Digging a well with your own hands: types of well structures + review of the best digging technologies

In areas where there is no centralized water supply, wells or boreholes have to be built.The type of source depends on the hydrogeological conditions of the area, the needs and personal preferences of the owner.

Digging wells is a labor-intensive and expensive process, but it can be made cheaper by doing it yourself. Therefore, we invite you to figure out how to make a well with your own hands and what you will need for this.

The content of the article:

At what horizon should we dig a well?

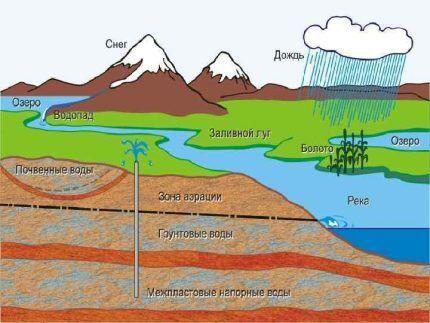

Aquifers can occur at several levels. The topmost one is usually located close to the surface of the earth. This layer is called perchal water. It may be contaminated by agricultural chemicals, fecal bacteria from sewage, etc.

Verkhodka is not suitable for feeding a well, unless the water is planned to be used exclusively for technical purposes or for watering garden plants. It should also be taken into account that during seasonal changes the amount of water can significantly decrease or increase.

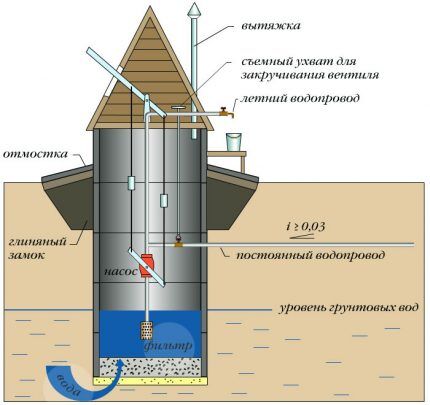

Wells are dug into the groundwater horizon. This aquifer lies below the perched water. The water in it is often free-flowing, so its level in the well is the same as in the aquifer. During the construction of hydraulic structures, groundwater is cut off from the perched water layers to protect it from contamination.

Artesian waters lie below groundwater. Wells are not dug to this horizon, and the construction of wells is very expensive. In addition, you have to obtain a permit to use water resources.

Artesian waters are pressure waters, so the water level in the well is higher than in the horizon, and even gushing is possible.

Finding a place for a water source

When building a well, it is important to correctly determine the depth of the horizon of clean drinking water, calculate and purchase the required number of concrete rings, equipment for arranging the hydraulic structure itself and the water distribution system. It is also important to choose the right place and time to dig a well.

Choosing the right location for a well depends on several factors:

- Geological exploration data. There are many ways to search for water in an area, but nothing more reliable than geological studies of the area has yet been invented.

- Information about nearby sources. It would be a good idea to ask your closest neighbors how deep their wells are built and what the quality of the water is.

- Suitability of water for drinking. It is imperative to submit a water sample for chemical and microbiological analysis to the nearest sanitary station. Experts will determine the concentration of chemicals and the presence of pathogenic bacteria.

- Soil type. The complexity of digging wells, the need to use special equipment, etc. depend on this. Ultimately, all this affects cost of a finished well. It is most difficult to build a well on rocky soils.

- Terrain. The greatest difficulties arise when building a well on a hillside. The ideal option is a flat area.

- Distance from pollution sources. Wells are dug at a considerable distance from cesspools, septic tanks, compost heaps, and barns. It is undesirable to place them in lowlands where rain and melt water flows, as well as water mixed with agricultural fertilizers.

- Degree of distance from home. The closer the water source is to the house, the more convenient it is.

In this case, the excavation should be placed so that it does not interfere with travel or block access to outbuildings or utility rooms.

The optimal distances are shown in the diagram below.

Features of wells of different designs

There are two types of structures – shaft and tubular. The first option is much more widespread, because Construction of such a well is usually cheaper and more convenient to use. The mine structure is universal, and water can be raised using buckets, hand and electric pumps.

Another advantage of the shaft structure over the tubular one is the ease of construction. You can find out how to dig a mine well with your own hands by reading specialized literature and articles.

If desired, everyone can take their advice and dig and arrange a quality water source on their own.

A tube well is built if the aquifer is located shallow, and the owner can use drilling equipment. The advantage of a tubular structure is faster construction. Due to their small diameter, tubular structures are less polluted. They can be built next to residential and commercial buildings.

Both types of wells have their own advantages and disadvantages. When choosing a suitable design, you should take into account all the nuances. Since it is easier to build a mine well without the use of special equipment, in the future we will consider the issues of digging just such a source.

The best time to start construction

When is the best time to dig a well? If you start work in the spring, after floods, you can make a mistake with the depth of the mine. Groundwater is rising, and until its level drops, it is not advisable to dig. Otherwise, there may be a need to deepen the structure, because There will not be enough water in summer and winter.

