How to build blades for a wind generator with your own hands: examples of self-made wind turbine blades

The use of alternative energy sources is one of the main trends of our time.Clean and affordable wind energy can be converted into electricity even in your home by building a wind turbine and connecting it to a generator.

You can build blades for a wind generator with your own hands from ordinary materials, without using special equipment. We will tell you which blade shape is more efficient and help you choose the appropriate drawing for a wind power plant.

The content of the article:

How does a simple wind generator work?

A wind generator is a device that allows you to convert wind energy into electricity.

The principle of its operation is that the wind rotates the blades, sets in motion the shaft, through which the rotation is supplied to the generator through a gearbox, which increases the speed.

There are two main types of wind generators:

- vertical;

- horizontal.

Vertically oriented models are built so that the propeller axis is perpendicular to the ground. Thus, any movement of air masses, regardless of direction, sets the structure in motion.

A horizontal wind generator resembles a weather vane. In order for the blades to rotate, the structure must be turned in the desired direction, depending on the direction of air movement.

To monitor and capture changes in wind direction, special devices are installed. The efficiency with this screw arrangement is significantly higher than with a vertical orientation. For domestic use, it is more rational to use wind generators of this type.

What blade shape is optimal?

One of the main elements of a wind generator is a set of blades.

There are a number of factors associated with these parts that affect the efficiency of the windmill:

- weight;

- size;

- form;

- material;

- quantity.

If you decide to design blades for a homemade windmill, you must take all these parameters into account. Some believe that the more wings on a generator propeller, the more wind energy can be produced. In other words, the more the merrier.

However, this is not the case. Each individual part moves against air resistance. Thus, a large number of blades on a propeller requires more wind force to complete one revolution.

In addition, too many wide wings can cause the formation of a so-called “air cap” in front of the propeller, when the air flow does not pass through the windmill, but goes around it.

The most efficient is a single-blade wind generator. But building and balancing it with your own hands is very difficult. The design turns out to be unreliable, although with a high efficiency. According to the experience of many users and manufacturers of wind turbines, the most optimal model is a three-bladed one.

The correctly selected blade shape for a wind generator is the foundation for its good operation.

The following options are suitable for home production:

- sailing type;

- wing type.

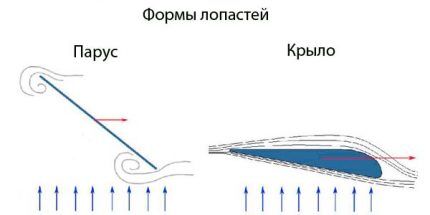

The sail type blades are simple wide stripes, like those on a windmill.This model is the most obvious and easiest to make. However, its efficiency is so low that this form is practically not used in modern wind generators. The efficiency in this case is about 10-12%.

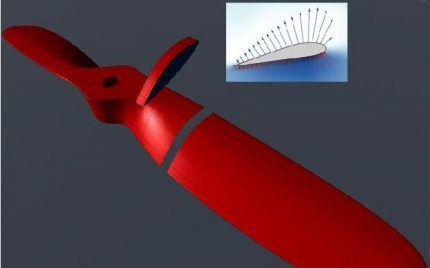

A much more effective form is the blades of a winged profile. It involves the principles of aerodynamics that lift huge aircraft into the air. A screw of this shape is easier to set in motion and rotates faster. The flow of air significantly reduces the resistance that the windmill encounters along its path.

The efficiency of this model reaches 30-35%. The good news is that you can build a winged blade yourself using a minimum of tools. All basic calculations and drawings can be easily adapted to your windmill and use free and clean wind energy without restrictions.

What are blades made from at home?

Materials that are suitable for the construction of a wind generator are, first of all, plastic, light metals, wood and a modern solution - fiberglass. The main question is how much labor and time you are willing to spend on making a windmill.

PVC sewer pipes

The most popular and widespread material for making plastic blades for wind generators is an ordinary PVC sewer pipe. For most home generators with a screw diameter of up to 2 m, a 160 mm pipe is sufficient.

