal) boiler or a stove, which is heated in the old fashioned way with wood. In environmentally friendly systems, the use of natural fuel (gas, coal, firewood, petroleum products) is excluded.

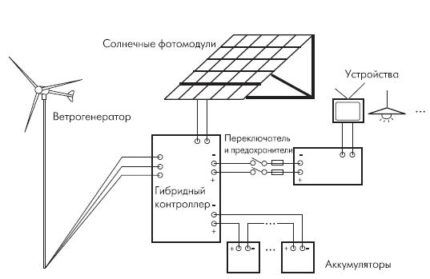

The following are recognized as optimal sources of energy and heat:

- hydrodynamic heat generator with cavitator;

- solar powered system;

- wind home generators;

- biogas plants (for farms).

Operation smart heating systems, energy saving and waste recycling are combined, and the result is complete autonomous maintenance of the house without any air or soil pollution.

It turns out that if you wish, you can build an absolutely “clean” house yourself, especially since there are plenty of examples - in the countries of Scandinavia, Austria, Germany, Denmark, and Great Britain, hundreds of ecological housing projects are being developed, not only by nature lovers and representatives of “green” groups, but and government agencies.

Principles of designing eco-friendly houses

If you still take a chance and decide to build an eco-friendly house with your own hands, you need to start with a project - detailed planning of all stages of building construction and connecting life support systems.

The first stage is choosing a construction site. The most favorable site is a flat area with a water source close to it, open to sunlight and wind. If northern winds often blow in the region, if possible, the northern part of the house should be protected (for example, by planting tall coniferous trees).

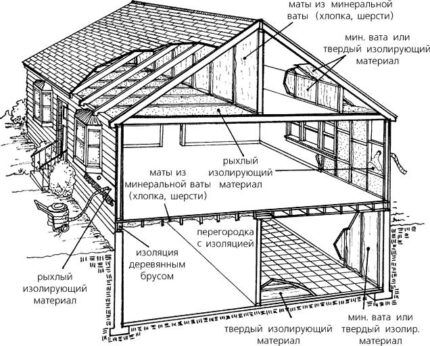

The second stage is to determine the nuances of building an eco-house. Thermal insulation of a house plays an important role - the more efficient the natural protection system is, the less energy will be spent on heating.

To increase the thermal insulation properties, several techniques are used, for example:

- strengthening thermal protection in areas with “cold bridges”;

- construction of a multi-layer wall structure (up to 4 layers with gaps filled with mineral insulation, waste from the cellulose or cotton industry);

- additional insulation of the foundation and basement.

An interesting architectural solution for the northern regions is the division of space into “winter” and “summer”. As you know, our ancestors also had a winter hut (with a Russian stove) and a summer one, which was not heated.

A lot of energy goes into keeping light bulbs running, so you should maximize natural light. To do this, one wall of the main room can be made of glass, using triple glazed windows with wooden frames and impact-resistant glass.

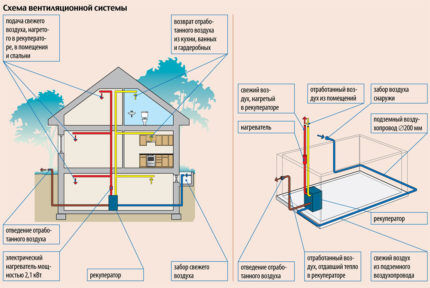

The airtightness of the house will be extreme, so it is worth thinking about ventilation. The more useful qualities are incorporated during construction, the less energy will be required to provide the residential area with heat, light, and clean water.

Secrets of planning: drawings and diagrams

Visualization of the project simplifies its implementation, and sketches, drawings, diagrams indicating the exact location, specific parameters and materials help “launch” the process of completing the task.

We remember that the construction of a house (including with the eco prefix) cannot be started without permits from government agencies, which give the go-ahead only after a thorough study of the project. We recommend that “serious” documentation be drawn up together with design engineers to avoid protracted red tape.

What needs to be displayed on diagrams for the construction of eco-houses? Anything that causes even the slightest difficulty - for example, location ventilation system.

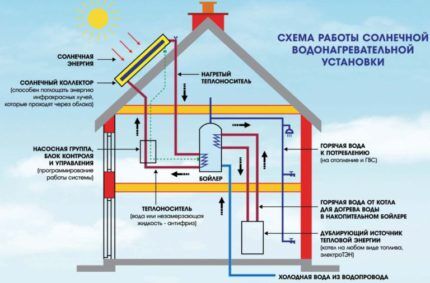

Saving energy generated solar panels, also implies the equipment of a complex set of various systems, including hot water supply.

