How to make a swing from metal with your own hands: the best ideas + construction instructions

On a summer cottage or near a cottage there is always a place to relax in the fresh air.And an indispensable attribute of such a holiday is an outdoor swing. Do you agree? Of course, you can order their installation from one of the many private companies or purchase a ready-made kit via the Internet and assemble it yourself. However, in both cases the cost of quality full size the model will be quite high.

But it’s much more interesting to build an outdoor swing yourself, especially since there’s nothing complicated about it. Next, we will tell you how to make a swing with your own hands from metal, what tools and materials you will need for the work, and also introduce you to popular swing options.

The content of the article:

Popular types of metal swings

First of all, you need to decide on the material of manufacture. Metal is the best choice due to its many advantages over other materials.

Firstly, it has high strength. Therefore, the metal structure has a minimum number of reinforcing elements, but can withstand significant weight

Secondly, metal is durable, it is much more resistant to external factors, such as high humidity, physical impacts, temperature changes, etc.

Thirdly, maintenance of a metal swing is reduced to a minimum. If an outdoor wooden swing needs to be painted annually, then by covering the metal with high-quality paint you don’t have to worry about re-protecting it for 5-7 years.

By design, outdoor swings are divided into single and multi-seat. In most cases, the choice is made in favor of the latter, since they can be used not only for sitting several people, but also for lying down.

The remaining differences related to the size of the seat, the materials used to make the roof and seat, and the presence of handrails are nuances related to the comfort of use. They do not have much influence on the fundamental design of the supporting frame.

Option number 1 - transformers

Despite the complexity of the design, transformers are becoming increasingly popular due to their high comfort. The seat has a reclining mechanism. As a result of the transformation, a small bed on suspensions is obtained.

The canopy, as a rule, has a large area and reliably protects from both precipitation and sunlight. In some models, the canopy design is supplemented with a canopy with the ability to change the angle of inclination. It will be able to protect the seat from sunlight falling at an acute angle.

Option No. 2 - children's swing

The main emphasis in design development is on safety.All-metal suspensions made of pipes do not allow them to swing diagonally, preventing them from hitting the racks. The seats are equipped with holders to prevent the child from falling out during loading.

The sizes also shrink to accommodate smaller children. The seat is most often single, so to avoid conflicts, the swings are made double or triple.

Option No. 3 - spherical models

Traditional designs with seating in the form of a bench have a lot of advantages, ranging from simplicity of design to good capacity. However, when it comes to design and unusual design solutions, then a spherical swing is beyond competition. In stores these products are called hanging chairs, and they are most often designed for one person.

At home, you can make a slightly larger chair. In this case, the shape of the seat can vary from a sphere to a drop. An arched post is used as a load-bearing element.

Compact models use a ring-shaped base located directly under the spherical seat. Larger, drop-shaped, designed for two or more people should have a more powerful stationary stand. It can be an independent structure or part of a structural element of a building.

To increase comfort, numerous pillows or small specially made mattresses are placed on the seat. To protect from the sun, the upper part of the sphere is draped with fabric.

You can only sit on such a seat while reclining; this provides for some difficulties when sitting down and getting up. So such models are suitable only for people without any problems with the musculoskeletal system.

Option No. 4 - hammocks

A recently popular variety that involves lying down on a seat. Hammocks swings have their own design features.

The seat consists of a metal frame with fabric stretched over it. This, in itself, provides a fairly high level of comfort. Such swings do not have a back or it is located at a large angle in a reclining state.

Swing installation method

Depending on the installation method, the swing can be stationary or mobile. In the first case, the load-bearing elements of the swing can be rigidly attached to the foundation. As a rule, such products have a bulky design and are highly durable and reliable.

Mobile models have racks in the form of trapezoids or triangles, connected by transverse elements to give the structure spatial rigidity. Most often they are intended for children and have restrictions on maximum load.

Materials, tools, drawings

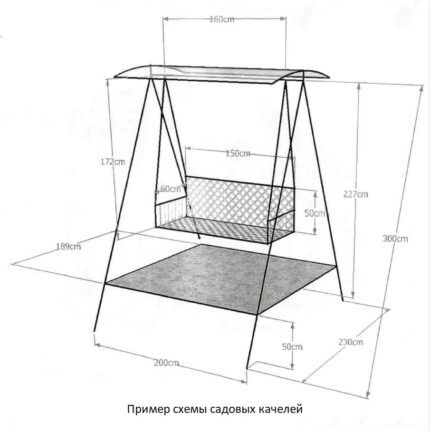

The simplest design of an outdoor metal swing is a frame of two A-shaped posts connected by a crossbar. Suspensions are attached to it through bearings, to which, in turn, the seat is attached.

