Types of solar panels: a comparative review of designs and tips for choosing panels

Alternative energy is developing to its maximum in Europe, showing its promise with results.New types of solar panels are appearing and their efficiency is increasing.

If you want to ensure the operation of an industrial building or residential premises using solar energy, you must first learn about the differences between the equipment and understand which solar panels are suitable for the climatic conditions of a particular region.

We will help you sort out this issue. The article discusses the operating principle of photoelectric converters and provides an overview of different types of solar cells indicating their characteristics, advantages and disadvantages. After familiarizing yourself with the material, you will be able to make the right choice for arranging an effective solar system.

The content of the article:

The principle of operation of solar panels

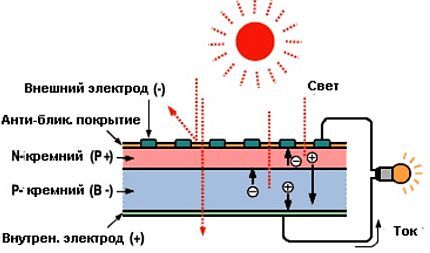

The vast majority of solar panels are, in the physical sense, photovoltaic converters. The electrical generating effect occurs at the site of the semiconductor p-n junction.

The panel consists of two silicon wafers with different properties. Under the influence of light, one of them develops a lack of electrons, and the other - an excess of them.Each plate has copper conductor strips that are connected to voltage converters.

An industrial solar panel consists of multiple laminated photovoltaic cells bonded together and mounted on a flexible or rigid substrate.

The efficiency of the equipment depends largely on the purity of the silicon and the orientation of its crystals. It is these parameters that engineers have been trying to improve over the past decades. The main problem with this is the high cost of the processes that underlie the purification of silicon and the arrangement of crystals in one direction throughout the panel.

Semiconductors of photoelectric converters can be made not only from silicon, but also from other materials - battery operating principle it does not change.

Types of Photoelectric Converters

Industrial solar panels are classified according to their design features and the type of working photovoltaic layer.

There are these types of batteries based on the type of device:

- flexible panels;

- rigid modules.

Flexible thin-film panels are gradually occupying an increasingly large niche in the market due to their mounting versatility, because they can be installed on most surfaces with a variety of architectural forms.

Based on the type of working photovoltaic layer, solar batteries are divided into the following types:

- Silicon: monocrystalline, polycrystalline, amorphous.

- Tellurium-cadmium.

- Based on indium-copper-gallium selenide.

- Polymer.

- Organic.

- Based on gallium arsenide.

- Combined and multi-layered.

Not all types of solar panels are of interest to the general consumer, but only the first two crystalline subtypes.

Although some other types of panels have high efficiency, they are not widely used due to their high cost.

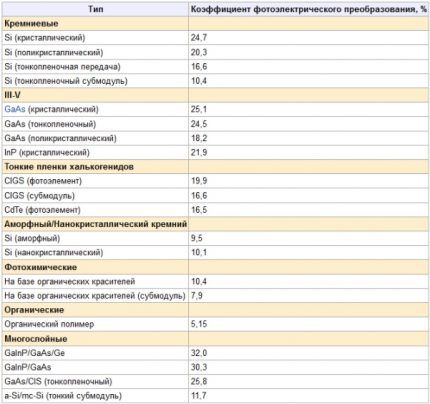

Silicon photovoltaic cells are quite sensitive to heat. The base temperature for measuring power generation is 25°C. When it increases by one degree, the efficiency of the panels decreases by 0.45-0.5%.

Next, solar panels that are of the greatest consumer interest will be discussed in detail.

Characteristics of silicon-based panels

Silicon for solar cells is made from quartz powder - ground quartz crystals. The richest deposits of raw materials are in Western Siberia and the Middle Urals, so the prospects for this area of solar energy are almost limitless.

