What to do if the gas boiler breaks down and the hot water does not turn on? Diagnostics and repair instructions

Installing a double-circuit gas boiler allows you to effectively solve the issue of hot water supply.But what to do if the hot water in the gas boiler does not turn on? Agree that you should not immediately panic and call the rescue service or service center.

We will get acquainted with the principle of operation of a double-circuit boiler, talk about the reasons that can lead to the cessation of hot water supply and ways to eliminate problems that arise.

Understanding the essence of the equipment’s operation, you can not only independently identify the causes of malfunctions, but also eliminate most faults, as well as restore the hot water supply in full.

The content of the article:

The principle of operation of a double-circuit gas boiler

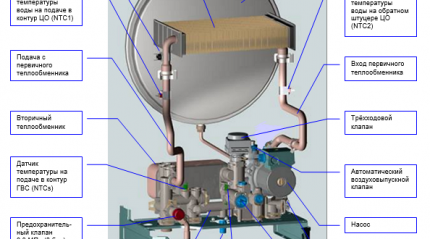

To understand why a gas boiler began to heat water poorly or there is no hot water supply at all, you need to understand how it works double-circuit unit. Almost any gas equipment of this type is equipped with several units.

The main unit ensures ignition of the gas mixture and its combustion. An additional water unit ensures the level of hot water supply and monitors the pressure in the line. The smoke removal unit is responsible for removing combustion products outside the home.

When the equipment starts, the pump is activated, pumping water into the system. The liquid begins to circulate through the heat exchanger tubes, where it is evenly heated due to the action of the burner.

The heating process is controlled sensors or a simple mechanical system or automatic gas boiler, depending on the model and complexity of the device. When the set temperature is reached, the gas supply stops. When the temperature drops to a critical value, the burner starts and the cycle repeats.

Distinctive operating patterns of double-circuit boilers

If problems arise with hot water supply, in order to find out the reasons, it is necessary to understand the operating diagram of the gas unit in DHW mode. There are two options with bithermal and secondary heat exchanger.

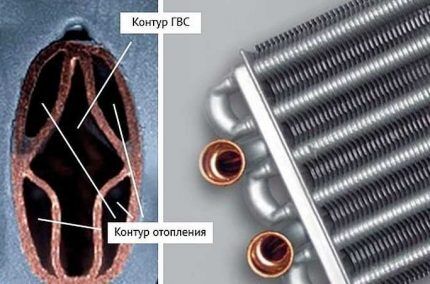

Boiler with bithermic heat exchanger

The operating principle of a unit with a bithermic heat exchanger is related to the configuration - essentially, it is one complex-shaped tube located inside another. The coolant flows through the outer section of the tube, and hot water water moves through the inner section.

When operating in heating mode, the burner ensures heating of the coolant to the set temperature and turns off. When the hot water tap is opened, the liquid begins to move along the internal circuit of the heat exchanger, and at the same time the blocking valve of the external circuit is closed.

The burner operates continuously at maximum power, providing heating of running water. After closing the tap, the coolant supply valve opens and the boiler begins to operate normally.

Boiler with secondary heat exchanger

In another type of boiler with a secondary heat exchanger, the operating principle is slightly different.It is not just the second circuit that is responsible for heating the water, but a separate plate heat exchanger equipped with a three-way valve.

When you open a hot water tap, the coolant is redirected from one heat exchanger to another, where heat is transferred to the flowing water. At the same time, the pump continues to operate, pumping coolant through a small circuit.

System with natural and forced circulation

The reasons why gas boilers stop heating water may also depend on the method of circulation of the coolant. But this has less to do with heating the water, and more to do with the operation of the device itself. The reason for poor operation of a boiler included in a natural circulation circuit is either non-compliance with slopes or the presence of air pockets.

In heating circuits with forced circulation there is no such problem, since the coolant moves through the system under the action of a circulation pump. Further, we will not dwell on the operation of the gas boiler itself, but will consider exclusively the problems of hot water supply, assuming that the boiler functions normally in heating mode.

What to do if the boiler does not heat the water?

When combining the functions of heating and hot water supply in a boiler, situations often arise when the heating system is working, but there is no hot water. DHW problems can also manifest themselves in another form - the volume of heated water may be insufficient or the temperature may be lower than required.

In some cases, a situation may occur when either hot or cold water flows from the tap. There is also a reasonable explanation for this, and the cause of this phenomenon is also easily eliminated.

Secondary heat exchanger clogged

Overgrowth of the heat exchanger with salt deposits is the most common cause of decreased efficiency of hot water supply. As a result of scale formation, not only the volume of the heat exchanger decreases, but also a significant decrease in water temperature occurs.

This is due to the fact that the water does not come into contact with the metal of the heat exchanger, but with scale, the thermal conductivity of which is significantly lower. Scale is very unstable and can crack and separate. Even a small piece or plate of scale can simply block the flow of liquid.

There are two ways to clean the heat exchanger - mechanical and chemical. The first one is very troublesome and its effectiveness is much lower. In addition, in some models, independent dismantling of the heat exchanger can be not only difficult, but also practically impossible.

Chemical cleaning of bithermic heat exchanger

Washing is carried out without dismantling the heat exchanger; to perform the procedure, you will need a booster with a volume of 20-30 liters. Before starting work it is necessary to drain coolant from the heating system using a Mayevsky tap.

