Heat recovery in ventilation systems: operating principle and design options

During the ventilation process, not only exhaust air is recycled from the room, but also part of the thermal energy. In winter, this leads to higher energy bills.

Heat recovery in centralized and local ventilation systems will allow you to reduce unjustified costs without compromising air exchange. To recover thermal energy, different types of heat exchangers are used - recuperators.

The article describes in detail the models of units, their design features, operating principles, advantages and disadvantages. The information presented will help in choosing the optimal option for arranging the ventilation system.

The content of the article:

The concept of recovery: the operating principle of the heat exchanger

Translated from Latin, recuperation means compensation or return. With regard to heat exchange reactions, recovery is characterized as a partial return of energy expended on a technological action for the purpose of application in the same process.

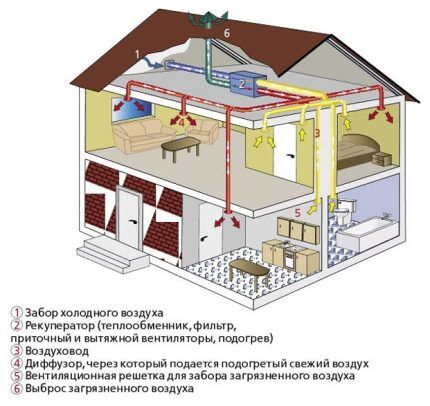

IN ventilation system The recovery principle is used to save thermal energy.

By analogy, cooling is recovered in hot weather - warm influent masses heat the exhaust waste and their temperature decreases.

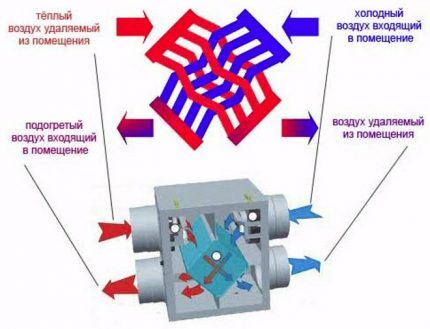

The energy recovery process is carried out in a recuperative heat exchanger.The device includes a heat exchange element and fans for pumping multidirectional air flows. An automation system is used to control the process and control the quality of air supply.

The design is designed so that the supply and exhaust flows are in separate compartments and do not mix - heat recovery is carried out through the walls of the heat exchanger.

Understand and understand what it is ventilation with recovery A visual diagram of air circulation will help.

The feasibility of a recuperator in ventilation

We can talk about the feasibility of installing recuperative ventilation by assessing the effectiveness of the system and comparing its advantages with disadvantages.

The need to use heat recovery is most relevant in buildings with forced air exhaust. As a rule, these are low-inertia buildings erected using innovative thermal insulation technologies (houses made of sandwich panels, gas silicate slabs, foam blocks).

In such buildings, the walls do not accumulate heat well, and natural air exchange is ineffective.

However, problems with air circulation are also typical for “traditional” buildings made of brick and concrete.The presence of sealed heat and sound insulating PVC windows blocks circulation with a natural impulse - the flow of fresh air stops, and the draft in the ventilation duct overturns or tends to zero.

The solution to the problem of “Euro-windows” is the organization of forced ventilation. The system restores air exchange, but heat loss increases up to 60%. And here it is no longer possible to do without heat recovery.

Ventilation heat recovery efficiency indicator:

- 0% - open window - warm air is removed into the atmosphere, and cold air enters, lowering the temperature in the room;

- 100% - the supply air is heated to the “exhaust” temperature - technically impossible to implement;

- 30-90% - an acceptable parameter, recovery with an efficiency of 60% or more is considered good, an efficiency of over 80% is excellent heat transfer.

The efficiency of the system depends on the type of recuperator, room dimensions and air flow. In any case, the use of recovery ventilation, even with an efficiency of 30%, is more profitable than its absence. In addition to significant savings on energy resources, heat “regeneration” improves the overall microclimate in the room.

Disadvantages of using a heat exchanger:

- Energy dependence. The purchase of climate control equipment is justified if the electricity consumption is significantly less than its savings after installing the recuperator.