The advantages of this method include:

- low price;

- availability in any region;

- ease of operation;

- a large number of diagrams and drawings on the Internet, extensive experience in use.

Pipes are different. This is known not only to those who make homemade wind power plants, but to everyone who has encountered the installation of sewerage or water supply. They differ in thickness, composition, and manufacturer. The pipe is inexpensive, so there is no need to try to reduce the cost of your windmill even more by saving on PVC pipes.

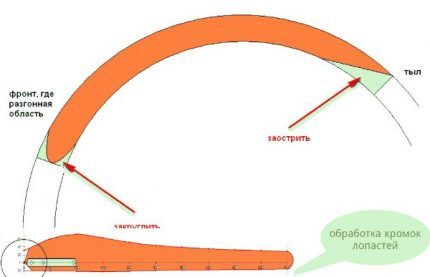

First you need to decide on the pattern. There are many options, each form has its own disadvantages and advantages. It might be worth experimenting first before cutting out the final version.

Since the price of pipes is low, and you can find them in any hardware store, this material is perfect for the first steps in modeling blades. If something goes wrong, you can always buy another pipe and try again; your wallet won’t suffer much from such experiments.

Amateur designers prefer PVC, since during testing a broken blade can be replaced with a new one, made in 15 minutes right on the spot if a suitable pattern is available. Simple and fast, and most importantly – affordable.

Photo instructions for making windmill blades from polymer pipes will help you visually master the steps and sequence of the process:

All preparatory steps have been completed, now the blades need to be attached to the part rotating with the wind:

Aluminum - thin, light and expensive

Aluminum is a lightweight and durable metal. It is traditionally used to make blades for wind turbines. Due to its low weight, if you give the plate the desired shape, the aerodynamic properties of the propeller will be excellent.

The main loads that a windmill experiences during rotation are aimed at bending and breaking the blade. If the plastic quickly cracks and fails during such work, you can count on an aluminum screw for much longer.

Another disadvantage of aluminum parts is the complexity of manufacturing. If the PVC pipe has a bend that will be used to impart aerodynamic properties to the blade, then aluminum, as a rule, is taken in the form of a sheet.

After cutting out the part according to the pattern, which in itself is much more difficult than working with plastic, the resulting workpiece will still need to be rolled and given the correct bend. It will not be so easy to do this at home and without tools.

Instead of expensive aluminum, you can use scraps of roofing sheet or pieces of corrugated sheeting left after installation:

Fiberglass or fiberglass - for professionals

If you decide to approach the issue of creating a blade consciously and are willing to spend a lot of effort and nerves on it, fiberglass will do.If you have not previously dealt with wind generators, starting your acquaintance with modeling a windmill made of fiberglass is not the best idea. Still, this process requires experience and practical skills.

For manufacturing, fiberglass is used - a thin and durable material that is produced in rolls. In addition to fiberglass, epoxy glue is useful for securing the layers.

Work begins by creating a matrix. This is a blank that represents a mold for a future part.

It is very difficult to make a blank yourself; you need to have in front of your eyes a ready-made model of a blade made of wood or other material, and only then a matrix for the part is cut out from this model. You need at least 2 such matrices. But, having made a successful shape once, it can be used many times and this way you can build more than one windmill.

The bottom of the mold is thoroughly lubricated with wax. This is done so that the finished blade can be easily removed later. Lay a layer of fiberglass and coat it with epoxy glue. The process is repeated several times until the workpiece reaches the desired thickness.

When the epoxy glue has dried, half of the part is carefully removed from the matrix. They do the same with the second half.The parts are glued together to form a hollow three-dimensional part. Lightweight, durable, and aerodynamically shaped, the fiberglass blade is the pinnacle of excellence for the home wind farm hobbyist.

Its main disadvantage is the difficulty of implementing the idea and a large number of defects at first, until the ideal matrix is obtained and the creation algorithm is perfected.

Cheap and cheerful: wooden part for a wind wheel

A wooden blade is an old-fashioned method that is easy to implement, but ineffective at today's level of electricity consumption. The part can be made from a solid board of light wood, such as pine. It is important to choose a well-dried piece of wood.

