Water pressure switch: what it is, how it works + how it is adjusted

Automation of the operation of an independent water supply system is impossible without the use of a pressure sensor.The sensitive device will almost instantly respond to a drop or increase in pressure in the network, start and stop the pumping equipment without the participation of the owners.

You can use an autonomous water supply system equipped with automation devices just like a city system. This is incredibly convenient, isn't it?

We offer you complete information about how a water pressure switch works and what type of device is best to choose for installation in an independent system. Here you will find a detailed analysis of the technological nuances of various types of sensors.

The presented article contains valuable information about the features of installing devices and setting up pressure switches. For better understanding, the text is supplemented with photos, diagrams and video reviews.

The content of the article:

Operating principle and types of pressure switches

Electromechanical models of pressure switches have been used for a very long time. They are designed simply, therefore they are reliable and easy to use. Inside the device there is a flexible plate, the position of which changes under the influence of water flow. The more active the flow, the greater its bend will be.

This element is connected to two springs that react to changes in the position of the plate. As a result, the contacts of a pair of electrical circuits are closed and opened, responding to user-specified pressure limits.

One spring is set to the maximum pressure value in the autonomous network, the second is set to the difference between the upper and lower pressure limits. The device is connected to hydraulic accumulator.

When the pressure reaches the minimum value set for the relay, the membrane inside the hydraulic tank weakens, the contact under the second spring is activated, and the pump turns on. Gradually the pressure increases, reaches the upper limit, after which the contact under the first spring opens, which turns off the pump.

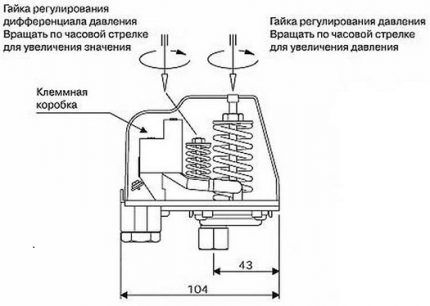

The springs that control the contacts are equipped with adjusting nuts. With their help you can change the degree of compression of these springs. To ensure that the device operates at a higher pressure, they are tightened tighter, but if you need to reduce the indicators, on the contrary, the element should be loosened.

This is the operating principle of the electromechanical version of the pressure switch; there are also newer electronic models.

Electromechanical sensor models

The operation of the pressure switch is closely related to the hydraulic accumulator, without which connecting the device to the water supply network becomes pointless. Instead of the already familiar electromechanical device, electronic versions and automation units with a dry-running protection function are now often used.

If there is a risk of drying up the source during water pumping, the pressure switch is simply supplemented with an automation unit.

However, in a number of electromechanical devices, there are pointer devices that can only be used with a pump.They also reduce the number of equipment starts and protect against operation when there is no water flow inside the pumping equipment.

Turning it off will help protect the motor from serious damage. In addition, with the help of such a relay it is possible to maintain in the water supply network comfortable pressure.

The main characteristic of the device is the nominal operating pressure. It can vary from 1.5 - 6.0 bar.

When choosing a suitable relay, you should also pay attention to such indicators as:

- connecting thread dimensions;

- level of protection against dust and moisture;

- weight and dimensions of the device;

- contact voltage;

- current ratings;

- sensor type, etc.

The pressure sensor can be installed directly on the hydraulic tank or mounted separately from it. It should also be noted that relays are manufactured to operate in different environments. For household purposes, a device designed for water is suitable.

You should not purchase a relay designed to work with refrigerant or other liquids. You also need to pay attention to the temperature of the working environment for a specific model.

Most often, the standard model RDM-5 is used for home plumbing needs. Such a device must first be connected to the hydraulic accumulator of the water supply system, then to the contacts connected to the pump on/off mechanism. After this, you need to provide the device with power.

Usually along with pumping station A pressure switch is also supplied. If it is intended to simultaneously use an electronic model, then the shutdown pressure will be set using the electromechanical option. To connect to the water supply, use a triple fitting with suitable thread sizes.