- Condensation. Due to temperature differences, moisture may condense on the walls of the heat exchanger. In winter, there is a possibility of icing, which can lead to a rapid decrease in efficiency or failure of the recuperator.

- Noisy work. Some models emit a hum during operation.If during the day this disadvantage is not particularly noticeable, then at night the noise causes discomfort. Recuperators with improved insulation operate quietly.

High initial investment is often the main argument against energy efficient ventilation.

Features of different types of heat exchangers

The design of the recuperator determines the flow pattern of the coolant, the efficiency of the ventilation system, the energy consumption class and the cost of the equipment. Five types of heat exchangers are used: plate, rotary, heat pipes, chamber devices and models with an intermediate coolant.

Plate recuperator – simplicity of design

The basis of the heat exchanger is a sealed chamber with many parallel air ducts. The channels are separated by partitions - heat-conducting plates made of steel or aluminum.

Gas flows move towards each other, intersect in the recuperator cassette, but do not mix. Heat exchange is carried out due to simultaneous cooling and heating of the plates from different sides.

Advantages of a cross heat exchanger:

- ease of installation and configuration of equipment;

- exclusion of contact of air masses;

- affordable cost and compact dimensions;

- absence of rubbing and moving parts.

The efficiency rate varies in the range of 40-70%.

The main disadvantage of the plate model is the settling of condensate in the exhaust duct and the formation of ice in winter. To defrost the unit, the incoming stream is redirected to bypass the heat exchanger, and the warm outgoing stream melts the ice on the plates.

There are two possible ways to solve the problem:

- Preheating of the incoming air flow to a temperature at which the formation of ice is excluded.

- Recuperator with plates made of hygroscopic cellulose. The material absorbs moisture from exhaust air masses and transfers it to newly incoming flows.

When choosing a cross heat exchanger, you should take into account the operational features of the plates.

Their characteristics depend on the material of manufacture:

- Aluminium foil – affordable cost, but limited performance in winter. In addition, it is not recommended for residential premises due to air drying. Modifications with aluminum “filling” are the best option for baths and swimming pools.

- Plastic partitions - similar in price to metal products, but differ in improved operating efficiency.

- Cellulose heat exchanger – prevent freezing and maintain normal moisture content indoors.

The hygrocellulose recuperator is the most economical and optimal for ventilation of residential buildings.

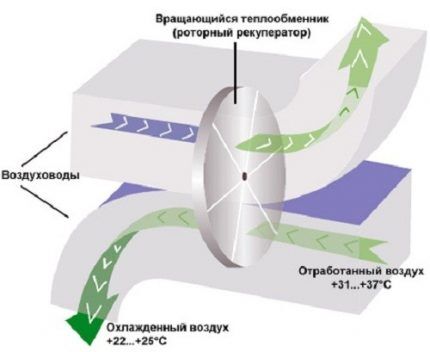

Rotary recuperator – high system efficiency

The heat exchanger is presented in the form of a cylinder filled with layers of corrugated metal. As the drum unit rotates, warm or cold jets of air alternately enter each compartment.

The efficiency of heat transfer is determined by the speed of rotation of the rotor; the operating efficiency can be adjusted.

Arguments for a rotary recuperator:

- heat return up to 65-90%;

- efficiency electricity consumption;

- partial moisture replacement – you can do without a humidifier;

- payback period – up to 4 years.

Despite its high efficiency, the drum-type heat exchanger has not become a leader among similar installations.

Disadvantages of the ventilation system:

- Adding polluted air into the supply. Exhaust and supply masses alternately circulate through the microchannels, so about 3-8% of the “working” is returned back. The drum often conveys the smell of the outgoing air.

- Complexity of design. The rotating parts of the rotor require regular maintenance and periodic replacement. Moving elements produce noise and vibration during operation.

- High price. The price for rotary models is higher than for plate products. This is due to the use of complex mechanics in the design of the drum heat exchanger.

- Big sizes. Installation is carried out in a spacious ventilation chamber.

Due to their bulkiness, rotary units are used mainly in industrial enterprises.

