Types of fans: classification, purpose and principle of their operation

The fan is the basis of any artificial ventilation system. The device is widely used in everyday life and is indispensable in many areas of human activity.When planning the purchase of ventilation equipment, you need to understand the specifics of its design and operation.

The article presented for review describes in detail the types of fans, their design features, operating principles and purpose of each unit. We will tell you about the priority areas for choosing the appropriate model. Here you will learn how to select a device depending on operating conditions.

The content of the article:

Classification of fans according to basic parameters

Fans are mechanical devices designed to move, supply or exhaust air and gas masses. Air circulation occurs due to the pressure difference between the inlet and outlet channels of the ventilation unit.

Fans are used everywhere. Indispensable devices when arranging supply and exhaust ventilation complex buildings, blowing working elements in air conditioners and heating devices.

The general classification of ventilation units is based on different parameters.

Among the main gradation criteria are:

- design and operating principle of the device;

- purpose and operating conditions of the fan;

- installation method;

- methods for connecting the device to the electric motor;

- technical features: IP degree of protection, generated pressure, power consumption, rotation speed, efficiency and acoustic pressure level.

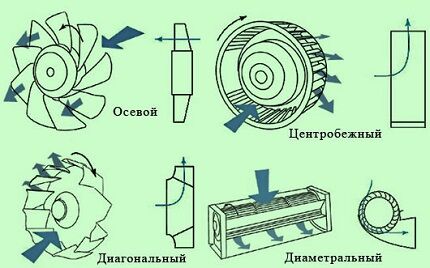

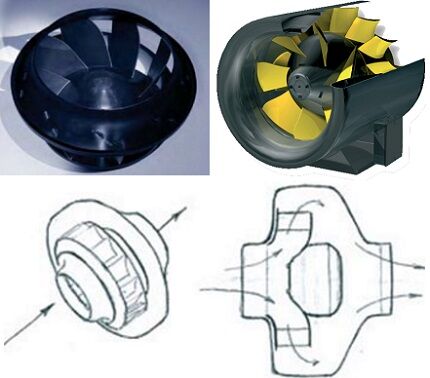

Based on the type of design, there are five modifications of fans: axial, centrifugal, diagonal, diametrical and bladeless.

Based on operating conditions, the following types of gas blowing machines are divided:

- general use appliances;

- fans for special purposes.

The first group includes units designed to work with air and inactive gas flows, the temperature of which does not exceed +50°C. The second group includes special equipment: heat-resistant, explosion-proof, dust-proof, corrosion-resistant and smoke-removing.

According to the installation method, they are distinguished:

- standard – installation is carried out on a support;

- roof - installation on the roof of a building;

- duct – placed inside the ventilation duct;

- multi-zone - models designed for connection to several air channels.

Electric motors are used to drive the ventilation unit.

There are several possible ways to couple the engine to the impeller:

- direct connection;

- V-belt transmission;

- stepless hitch.

After determining the appropriate type of fan, a model with optimal technical characteristics is selected.

The principle of operation of different types of devices

The main criterion for choosing a fan is its design and operating principle. Design features and technical nuances determine the efficiency of the device, noise level, operating efficiency and the possibility of its use in certain conditions.

Axial unit – classic fan

Axial (axial) fan is widely used in household ventilation systems of private houses, in bathroom hoods, in complex exhaust hoods, as a cooling element for various equipment and electronics, as well as in wind tunnels and turboventilation engines in the aviation field.

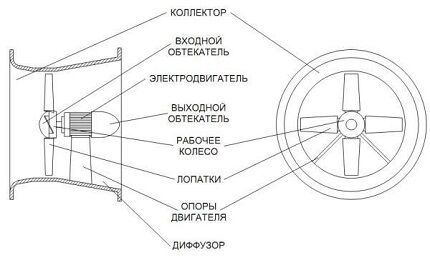

The design of the models is characterized by simplicity of execution and small dimensions. Main elements: cylindrical body, wheel with blades and drive.The internal diameter of the cylinder must ensure unimpeded rotation of the impeller. The spacing between the blades and the housing is limited to 1.5% of the length of the rotating blade.

