Operating principle and design of a typical water supply pumping station

Believe me, a private house can be equipped with such a high level of comfort that living in it will become much more convenient than in a city apartment.In any case, the water supply can be used with no less convenience. In the same way, to get water you will only need to open the tap, which is not yet very compatible with suburban infrastructure, do you agree?

But this is not a “rosy” dream at all. To implement the idea, it is enough to include a pumping station in the water supply scheme. She will do a colossal amount of difficult physical work for her owners. True, to properly connect and operate it, you need to know the equipment design well.

We offer you valuable information about the specifics of using this technology. Our article will help you understand the operating principle of the pumping station and introduce you to the installation rules. The information we provide is supplemented with extremely clear diagrams, photo collections and video tutorials.

The content of the article:

Water supply station design

For organization water supply in a private house stores offer pumping stations in the form of a compact unit consisting of a hydraulic tank, an automation unit and an electric pump. It is also possible to assemble a similar water supply installation from individual parts and equipment.

Both options are acceptable, but it is better to choose a ready-made kit with a manufacturer's warranty. This will be cheaper and more practical for future maintenance.

Main operating components

The design of a factory-assembled water supply pumping station differs from a surface pump in the presence of a pressure control system.

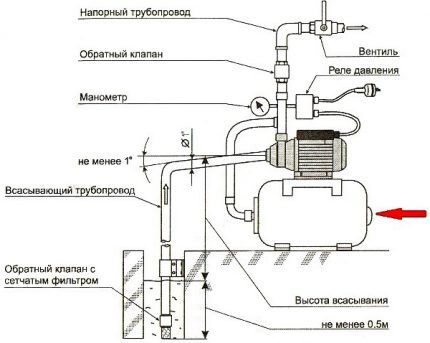

The composition includes the following functional components:

- Surface electric pump.

- Hydraulic accumulator with nipple and internal rubber bulb.

- Pressure gauge.

- Pressure switch.

- Connecting fittings.

To draw water, a suction pipe with a check valve and a strainer is connected to it. And a line is connected to the outlet of the installation, transporting the pumped liquid to the points of consumption. Moreover, if the station has a built-in filter and valve, then the suction hose does not need to be supplemented with them.

A hydraulic membrane tank, coupled with a centrifugal pump, is capable of maintaining a pressure of 1.5 atmospheres in the cottage water supply. This is quite enough for the stable operation of all household appliances that are installed in private homes. Moreover, most of the models hydraulic accumulators designed for 4.5 atmospheres of maximum possible pressure, which is more than enough even for a cottage of two or three floors.

The automatic station is compact and does not require heavy concreting of the area under the equipment. Its largest element is a water storage tank. However, its installation requires a separate room due to the noise created during operation. Most often, the entire installation is installed on the ground floor or in the basement, where it is most convenient to operate and maintain it.

A somewhat expensive, but quite reasonable solution for placing equipment can be a caisson, in which both the entire complex of units and an automatic pump without a hydraulic tank installed in the house can be located. The budget option for locating the station at the dacha involves the construction of a separate pavilion that protects the unit from atmospheric negativity.

Operation and features of the control unit

The task of the automation that controls the pumping station is to monitor the pressure in the system and turn on/off the hydraulic pump motor as needed. To do this, the control unit turns on the pressure gauge and relay. The first controls the current pressure, and the second controls the pump.

The main elements of the relay are two springs. The large one is configured to close the circuit at the lowest pressure in the membrane tank, when there is little water in it. And the smaller one controls the maximum pressure, opening the circuit when the last one is reached.

When purchasing a pumping station for operation in circuits with the possibility of short-term operation without water, you need to pay attention to the presence of a flow controller device.

It is designed to protect the engine from overheating in the event of a lack of water in the water intake. In such units, the control unit is focused not on the maximum pressure values, but on reducing the flow.

In how competently select a pumping station for arranging a summer cottage, our proposed article will help you figure it out. In addition to valuable recommendations for equipment buyers, it provides a rating of the best offers on the domestic market.