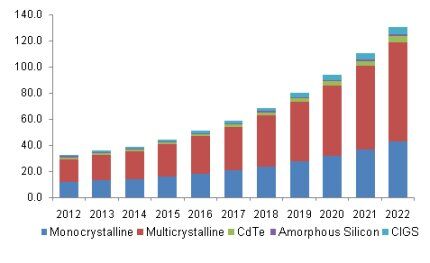

Even now, crystalline and amorphous silicon panels already occupy more than 80% of the market. Therefore, it is worth considering them in more detail.

Monocrystalline silicon panels

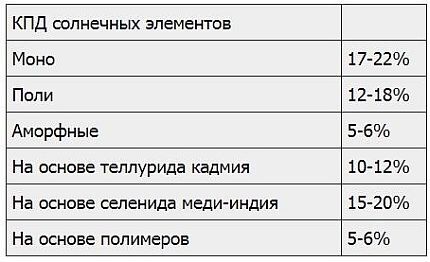

Modern monocrystalline silicon wafers (mono-Si) have a uniform dark blue color over the entire surface. The purest silicon is used for their production. Monocrystalline solar cells have the highest price among all silicon wafers, but also provide the best efficiency.

The high cost of production is due to the difficulty of orienting all silicon crystals in the same direction. Due to these physical properties of the working layer, maximum efficiency is ensured only when the sun's rays are perpendicular to the surface of the plate.

Monocrystalline batteries require additional equipment that automatically rotates them during the day so that the plane of the panels is as perpendicular to the sun's rays as possible.

Layers of silicon with single-sided crystals are cut from a cylindrical block of metal, so the finished photovoltaic blocks look like a square rounded at the corners.

The advantages of monocrystalline silicon batteries include:

- High efficiency with a value of 17-25%.

- Compactness - smaller equipment area per unit of power compared to polycrystalline silicon panels.

- Durability — sufficient efficiency of electricity generation is ensured for up to 25 years.

There are only two disadvantages to such batteries:

- High price and long-term payback.

- Sensitivity to pollution. Dust scatters light, so the efficiency of solar panels coated with it sharply decreases.

Due to the need for direct sunlight, monocrystalline solar panels being installed mainly in open areas or at heights. The closer the area is to the equator and the more sunny days it has, the more preferable it is to install this particular type of photovoltaic elements.

Polycrystalline solar cells

Polycrystalline silicon panels (multi-Si) have a blue color that is uneven in intensity due to the diversified orientation of the crystals. The purity of silicon used in their production is slightly lower than that of monocrystalline analogues.

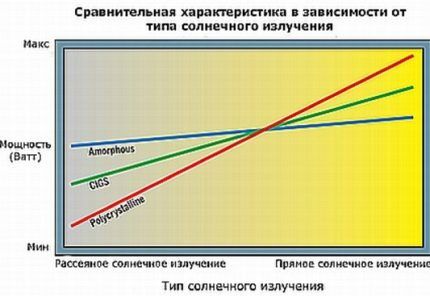

Multidirectional crystals provide high efficiency in diffused light - 12-18%.It is lower than in unidirectional crystals, but in cloudy weather conditions such panels are more effective.

The heterogeneity of the material also leads to a reduction in the cost of silicon production. The purified metal for polycrystalline solar panels is poured into molds without any special tricks.

In production, special techniques are used to form crystals, but their directionality is not controlled. After cooling, the silicon is cut into layers and processed according to a special algorithm.

Polycrystalline panels do not require constant orientation towards the sun, so the roofs of houses and industrial buildings are actively used for their placement.

The advantages of solar cells with multidirectional crystals include:

- High efficiency in diffuse light conditions.

- Possibility of permanent installation on the roofs of buildings.

- Lower cost compared to monocrystalline panels.

- Duration of operation — the drop in efficiency after 20 years of operation is only 15-20%.

Polycrystalline panels also have disadvantages:

- Reduced efficiency with a value of 12-18%.

- Relative bulkiness — more installation space is required per unit of power compared to monocrystalline analogues.

Polycrystalline solar panels are gaining an increasing market share among other silicon batteries. This is ensured by wide potential opportunities for reducing the cost of their production.The efficiency of such panels also increases every year, rapidly approaching 20% for mass-produced products.