Operating principle: rotating blades capture air and push it along the axis of the impeller. There is almost no movement of air flows in the radial direction. The performance of the equipment is regulated by turning the blades.

Distinctive features of axial models:

- do not require a large area for installation;

- economical energy consumption;

- low noise level;

- ease of operation and repair;

- low cost.

The advantages of the operation and use of axial fans have led to their wide popularity in everyday life. Case models for cooling electrical appliances and portable axial units with grilles are widely used.

Centrifugal model - strength and high power

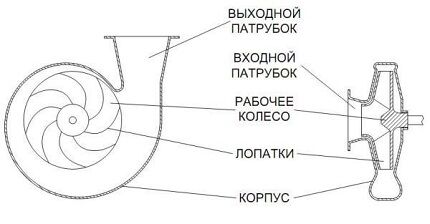

Centrifugal (radial) fans are highly efficient - the units are capable of generating high pressures and operating in harsh conditions. The equipment design includes the following elements.

Frame. The diffuser casing is made of riveted or welded sheet metal. The hollow body has a spiral shape of a snail; the design includes suction and discharge pipes. To add rigidity, the casing is reinforced with ribbing or transverse stripes.

Working wheel. The vane rotor consists of two discs, blades and a hub.

The design of the wheel determines the conditions for using the fan:

- discless – transportation of flows with solid components;

- single-disk – movement of air media with a low content of solid fractions;

- double-disc – circulation of clean air masses in different pressure ranges;

- three-disc – providing two-way suction.

The wheel is attached to the shaft using hubs. The blades are fixed to the disks and hubs.

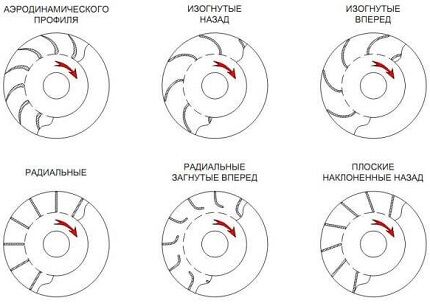

Shoulder blades. The performance characteristics and efficiency of the unit as a whole largely depend on the shape of the blades:

- aerodynamic wing – ensures noiselessness, good performance, and resistance of the device to high temperatures;

- backward curved – prevents the accumulation of dust inside the fan, suitable for use in environments with high oppression;

- curved forward – fans with “front” fins are designed to work with large volumes of air and high pressure, and are resistant to erosion;

- radial - installations of compact size with average efficiency, the rotor guides are treated with a protective compound against erosion.

In wheels with “rear” blades, the difference between static and total pressure is not large, so their efficiency level is high. Operating efficiency reaches 80%.

In centrifugal installations, air enters in the axial direction and is expelled in the radial direction. Air masses move under the influence of centrifugal forces in a cylindrical body.

The whole process can be divided into several stages:

- When the wheel rotates, the air between the space of the blades rushes to the edge of the rotor.

- As a result, a low pressure zone is formed in the center of the wheel. This leads to the absorption of air masses from the outside.

- In the center of the chamber, air flows change direction from axial to radial, entering the compartments between the blades.

- Due to rapid rotation, air masses rush to the inner wall of the housing.

- The kinetic energy is partially converted into compression energy and the air speed decreases - a volumetric air flow collects inside the “snail” and excess pressure is formed.

- The gaseous mass rushes to the outlet pipe, enters the pipeline, and then into the working area.

Centrifugal units are used in supply and exhaust systems of large premises, garages, shopping centers and buildings where continuous powerful ventilation is required.