Usually they take a quarter-inch element. If you have at least a little experience in plumbing work, then this operation will go without difficulty. Of course, all threaded connections should be sealed using FUM tape, linen thread or other suitable material.

The mechanical part of the installation of the pressure switch is completed by installing a pressure gauge in order to obtain up-to-date information about the current state of the water supply system.

During installation of the device, you should select the correct cable cross-section, and also ensure its grounding using socket with three contacts. If it is necessary to protect against dry running, then you need to ensure the correct position of the pump. It must be installed above the check valve.

After installation, you need to adjust the water pressure switch. For this, as mentioned above, there are two screws with springs. They are under a cover that needs to be removed. In production, the device is usually configured. Indicators from 1.4 atmospheres (minimum) to 2.8 atmospheres are considered standard.

Even if these data correspond to those required for a particular pump, they should be checked. During storage and installation, the settings may have gotten a little lost. Here is the procedure for setting up a relay connected to a system with a hydraulic accumulator.

First, you should measure the pressure in the tank using a car pressure gauge, which is connected to the nipple connection. The nipple is located on top on vertical models of hydraulic tanks, on the side - on horizontal ones, but always on the side opposite to the location of the flange.

It is better to take devices with a fairly high gradation of the measuring scale. Cheap Chinese models do not always meet this requirement. The tank must be left empty; the pump or station does not need to be connected to power.

The normal pressure in an empty tank is set depending on its volume. Small containers (less than 25 l) should be inflated to 1.4-1.7 bar. Tanks of 50-100 liters need to be pumped up to 1.7-1.9 bar. If the pressure in the new tank does not correspond to these parameters, the situation must be corrected, i.e. pump up the missing air or vent its excess.

It is recommended to check the condition of the hydraulic accumulator monthly, monitoring and, if necessary, adjusting the air pressure. These simple measures will help not only maintain the required level of pressure in the tank, but also prevent rapid wear of the rubber membrane.

Before setting up, you need to carefully study the documentation that comes with the pump.

It is necessary to take into account such indicators as:

- maximum pressure;

- operating pressure;

- water consumption rate.

This data must be used when setting up the relay; the set pressure values must be within these values.

The hydraulic tank data is also taken into account. The power of a household pump is usually not enough to pump a conventional hydraulic accumulator, but you should not take risks and deliberately set incorrect settings.

The cover must be removed from the relay installed in a suitable location. To do this, unscrew the fastener. There are two springs there. Next to the larger one is the designation P, the smaller one is designated ΔP. Now you can connect the pump or pumping station to the electrical network and begin the process of filling the tank with water.

When the pressure in the tank reaches the upper value, the relay will turn off the pump. The pressure gauge readings should be determined at this moment. If the obtained data differs from the recommended ones, you need to adjust their value using a large spring.

To increase the limit, rotate the nut clockwise; if you need to decrease the settings, turn it counterclockwise.

Now you should open the water and empty the hydraulic tank. Over time, the relay will operate and turn on the pump. You need to record the pressure gauge readings again and adjust the relay settings if necessary. To adjust the lower pressure limit, turn the small spring.

All manipulations with the adjusting springs must be performed extremely carefully. These are very sensitive elements; you need to turn the screw gradually, by a small part of the circle; you should not make several full turns at once, as this can completely damage the device.

In this case, the following important point must be taken into account: since the small nut regulates the difference between the limits, when adjusting the lower value, the data for the shutdown pressure will change.

Therefore, after adjusting the position of the large nut, you should wait until the tank is full and check the data for the upper limit again and change them if necessary.

When setting the upper limit settings for the relay, you need to remember that this indicator must be at least 10% lower than the pressure in the empty hydraulic tank, which was recorded and adjusted at the very beginning. Otherwise, the rubber membrane of the accumulator will be under unreasonably high pressure and will quickly wear out.

During operation, it may turn out that the recommended settings are not suitable for this particular water supply. Then you need to re-configure according to the scheme described above. It should be remembered that the difference between the limits recommended by manufacturers varies in the range of 1.2 - 1.6 bar.