Amorphous silicon solar panels

The mechanism for producing solar panels from amorphous silicon is fundamentally different from the production of crystalline photovoltaic cells. Here it is not a pure non-metal that is used, but its hydride, the hot vapors of which are deposited on the substrate.

As a result of this technology, classical crystals are not formed, and production costs are sharply reduced.

At the moment, there are already three generations of amorphous silicon panels, each of which significantly increases efficiency. If the first photovoltaic modules had an efficiency of 4-5%, now second-generation models with an efficiency of 8-9% are widely sold on the market.

The latest amorphous panels have an efficiency of up to 12% and are already starting to appear on sale, but they are still quite expensive.

Due to the features of this production technology, it is possible to create a layer of silicon on both a rigid and flexible substrate. Because of this, amorphous silicon modules are actively used in flexible thin-film solar modules. But options with an elastic backing are much more expensive.

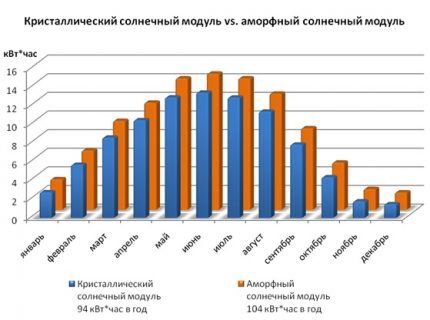

The physicochemical structure of amorphous silicon allows maximum absorption of photons of weak scattered light to generate electricity. Therefore, such panels are convenient for use in northern regions with large free areas.

The efficiency of batteries based on amorphous silicon does not decrease even at high temperatures, although they are inferior in this parameter to gallium arsenide panels.

To summarize, we can point out the following advantages of amorphous solar panels:

- Versatility — the ability to manufacture flexible and thin panels, mounting batteries on any architectural form.

- High efficiency in diffused light.

- Stable work at high temperatures.

- Simplicity and reliability of design. Such panels practically do not break.

- Maintaining performance in difficult conditions — less drop in performance when the surface is dusty than with crystalline analogues

The service life of such photovoltaic cells, starting from the second generation, is 20-25 years with a power drop of 15-20%. The only disadvantages of amorphous silicon panels include the need for larger areas to accommodate equipment of the required power.

Overview of silicon-free devices

Some solar panels, made using rare and expensive metals, have an efficiency of more than 30%. They are several times more expensive than their silicon counterparts, but still occupy a high-tech trading niche due to their special characteristics.

Rare metal solar panels

There are several types of rare metal solar panels, and not all of them are more efficient than monocrystalline silicon modules.

However, the ability to operate in extreme conditions allows manufacturers of such solar panels to produce competitive products and conduct further research.

The main alloys used to make photovoltaic cells are cadmium telluride (CdTe), indium copper gallium selenide (CIGS) and copper indium selenide (CIS).

Cadmium is a toxic metal, and indium, gallium and tellurium are quite rare and expensive, so mass production of solar panels based on them is even theoretically impossible.

The efficiency of such panels is at the level of 25-35%, although in exceptional cases it can reach up to 40%. Previously, they were used mainly in the space industry, but now a new promising direction has emerged.

Due to the stable operation of photocells made of rare metals at temperatures of 130-150°C, they are used in solar thermal power plants. In this case, the sun's rays from tens or hundreds of mirrors are concentrated on a small panel, which simultaneously generates electricity and ensures the transfer of thermal energy to a water heat exchanger.

As a result of heating the water, steam is formed, which causes the turbine to rotate and generate electricity. In this way, solar energy is converted into electrical energy simultaneously in two ways with maximum efficiency.

Polymer and organic analogues

Photovoltaic modules based on organic and polymer compounds began to be developed only in the last decade, but researchers have already made significant progress.The European company demonstrates the greatest progress Heliatek, which has already equipped several high-rise buildings with organic solar panels.

The thickness of its roll film structure is HeliaFilm is only 1 mm.