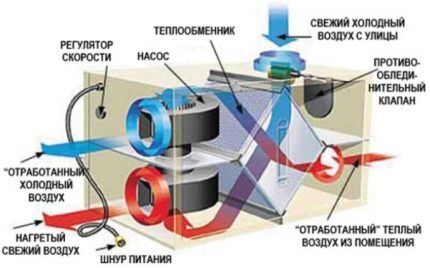

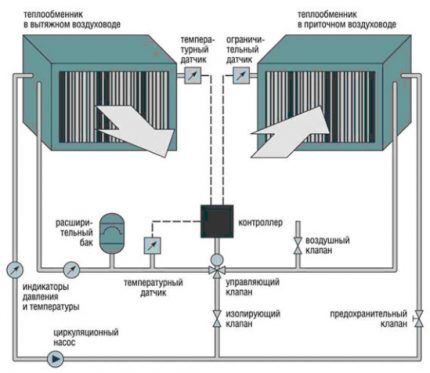

Coupled Heat Exchangers – Glycol Model

Due to its design features, a recovery unit with an intermediate coolant is often called coupled heat exchangers or a glacier unit. This is one of the most flexible heat recovery systems. One heat exchanger cuts into the supply duct, and the second into the exhaust duct.

Principle of operation. The glycol composition circulates between the heat exchangers. The temperature of the coolant increases due to the heated exhaust flow, and then the thermal energy is transferred to fresh air. The closed system eliminates the mixing of oncoming air masses.

Features of operation of heat exchangers with coolant:

- Efficiency – 45-55%;

- efficiency adjustment using a pump - the speed of antifreeze movement is selected;

- possibility of placing supply and exhaust air ducts remotely from each other (up to 800 m);

- the recuperator is installed vertically or horizontally;

- in severe frost, the surface of the exhaust heat exchanger freezes and ice appears; the use of antifreeze allows you to operate the recuperator without resorting to defrosting;

- payback period of the system – up to 2 years;

- a combination of 1 hood and several inflows or vice versa is permissible.

The volume of exhaust and intake air should be approximately equal. Such recuperators are usually used if the influent is toxic or heavily polluted, when mixing of streams is unacceptable.

Chamber unit – versatility of use

Structurally, the chamber heat exchanger is a closed box, divided inside by a moving damper.The opening partition determines the operation scheme of the recuperator.

As a result, the inflow moves along the warm walls of the first air duct, and the “exhaust” heats the surface of the second chamber. At a certain point, the septum comes back and the cycle repeats.

Advantages of a chamber heat exchange unit:

- Efficiency – 80-90%;

- in tandem with high-quality thermal insulation, heating costs are reduced to a minimum;

- ease of installation - specialist help will be needed when choosing the parameters of the ventilation unit;

- maintaining humidity levels;

- freezing of the system is excluded.

A chamber heat exchanger is an excellent option for regions where there is a significant imbalance between indoor and outdoor temperatures for a long period of the year.

The disadvantages of the heat recovery unit include:

- the need for regular maintenance of moving elements;

- counter air currents partially mix - odors and impurities can flow back into the building.

To reduce admixture, the system is equipped with filter element. The air becomes cleaner, but the efficiency of the recuperator decreases.

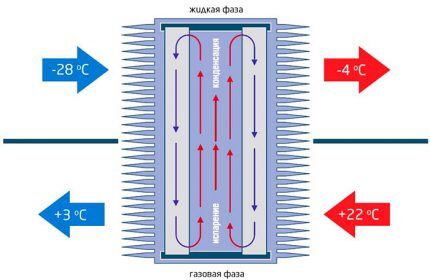

Heat pipes – closed heat exchange system

The recuperator consists of many copper or aluminum tubes filled with an easily evaporating substance, such as freon. The operating principle of a tubular heat exchanger is based on physical processes - changes in the state of a substance when heated.

The gas rises and releases thermal energy to the inflow, after which the freon condenses and flows down the recuperator. The thermal cycle repeats itself in a circle.

Technical and operational characteristics of the tubular heat exchanger:

- device efficiency – up to 65%;

- quiet operation due to the absence of moving elements;

- simplicity of design and low maintenance;

- compactness — small dimensions and low weight;

- energy independence – the coolant circulates naturally;

A significant advantage is that the inflow and return air flows do not mix.

