Do-it-yourself wind generator from a washing machine: instructions for assembling a windmill

Electricity is an expensive resource, and its environmental safety is questionable, because...Hydrocarbons are used to generate electricity. This depletes the mineral resources and poisons the environment. It turns out that you can power your home with wind energy. Agree, it would be nice to have a backup source of electricity, especially in areas where there are frequent power outages.

Conversion units are too expensive, but with some effort they can be assembled yourself. Let's try to figure out how to assemble a wind generator with your own hands from a washing machine.

Next, we will tell you what materials and tools you will need for the job. In the article you will find diagrams of a wind generator from a washing machine, expert advice on assembly and operation, as well as videos that clearly demonstrate the assembly of the device.

The content of the article:

Design and features of using a windmill

Wind generators are rarely used as the main sources of electricity, but they are ideal as additional or alternative ones.

This is a good solution for dachas and private houses located in areas where there are often problems with electricity.

Homemade wind generator from a screwdriver, car generator or a washing machine engine will cost literally pennies, but will help save decent amounts on energy bills.

This is a good option for thrifty owners who do not want to overpay and are willing to make some efforts to reduce costs.

A standard wind generator consists of several mechanical devices, the function of which is to convert wind kinetic energy into mechanical, and then into electrical. We recommend you look at the article about wind generator device and its operating principle.

Most modern models are equipped with three blades to increase efficiency and begin to work when the wind speed reaches at least 2-3 m/s.

Wind speed is a fundamentally important indicator on which the power of the installation directly depends.

The technical documentation for industrial wind generators always indicates the nominal wind speed parameters at which the installation operates with maximum efficiency. Most often this figure is 9-10 m/s.

There are also parameters for the maximum permissible wind speed - 25 m/s.With such indicators, the efficiency of the wind turbine is already significantly reduced, because the blades of the installation change position. If we are talking about a homemade design, it is difficult to determine its technical characteristics.

It makes sense to focus on average indicators and calculate the amount of energy required for basic needs.

If you need to make a homemade 220V windmill, we recommend that you read the detailed assembly instructions.

What energy costs can the installation cover?

Installing a wind generator is cost-effective if the wind speed reaches 4 m/s.

In this case, almost all needs can be met:

- A device with a power of 0.15-0.2 kW will allow you to switch room lighting to eco-energy. You can also connect a computer or TV.

- A wind turbine with a power of 1-5 kW is enough to power basic household appliances, including a refrigerator and a washing machine.

- For autonomous operation of all devices and systems, including the heating system, you need a 20 kW wind generator.

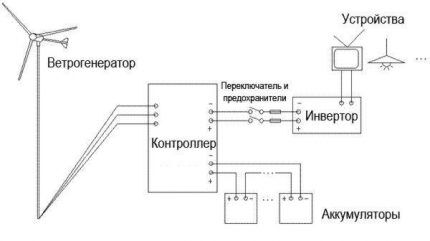

When designing and assembling a windmill from a washing machine engine, the instability of wind speed must be taken into account. Electricity can disappear at any second, so equipment should not be connected directly to the generator.

Requires batteries and charge controller, because electrical appliances require a voltage of 220V.

Types of wind generators and their operating principles

Both industrial and homemade wind generators are different.

They are classified according to several criteria:

- Features of rotor rotation with blades attached to it - vertical or horizontal. The former react less to negative environmental factors, while the latter are characterized by higher efficiency.

- Number of blades. Three-blade installations are considered the most practical, but there may be more or fewer blades.

- Material. For the manufacture of blades, various materials are used - hard or sailing. The former are usually more durable, while the latter are cheaper.

- Blade pitch. It can be fixed or changeable.

When making a wind generator with your own hands, you have to decide on the design yourself. In this case, it is necessary to calculate the required power and take into account the operating conditions of the installation. We reviewed the detailed calculation of a wind generator using formulas In this article.