In the production of polymer panels, substances such as carbon fullerenes, copper phthalocyanine, polyphenylene and others are used. The efficiency of such photovoltaic cells already reaches 14-15%, and the production cost is several times less than crystalline solar panels.

The issue of degradation time of the organic working layer is acute. So far, it is not possible to reliably confirm the level of its efficiency after several years of operation.

The advantages of organic solar panels are:

- possibility of environmentally safe disposal;

- low cost of production;

- flexible design.

The disadvantages of such photovoltaic cells include relatively low efficiency and the lack of reliable information about the periods of stable operation of the panels. It is possible that in 5-10 years all the disadvantages of organic solar cells will disappear, and they will become serious competitors for silicon wafers.

Which solar panel to choose?

The choice of solar panels for country houses at a latitude of 45-60° is not difficult. There are only two options worth considering here: polycrystalline and monocrystalline silicon panels.

If there is a shortage of space, it is better to give preference to more efficient models with one-sided crystal orientation; if there is an unlimited area, it is recommended to purchase polycrystalline batteries.

It is better to choose a specific manufacturer, the required power and additional equipment with the participation of managers of companies involved in the sale and installation of such equipment. You should know that the quality and price of photovoltaic modules from the largest manufacturers differ little.

It should be taken into account that when ordering a set of turnkey equipment, the cost of the solar panels themselves will be only 30-40% of the total amount. The payback period for such projects is 5-10 years, and depends on the level of energy consumption and the possibility of selling excess electricity to the city grid.

Some craftsmen prefer to assemble solar panels with their own hands. On our website there are articles with a detailed description of the manufacturing technology of such panels, their connection and arrangement of solar heating systems.

We advise you to read:

- How to make a solar battery with your own hands: instructions for self-assembly

- Solar heating systems: analysis of heating technologies based on solar systems

- Connection diagram for solar panels: to the controller, to the battery and serviced systems

Conclusions and useful video on the topic

The presented videos show the operation of various solar panels in real conditions. They will also help you understand the issues of choosing related equipment.

Rules for choosing solar panels and related equipment:

Types of solar panels:

Testing of monocrystalline and polycrystalline panels:

For the population and small industrial facilities, there is currently no real alternative to crystalline silicon panels.But the pace of development of new types of solar panels allows us to hope that solar energy will soon become the main source of electricity in many country houses.

We invite everyone interested in the issue of choosing and using solar panels to leave comments, ask questions and participate in discussions. The contact form is located in the lower block.

An interesting topic, especially considering the ever-increasing tariffs. Of course, I would like to install a couple of batteries for myself, but in case of personal calculation, the payback will have to wait a long time, and you need to invest a lot right away. Although they are quite profitable when installed in apartment buildings. If you make lighting in the entrance with LEDs with motion sensors for consumption during the day from the battery, and at night from the network (and with a two-tariff meter), then the savings will be significant - instead of 1000 kW/month there will be up to 200 kW/month.

I didn’t know about many of the technical characteristics and realized that I was unlikely to switch to using panels in the near future. But at the same time, I agree with Igor - developers could well have calculated the benefits of equipping multi-storey new buildings with solar panels during the design period. I think there are many advantages, and the cost of systems for large volumes should be somewhat less.

Are you kidding me or what? Even in Europe, solar panels are the preserve of private households. And you propose installing it on apartment buildings in Russia. What are the advantages and what is the efficiency in the conditional St. Petersburg with 72 sunny days a year and a leaden sky overcast the rest of the time.

Well, you know, St. Petersburg and Moscow are not all of Russia! There is also the south of the country, where sunny days are enough for solar panels to reach their normal payback period.

In St. Petersburg it is simply unprofitable to install solar panels, but in Moscow, for example, I noticed such solutions even on ordinary nine-story panel buildings. It is clear that such a solution is not enough to fully provide electricity. But you can still charge phones, tablets and use other equipment - this is already a nice bonus.

But the further I travel south in our country, the more often I see full-fledged solar power plants in private households. Europe, by the way, is also not small and in England, for example, there are no more sunny days than in St. Petersburg. Therefore, not everything is as simple as you described.