Diagonal – a combination of axial and radial fans

The diagonal model is a synthesis of two types of fans: axial and centrifugal. The impeller of the device has a special shape - the structure of the impeller resembles the structure of a drum in a radial fan. The impeller blades are located parallel to the axis of rotation.

Combination fans have a cylindrical body and are more similar in appearance to axial models.However, their operating principle is different due to the design features of the impeller. The air first moves along the axis and then changes its direction by 45°.

The main advantage of a mixed-type fan is achieving a compromise between noise characteristics, performance and dimensions of the device.

Most often, centrifugal-axial units are used as duct fans in small and medium-sized ventilation systems with long air ducts. They are used as exhaust units and inlets in supply-type pressure systems.

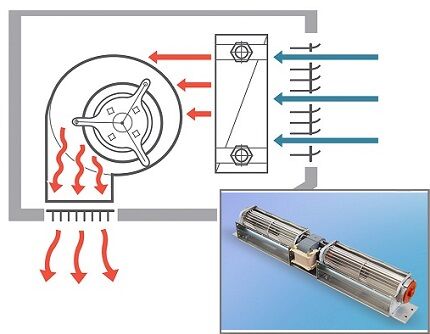

Tangential installation - uniform air flow

A tangential (diametrical) fan consists of an elongated housing equipped with a diffuser and nozzle, and a drum-type impeller with inclined blades. The air moves twice perpendicular to the axis of rotation of the cylinder.

Distinctive features of diametrical devices:

- high aerodynamic performance;

- ability to supply a uniform flow;

- the ability to rotate the fan, choosing the direction of the air flow;

- quiet operation;

- high efficiency rate - up to 60-70%.

Scope of application: creation of air curtains, fan coil units and use in split systems.

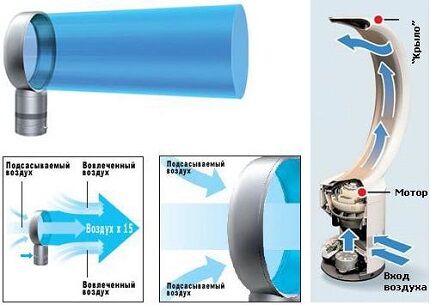

Bladeless fan - innovative technology

Household bladeless fans have recently appeared on the domestic market of ventilation systems.Their operating principle is radically different from the modifications discussed above.

Device components:

- a round or oval frame designed to draw in and eject air masses;

- base for fixing the frame;

- mini-turbine mounted in the base of the fan;

- motor.

The innovative fan works on the following principle:

- After turning on the engine, the turbine is activated.

- As the turbine rotates, it draws air through perforations in the base housing.

- Under the influence of turbulence, the air is accelerated 15 times and exits through the outlet slits located along the perimeter of the frame.

Air currents bend around the surface of the ring and rush in the desired direction.

Compared to traditional models fans without blades have a number of advantages:

- smooth adjustment of air flow intensity;

- convenience and absolute safety of use;

- changing the direction of air by adjusting the position of the ring;

- operational efficiency - energy consumption is 20% less compared to axial models.

The main disadvantages of the device: high cost and high noise level.

Dependence on operating conditions

When choosing a fan, it is important to consider the conditions of its use. Highly specialized installations have been developed for use in aggressive environments.

Units for normal use

General purpose fans are made of carbon steel.

The devices are permissible for installation subject to the mandatory operating conditions:

- dust content in the air for radial units – no more than 0.01 g/cub.m, for axial devices – up to 0.01 g/cub.m;

- working environment temperature – up to +50°С;

- absence of chemically aggressive, explosive components, fibers and sticky particles in the air.

The gas-vapor-air environment should not provoke accelerated corrosion processes; the permissible rate of metal destruction is 0.1 mm per year. If the operating temperature rises above the limit value, then the operation of the engine, which is usually located in the flow of moving air masses, deteriorates.

General purpose models are used in systems air heating and ventilation of public, residential and industrial buildings, as well as for other sanitary and technical purposes.