But you shouldn’t be overly zealous, because the greater this difference, the greater the pressure fluctuations in the water supply. The cut-out pressure should be set lower than the maximum pump pressure.

If this point is not taken into account, the equipment will work constantly, since it will not be able to provide the level of pressure necessary to turn off the device.This situation makes using a relay pointless.

It is recommended to check the settings every three months. The same operations must be performed after pumping station repair, replacing the hydraulic tank, etc.

Manufacturers of water pumping systems do not recommend adjusting the settings, but if necessary, it is better to make adjustments after each new filling of the system with water, for example, at a dacha after re-opening the systems in the spring.

For more information on adjusting the pressure switch for the pump, see this article.

Electronic relay options

Electronic models of pressure switches are an order of magnitude more expensive than their electromechanical counterparts, but these costs are well worth it. Such devices are easier to configure, and the limit values can be set much more accurately.

Each such model is equipped with a flow controller that instantly turns off the pump when there is no water. This reliably protects the pump from operating in the dangerous “dry running” mode.

Typically, an electronic pressure switch is equipped with a small hydraulic tank, the volume of which is only 400 ml. This is not much, but in this way the system is reliably protected from possible water hammer network. If an expensive high-quality pump is used for a well, it makes sense to invest in a good electronic pressure switch.

Such models look quite attractive, are highly reliable and have a long service life. But they can be sensitive to the quality of the water entering the water supply system. To protect the relay from damage, you need to take care of the installation necessary filters.

Such devices do not have adjustment springs, so you do not have to periodically readjust the device due to the fact that they have weakened. And the setup itself is much easier. First you need to study the instructions.

After the first connection to the network, some models turn on with a delay of 15 seconds. This is not a breakdown, the device is just being adjusted.

In the future, the pump can also be switched off with a delay of about 7-15 seconds. This is necessary so that the pump turns off less often if the pressure increases again during this short period. An electronic model of such a controller can be used in conjunction with a pumping station that already has a pressure switch.

Here the upper limit is set on this built-in device. And the switching pressure is set by adjusting the electronic relay. The power is first connected to the electronic device, then the contacts are transferred to the station relay, after which the pump is powered.

If the electronic relay is connected to a hydraulic accumulator, the setup is easier. The relay sets a lower limit, which should be slightly higher than the same data indicated on the pump body. The water flow is turned off after the maximum pressure is reached in the system, which depends on the power of the pump.

The installation location of the electronic relay is chosen between the pump and before the first point of water intake from the system. The direction of water movement, indicated by the arrow, should be taken into account.

If the device is used with a pump with a power of more than 10 atm, it is recommended to install a pressure reducer in front of the electronic relay to relieve the device of unnecessary loads.

If the existing settings are not suitable, they can be changed. To do this, you need to tighten the corresponding screw with a screwdriver or use other adjustment elements described in the instructions. There must be a difference of at least 0.6 atmospheres between the maximum pressure that the pump can provide and the minimum value of the electronic relay.

To seal the threaded connection of such a device, it is best to use Teflon tape. Electronic pressure switches usually have a built-in valve. This point should be taken into account when emptying the water supply.

Before starting the relay for the first time, you must first fill the supply line with water, then apply power to the device, and then open the tap.

The activation of the dry-running protection mode is usually signaled by the inclusion of a red LED on the housing. To reboot the system, you should press the “reset” button, of course, having first eliminated the causes of the dangerous situation.

Conclusions and useful video on the topic

The standard mechanical model setup is shown here:

This video describes in detail the setup procedure and operating features of an electronic pressure switch using the BRIO 2000 model as an example:

The pressure switch is an extremely useful device. Once you have figured out how to set it up, you will be able to regularly adjust the state of pressure in the water supply system and reliably protect the pump and other equipment from possible breakdowns.

Do you have any questions or want to share your personal experience in choosing, installing and using a pressure switch? Please leave comments on the article and participate in discussions - the contact block is located below.