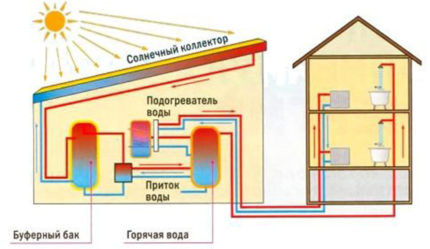

Here is another option for installing a solar system with a water collector. The disadvantage of such systems is that the heated water can only be used as a coolant or sanitary water. Moreover, only immediately after heating.

For those wishing to accumulate solar energy and use it to charge household appliances, it is better to build a solar system from solar panels.

It is irrational to install wind generators in regions with forest plantations or other protection from the wind, but on the seashores, reservoirs, in the steppes and mountains they justify the installation costs.

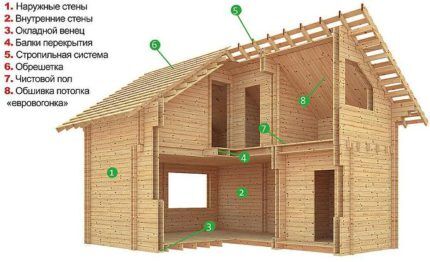

Before building a country house or village house from timber or logs, it is necessary to consider the arrangement of a heat-insulating layer.

This is the kind of house scientists from Wales came up with. It spends less energy than it produces. A miniature “electrical factory” is a standard project, meaning anyone can buy a house. It is said to cost almost the same as a regular house.

Ready-made diagrams can be found on the websites of companies involved in the construction of eco-houses and passive energy-saving buildings.

Now let’s take a closer look at two projects - the construction of eco-houses from straw and firewood with the addition of clay, which plays the role of a binding material.

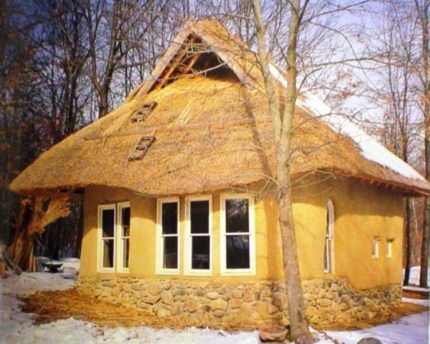

Construction of an eco-house from straw and clay

Straw with excellent heat-saving qualities, has long been used in peasant houses - it was used to cover roofs, stuff mattresses, and insulate grooves between logs. In the southern regions you can find huts made entirely of straw bales.

Knowing the properties of the material and the features of the frame assembly technology, you can build a “straw house” on your own.

Pros and cons of straw bale

The first thing worth noting is the availability of the main building material. It is obtained as a result of growing and processing agricultural crops (legumes, grains, hemp, flax, etc.).

Grains, inflorescences, and seeds go into further processing, and the stems with the remains of leaves are dried and sent to feed livestock. Straw is also suitable for making rustic decor.

With the growing demand for environmentally friendly raw materials, a whole industry has emerged for the production of adobe bricks (a building material made from pressed straw and clay) and biofuels.

Adobe and just straw bales are actively used for the construction of private houses, as they have the following qualities:

- have a low degree of thermal conductivity;

- do not ignite, but only smolder (we are talking about pressed plastered material);

- do not contain chemical inclusions;

- have a budget price.

The disadvantages are hygroscopicity and the associated predisposition to rapid decay. In addition, straw bales are an attractive place for rodents, who also value environmental friendliness.

To get rid of the shortcomings, they increase the density of the building material to 300 kg/m³, reinforce the blocks and cover them with plaster with the addition of slaked lime.

Rules for preparing material

To build a house faster, you can purchase ready-made straw bales or adobe bricks. Both options are easy to prepare on your own, having prepared a sufficient amount of material in advance. The procurement period occurs at the end of summer or autumn - harvest time.

Only during this period do dry stems fully correspond in their characteristics. Straw rarely survives until spring without changes, as it deteriorates due to dampness and becomes moldy.

To store the material, it is necessary to build a large barn with a strong insulated roof, a dry microclimate and good natural ventilation. Mats also made from straw (preferably rye, since that’s what mice don’t like) are used as natural insulation.