You need to choose a suitable shape, but take into account the fact that the wooden blade will not be a thin plate, like aluminum or plastic, but a three-dimensional structure. Therefore, it is not enough to give the workpiece a shape; you need to understand the principles of aerodynamics and imagine the outline of the blade in all three dimensions.

The main disadvantage of this design is the large weight of the screw. To move this colossus, the wind must be strong enough, which is difficult to achieve in principle. However, wood is an affordable material. The boards suitable for creating a wind turbine propeller can be found right in your yard without spending a penny. And this is the main advantage of wood in this case.

The efficiency of a wooden blade tends to zero.As a rule, the time and effort that goes into creating such a windmill is not worth the result obtained, expressed in watts. However, as a training model or test piece, the wooden part has its place. And a weather vane with wooden blades looks impressive on the site.

The following selection of photographs will familiarize you with the steps of making a windmill with blades cut from plywood:

The working part is ready and tested for functionality, which means that all that remains is to paint it and screw it to the mast:

Drawings and examples of blades

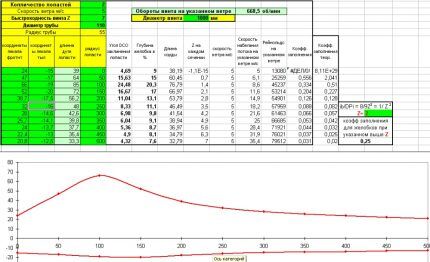

It is very difficult to make the correct calculation of a wind generator propeller without knowing the basic parameters that are displayed in the formula, as well as having no idea how these parameters affect the operation of the wind turbine.

It’s better not to waste your time if you don’t want to delve into the basics of aerodynamics. Ready-made drawings and diagrams with specified indicators will help you choose a suitable blade for a wind power plant.

Such a small wind generator will not be able to provide you with high power.Most likely, you are unlikely to be able to squeeze more than 50 W out of this design. However, a two-blade propeller made of a light and thin PVC pipe will give a high rotation speed and ensure the operation of the windmill even in light winds.

A three-blade propeller of this shape can be used for more powerful units, approximately 150 W at 12 V. The diameter of the entire propeller in this model reaches 1.5 m. The wind wheel will rotate quickly and be easily started. The three-wing windmill is most often found in home power plants.

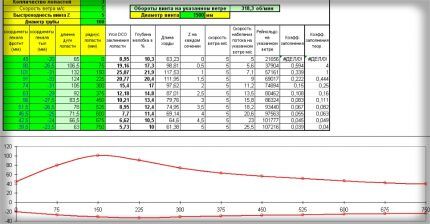

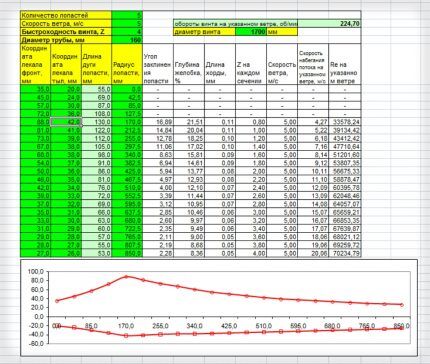

Such a five-blade propeller will be able to produce up to 225 revolutions per minute with an estimated wind speed of 5 m/s. To build a blade according to the proposed drawings, you need to transfer the coordinates of each point from the “Front/rear pattern coordinates” columns to the surface of the plastic sewer pipe.

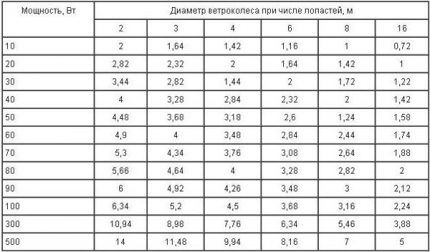

Using the table below, you can calculate the diameter of a windmill with 2-16 blades. In this case, you can select the size taking into account the desired output power.

As practice shows, it is quite difficult to maintain a wind generator larger than 2 meters in diameter. If you need a larger windmill according to the table, consider increasing the number of blades.