Special purpose ventilation units

Special-purpose fans are usually divided into five groups:

- dusty;

- heat resistant;

- explosion-proof;

- corrosion resistant;

- smoke extractors.

Dust units are used to clean air masses from dust and dirt particles: wood and metal sawdust, welding slag, grain waste. The air flow, passing through the nozzles, changes its direction from axial to radial. Due to the centrifugal force, the speed of the air flow also changes.

Low-power radial dust fans are installed on vehicles transporting grain compositions. High pressure devices are used in large production workshops.

Heat-resistant units are designed to move air whose temperature exceeds +80°C.

Due to harsh operating conditions, fans must have special characteristics:

- thermal insulation of the electric motor and its removal outside the air flow;

- high level of engine protection – IP44 and higher;

- production of structural elements from heat-resistant materials (heat-resistant polyamide, aluminum alloy, stainless or carbon steel);

- wide range of operating temperatures.

Heat-resistant fans are used in furnishing bath ventilation systems and saunas, removal of high-temperature exhaust air from a fireplace or stove, removal of combustion products from production areas.

Explosion-proof ventilation equipment is designed to remove explosive gas mixtures. This category includes compositions in which when the slightest particle ignites, the entire remaining volume of gas ignites.

Explosion safety requirements for electrical equipment are regulated by ATEX EC directives. Depending on the degree of explosion hazard of the area, ventilation units can be protected by:

- quartz or oil filling of the shells of conductive parts;

- sealing with a compound – polymer material;

- explosion-proof coatings.

The materials used to manufacture inlet manifolds, impellers, and housings are stainless steel, aluminum alloys and groups of dissimilar materials: stainless steel-brass, bronze, electrically conductive plastic.

Corrosion-resistant fans are designed for transporting aggressive, non-explosive air-gas mixtures with low dust content and the absence of fibrous and sticky components.

Materials for manufacturing parts of the device: titanium alloys, polypropylene, vinyl plastic. As an option, the working elements are sprayed with an anti-corrosion coating - corrosion-resistant steel grade 08Х13 or titanium alloy.

Scope of application of “anti-rust” fans:

- ferrous metallurgy;

- technological lines for the production of mineral fertilizers;

- carbon production;

- air supply to boilers with boiling composition;

- organization of circulation of water vapor with impurities of phenol, alkali and hydrogen sulfide;

- lines of coke plants.

Smoke extraction fans are powerful fireproof units that are built into the ventilation system of a building and work to blow smoke out of the room. The units are subject to high technical requirements.

Scope of application: smoke ventilation systems for buildings for various purposes. “Smoke exhausters” are installed on the roof of the room using a mounting flange and connected to smoke exhaust ducts.

Depending on the design of the fan, two- or four-way smoke emission can be carried out in a horizontal or vertical direction. It is possible to operate the units in the mode of general ventilation of the house.

Types of fans by installation method

As indicated above, according to the installation method, ventilation devices are divided into 4 groups: standard, roof, duct and multi-zone.

Conventional fans usually come complete with a support frame or holder. Their installation does not cause any difficulties.

Roof units are installed on the roof of a building and act as the final link in the building’s ventilation system. Such fans are exposed to negative external factors (rain, snow, gusts of wind), so they are made of especially durable materials. Almost all models are equipped with a protective cone to prevent clogging of the housing.

When choosing a roof fan, take into account the specifics of the room being equipped. For example, a model with a low noise level is selected for a kindergarten, hospital or school. For a production workshop, the priority will be the power of the equipment.

Duct ventilation units are placed in ventilation ducts and provide air exhaust and supply through the air duct system. The design of duct fans is usually of a diagonal or radial type, less often - axial.

The choice of device is carried out in relation to the shape of the air duct. Units are produced for round, square and rectangular shafts.