Construction of foundation and frame

While the material is “ripening”, the foundation can be prepared. It is equipped according to the usual scheme for a frame house. Experts recommend a lightweight belt version because the bales are light in weight.

For the foundation, a shallow pit is dug, formwork is knocked together from boards around the perimeter and filled with a thick mixture of clay and sand. By the way, straw is sometimes added to the foundation of the house.

Until the clay sets, metal reinforcement is fixed in the corners and along the walls for future strapping. Then, when the foundation is stronger, a frame is assembled from wooden beams (15 cm x 15 cm). First of all, fix the corner posts, then the auxiliary supports for the walls. Horizontal elements are added to the vertical elements - boards or bars of smaller cross-section.

Straw bale tying

The blocks are stacked alternately, in rows, according to the principle of brickwork. The seams between the rows are caulked. Each block is secured with a metal rod and strapping. After filling the entire frame, shingles are made diagonally with thin boards to give the walls more stability. The roof is installed at the very end, using conventional technology.

The resulting seams and gaps are sealed with adobe mixture. If protection from rodents is necessary, the walls around the entire perimeter are covered with a metal mesh with a fine mesh. Sometimes a second layer of thinner straw mats is laid out for insulation.

The outer part of the thatched hut is plastered with a lime mixture (2.5-3 cm thick) and decorated with white or colored paint. Ultramarine, umber, violet cobalt, red lead and chromium oxide are used as colors.

The last stage is interior finishing, which simultaneously involves equipping the building and the adjacent area with life support systems.

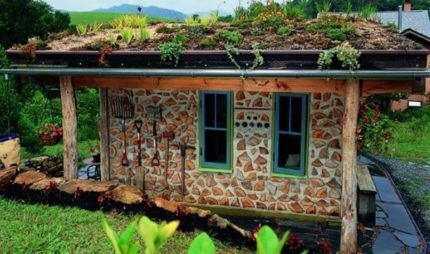

Technology for constructing a building from wood and clay

Firewood, which is perceived by everyone as a traditional but obsolete type of fuel, can be used differently - as a material for building walls.

For the technology of constructing buildings from logs in Russia they came up with an interesting name - “clay mortar”, and in America, where this construction method is also known, it is called Cordwood. If a house made from wood is equipped with a smart energy saving system, then it can be safely classified as environmentally friendly and does not pollute the environment.

Advantages of the clay pot method

Ancient buildings with walls made of wooden blocks held together with clay mortar have been found all over the world.Some of them are several hundred years old, which means that the technology is justified, at least in terms of strength and stability. Having wall thicknesses from 15 cm to 45 cm, the houses not only retained their shape, but also still function.

Clay and pieces of wood are not only the main, but also the only materials for masonry. They complement each other perfectly, creating a pleasant, comfortable microclimate for living in the house.

People who have lived in houses like cordwood masonry claim that they are quite warm in winter, and amazingly cool in the summer heat. The walls absorb excess moisture and keep it inside.

Another advantage of natural material is its low cost. Residents of secluded communities, living far from cities and accustomed to saving on everything, willingly use wood to build housing, including “clay” ones.

Features of building houses from chocks

The method of assembling a clay “woodpile” is reminiscent of ordinary brickwork, with the difference that the logs can have different diameters and shapes. Their length is equal to the width of the wall, so they should be the same.

For central Russia, it is recommended to use logs 50-60 cm long, for northern regions - up to 80 cm. The long length is explained by the fact that the longitudinal thermal conductivity of wood is 2 times higher than the transverse one.

The clay solution is prepared as follows:

- take clay and sand, mix it with water;

- add chopped straw as a reinforcing element;

- bring to the desired consistency;

- laid on firewood like mortar.

For strength, cement is sometimes used instead of clay, lime is added, and then the technology turns into “chock concrete.” It's a little different from the previous one. The cement mixture is spread only along the edges of the logs, and the middle is filled with insulation - adobe mortar or sawdust mixed with lime.

As a finishing layer, plaster is used, also made from natural ingredients. To soften the structure of the finishing solution, manure is added to the clay - a natural antiseptic.

The clay mortar hardens for at least one and a half months - during the entire period the walls must be kept dry. To do this, a large canopy is erected over the building body. As the clay dries, it will crack, so it is necessary to regularly cover the cracks and monitor the integrity of the structure.

