Bottom filter for a well: arrangement technology and review of filtration materials

If you plan to use well water for drinking, it will require serious preparation.To get rid of particles of soil and organic matter that fall into the mine during collection in a bucket, you need to install a filter for the well. An inexpensive, structurally simple system will purify and, in some cases, even disinfect water. Safety in such conditions is extremely important, don't you agree?

You will find everything about the types of well filters and methods of their construction in our article. We have carefully examined all effective types of filtering well circuits, their design options, and described the materials approved for use in this matter.

With our help, you will receive detailed answers to questions that owners of land with a well have. We present to your attention useful tips on caring for bottom filters. Photo and video applications will help you perceive information faster and easier.

The content of the article:

Functional purpose of the bottom filter

A bottom filter is a layer-by-layer embankment made of various natural materials that are not washed away by well water.Water passing through the filter is cleaned of debris, harmful impurities and suspended particles present in the well.

The installation of a bottom filter is mandatory in the following cases when:

- it is necessary to protect the bottom of the well from erosion;

- water flows under high pressure;

- at the bottom of the well there is fine or dusty sand;

- the well is opened by quicksand;

- protection of pumping equipment sensitive to clogging is necessary;

- the water level in the well is characterized by large differences, for example, during pump operation or precipitation;

- water quality is unsatisfactory: turbidity, sediment, unpleasant odor. You can read more about the causes of unsatisfactory water quality and how to eliminate them in this material.

Installing a bottom filter is not necessary if the well has exposed hard, fractured clay or rock formation. Do not use bottom protection if the water comes from natural springs. If the dense bottom of the well is not clogged with impurities and suspended particles, additional filtration is not necessary.

In other cases, to obtain high quality water, installing a bottom filter for a well is a mandatory step.

Materials for arranging a well bottom

The bottom filter consists of filtering bulk materials, passing through which the water is purified physically and chemically. Physical cleansing means cleansing from debris and suspended matter, and chemical cleansing means cleansing from impurities and harmful compounds.

Today in the store you can buy ready-made bottom filters for wells based on silver, activated carbon and river pebbles. Unfortunately, the cost of such filters is quite high, so most well owners prefer to make bottom filters with their own hands.

The materials used to construct bottom filters must meet the following requirements:

- sufficient density and weight not to float in the well;

- resistance to rotting, resistance to mold formation;

- neutrality, absence of chemical reactions;

- high level of filtration;

- environmental Safety.

The following materials are used for filters installed at the bottom of wells:

Tribute to tradition - quartz sand

This material is easy to find on the banks of rivers and natural lakes. The grains of sand have a diameter of up to 1 mm, the color is yellowish, translucent. Before placing it in the well, quartz sand must be washed several times.

You can do this as follows:

- Pour a 5-10 cm layer of sand into a container and fill it with water.

- Mix thoroughly and leave for 30 seconds.

- Carefully drain the water, in which particles of debris and silt will remain, and the sand will settle to the bottom of the container.

- Repeat 2-3 times until the drained water is clear.

Flushing will help remove clay particles and organic inclusions.

Large and medium river pebbles

A common loose material also found on river banks. Pebbles of different sizes, round in shape without sharp edges.

Before using as a bottom filter, the pebbles should be washed with clean water. Some people advise treating the pebbles with high temperature by placing them in the oven for a few minutes.

Natural gravel

Loose rock of natural origin, gravel particle sizes are 2-20 mm.

Before being placed in a well, this material must undergo a thorough multi-stage flushing, because... due to the impressive amount of voids between the components, gravel is capable of accumulating clay and silt particles.Slag gravel cannot be used due to the likely high amount of harmful impurities.

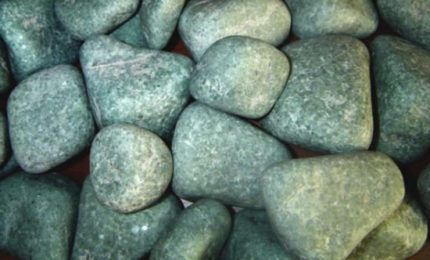

Jadeite - aerobatics

Jadeite or bath stone is a mineral semi-precious stone of natural origin, which contains silver and silicon.

This mineral has many positive properties that make it possible to effectively use it for constructing a bottom filter:

- purifies water from heavy metals;

- disinfects;

- prevents the movement of bottom materials (sand, sandy loam);

- does not absorb water, which means it will last a long time.

The disadvantages of this material include the need to purchase it (jadeite is mined in quarries; it is not a fact that the deposits are located in your region). The cost of the mineral is from 60 rubles/kg.

Shungite is a water purification agent

Material consisting of large particles of fossilized oil.

Shungite has the ability to effectively purify well water from:

- petroleum products;

- heavy metals;

- organic impurities;

- microorganisms;

- excess iron (iron taste in water);

- suspensions, turbidities.

Shungite also has the beneficial property of saturating well water with microelements valuable for living organisms.

This material is quite expensive, but its use is indispensable for wells located near industrial enterprises and highways.