The autumn rainy season is also not the most favorable time for building a well. But in the summer heat or winter it is quite possible to start work. During these periods, the water drains away. If you can build a working well, it is guaranteed to maintain productivity in other seasons.

Winter construction is complicated due to soil freezing, but in summer or early autumn nothing prevents excavation work from starting. However, there is one exception. If the well is built on quicksand, it is better to dig it in winter.

Two main ways to dig a mine

Before digging a well at home or in the country, you should decide on the type of soil and choose the appropriate method for constructing the shaft. There are only two methods - open and closed. They differ significantly, each of them has its own characteristics.

Method #1 – open digging technique

The open method of digging a well is convenient and simple. Its essence is that you first need to dig a shaft to the required depth, and then install concrete rings. This method is suitable for areas with dense soil that is not prone to crumbling.

The mine is dug down to the aquifer. If necessary, the walls are strengthened as they go deeper into the ground. The diameter of the pit should be slightly larger than the calculated dimensions of the finished structure. When the shaft is dug, its walls and bottom are constructed, and the remaining gap is filled with a layer of sand or crushed stone.

Method #2 – features of the closed method

If the soil on the site is sandy, then the open digging method is not suitable, because... the risk of the mine walls collapsing is too great. This makes work difficult and can be potentially dangerous for construction workers. Then they use the “ring” method of digging a well.The technology itself is more complex than the open method, but safer.

Having chosen a place for the well, you should dig a shallow hole for the first ring. The recess can be from 20 cm to 2 m. The diameter must correspond to the size of the rings. Having installed the first ring, they begin to select soil from inside the structure. A heavy concrete ring will sink under its own weight.

Gradually the first ring will lower enough that the second one can be installed. It is placed exactly on the previous one, fastened with metal staples and mortar. It is important to avoid distortions, otherwise in the future this will lead to loss of tightness of seams and joints. This is how all the rings are gradually installed.

When the walls of the shaft are ready, all that remains is to waterproof them and arrange the bottom and top. These steps are the same regardless of which digging method was chosen.

When choosing a digging method, you need to take into account that many nuances arise during excavation work. Sometimes you need to get a large boulder that prevents you from going deeper into the ground, or you may stumble upon quicksand. It is much easier to deal with these problems if the open digging technique is chosen.

The disadvantage of the closed method is that water appears in the well. It contains more unnecessary impurities than groundwater and can contaminate the well. It is not always possible to get rid of perched water.

The open digging method is also not ideal. You have to dig a hole larger than the well itself. This involves a lot of labor.

Construction and arrangement of a mine well

Most often, mine wells are built from ready-made concrete rings. This is the most convenient option. The design is strong, reliable and can last for several decades. It is better to carry out work on the construction of a well by two or three people.

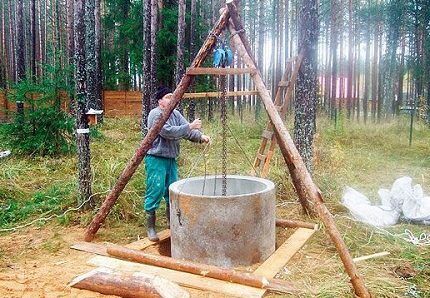

Lifting mechanisms will be required. You need to install a tripod with a winch or winch. With its help, buckets with dug up soil are lifted up and concrete rings are lowered into the hole. You will also need strong ropes, cables or chains.

First of all, you need to calculate the desired diameter of the well. The optimal option is 1 m. For this design, standard rings are used. It is better to choose products of small height. This will make it easier to install them one on top of the other. At the same time, you will have to spend more time sealing the seams, because... there will be more of them.

How to make the walls and bottom of the structure?

To arrange the walls and bottom of the structure, you need to follow the following instructions, which are not complicated:

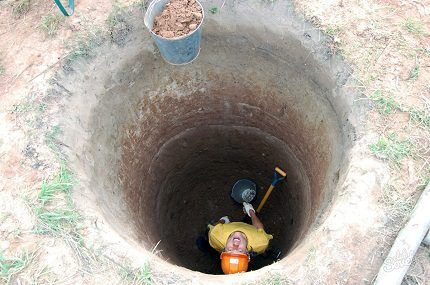

- Dig a hole 0.5–1 m deep. A shallower or greater depth will be inconvenient for work.

- Install the first ring. The ideal option is installation on a cutting shoe.

- Dig the bottom of the hole, removing soil evenly over the entire area of the shaft.

- When the ring is deepened, install the next one and fasten it.

- Continue working until you reach the aquifer. This usually takes several days.

- The signal that you have reached the aquifer is the water at the bottom of the shaft. It's dirty and muddy. To clean it, you will need to pump out the water and install bottom filter.

- When the shaft is ready, remove water and dirt with buckets or a pump, go deeper another 10-15 cm, and level the bottom.