Weaknesses of heat pipes:

- high level of efficiency is achieved over a narrow temperature range - with sudden overheating, all freon evaporates, and with insufficient heating, the intensity of vaporization slows down;

- low strength of tubes – change in shape or depressurization reduces the performance of the equipment.

Tubular heat exchangers are used in private construction, administrative and office buildings and small industrial areas.

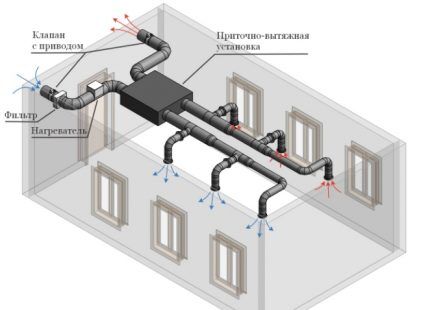

Methods for organizing recuperative ventilation

Recovery is arranged in one of the following ways: centralized and decentralized. In the first case, ventilation flows from the entire room pass through the heat exchanger, in the second - from one room.

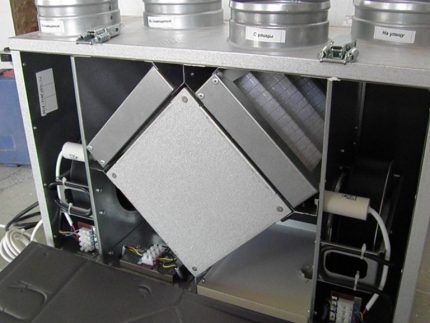

Centralized complex – air handling unit

A centralized system is installed at the stage of construction or major modernization of the ventilation system.

A PVU with a recuperator ensures sufficient air exchange even in houses with sealed windows. At the same time, air flows are distributed evenly without creating drafts.

Complex air handling units monoblock type equipped with:

- fans – round-the-clock supply of clean air and emission of jets saturated with carbon dioxide;

- heaters – preheating of inflow;

- filters – trap dust and microparticles;

- recuperator — different types of installations can be used.

The functionality of some PVUs is expanded with a delay timer, power regulator, humidity level sensors, etc.

Recuperative monoblock PVUs produced have proven themselves well: "Vents" (Ukraine), Dantherm (Denmark), "Daikin" (Japan), "Dantex" (England).

Local units - an addition to the existing ventilation system

To restore the circulation of air masses in the room being used, decentralized air inlets with heat recovery are suitable.

They cut into the façade of a building or are mounted through a window. Their main task is to improve supply ventilation in the house.

Features of decentralized ventilation systems with recovery:

- Efficiency – 60-96%;

- low productivity – the devices are designed to provide air exchange in rooms up to 20-35 sq.m;

- affordable price and a wide selection of units, ranging from conventional wall valves to automated models with a multi-stage filtration system and the ability to adjust humidity;

- ease of installation – no air ducts are required for commissioning, install wall valve you can do it yourself.

Popular manufacturers of local recuperators: Prana (Ukraine), O.Erre (Italy), Blizzard (Germany), Vents (Ukraine), Aerovital (Germany).

Conclusions and useful video on the topic

Comparison of the operation of natural ventilation and a forced system with recovery:

The principle of operation of a centralized recuperator, calculation of efficiency:

Design and operating procedure of a decentralized heat exchanger using the Prana wall valve as an example:

About 25-35% of the heat leaves the room through the ventilation system. Recuperators are used to reduce losses and effectively recover heat. Climatic equipment allows you to use the energy of waste masses to heat the incoming air.

Do you have anything to add, or do you have questions about the operation of different ventilation recuperators? Please leave comments on the publication and share your experience in operating such installations. The contact form is located in the lower block.

Interesting article, thanks for the useful information. Recuperators are an indispensable thing not only for householders, but, first of all, for owners of large premises. For example, our store is quite large and for a long time we had to spend a significant amount on cooling in hot weather and heating in winter. After installing the recuperator, I gained both in time (less hassle) and in money - saving money. If you're interested, I bought a recuperator in this store https://aqua-life.ua/chto-takoe-rekuperator-vozdukha/