Zeolite is an elite material

Zeolite is a natural porous material of volcanic origin. It is a natural sorbent that absorbs nitrates and heavy metal compounds.

Helps reduce background radioactivity, destroys phenols and other substances harmful to humans, plants and animals. The effectiveness of this material as a bottom filter is expensive - from 600 rubles per 10 kg.

Geotextiles - a barrier against pollution

Sometimes a polymer material, high-density geotextile, is used to construct a bottom filter. The peculiarity of this filter is that it perfectly filters physical suspended matter without improving the chemical and bacteriological parameters of water.

Using dense geotextile as the main material for the filter is advisable if a small amount of gas, such as hydrogen sulfide, enters the well.

Prohibited materials

Many well owners make a serious mistake by using the following materials to construct a bottom filter:

- Recycled construction gravel. The material obtained by crushing dismantled reinforced concrete structures will absorb water without filtering it.

- Expanded clay. It has low density and floats in the well over time. Releases harmful substances.

- Granite crushed stone. In most cases, this material has an increased background radiation.

- Construction limestone crushed stone. Contains a large amount of lime, the excess of which will reduce the quality of well water.

Washed gravel, sand and naturally occurring crushed stone are suitable for constructing bottom filters.

Installation of a soil filter at the bottom of a well

An effective bottom filter cannot be created using only one of the materials described above; the best option is to create a multilayer filter using several types of materials of different sizes.

There are two types of filter installation: direct and reverse. The choice of one type or another depends on the soil lining the bottom of the well and the pressure of the incoming water. In 9 out of 10 cases, a more efficient reverse filter is used.

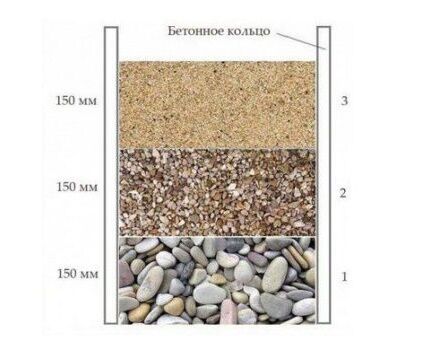

Direct backfill option

A three-layer direct filter is a type in which the material of the largest fraction is at the bottom, then there is a middle layer - the size of the fraction is 5-7 times smaller than the first layer, and at the top the third layer is quartz sand or small river pebbles. The thickness of each layer should be 15-20 cm, which means that the entire filter will occupy 50-60 cm of the depth of the well.

Procedure for installing a direct bottom filter:

- preparing the well bottom: garbage removal, silt and other contaminants;

- bottom filling a layer of 15-20 cm of coarse fraction: jadeite, zeolite, large river or sea pebbles;

- backfill materialand the middle fraction: river or sea pebbles, medium gravel, fine zeolite, shungite;

- formation of the top layer fine fraction: quartz sand, small pebbles.

The direct filter is used on floating soils (together with a shield), as well as on sandy and loose soils with a low pressure of incoming water. In this case, the main function of the direct filter is to carry out step-by-step water purification.

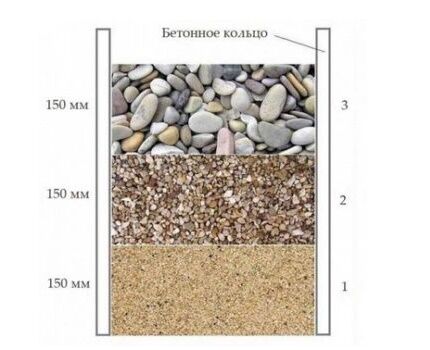

Reverse installation scheme

A return filter is a type of well filter in which the installation is carried out in layers from fine material to larger filter elements. The main function of the return filter is to prevent fine debris and sand from penetrating into the upper layers. The return filter protects the bottom of the well from erosion. It is used on sandy and sandy loam soils with calm water flow.

Procedure for installing a return bottom filter:

- Preparation of well and bulk materials.

- Filling of the lower fine-grained layer: quartz sand, small pebbles.

- Filling of the middle fraction layer: river pebbles, gravel, zeolite, shungite.

- Coarse layer filling: large stones over 5 cm, jadeite, pebbles, geotextiles.

As with the installation of a direct filter, the thickness of each layer should be 15-20 cm. All bulk materials must be washed with running water to remove clay particles and organic contaminants before placing them in the well.

Types of well shields

Bottom shield - a wooden shield made of boards in the shape of a circle, used when the influx of water into the well occurs with high pressure, as well as in the presence of quicksand. The main function of the bottom shield is to protect the bottom and filter from erosion. For installation in a well, two types of shields are used: wooden and metal (mesh).

Wood panel for laying on the bottom

Compared to metal panels, wooden panels have the following advantages:

- Environmental Safety.

- The wood used has bactericidal properties.

- Not subject to corrosion.

- Lower cost and ease of manufacture.

You can make a wooden bottom shield yourself using one of the materials:

- oak - durable, strong rock that can impart a specific bitter taste to water;

- larch - durable material that does not affect the quality and taste of well water. The service life is significantly shorter than that of oak;

- aspen — wood of high strength, has disinfecting properties, does not rot, and has a long service life.