Interaction of the pump with the hydraulic accumulator

The capacity of the membrane tank is selected taking into account the volume of water consumption. A 25–40 liter option will be enough for a married couple, but for a family of several people you will have to select a device from 100 liters.

It is recommended to buy tanks less than 15 liters only for seasonal use in the country. Due to the constant pumping of water, the membrane in them wears out quickly.

It is believed that the larger the capacity, the longer the pumping equipment will last, because the number of on/off cycles will be reduced. However, a large capacity tank costs a lot.

According to the rules, the hydraulic tank is selected on the basis of calculations based on the values of the on and off pressure indicated by the manufacturer, and the actual water flow when the water intake points are turned on at the same time.

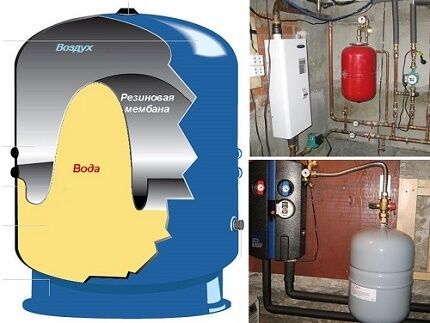

The fluid reserve in a hydraulic tank is usually about a third of the total tank volume. All remaining space is given over to compressed air, which is needed to maintain constant water pressure in the pipes.

If a hydraulic accumulator is built into a water supply system to minimize the risks associated with hydraulic accumulators, then the tank can be selected in a small size. In this case, it is not the volume of the container that is important, but the presence of the membrane and air behind it. It is they who, if anything happens, will take the blow, smoothing out its consequences.

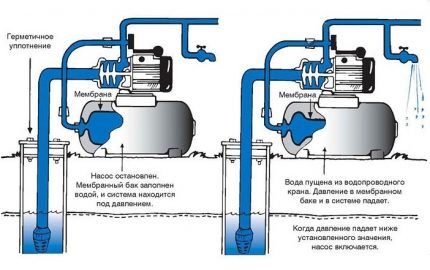

The automatic pumping station operates in two cycles:

- First, water is pumped into the accumulator from the water intake by a pump, creating excess air pressure in it.

- When the tap in the house is opened, the membrane tank is emptied, after which the automation restarts the pumping equipment.

The design of a hydraulic accumulator for a water supply pumping station is extremely simple.It consists of a metal body and a sealed membrane that divides the entire space inside into two parts. The first of them contains air, and the second is pumped with water.

After the accumulator is filled, the relay turns off the pump. Opening the faucet in the washbasin causes the water squeezed out by air pressure onto the membrane to gradually flow into the water supply system. At some point, the tank is emptied to such an extent that the pressure weakens. After this, the pump turns on again, starting the operating cycle of the pumping station again.

When the tank is empty, the membrane partition is crushed and pressed against the flange of the inlet pipe. After turning on the hydraulic pump, the membrane expands with water pressure, compressing the air part and increasing the air pressure in it. It is this gas-liquid interaction through a changing barrier that underlies the principle of operation of the membrane tank of the pumping station.

Equipment selection criteria

Factory-built pumping stations come with a surface hydraulic pump, often having an internal or external ejector. However, hydraulic accumulators can also be used with submersible pumping equipment, but are given the slightly different technical term "pumping system".

When operating in tandem with a station, membrane tanks may be smaller in volume than hydraulic tanks for systems with submersible pumps. This is due to the fact that submersible pumping units have less permissible on/off switching times per hour than surface pumping machines.

Surface pumps, having an internal ejector, have serious restrictions on the depth of water intake. They can only lift water from 7–8 meters. However, they produce a powerful water pressure at the outlet with a water column of 40–60 meters (4–6 bar).

The internal ejector is not afraid of air jams. They first pump air without any negative consequences for themselves, and then they begin to pump water from the well into the system.