Our water supply comes from a well. I use an electromechanical type of relay with dry-running protection. There were no problems with it, but recently doubts have arisen as to whether the sensor’s operation corresponds to the configured settings. The pump turns off faster than usual, and there is low pressure at the water intake points. The water source is fine and the entire system is working. I think this is the problem, so I decided to replace it. In this regard, there is a question: is it worth taking an electronic one, which, as I heard, does not have such defects?

Dmitry, first of all, if the pump began to turn on/off frequently, I would check the pressure with a machine pressure gauge in the hydraulic accumulator when it is completely empty, opening the tap and turning off the pump. It should be according to the passport or 10% less than the minimum pressure to turn on the pump itself.

We often experience pressure failures in the pipeline, and as a result the water flows weakly or stops flowing altogether. To ensure that the pressure drop does not interfere, we use a special pressure regulator, namely an electronic relay with settings and a display for easy monitoring. Recently purchased with an official warranty. As long as it works properly, water flows at the pressure we set, without failures. Satisfied with the quality.

“When setting the upper limit settings for the relay, you need to remember that this indicator must be at least 10% lower than the pressure in the empty hydraulic tank, which was recorded and adjusted at the very beginning. Otherwise, the rubber membrane of the hydraulic accumulator will be under unreasonably high pressure and will quickly wear out.” - Something is wrong here. Air pressure in HA d.b. 10% less than the lower pressure limit in the system (pump included).

I had a Pedrollo hydrophore in my private house for more than 7 years. Finally, the cut membrane broke and it began to turn on very often for 1 second. I decided to remove all this and installed an electronic relay “Aquatika - 779556”. There is a ball valve at the outlet from the relay into the internal pipeline. When the valve is closed, the relay maintains pressure on the pressure gauge for a long time (even all night). However, when this tap is opened, but in the absence of water use, the pump runs for 6-8 seconds, the pressure on the pressure gauge rises to almost 4 bar and the pump turns off. But the pressure on the pressure gauge begins to slowly drop when there is no water use, and after about 5 minutes the pressure drops to 1.5 bar and the pump turns on again. So it feels like my internal plumbing is not sealed? But the pipes are under the screed... What should I do? Buy a hydrophore with an electromechanical relay and a bulb, or dig up a pipeline and look for a leak? Please tell me, since financially this is all very critical for me...

Maybe the check valve doesn't hold, sometimes a grain of sand gets in and water leaks back.

Great article, thanks!

I installed an additional pressure switch. I tried to regulate it, but in vain. The engine continues to turn on and off periodically.Apparently the problem is in the electric relay, its board (something burned out or got hot), has anyone encountered such a problem, where to look for the cause? Thank you.

See photo. With this assembly, when the water opens, the electronic relay will turn on and off at almost equal intervals. Is it this relay or is it necessary to install an additional pressure switch?

A hydraulic accumulator will help you.

Good luck to you. The situation is a private house, the system is autonomous, we pump it from a well. Everything worked for several years, but the aquarobot died. I bought a new one, but of a different brand, and installed it (everything seems to be as it should be). The problem is that it turns off only if you hit it lightly. Tell me if you know. THX!

Hello! Tell me what relay to install so that the voltage to the pump is cut off when water pressure appears in the water supply system. I have an adjacent water supply from the tank.

Hello! Can you tell me which relay needs to be installed so that the circuit to the pump breaks when the water pressure in the hose used for irrigation increases. Water supply from a well, a trickle pump.

Please tell me. We haven't been to the dacha for a week. Today is 12/05/21, the pump in the well does not turn on. The relay shows no signs of life. The inlet water pipe is heated. The pressure gauge shows 0. Is the relay to blame? Or what?

The same story. The relay shows no signs of life. The inlet pipe is heated.

During the period of absence, the entire system was disconnected from electricity. networks. When leaving, the pressure was 3 at., upon arrival - 0 at. Relay – Belamos PS-02c