Recommendations for beginning builders

If you decide to buy a house made of logs, start preparing the wood about a year before the start of construction. It must be dried for at least 10 months so that the structure does not deform in the future.

For a small country house with an area of 40 m², you will need about 30 m³ of wood. It is better to take not round logs, which can crack along the fibers during the laying process, but chopped firewood, freed from the bark. The length of the blanks is 50-60 cm.

The same length of logs can be easily achieved using a bench saw, but some people can easily cope with the task by placing the logs on regular sawhorses. On one side they make an emphasis, on the other, at a certain distance, they make a mark - along it they make a cut.

The procedure for building a house:

- installation of a strip foundation;

- assembly of the frame (with a circular laying principle it is not needed);

- step-by-step laying of a “woodpile” with openings for windows and doors;

- pause for clay maturation (at least 2 months);

- roof construction;

- plastering and interior finishing.

When constructing walls, you can use traditional technologies. For example, timber is used for corner trim. To ensure that the firewood lies evenly, a large shield is placed vertically on one side - it acts as a limiter. To increase the horizontal stability of the structure, it is recommended to lay barbed wire after every 4 rows.

Conclusions and useful video on the topic

Thematic videos will help you understand the nuances of building eco-houses.

Video #1. Review of eco-friendly houses:

Video #2. Film about the construction of an adobe house in a northern eco-village:

Video #3. Do-it-yourself clay pot technology:

As you can see, it is quite possible to build a house using one of the well-known eco-technologies on your own. You can start not with a residential building, but with a small utility room, summer kitchen or country decor. Try to apply the principles of building an energy-efficient home - it will be a small step into the future and a wonderful personal experience.

Would you like to tell us about another original way of constructing and furnishing an eco-house? Do you have any questions while reading the information we provide? Please write comments in the block below.

In my opinion, building a completely environmentally friendly house, with the installation of autonomous power supply, water drainage, etc., is a luxury for most people today. Too much financial investment is required at the initial stage for a house to be truly environmentally friendly and not harmful to the environment. Perhaps these investments will pay off, but not everyone has enough money to invest them one-time in such a project.

Yes, an eco-house is certainly a dream. But if recycling waste and drains is no longer new, then how much does solar heating save you from the cold in winter at minus 20? You write about European countries where eco-heating is practiced, but they also have Euro-winter, unlike Ukraine. You need to think carefully about the idea of an eco-house before construction, study already successful projects in your geographical area, and then get started.

Yes, you are right, in our latitudes the efficiency of solar panels decreases significantly in winter, but this does not mean that this indicator is zero. The lowest efficiency indicators of solar panels are three months of the year: November, December, January.

I propose to consider an example of the operation of a solar station for a 5 kW home. I am attaching a diagram showing the output of the modules and the station.As you can see, the peak efficiency occurs in May-August, which means that during these four months the station can be an autonomous source of energy for the home. A station with greater power will be able to provide the house with an autonomous energy supply during the period April-October.

My husband and I have always dreamed of an eco-friendly house, and finally our dream is slowly starting to come true. Yes, construction using such technologies is not cheap, but then it will only pay for itself throughout the life of our house. Of course, solar panels were installed - I think this is the first thing people think about when it comes to the environmental situation. But we also took care of the central heating supply - ecology is ecology, but in the cold winter you want to live warm)

And what, you want to say that solar panels are the only source of energy in this eco-house? To be honest, I can't believe it. In general, the concept of a completely eco-friendly house seems to me unrealistic in Russian conditions.

I will say this - nothing is impossible, but everything depends on a limited budget. Building the house itself from environmentally friendly materials is not a problem; the article presents more than one budget option. The problem here is different, namely, to make the housing completely autonomous, otherwise it will not be environmentally friendly. Unless the electricity comes from local solar and wind power plants, which is unlikely.

It is clear that in the period from May to October you can get by with solar panels, but in winter they will barely be enough for heating. Perhaps the best option would be to arrange geothermal heating at home - an environmentally friendly solution that does not require large amounts of electricity. With this option, a completely autonomous house is already possible.

Eco-friendly houses made from TERMOMONOLIT panels are inexpensive to breathe, heat and noise insulating, earthquake resistant, fire resistant and are cheaper than any material purchased on the market + has a number of advantages.

The mass of buildings exceeds the volume of any building materials. Affordable construction prices, any finishing, environmental friendliness and ease of construction, durability in any conditions.