The main disadvantage of stations with an internal ejector is the high noise level during operation. If these models of pumping equipment for autonomous water supply are planned for installation in an honest home, then it is recommended to do this only in utility rooms with good sound insulation.

Usage remote ejector allows you to take water from depths of up to 50 meters. These pumps are more economical, but have low efficiency (no more than 40%). But they make much less noise than analogues with a built-in ejector.

The choice of the type of pumping unit for a station depends on the quality characteristics of the medium planned for pumping:

Determining a location for a water supply station

When choosing a location for a pumping station, you need to focus on the characteristics of the hydraulic pump. Every ten meters of horizontal pipe between the water source and the pump reduces its suction capacity by 1 m.

If they are expected to be separated over a distance of more than ten meters, then the model of the pumping unit must be selected with an increased suction depth.

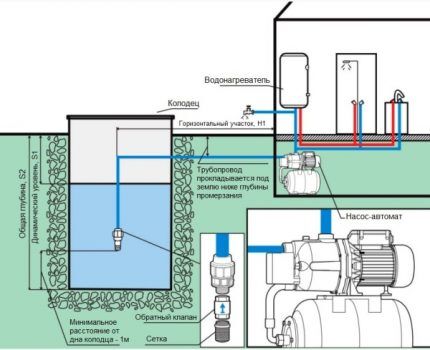

An automatic station for an autonomous water supply system can be located:

- on the street in a caisson near a well;

- in an insulated pavilion built specifically for pumping equipment;

- in the basement of the house.

The stationary outdoor option provides arrangement of the caisson and laying a pressure pipe from it to the cottage below the ground freezing level. When installing a pipeline that operates year-round, its laying below the depth of seasonal freezing is mandatory.

When installing temporary summer pipelines for the period of residence at the dacha, the pipeline is not buried below 40 - 60 cm or is laid on the surface.

If you install the station in a basement or basement, you will not have to worry about the pump freezing in winter. You just need to lay the suction pipe below the freezing line of the soil so that it does not freeze in extreme cold.

Often a well is drilled right in the house, which then significantly reduces the length of the pipeline. But such drilling is not possible in every cottage.

Installation of water supply pumping stations in a separate building is possible only if the equipment is operated during periods of positive temperatures. However, for areas with very low winter temperatures, this option, designed to operate all year round, must be insulated or a heating system installed. It is better to immediately install the pumping station directly in the heated house.

When choosing a location for a water supply station, it is necessary to take into account the temperature limits specified in its passport by the manufacturer:

Pressure parameters in the accumulator

For proper operation of household plumbing fixtures in the cottage water supply, it is necessary to maintain a pressure of 1.4–2.6 atmospheres. To prevent the accumulator membrane from wearing out too quickly, manufacturers recommend setting the pressure in it 0.2–0.3 atm higher than the tap pressure.

The pressure in the water supply of a one-story house is usually 1.5 atm. This figure should be used as a starting point when adjusting the hydraulic tank. But for larger residential buildings, the pressure must be increased so that there is water in all the taps farthest from the riser. This requires more complex hydraulic calculations, taking into account the length and configuration of pipelines, as well as the number and type of plumbing fixtures.

You can simply calculate the required pressure for the indoor water supply using the formula:

(H+6)/10,

where “H” is the height from the pump to the highest point of water supply to the plumbing on the top floor of the house.

However, if the calculated indicator pressure in the autonomous water supply will exceed the permissible characteristics of existing plumbing and household devices, then when such pressure is set, they will fail. In this case, it is necessary to select a different layout of water pipes.

Possible problems with the installation

If the pump turns on and then turns off too often, you must immediately check the air pressure in the accumulator. If the indicators are underestimated, it will be necessary to pump it up.But it will be possible to fix the problem in this way only if the membrane and tank body are not damaged. Here, only contacting a service center with repairmen will help.