Fill the booster reservoir with the flushing solution, and lower the hoses into the container, the free ends of which are connected to the heat exchanger pipes. Liquid movement is possible only under the action of a circulation pump; it must be connected to one of the hoses.

It would be ideal to connect a reversible pump with the ability to change the direction of fluid flow. All that remains is to start the boiler for heating at a set temperature of 50-60 degrees and leave for 15 minutes, periodically changing the direction of circulation.

Chemical cleaning of the secondary heat exchanger

Flushing the secondary heat exchanger of a double-circuit gas boiler can be performed in a similar way to flushing a bithermal heat exchanger. However, you need to take into account that the secondary heat exchanger is easily removed, so you can improve the quality of cleaning by dismantling it.

To gain access to the heat exchanger, it is necessary to dismantle the front panel of the unit and move the control unit to the side. The heat exchanger is secured with two bolts at the bottom, which can be easily removed by unscrewing them.

Most effectively extracted from a regular place heat exchanger for flushing place in a container with a salt-dissolving solution and boil. Instead of a suitable household product, you can use a 20% citric acid solution.

When cleaning any heat exchanger, the final stage is rinsing with clean water. This measure is necessary to remove traces of a chemically aggressive substance and stop its effect on the walls of the heat exchanger.

There is another way to clean the heat exchanger - hydrodynamic. Its implementation requires special equipment and pressure control at each stage of cleaning. Therefore, without special knowledge and skills, doing it yourself can be dangerous.

Regular cleaning of the heat exchanger will avoid the need to use very aggressive compounds and will make it possible to extend its service life. It is recommended to clean the heat exchanger annually at the end of the heating season.

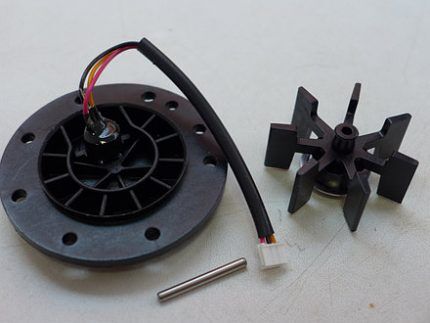

Problems with the flow sensor

A possible reason why a gas boiler may stop heating water is a problem with the flow sensor. The device is a small fan that rotates under the influence of water flow. As a result of rotation, a signal is sent to the control board to heat the water. Due to clogging, the fan may stop rotating.

You can clear the blockage without dismantling the device. To clean it, just open and close the water supply tap several times. If such actions do not give the desired result, you will have to remove the sensor and clean it.

To do this you need:

- Disconnect the gas boiler from the electrical network;

- Turn off the water supply tap;

- Drain the water from the unit.

Typically, the flow sensor is secured with a bracket, by removing which you can easily remove the device. The assembly is removed completely; to remove the inner part, you need to turn the parts in the groove. During disassembly, you should clean the filter mesh and remove the turbine.

Often, turbine blades are covered with a layer of rust that needs to be thoroughly cleaned. If you remove the three clamps, you can remove the turbine itself to clean the internal plane of its landing. Now all that remains is to reassemble in reverse order.

If cleaning the flow sensor does not bring the desired result and there is no hot water, you will have to replace the entire assembly.

Malfunction of the DHW temperature sensor

The problem manifests itself in the fact that the boiler starts, but after a few minutes it goes out, giving an error code. This indicates a malfunction of the sensor that determines the temperature of the water supply to the DHW circuit. To find out if the sensor is working, you need to measure the resistance with a multimeter.

Having looked at the instructions, you need to check the result obtained with the actual temperature of the sensor. If the sensor at room temperature shows a result corresponding to a water temperature of 60 degrees, then it is obvious that the sensor is faulty and requires replacement.

Considering that the sensor is in direct contact with water, to replace it you will need to not only turn off the water supply tap, but also completely reset the pressure.

Problems with the three-way valve

If, when turning on the hot water supply, it is noticeable that the gas boiler heats the water poorly or the water flows completely cold, then this indicates that the coolant is circulating only through the heating circuit. The reason lies in clogging or failure three way valve.

Typically, a three-way valve fails due to excessive contamination. In addition, as a result of operation, wear of the rod and failure of the electric motor due to loss of tightness may occur. To remove the three-way valve, you need to disconnect the boiler from the network and drain the water from the system.

The problem unit must be disconnected from all tubular connections, and all electrical wires must be disconnected. The three-way valve can then be removed for inspection and cleaning.Be prepared for the fact that some water may spill out when the tubes are disconnected.

Most often, scale residues are found inside the three-way valve, which interfere with the normal passage of water. After they are removed, the device performs its functions again. If the motor that moves the internal ball fails, it is better not to resort to repairs, but to replace the entire assembly.

Conclusions and useful video on the topic

The following video will show you how to clean the flow sensor:

A double-circuit gas boiler is a rather complex device, the repair of which is not always possible with your own hands. But if problems arise with the water supply, then, based on the material presented, you can independently identify the cause of the breakdown.

Knowing which components and parts affect the operation of the hot water supply and taking appropriate preventive measures in a timely manner, you can ensure long-term and uninterrupted operation of the equipment.

Would you like to tell us how you restored the operation of the hot water preparation circuit with your own hands? Do you have useful information on the topic of the article? Please write comments in the form below, ask questions, post photographs on the topic of the article.

Is it possible to operate an open heating system exclusively without hot water supply?

from a double-circuit gas boiler?