With rules and principles wind generator calculation Read the article, which outlines the process of performing calculations step by step.

Balancing a wind turbine

Balancing the blades of a wind generator will help make it work as efficiently as possible. To carry out balancing, you need to find a room where there is no wind or draft. Of course, for a wind wheel larger than 2 m in diameter it will be difficult to find such a room.

The blades are assembled into a finished structure and installed in the working position. The axis must be positioned strictly horizontally, level. The plane in which the propeller will rotate must be set strictly vertically, perpendicular to the axis and ground level.

A propeller that is not moving must be rotated 360/x degrees, where x = number of blades. Ideally, a balanced windmill will not deviate by 1 degree, but will remain motionless. If the blade has turned under its own weight, it needs to be adjusted a little, the weight reduced on one side, and the deviation from the axis eliminated.

It is also important to check that all parts rotate strictly in the same plane. To check, control plates are installed at a distance of 2 mm on both sides of one of the blades. During movement, no part of the screw should touch the plate.

To operate a wind generator with manufactured blades, you will need to assemble a system that accumulates the received energy, stores it and transmits it to the consumer. One of the system components is the controller. About how to do wind turbine controller, you will find out by reading our recommended article.

Conclusions and useful video on the topic

It is quite possible to build a windmill with your own hands from scrap materials. If you start with simpler models, your first attempt will probably be successful. With experience, take on more complex ideas to get the most efficient and powerful wind generator.

Video #1. How to make a windmill from PVC pipes:

Video #2. DIY wind generator:

Video #3. Wind turbine made of galvanized steel:

If you want to use clean and safe wind energy for your household needs and do not plan to spend a lot of money on buying expensive equipment, homemade blades from ordinary materials will be a suitable idea. Don't be afraid to experiment, and you will be able to further improve existing models of windmill propellers.

Would you like to tell us how you made the blades for a windmill that supplies electricity to your dacha with your own hands? Would you like to share useful information with site visitors or ask a question? Please write comments in the block below.

I installed a wind generator in my private house. I spent a long time searching for the best material to make blades from. In the end I settled on PVC pipes. The tree seemed heavier and less efficient at generating electricity. And in this article, it seems that the wooden windmill is used as a test one. I was interested in making fiberglass blades. I wonder if there is a big difference between them in Watts received?

If you do it yourself, then blades made from plastic water pipes are unrivaled. Lightweight, inexpensive material, and the process of making a blade from it is very simple. Aluminum ones are stronger and more durable, but the high price is a deterrent.Fiberglass ones are too difficult to manufacture. Wooden ones are a bit heavy, although, in my opinion, it is possible to make adequate wooden blades that will work normally. The main thing is that the tree is dry and without knots.

Which is better: three long blades or six short ones? Your opinion

It doesn't matter whether it's 3 short or six short. The main thing is the diameter of the surface covered. So - three long ones. According to rough estimates, to get 1 kW with all losses (directly into the network, excluding the battery-inverter circuit) at a speed of 4 m/s, you need a diameter of 13 m. The same diameter at a wind speed of 10 m/s already gives 17 kW. If you pour all this into the battery and then back, then somewhere else there will be half a loss. It depends very much on the wind speed. If the area is always almost calm, there is no point.

Only blades from Wind-Power model 2021. But unfortunately they are not finalized. If only someone would undertake to do the same thing, but in a human way. The transition from the blade to the pulley has not been completed. They are two times lighter than from a pipe. Balancing is up to the buyer. Otherwise the design is excellent.

The Wind-Sil has excellent blades, but the transition from the blade to the pulley has not been finalized. If only someone would undertake to do the same thing, but in a human way.

A windmill with a generator is very useful in your home in winter. To do this, you need to bury a spiral of steel wire under the house, deeper into the ground. When the battery was charged, the generator was switched to a spiral. One winter, the boiler was not heated for a week. The temperature in the cabin did not drop below 16*. This is the Vladimir region.

There is equipment in the robot to make blades for a wind generator from ABS plastic plus additives.

That is, you need to make a pattern. If there are worked out sizes, I'm waiting for suggestions. 0673251548