Despite its apparent simplicity, the manufacture of such a design has many nuances and requires a certain skill, as well as a solid set of tools:

- Power tools:

- drill;

- corner sander - Bulgarian;

- inverter welding machine.

- Hand tool:

- drills for wood and metal;

- screwdrivers, wrenches;

- building level, tape measure;

- Consumables:

- metal profiles of design cross-section;

- boards or bars for the seat frame;

- roof material: polycarbonate, textile (tarpaulin), metal tiles, soft tiles (on a base of thin boards);

- self-tapping screws for metal with plastic washers for fastening polycarbonate, nuts, bolts, washers.

Since dynamic loads act on the supporting frame of the swing, it is better to make all connections permanently using electric welding. Its use is much faster and more reliable than the use of nuts and bolts in prefabricated joints. It should be noted that when loosened, the thread will relax, causing backlash.

The main material used for production is rolled metal. It is necessary to carefully select the type of profiled steel, since not only the strength and durability of the structure depends on it. By choosing thick-walled metal, the master will significantly complicate all work processes. Since such material is much less susceptible to drilling, cutting and bending.

For the racks and crossbars of a swing designed to support the weight of two or three adults, a pipe with a diameter of 70 mm is sufficient. It is advisable to make the seat frame from pipes with a diameter of 40 mm. If a chain is used for suspensions, the thickness of the link must be at least 5 mm.

Instructions for building a swing

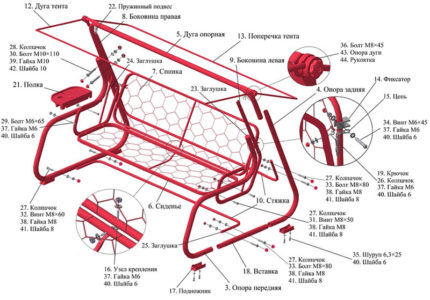

Let us consider the sequence of actions of the option presented in the diagram in more detail. First, you need to use a grinder to cut profiled pipes for racks 3 m long (4 pcs.). The overall height of the swing will be slightly lower, but it is necessary to have a supply of pipes for concreting.

Then 4 pipes 2 m long are cut for the crossbars that create stiffening ribs. In the future, they will be fixed around the perimeter and will create a base on which the swing will rest.

After this, stiffening ribs are applied to the bottom of the racks to form an isosceles triangle. Mark the cut angle on them, cut them with a grinder and weld them. The top horizontal crossbar is cut out and welded to the top of the rack.

The bench will have a back and seat made of wooden blocks with a cross-sectional area of 30x30 (30x70, 30x50) mm.The workpieces must first be sanded using sandpaper, angular sanders with with an appropriate nozzle or surface planer. Suitable for applying to wood protective covering before installation work begins. Thus, the entire area of the workpiece will be processed.

The seat frame is assembled. If you have a pipe bending machine, the arcs for the armrests are bent. If there is no such device, welding of several parts is allowed. Then the slats are screwed to the frame in increments of 20-30 mm.

Holes are drilled in the top crossbar into which bolts with hooks are inserted to secure eye-shaped nuts or welded. Chains are threaded through the hooks, which are attached to the frame of the bench using a carabiner.

Sections of profiled pipe are welded to the top crossbar at an angle of 15-20 degrees. They will serve as a load-bearing base for the roof.

Next, wooden slats of the appropriate size are screwed to the pipes, onto which the roofing covering is laid. To protect against corrosion, the metal is painted in 2 layers of oil paint.

After which small holes 50 cm deep are dug in the ground. Snacks and the bottom is lined with roofing felt or other similar material. It will serve as formwork and will prevent moisture from absorbing into the soil too quickly.

The swing legs are lowered into the recesses, after which the space is filled with rubble stone and filled with liquid cement-sand mortar. All you have to do is wait until the concrete hardens and you can use the homemade product.

Conclusions and useful video on the topic

How to make your own metal swing with decorative elements:

Making a swing from metal profiles yourself is not very difficult for a person who has even basic skills in working with metal. The main thing is the availability of appropriate tools and accuracy in performing electric welding work.

If desired, the structure can be decorated with various decorative elements imitating forging. They can be purchased in construction supermarkets or made independently from 8-10 mm wire using the cold bending method.

If you have already made a metal swing with your own hands, please share your own experience with our readers. Write your comments, upload photos of your own swing in the comments block. There you can ask our experts questions about the topic of the article.