Horizontal windmills are convenient because their creation does not require high-precision calculations; the design itself is easier to manufacture and starts at the slightest wind. Cons: loud noise during operation and bulkiness.

A vertical wind generator is suitable for people who are willing to spend time and effort on assembling and maintaining a complex but compact design. We recommend watching the step-by-step instructions for manufacturing of a vertical wind generator with your own hands.

A wind generator operates by rotating blades attached to a rotor. The rotor itself is fixed on the generator shaft, which generates electric current. The energy is transferred to batteries.Here it accumulates and powers household electrical appliances.

The wind turbine is equipped with a controller that converts three-phase alternating current into direct current and controls battery charging. The installation diagram must take into account that an inverter must be connected after the battery.

Comparing the pros and cons of installation

Wind generators have been used for many years, their designs are constantly being improved, and wind is an easily accessible source of energy.

Devices powered by it are absolutely safe for the environment and convenient, because... are located on masts and do not occupy useful space. They are easy to maintain and repair.

Windmills make noise when operating. The sound may be louder or quieter, but it is always there. Sometimes this bothers home owners and even neighbors.

There are other inconveniences that can be noted. Wind is an unpredictable element, so the operation of generators is unstable and it is necessary to accumulate energy so as not to be left without electricity during periods of calm.

Instructions for assembling a windmill from a washing machine

Let's look at how to assemble a simple installation with your own hands, using an electric motor from a washing machine as a basis.

Stage #1 - preparing the necessary materials

To create a homemade windmill from a washing machine engine, you need to purchase several parts.

Some of them will probably be found in old household appliances, and some will have to be purchased:

- rotor with blades - make blades you can do it yourself;

- a gearbox that will regulate the speed of rotation of the windmill rotor;

- a casing designed to protect windmill elements from moisture and other negative environmental factors;

- a battery, the function of which is to store energy and power electrical appliances when the blades are not rotating;

- inverter for current transformation;

- the tail section, with the help of which the installation turns in the wind;

- the mast on which the structure will be attached.

All these parts cost money individually, and to assemble them into a complete structure will take a lot of time.

To make a generator, you will need a 1.5 kW electric motor from a washing machine.

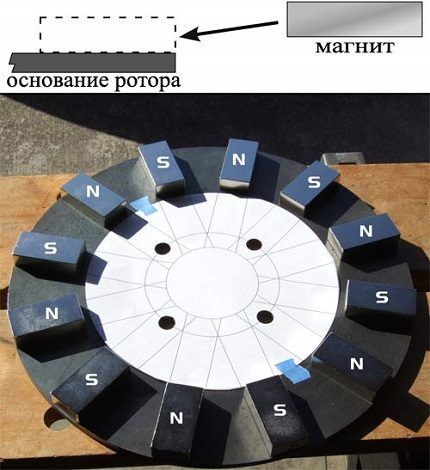

You will also need to buy 32 neodymium magnets of 0.5, 1, 2 cm, glue, sandpaper and cold welding or epoxy resin.

Neodymium magnets can be ordered online or purchased at offline retail outlets. They will need to be installed on the rotor.

Stage #2 - manufacturing the windmill frame

The cores are removed from the rotor of an asynchronous motor and partially cut off using a lathe (depth 2 mm). Grooves 5 mm deep are cut into the cores.

When the cores are ready, you need to install the magnets in their proper places. First, they make a tin covering for the core, after which the magnets are placed at an equal distance from each other.

It is important to maintain the correct distance, otherwise over time the magnets will stick together and the power of the wind generator will decrease significantly.

The finished template with magnets is placed on the rotor, and the gaps are filled with elastic cold welding or epoxy resin. When the work is finished, you need to carefully clamp the rotor in a vice and sand the surfaces with sandpaper.

All that remains is to ensure the strength of the housing and bearing bolts. If parts are worn out, it is better to replace them.

