Ventilation in a house made of sip panels: the best options and arrangement schemes

If you love warmth more than coolness, or live in a cold region, then housing made from SIP panels is quite suitable for you.But along with the heat, you get a house where the air often stagnates, the smell quickly deteriorates, a lot of moisture accumulates and it becomes stuffy. To ensure that ventilation in a house made of SIP panels does not reduce its usefulness and is powerful enough, you need to think about air exchange in different weather conditions.

Agree, it won't hurt you to read about this before you start building. If you already own such a house, then there is an opportunity to improve it thanks to the steps that we wrote about.

We have prepared a simple guide about ventilation in a SIP house, but with all the details. You will be able to understand which of these is better, simpler and more justified. The article contains almost no general information, except for brief information about the features of the material.

The content of the article:

Why do we need SIP panels?

Housing made from SIP panels does not need insulation, but will not be comfortable without good ventilation. Its walls allow almost nothing to pass through. Get ready for the fact that you will need a developed air distribution system. There are three main options for its organization.

SIP panel (structural insulated, or structural insulated panel) is a type of sandwich panels. It consists of two large oriented strand boards (OSB) with insulation pumped or glued between them.

SIPs are used in low-rise construction. Homes receive good protection from external factors. Thanks to high quality wood and chip laying technology, the walls will have sufficient mechanical strength.

Buildings made from SIP panels receive a lot of usable space and built-in thermal insulation. They are built in warm and cold weather, in a short time thanks to simple assembly technology.

A SIP house, like other frame buildings, needs effective ventilation. Due to the fact that the walls do not allow air to pass through well, condensation and dampness appear.

Pipes in SIP houses are selected with sound insulation, since the materials and design of the walls/floors significantly amplify sounds.

Ventilation of houses made of SIP panels

In cold weather, more moisture condenses in a building made of SIP panels than in other houses. In summer, condensation also actively appears, but mainly only on the windows. Even during the design process, you will have to lay out paths for air ducts, find places for valves, a block supply and exhaust ventilation. At about the same time as for other utilities.

It would not hurt to install one ventilation hole in each room, and in the kitchen - both an exhaust and a supply. The most difficult thing will be with air exchange in technical rooms: in bathrooms, kitchens, rooms without windows for utility purposes.

There are general requirements for air exchange:

- constant movement of air, its renewal;

- uniform ventilation of all rooms;

- elimination of dirty air;

- comfortable temperature;

- no drafts.

For normal air exchange, natural ventilation with air supply and exhaust is required.Fans and ducts with blowers are added to the natural one (windows, ventilation ducts with gravity flow).

The second question is how to make balanced ventilation: strengthen conventional ventilation or shift the emphasis to heat exchange or mechanical fans powered by electricity.

Option #1 - improved ventilation scheme

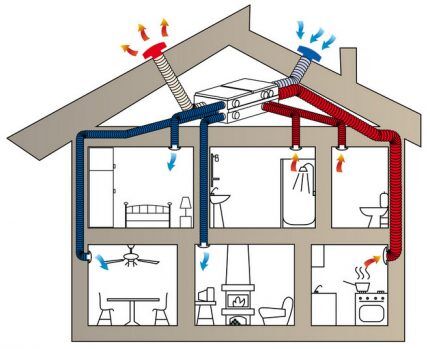

We are talking about a natural supply and exhaust system in combination with mechanical ventilation as an auxiliary one.

In this case, separate exhaust ducts are made for the kitchen, bathroom, toilet, rooms without windows and small rooms. The pipes are ideally combined into one at the level of the top floor/attic/attic and lead above the roof through one hole.

Supply system assembled from one pipe on the roof and lowered to the height of the attic, giving it a horizontal position. The channel at this level is laid to its maximum length. Ideally, the pipe on both sides reaches the most distant places in the house. Already from this horizontal branch, channels are led to each residential premises and, if desired, to technical ones.