Multi-zone ventilation units are equipped with a housing that allows the connection of several suction air ducts that originate from different zones. Such fans are indispensable in rooms where it is necessary to install a hood in different rooms, but there is only one exhaust air duct.

An additional benefit is ease of use. It is necessary to service one fan, not several.

Varieties of household ventilation models

Domestic fans are further classified according to their installation location.

Window. The device is mounted in a window or wall near a window; there is no air duct. Such equipment is mainly used in public institutions: cafes, hairdressers, etc. Independent installation into installed PVC windows is problematic.

Kitchen. Removes fumes and various odors that arise during cooking. The fan is mounted directly into the exhaust hood. Based on the design, there are flat, dome and built-in hoods. Kitchen fans must be heat-resistant and have an external protective mesh.

Bathroom equipment. To increase the efficiency of the exhaust ventilation of toilet and bathroom overhead wall and ceiling fans are used. Compact units are economical and easy to install.

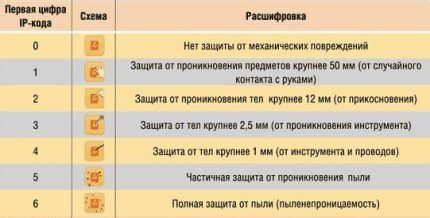

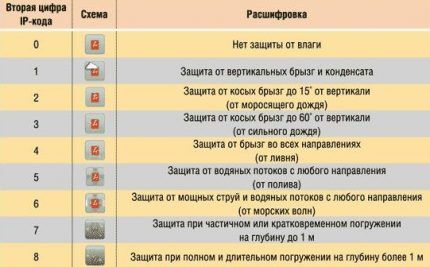

Regardless of the type of fan chosen, special attention should be paid to the marking of the device, namely the IP protection degree. The IP standard characterizes the security of equipment in a non-aggressive environment.

The level of protection against moisture getting inside the housing is indicated by the second digit of the marking.

Conclusions and useful video on the topic

Video #1. Operating principle and competitive advantages of a bladeless fan:

Video #2. Design of the centrifugal fan VTsUN:

Video #3. Round duct fan design:

The model design and technical and operational characteristics of fans allow us to select the optimal equipment for both domestic and industrial use. The designs of ventilation units are constantly being improved, adapting to the needs of customers.

Did you have any questions while reading the article? Would you like to inform us about useful nuances in choosing equipment? Please write comments in the block below.

I'm interested in a bladeless fan. A child won't put his hand into this. I touched a similar unit several times myself.True, its blades are soft and it stopped immediately, but it still feels unpleasant. In the bladeless, these things are eliminated in principle. The noise is no louder than a compressor running in an aquarium. And manufacturers will work on the price; such a fan can be sold en masse.

I have only one ventilation device: in the kitchen, combined with a hood. Completely ordinary, cost a few pennies, and still works.

Now I’m thinking about installing a fan in the toilet, but what they offer is too expensive, costing 15-20 thousand. So I’m thinking, if you install a simple axial fan in the hood yourself, will it cope with removing odors?

Hello, Vadim. Most likely, the consultants at the store where you learned about the toilet exhaust fan decided to use you to increase their sales.

For your case, you can apply standard calculations taking into account the typical dimensions for a bathroom of 1.7×1.5×2.5m. The exchange rate is about eight, so a hood with an indicator of at least 50 cubic meters is required. m/h. If you choose axial fans, then they have a minimum power of 80 cubic meters. m/h, and centrifugal fans 40-100 cubic meters. m/h. This means that choosing a suitable fan for the toilet hood will not be difficult.

The following models will suit you:

— ERA axial exhaust fan Slim 5, d 125;

— Fan ERA 4S-02, axial exhaust d 100.

The price of the listed models is within 1 thousand rubles. This is a completely reasonable cost for equipment for a hood in a standard-plan bathroom apartment. Exhaust fan connection It is produced according to the simplest scheme; you can do everything yourself.