If water drops appear on the air valve nipple, the accumulator must be immediately disconnected from the water supply system. This is a direct sign of membrane damage. In such a situation, you cannot do without replacing it. Air should not enter the water supply system of a private house through a membrane tank.

If the pump does not want to turn on at all, then you should look at adjusting the pressure switch. There are times when it is set to too high a pressure. But it is also possible that air gets into the suction hose, which triggers the dry-running protection.

Advantages of a pump unit with a hydraulic tank

The pump unit is an integral part of an autonomous water supply system. It provides water supply from a well or a well, the water distribution of which further around the cottage is carried out through the operation of the pump itself, the use of a water tank or the use of a hydraulic accumulator.

Using only one pump to distribute water throughout a cottage is associated with many problems. With this arrangement autonomous water supply pumping equipment is forced to constantly turn on/off, which is why its service life is sharply reduced. And in a situation where the power supply is cut off, the home is left without water at all.

To reduce wear on the pumps and protect the house in case of accidents on electrical networks, an additional storage device is included in the water supply system of the house. This can be a water tank in the attic, from which water flows to plumbing fixtures by gravity, or a hydraulic accumulator that artificially maintains the pressure in the network (also known as a membrane tank or hydraulic tank).

In both cases, the pump is turned on to form a supply of water in the container. Only in the second case, the reserve is created automatically by a control system based on pressure parameters. At the same time, the storage tank allows you to create a water reserve in case of a power outage, and a system with a hydraulic tank without electricity will not work at all.

However, when filled, the storage tank is quite heavy and, when installed within the attic, requires reinforcement of the ceiling and thermal insulation.

The option with a membrane tank is more convenient and practical. The operating principle of a water supply system with such a pumping station is based on artificially maintaining water pressure in the pipes. The pump itself, pumping water from the water intake, is turned on only to fill the tank. It is then supplied to the system using compressed air.

Unlike the option with an expansion tank, the hydropneumatic installation is more compact. Plus, the use of a membrane-type hydraulic accumulator guarantees the absence of water hammer in the network and constant pressure in the water supply pipes, and also simplifies the maintenance of the water supply system for consumers in a private home.

The only drawback of pumping stations with hydraulic accumulators is their energy dependence. The water storage tank is often small in size, 25–50 liters. The pump has to be turned on frequently to fill it, and when the lights go out, the water reserve does not last very long. In order to eliminate such situations, it is advisable to stock up on an autonomous generator.

Conclusions and useful video on the topic

Video #1. From what depths can pumping equipment lift water?

Video #2. How to assemble a pumping station yourself from a household centrifugal pump:

Video #3. Everything about the principle of operation of the hydraulic accumulator included in the pumping station:

Automatic autonomous water supply systems make it possible, when living in a country house, not to bother carrying water in buckets. Thanks to their simple design, pumping stations are easy to install and maintain.

Almost anyone can install them. Fortunately, there are many configurations of pumping equipment of various types with hydraulic accumulators; the optimal solution can be selected for each cottage.

Do you want to share your own experience in using a pumping station, have questions or found flaws in the article? Please write comments in the block below.

We have a small one-story house with a kitchen, shower room and 3 rooms. We installed such a station at our place. In our case, it was assembled at the factory. That is, the control system is adjusted to standard pressure values, and everything can be controlled. The master arrived and installed everything, but he spent a long time fiddling around. The station has been operating for a year now, and in general there are no problems so far, there are no leaks anywhere.I heard that the neighbors had various problems. We are afraid of this, since we ourselves are not technicians, but we hope that we will find a master, if necessary. Overall, we are happy with the installation. Our tank volume is 40 liters, but there are two of us and it seems to be enough, we don’t spend much.

In what cases is it necessary to purchase a pumping station? You live in your house with your wife (the children have grown up and live separately), the amenities are in the yard, you like to wash in the bathhouse (thank God, this is not a problem now), there is a well on the property. Well, why spend a lot of money to deliver two buckets of water to the kitchen? But you have a warm toilet, bath (jacuzzi), shower, in the kitchen there is a washing machine, a dishwasher, then you physically cannot live without a station!

