Pumping station for a well: rules for selecting, installing and connecting equipment

The use of a pumping station to draw water from a mine well significantly increases the level of comfort of country life.The process of filling containers for cooking and hygiene procedures takes a few minutes and does not require the slightest effort from the owners. Don’t you think that saving both energy and time is extremely useful?

We offer carefully selected information to everyone who strives for effective landscaping. Here you will find information about which well pumping station will be the ideal solution. We will tell you how to install the equipment and make the connection.

The article describes in detail the installation of a water supply system based on a pumping station. The nuances of connecting the water supply and electrical parts are thoroughly analyzed. The information offered for consideration is perfectly complemented by photo collections, diagrams and videos.

The content of the article:

Pros and cons of a pumping station

U pumping station has its own disadvantages and advantages. First of all, it is very convenient - all the main mechanisms are arranged in a single unit, and therefore easy to purchase, adjust, install, and maintain.

Requires a minimum of additional expenses. The system has innate immunity to water hammer — pressure surges when opening and closing supply valves.

There are only two disadvantages, and both are minor. The installation is noisy.The second relative disadvantage is the impossibility of raising water from depths above 8-10 meters without additional mechanisms.

Noise is neutralized by installation and placement conditions. The lifting depth can be increased by introducing an additional device - ejector.

They come in two types. Built-in and external, remote. The built-in one has better performance, but increases the noise of the entire structure. As already mentioned, this deficiency can be cured by attention to installation and placement.

Selection of power and model

Even a small and low-power installation can provide solid performance, sufficient to supply water to several consumers. Arguing about the merits of this or that brand is completely useless - it’s like discussing cars. Everyone has their fans.

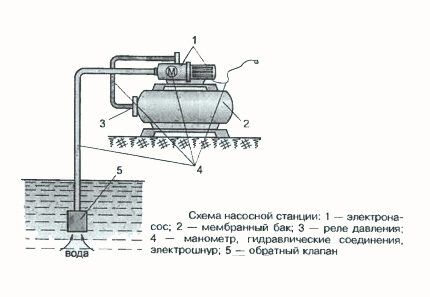

The main factor affecting performance is the storage volume - the pump operates intermittently. Its task is to pump water into hydraulic accumulator, as soon as the pressure drops below the set level.

But the water flow and pressure in the network are supported by a hydraulic accumulator. Consequently, the larger it is in volume, the less often the automation operates, the less the starting load on the engine.

It should also be taken into account that half the volume of the storage tank is occupied by compressed air, which provides pressure in the system and displaces water. Consequently, only part of the tank volume is filled with water. And, when the pump is turned off, the consumer can only rely on it.

The required volume depends on many factors: the number of residents, installed equipment, and so on.

But schematically it looks like this:

- one or two people or a cottage where there is only one washbasin or a primitive shower - the volume of the hydraulic accumulator is 24 liters;

- three to four people should already be looking at sizes of 50 liters or more;

- over 5 people — minimum tank volume is 100 liters.

In addition to the performance characteristics that should definitely be taken into account, there are optional options. For example, the presence of a dry start relay. It is not necessary in the design, but under certain conditions it is quite capable of extending the life of the station or preventing its breakdown. Unfortunately, it slightly increases the cost and complexity of the system.

Determining the installation location

It is best to locate the pressure station as close as possible to the intake point. In this case, the inertia of the system is reduced.It reacts faster to water consumption and quickly replenishes it.

That is, the entire system operates more smoothly, without pressure surges, and more stably. So in an ideal world, the best solution would be to install a pumping station in a well. Which is not always possible.

Option #1 - installation directly in the well

At installation in a well the problem of removing the station from the source is solved. The noise of the mechanisms also does not in any way affect comfortable operation - the engine operates outside a residential area.

There are also disadvantages. First of all, the operating conditions of the mechanisms improve—mainly increased humidity. Waterproofing and sealing measures do not give the expected effect - due to condensation.

Installation of the station inside a well shaft can be done in two ways:

- removable mount with fastening to the upper surface of the well shaft;

- wall bracket in a well shaft.

Both methods are approximately equivalent. The first one is a little simpler, the second one is more compact. Both of them interfere with other methods of raising water - a bucket, for example, is already inconvenient to manipulate, and inevitably dripping water does not add to the service life of the station.

Additionally, the well will require insulation of the ground part. Of course, the temperature of water and soil at such a depth is invariably positive, but superficial, local freezing of water and ice formation are possible - even this is completely contraindicated for a pumping installation.

Option #2 - caisson or separate room

There is also the option of installing a pumping station in a special service well dug near the main one used for water supply - this is called installation in caisson. An alternative would be to install the equipment in a ground-based service room.

The coffered installation method has the same advantages as installation directly in the well. Quiet, close to the pick-up point, convenient. Most often, the caisson is mounted as close as possible to the well rings - at a much shallower depth, of course.