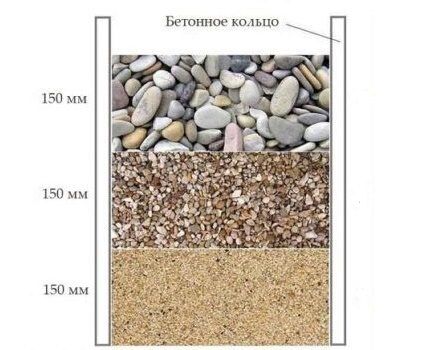

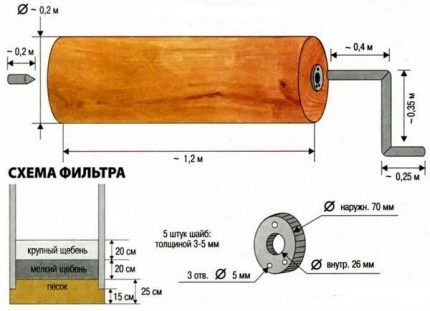

- The bottom of the well should be covered with a 25-centimeter layer of sand. It is best to choose river, coarse-grained. The next layer is fine crushed stone. Its thickness should be at least 15-20 cm. The last layer is large crushed stone. The thickness is the same.

Crushed stone should be disinfected with a weak lime solution before laying. It is not always convenient to place the bottom filter directly on the bottom of the pit. It happens that the soil is too liquefied due to too much water. In this case, first lay a boardwalk with gaps, on top of which a bottom filter is poured.

When the structure is ready, the water is pumped out. After this, you need to wait until it fills up and pump it out again. This procedure is repeated several times until the water is cleared. Now you can take a sample for laboratory analysis.

We also recommend that you read the article about reasons for water turbidity in the well and ways to eliminate it.

External waterproofing – clay castle

As external protection against water, the so-called clay castle. It is necessary to cut off the perched water and prevent rain and melt water from entering the well. The clay castle can hardly be called an impeccable structure. It can contribute to deformation of the well structure, because changes in volume.

To achieve good external waterproofing, roll materials are often laid, the surfaces are treated with liquid glass, and then a clay castle is made. This results in double protection from moisture. This leads to higher construction costs, but helps maintain water quality.

For the castle, choose clay with a small sand content - up to 15%. It is frozen out by leaving it outside during the winter. Then the material is mixed with lime (4 parts clay and 1 part lime), thoroughly mixed until a homogeneous plastic mass is obtained.

The “correct” clay does not crack if you make a lump out of it, does not spread, and holds its shape perfectly. It is placed in a trench dug around the well. The width of the trench must be at least 0.5 m, and the depth - 1 m. The walls of the trench are reinforced with formwork.

The clay castle is laid in layers of 15-20 cm. Each layer is well compacted. When the clay castle is ready, it is covered with geotextiles, and concrete or paving slabs are laid on top. External finishing is necessary so that the clay does not become limp during rains and does not turn into a dirty mess.

Arrangement of the well head

The above-ground part of the structure should rise by 0.7-1 m. The easiest way to arrange it is to install an additional concrete ring. The junction of the underground and above-ground parts is well sealed.

The concrete ring does not look very aesthetically pleasing. Therefore, to improve the appearance of the head, they are often trimmed with wood or stone, and houses are built that completely or partially cover the above-ground part of the structure.

Be sure to install a lid and canopy over the well. This is necessary to protect the water from rain, snow, debris, and insects. The tighter the lid closes, the better. Otherwise, the water can quickly become polluted and rot, becoming dangerous to human health. Also, to avoid interruptions in water supply during the cold season, you need a well insulate for the winter.

A canopy is often made in the form of a gable roof made of boards, clapboards, sheet metal or tiles. There is huge scope for imagination here. The upper part of the well can be decorated so that the structure turns into a spectacular landscape decoration.

Even if water from the well will be supplied to the house by pumps, it is advisable to install a mechanical device to raise it. This will help provide your home with water in the event of prolonged power outages.

Classic options are crane and collar. The first type of construction will look perfect on a site decorated in a “rustic” style. The collar is universal. It can be built from ordinary logs and decorated in any way you like.

Conclusions and useful video on the topic

All stages of well construction are described in the video below:

Internal waterproofing of the seams between the rings is a mandatory procedure.How to make it, watch the video tutorial:

We offer an option for arranging the above-ground part of the well:

The technology for constructing a well is simple, but its implementation requires serious labor costs. During work, you must adhere to safety regulations. Be sure to wear a work helmet, take care of the ventilation of the mine so as not to be poisoned by gases, and duplicate the main cables with safety ones. Your life may depend on it!

Trying to dig it yourself well in the country or a suburban area? Or maybe you have already done this work several times and can give practical advice to our readers? Please leave your comments, share your experience, and ask questions in the block below.

I learned that the work of digging a well is very expensive when it was necessary to build one on a summer cottage.

I decided to try to make it myself with the help of friends, especially since I calculated the depth of the water in it in advance from neighboring wells and learned from them the average number of rings needed. The most difficult thing was their delivery and one-by-one installation into the already formed pit.

Well, it’s quite possible to dig a normal well without hiring diggers, and the result is no worse. I’m also planning to organize a water supply from the well to the house, but I haven’t fully thought through such a system yet.