If a private home requires normal water supply, then installing a pumping station is justified. The type and power are already calculated based on needs, distance of the source, and other things. Of course, there are people for whom outdoor amenities are the norm. But in winter, for example, many of them definitely think that water supply in the house would be very useful now.

The implementation of the simplest pumping station will not cost that much to save and give up something common for many, like water in the house!

The house is 250 m from the lake, what pumping equipment do you recommend? We want to install a submersible pump in the lake, then 250 m further, a HDPE pipe, then a surface pump, a hydraulic accumulator, and a pressure switch in a caisson. Will this work?

Since your home is located a considerable distance from the lake, there are many factors to consider.For example, elevation differences for a distance of 250 m play a very important role. Accordingly, the greater the difference, the more power is required for the pump to ensure normal water supply.

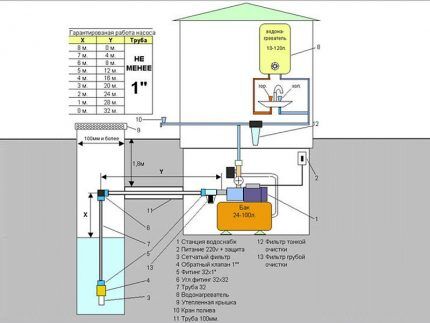

I am attaching for you a detailed diagram of the water supply to the house from the lake. It’s not difficult to add a caisson, a hydraulic accumulator and a pressure switch. The last element will need to be manually calibrated so that there are no interruptions in the water supply. The website has up-to-date instructions on this matter.

Overall, you have a very good idea, but I am concerned about the height difference. If the slope to the lake is not very steep, then no difficulties should arise.

Good evening! I bought a house, it has a pumping station installed, which consists of a relay, a filter, a submersible pump and a motor, which is installed outside (fixed to the wall of the house). This engine runs noisily and constantly.

My question is: should the engine run constantly? And can it be placed outside in the cold? Thank you!

If the noise of the electric motor bothers you, then there are two options to solve the problem: move it to another location or install a different type of pump. Regarding the operation of an electric motor in cold weather, it all depends on the model, but I think that it is unlikely that it will work normally even at -20 * C.

Is it permissible to turn off the pumping station for 2-3 days when leaving and how to connect it later?

As I understand it, you have already installed a pumping station to supply water to your house. There is no particular need to disable it, since this equipment should operate in automatic mode.The specialists who installed the station for you should have given you instructions, including how to turn off the pumping station.

I advise you to call the company to get advice on this issue or look at the technical documentation that you should have.

If you want an answer from me, please tell me the make and model of your pumping station.

Good afternoon. Two Jumbo 60/35 water supply stations have been installed. Connected to the water supply network in parallel. Tell me, is it necessary to install a check valve on the supply pipes (when using two stations simultaneously)? A check valve is installed on the suction pipes. The source of water for pumping is a container.

Good afternoon, Ruslan. If you had one pumping station installed, then a check valve on the supply pipe would not be needed. But since in your case two stations are connected in parallel, pressure differences or some other failure are possible (for example, one station turns off).

Therefore the installation check valves on the supply pipes - this is a necessary precaution that will help maintain the integrity of the equipment in the event of an emergency.

There is nothing complicated in the connection diagram; it is necessary to duplicate the check valves. If you attach your connection diagram, I can give more precise recommendations.

Hello. Please tell me, our pumping station does not turn off when filling the pool, that is, the water flows constantly, the station hums continuously.This is fine? Or should it still turn off? Will this affect the service life? If this is bad, then tell me what to do, please. Oasis station 70/50NL-24.

Hello! The pumping station operates with frequent jerks when opening one tap in the kitchen! When opening two taps in the bathroom and kitchen it works fine! What could be the problem? Thank you!

The engine is running but no water is flowing, what should I do?