Among the negative aspects, it is worth noting the possibility of condensation formation. And necessity serious insulation, and the most thorough. And, if possible, combating condensation. This is all with the highest quality waterproofing - ground moisture in the caisson is completely unnecessary.

There are also mandatory measures to prevent melt or rain water from getting inside the caisson - in most cases they are solved by the design of the hatch. You'll have to tinker with the rest.

The construction of a ground support facility specifically for a pumping station is quite simple from a technology standpoint. But even here insulation is required. And, since the location is above ground, heating concerns are added to the need for insulation. Sub-zero temperatures are unacceptable in the room where the pumping station is installed.

Option #3 - inside the house

The third placement option is inside the house where the water supply is organized. Due to the noise of the equipment, it is best to install it separately - usually a boiler room or basement is used for these purposes.But, if space is at a premium, installation can be done in the bathroom or laundry room, basement or under the stairs.

In any case, you should take care of sound insulation. Otherwise, living in such a house will not be very comfortable, to put it mildly. And if you choose the option of installing the station in the basement, then you should check the need for additional waterproofing. If the basement is humid.

When a pumping station is installed in a house, we always remember to remove it from the supply well. This factor can also adjust the installation point relative to the internal geography of the house.

Main unit installation requirements

The station itself should also be installed according to certain rules. It is bolted to the base. The base is preferably concrete. A rigid steel frame made of rolled profiles is allowed. Its design is welded or bolted.

It is very useful to install it on a thick sheet of hard rubber - this shock absorber will reduce shock loads when turned on and reduce operating noise.

Much less often for these purposes, spring steel shock absorbers are used, placed under the base, similar to the type of fastening of the eccentric exciter of the vibration table.

But such fastening, at the slightest loosening or violation of the adjustment, can break the mounting sockets on the base of the station and create unnecessary loads on plumbing fittings - vibration amplitude is too large. So the best option would be a hard rubber sheet up to 3 centimeters thick. The rigidity is approximately the same as that of a summer car tire tread.

It is important to pay due attention to the electrical part. It is mandatory to connect the station housing to the grounding loop, regardless of the choice of installation location. Very helpful application of RCD (residual current device - the second name for this mechanism is “residual current device”) - especially if the option with a caisson is chosen or the installation was made directly in the well.

In any case, the station must have an individual protective electrical circuit - at least a circuit breaker with an operating current slightly higher than the rated starting current of the installation.

In addition, the service life of the electrical part of the station is positively affected by the presence of stabilizers, network filters and uninterruptible power supplies. Maybe they won’t be able to have a significant impact on the engine itself, but for the electronics as part of the station’s automation unit, such an addition will be very useful.

Construction of a water supply network

Technically, connecting the pumping station to the well can be divided into two sections. Before and after the station. There is an important difference between them. Figuratively speaking: up to the station is the sphere of influence of the pump itself.

After the station, the accumulator tank is the area of concern, since it is responsible for water flow and creating pressure in the water supply system. Therefore, it is easier to consider them separately. Moreover, they can use a wide variety of pipes.

Intake part of the water supply system

This part of the overall scheme is located between the pumping station and the well.It is through this that water is drawn in and the system is powered. Its device is simple, but there are several important points.

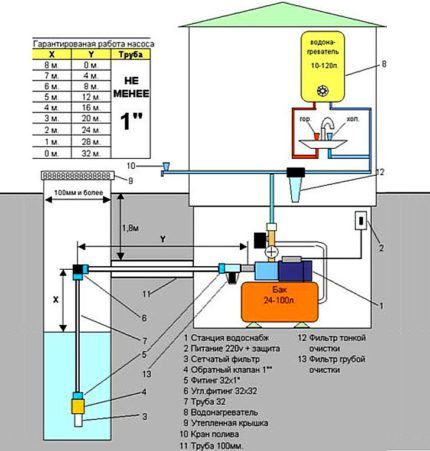

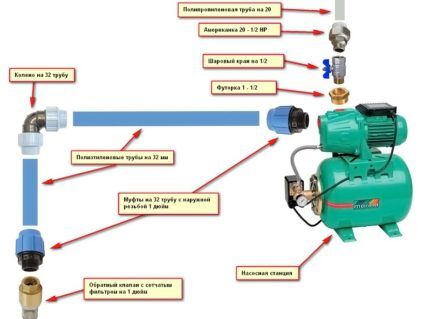

Most often, a HDPE pipe with a diameter of 32 mm is used for the fence. A supply pipe of this cross-section will not create unnecessary loads on the pump. A plastic pipe is more resistant to freezing and water hammer. Not afraid of corrosion. That’s why she’s preferred in this role. One end of it is lowered into the water, the other is connected to the station.

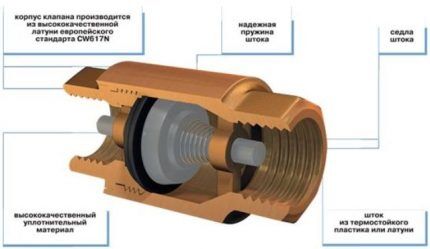

On the water side, a casing coupling is attached to the pipe. A check valve is screwed onto it, preventing the flow of water from moving back into the well. Thus, the valve prevents the system from emptying - it always remains full.