Stage #3 - checking the functionality of the homemade product

To test the assembled generator, you will need some additional devices:

- battery;

- rectifier;

- controller;

- tester.

First, it is determined which two wires lead to the working winding, and all the others are removed. These wires are connected to the rectifier, which in turn is connected to the controller connected to the battery. The system is ready for testing.

The power of the generator is checked as follows: the voltmeter probes are connected to the battery, and the assembled device is spun using a conventional drill or screwdriver (the speed should be at least 800 rpm, preferably 1000). Voltmeter readings of 200-300 V are considered good.

When assembling a wind turbine with a generator from a washing machine, difficulties arise with the manufacture of the impeller. You need to choose a durable but lightweight material.

A good solution is blades made from pieces of fiberglass. They are lightweight, but at the same time durable and wear-resistant. Steel pipes with a diameter of 32 mm are suitable for the mast.

So you see, assembling a windmill is not that difficult, but you will need to spend time and select the right materials.

If you order a ready-made wind station with installation, you will have to pay 70-80 thousand rubles. But a wind generator assembled from a washing machine engine will cost no more than 3.5 thousand rubles.

The difference in price is so noticeable that the decision to assemble and install a wind turbine yourself seems advisable. As a result, you can get a device with a power of 2.5 kW, and this is quite enough to operate home appliances.

If you don’t want to fool yourself with calculations, searching and purchasing materials and assembly, you can always purchase a ready-made installation. We discussed in detail what types of commercial wind generators there are and how to choose the best one in another article.

Conclusions and useful video on the topic

Self-assembly of any technical devices is a complex task that requires attention to detail. When it comes to power systems, the work must be done especially carefully. We offer video instructions that will help you avoid mistakes.

You can see how a homemade wind generator looks and works in the video:

Description of the process of assembling a wind generator from a washing machine:

Unnecessary household appliances can help out in the most unexpected situations. A hopelessly outdated washing machine can become a new source of “green energy”.

The wind generator will last for many years and will help you save a lot of money. The best part is that such a transformation will cost a reasonable amount. The main thing is to search, learn from other people’s experiences and not be afraid to experiment.

Have you assembled a wind generator yourself using an electric motor from a washing machine? Share a photo of your homemade product and your assembly experience - leave a comment under this article.

Or maybe you are just starting to assemble the installation and you have questions that we have not touched upon in this material - ask them, and we will try to help you with practical advice.

Of course, it is useful to be able to assemble a wind generator yourself. You never know, you might suddenly find yourself on a desert island :) But the question that arises is whether it will work at full capacity, given the artisanal method of production. Not all Chinese products made in factories work as they should, but here you do it yourself. Moreover, I would like to note the uselessness of wind generators in Russia - there is little wind, there are cheap energy resources. In general, it would be interesting, but useless to build a wind generator yourself.

In a factory, a worker assembles dozens and sometimes hundreds of devices per shift (alternatively, a robot assembles and the worker controls), so in pursuit of numbers, he cannot always devote an adequate amount of time to each product. Hence the low quality. You will devote all your attention and time to one single wind generator. Even the initial directness of the hands is not so important; there would be a desire to learn and do it.

Do you go into the forest/taiga, build your own log house there like in Alaska, and expect cheap energy from the state? Now tell us about the gasification or electrification project in your hole?

If you try, absolutely anyone can assemble a wind generator with their own hands. My husband repurposed an old metal barrel and installed it directly on the roof.The main thing is to protect the body itself from precipitation. Of course, the efficiency of the power generator will depend on the complexity and efficiency of the design. But even the simplest option brings considerable benefits.

garage wind energy is a complex science and it is not given to everyone... and those who are not given it will constantly complain about the wind... and there are a lot of sofa YouTube wind-generalissimos... ahhhh, I would like to hear the opinion of "Aftar" about the use of single-phase generators asynchronous in standard. execution...

Hello Larisa, can you find out more about your wind generator?