The exhaust and supply parts of the system are combined in a block in the attic. A heat exchanger is sometimes installed in the unit. The latter are often used as elements of complete ventilation.

The supply and exhaust unit usually looks like a box with four holes. The supply and exhaust channels enter and exit them. The inflow pipe above the block should be made curved and horizontal on the street side - so that air can get inside more easily.

To clean the air mass, it does not hurt to install a filter.They try to keep the air exhaust channel as straight as possible from the block to the space above the roof.

Branches of the main air supply and removal channels are led to the upper parts of the premises. Controlled valves are installed at the ends of the supply paths. Exhaust ducts are covered with lattice hatches, and they are located as far as possible from the entrance openings.

Rooms with poor circulation are provided with portable fans. In the kitchen, a mechanical hood is placed above the stove, and the air duct of this device is directed to the street. You can do this in a private house.

This entire system is supplemented with passive ventilators. The devices operate in two modes. The supply and exhaust operates due to the pressure difference. There is also through ventilation, which is organized by two such devices.

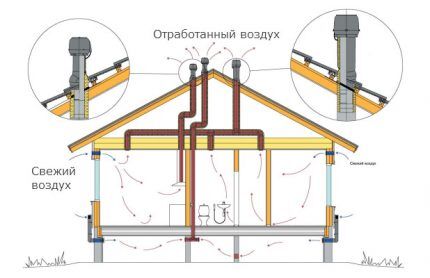

Option #2 - use mechanical devices

The provided ventilation shafts become clogged over time. Taking this into account, we can take a different route. Let's add superchargers that operate from a power source. Let's calculate their power so that they can perform their tasks without the help of natural air exchange.

Installing mechanical ventilation in a house made of SIP panels will not be easier than installing natural ventilation.

Good mechanical ventilation consists of:

- several independent exhaust ducts;

- supply fans;

- valves of different types.

Let's start with the exhaust system. Mechanical fans can be installed in ready-made pipes or in separate ones with the ability to implement a more efficient pattern.We make at least 2-3 exhaust outlets on the roof.

Inside the house we lower the channels to the bathroom, toilet, kitchen, basement. Preference should be given to a system with fans in the inlets and in the roof hoods.

We organize the inflow through wall supply fans. We will place them on the external walls, one per room, and in the basement - two on opposite sides. In rooms without external walls we provide supply ducts with an exit through the roof.

Some simply leave small openings in these rooms to allow air from the outside to enter. These passages are closed with plugs.

There are two types of supply fans for walls:

- for wall installation;

- for installation in thick walls.

They are installed from the inside, i.e. in the house.

Unforgettably wall valves three types, including mixed supply and exhaust. We place them where the air exchange is expected to be weaker. In the kitchen we add a valve to the double-glazed window profile. This type of window ventilator provides powerful microventilation. We make the kitchen hood autonomous and equip it with an adsorption filter.

If necessary, add a supply and exhaust fan in a window or wall. The device is most suitable for kitchens. We can deactivate it at any time, but in cold weather the device will have to be turned off. The system is not suitable for ventilation without other devices.

Option #3 - ventilation with recovery

There is also an option with high-power ventilation, and to prevent the air from getting too cold, it should be heated somehow.Read more about what heat recovery is Further.

They bring benefits supply air heaters, thanks to which it becomes possible to supply a lot of air from the street without disturbing the temperature regime. The devices operate on coolant, and their fans are powered by an electric motor. The air passes through the body and enters warmly.

Temperature comfort is achieved in other ways. Circulation systems move air from inside the house to the outside. There he mixes with the street. This mass is sucked inside. By the time the resulting air reaches the rooms, it will become warm and much fresher. There will be no harmful substances or unpleasant odors left in it.