A special mesh tip should be screwed onto the valve. The mesh plays the role of a coarse filter that retains suspended sand and large fractions that may be found in the water.

Most often, the return filter has an inch fitting thread. So this unit will require couplings with a transition of 32 - 1РН.

It is better to remove the pipe from the well at a level below the depth of soil freezing. You can insulate the pipe and pass it through the top, but it is still better to run it to the house at a depth. If this is not possible, then it is good to supplement the heat-insulating shell with a special electric heater for pipes - it will prevent the water from freezing.

The pipe is led underground, at a depth below the calculated freezing point. Most often this value is 1.4 - 1.8 meters. Depends on the region. It is better to enter the house at the same depth. If this does not work, then the input must be insulated, and very, very carefully.The insulation should start below the freezing depth.

When running a pipe through a trench, it would be a good idea to cover it with sand before filling it with soil. A layer of sand will not provide any major advantages for drainage or similar things, but later it can serve as a good indicator - the sand will serve as a signal when digging when the pipe is close.

The supply pipe ends with a crimp coupling with a transition to an inch thread for connection to the station. In this area it would be nice to install another additional mesh filter (optional) and a collapsible American fitting. Already a must - it is needed in case of preventative maintenance or repair of the station. There is no need for shut-off valves or additional water purification systems in this area.

Water supply after the pumping station

The outlet of the pumping station usually has a 1-inch thread. But this diameter is no longer so important when installing the system - it can be easily reduced to half an inch. It is no longer the pump that operates on the flow line, but the hydraulic accumulator. Therefore, a possible increase in load due to the smaller cross-section of the pipeline does not play a role.

So during installation, many people install a transition fitting from an inch to a half - this way they save money on further assembly of the system, since pipes and fittings of a smaller diameter are cheaper.

A shut-off ball valve is screwed into the fitting in case of carrying out preventive and repair work on the system. From the ball valve, through a collapsible “American”, an outlet is already made into the water supply system of the house.Its features already depend on what kind of pipes are used in the house - polypropylene, metal-plastic or traditional metal pipes.

Immediately behind the shut-off ball valve, a flask with a water purification filter is also installed. It is not advisable to place it before the station. It works better with a uniform flow of water, which is only possible after pumping station — on the supply line to the station, the water moves too impulsively, with a higher peak power. After the hydraulic accumulator, its movement is more predictable and stable.

The filter should also be cut off from the system by taps in case it is replaced. And then it’s a good idea to provide a bypass line - in case this replacement is delayed for one reason or another. Naturally, this bypass must also be closed. Otherwise, the water current will always flow through it - according to the rule of least resistance.

After the filter, it is already possible to branch the main line - to cold and hot water supply, to the supply branch for the heating system, and so on. Before the filter, you can make a diversion for the needs of watering the site - plants are not as demanding of water quality as humans. For other purposes, it is better to use prepared water.

The characteristics of the filter depend on the characteristics of the water in the well. They can be determined after making a conclusion about the composition of the water. Sometimes even several filters may be required - for example, against limescale inclusions and ferrous compounds. Universal types do not exist in nature.

If you plan only seasonal operation of the water supply system (for example, in a country house), then fittings for draining the system should be installed.Usually this is a simple tap at its lowest point.

Commissioning of the station and testing

The first start-up after installation or restoration of the system after a long “dry” period is simple, although it requires certain manipulations. Its purpose is to fill the system with water before the first connection to the network.

This is a simple procedure that does not require special skills. There is a plug on the pump that needs to be unscrewed. A simple funnel is inserted into the hole, through which the system is filled - it is important to fill the supply pipe and the pump with the hydraulic accumulator. A little patience is required at this stage - it is important not to leave any air bubbles.

Fill with water up to the neck of the plug, which is then screwed in again. Then, use a simple car pressure gauge to check the air pressure in the accumulator. The system is ready for start-up.

To make it clearer how to test a pumping station, we have prepared 2 galleries for you.

Part 1:

Part 2:

Conclusions and useful video on the topic

A short video guide on installing a pumping station:

In the future, the pumping station does not require special care or special attention. And, subject to the installation and operation rules, it serves for a long time and reliably.

Have you already encountered the selection and installation of a pumping station for a well and can you supplement our material with practical advice? Please share your experience and knowledge with site visitors in the block below.

They recently dug a well at their summer cottage. We read on the Internet that it is necessary to install a pumping station for the convenience of supplying water to the house. All the pros and cons of a pumping station are, in principle, clear. Tell me, is it possible to install such a station yourself or do you need to turn to professionals? How often do you need to replace the filter, and is it possible to replace it yourself?

Hello. The frequency of replacing and cleaning filters depends on the type of equipment purchased and, of course, on the quality of the water. Cleaning and changing it yourself is quite possible.

It's a rare case when everything is in its place. Bow!