To make a shield, you need to take several wooden boards and fasten them tightly with stainless steel nails. It is better to connect with wooden tongues, under which counter holes are drilled in advance in adjacent boards. The diameter of the shield should be slightly less than the diameter of the well; for this, a circle is drawn and the excess boards are cut off with a jigsaw.

Holes 5-10 mm in size are made on the entire surface of the shield, through which water will flow.

To ensure better water circulation, the shield must have wooden “legs”; their role is played by two bars 5-7 cm thick, onto which boards are hammered on top.

Elements of a reverse bottom filter are placed on the shield: first, coarse materials that prevent the shield from rising under the influence of water flows. In the presence of strong quicksand, the shield will gradually be sucked into the ground, so its installation will need to be carried out every 3-7 years.

Metal bottom device

The bottom shield for a well can be made with your own hands from a metal mesh with a fine-mesh structure.

The advantages of such a shield:

- high strength and durability;

- does not affect the taste of water over time;

- Reliably filters sand and debris of various sizes and origins.

To make a metal shield, a stainless mesh with a cell size of no more than 2 by 2 mm is used. The mesh is placed between two identical metal circles. The circles are cut out of sheet iron and correspond to the diameter of the well. The shield is installed on a layer of backfill made of large stones 10 cm thick, fastening is carried out using pins mounted in the walls of the well.

Bottom filter elements are poured onto the mesh. It is worth noting that the service life of the mesh is from 5 to 10 years; over time, the metal begins to deform and rust, losing its filtering properties, which means the mesh shield needs to be replaced.

Wall filter in a well

In the case when the flow of water entering the well is very weak, and filtration is also carried out through its walls, then installing a bottom filter is not advisable. In such a situation, the best option would be to install a wall filter.

To make a wall filter, it is necessary to cut V-shaped holes located horizontally in the lowest part of the well (the lower reinforced concrete ring), where filter elements made of coarse-cell concrete are installed.

Concrete for filters is prepared using medium-fraction gravel and cement grade M100-M200 without adding sand. The cement is diluted with water until the consistency of the mixture becomes creamy, after which pre-washed gravel is poured into it and mixed thoroughly. The resulting solution is filled into the cut holes and left until completely hardened.

Caring for the bottom filter

Once you have installed a bottom filter in your well, do not forget to clean it at least once a year. In addition, do not forget to regularly carry out preventive water disinfection in the well

The technology for cleaning the bottom filter consists of the following steps:

- Removing filter elements and bottom shield from the well.

- Cleaning the bottom shield or replacing it.

- Flushing or replacing excavated rocks.

- Laying materials in the same order.

Timely cleaning of the bottom filter will help maintain conditions for drawing clean water from the well all year round.

Conclusions and useful video on the topic

Making a bottom filter with your own hands using materials of various fractions:

Construction of a bottom filter using a wooden board and shungite:

Making an aspen shield for a bottom filter on quicksand:

Installing filters for water from a well is not a complicated process that can be done independently without the involvement of specialists and unnecessary financial investments.

The cost of installing a well filter depends entirely on what materials you choose as filtrates. With proper installation and timely cleaning of the bottom filter, you will always have access to clean and tasty water.

Do you have any questions about installing a bottom filter for a well? Or do you have experience in installing well filters and can you share useful information? Please ask your questions, leave comments and suggestions in the block below.

The well is very important, because in my dacha, for example, it is the main source of drinking water, and if you approach the creation of a bottom filter responsibly, the quality of the water will be an order of magnitude higher than from the tap in the apartment! I made a similar direct filter for myself, from the materials described, plus I added some nuances of my own, for reliability. The water is filtered amazingly, the color is transparent, without impurities, no odors!

Is it possible to reuse a used bath stone? Doesn't it lose its properties? We want to buy new stones for the new bathhouse, and use the old ones as a filter for the well. We were no longer satisfied with the composition of the water; the well was not equipped correctly. We’ll also try to remove 50 cm of soil from the perimeter of the well and fill everything with red clay, our rural area is full of it, we’ll make a water seal. Afterwards we want to pour sand around the well in the form of a hill so that the embankment is higher than the ground level around it. I hope this helps improve water quality.

The general problem with the quality of drinking water or its shortage makes you think about building your own well. After all, we used to have wells in many yards. But it seems that everyone is in the same village, and the quality of water is different for everyone. We don’t have a well, but we go to our neighbors for well water. It is very old, the walls are lined with stone. They say that the water in the well must be constantly renewed, then it will be fresh and clean.

I'm racking my brain about what to do with the well. There was normal non-potable water - they watered, washed, washed, and washed the dishes. I decided to clean it. Seven rings - covered up the leaking seams and cleaned them. Now the water comes from the bottom rusty 16 mg per liter.

They advised to fill the bottom ring with sand and put something else on top. Someone says that white limestone chips help, someone shouts “granite!”, but I’m thinking about shushgit. I also decided to open the seams back up.

Grandfather, in the 70s, had a well near a log house and cleaned it, once every 5 years the water was very good and clean