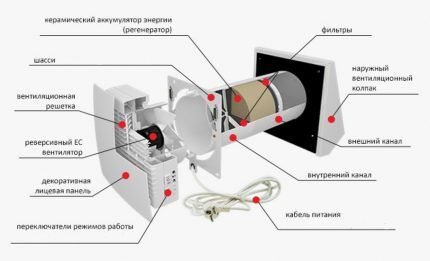

Another option is a recuperator. The device uses warm air from various heat sources (kitchen hood, etc.) or simply from the room. In the exchanger, the air gives off heat and then goes outside, and from it the cold street air is then heated. The transfer of thermal energy occurs thanks to a ceramic element capable of accumulating it. The outer end of the recuperator is protected by a visor from gusts of wind, snow and rain.

If the temperature difference is more than 40 degrees between the room and the street, the air coming in will be about 5 degrees colder than the air leaving. The energy efficiency of the house will remain high.

On the side of the house's facade, the hole is placed a little lower so that warm and cold flows move better. Recuperators can be installed in several rooms at once. Primarily in those where there is access to an external wall, as well as in basements.

Recuperators have an electric motor and several speeds (usually three). At maximum, medium-power devices consume about 10 watts. If you add up the power of all such devices for a large house, the electricity consumption will be low. Only the initial costs will be high.

Let's consider preparing recuperators for installation using the example of one unit:

- Remove the casing of the device.

- We connect the wires. We simply attach them as needed: the recuperator should already have special adapters. After installation, connect the device to the power supply.

- We remove the filter from the tube, which was covered by the outer shell.

- There will be a line with serifs on the surface. The one closest to the room edge of the recuperator indicates the minimum permissible length of the device.

- We take into account the thickness of the walls. For an external one in a SIP house it is most often 124 mm, 174 or 224 mm. Usually it is not enough for the recuperator to completely “hide” in the wall.

- We cut the tube and follow the markings. If the thickness of the walls is insufficient, we shorten it along the notch closest to the room side.

- We push the filter back.

- If the walls are not thick enough, we will simply install a hood - at the place where the heat exchanger is installed, inside or outside the house. Sometimes it comes included.

Recuperators are sometimes installed without a shell, but with a dense layer of thermal insulation. This is how the highest density is achieved when the available hole diameters do not match the casing parameters.

If you find a more or less suitable bit for cutting, you can install the ventilation yourself: in a SIP house, the walls are easy to drill.

If you attach the hood from the outside, but it does not coincide with the topography of the facade, then simply trim it and seal it with sealant.

Buildings made from SIP panels retain heat well; there is no point in spending a lot on heating the incoming air. Moreover, warm weather occupies a considerable part of the year. In terms of thermal insulation properties, a SIP panel is more than five times more effective than brickwork.

At temperatures below 10 °C without preheating it will still be bad, but at negative temperatures the incoming cold air will neutralize the entire effect of SIP panels.

The task is simplified by selective forced ventilation. Parts of the building are excluded from the street air supply system. You can’t do without a thoughtful layout of rooms where the air makes fewer turns. The supply system is ideally distributed to all rooms.

Valves are made with an adjusting plug in the hole. They are placed at a height of 0.5 meters above the floor, and the installation site is sealed with foam. With a well-organized supply of other appliances, less will be needed, and the rooms will always be fresh and warm.

Conclusions and useful video on the topic

Video instructions for installing ventilation devices in the premises of a house made of SIP:

Installation of the supply valve with detailed explanations:

Nuances for organizing ventilation in a SIP house according to the characteristics of a particular structure:

You have read about the strengths of SIP houses and what will definitely make itself felt. Consider increasing existing ventilation. Add mechanical devices. Make them the main sources of fresh air if air conditions are unsatisfactory.

Assemble the new system with high traffic flow and a large number of hoses. Consider powerful heated systems for the incoming air. You can install these with the least effort.

Write comments and ask questions. Tell us about the amenities and disadvantages of your home made from SIP panels. Write how successful you think the ventilation in it is. The feedback form is located below.