Installation of fans on the roof: features of installation and fastening of roof fans

Clean air in living and working areas is extremely necessary. Agree, the musty atmosphere in the house is very unpleasant.However, a change in air volume is achieved not only by the influx of air, but also by its removal beyond the walls of the building. And exhaust ventilation systems often fail to cope with the latter task.

Modern buildings, whether multi-level office complexes, residential facilities, sports complexes or industrial workshops, consist of spacious, high-ceilinged rooms. To regularly replace the air in them, forced exhaust by several roof-type ventilation devices is required.

We will tell you how ventilation equipment is selected, how fans are installed on the roof, and why it is impossible to do without a glass.

The content of the article:

Features of roof fans

These appliances are intended for rooftop installation only. They are most effective in systems forced ventilation large-area objects. By installing roof fans on a building with or without integration into the air duct system (for example, above an airport hall), it will be possible to solve the problem of removing polluted air.

Ventilation units are capable of removing smoky, exhaust (with impurities, unpleasant odors), polluted and moisture-saturated air from large-sized premises served. The use of roof fans is possible for both above-ground and some underground objects.

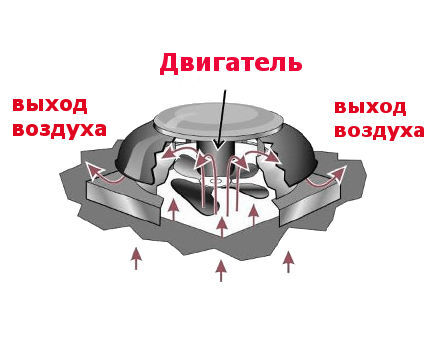

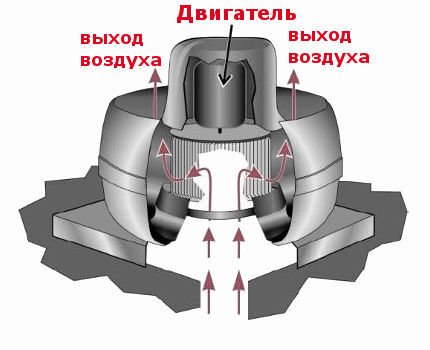

Ventilation devices placed on buildings, depending on the method of air capture and removal, are divided into axial, radial and diagonal.

Types of ventilation structures

Axial fans. They combine simplicity of design, reliable operation and easy maintenance. Structural endurance allows them to be used equally effectively both for air exchange and for creating smoke ventilation, as well as for pressurizing air in case of fire (they operate at air flow temperatures above 400OWITH).

The devices are highly resistant to chemical compounds in the exhaust air, which makes it possible to mount axial fans on the roof of industrial facilities in the pharmaceutical and chemical fields.

Most household fans belong to this group: duct devices, devices installed in wall supply and exhaust valves, bathroom fans, combined and separate bathrooms.

Radial fans. These ventilation devices are characterized by a volute housing that directs air at right angles to a blade wheel with centrifugal rotation. They can pump air volumes containing mechanical pollutants in concentrations up to 100 mg/m3, remove air properly even in strong winds.

The characteristic structure of the blades provides the device with high performance, but also with high noise. Therefore, radial roof fans are mainly used in industrial facilities.The temperature of the air pumped out by the radial device must be less than 80OWITH.

Diagonal fans. These ventilation devices are a combination between axial and radial type models. Their suction impeller takes in air in the axial direction, and before releasing the air flow, it deflects it by 45O. This gives an increase in power due to the centrifugal force characteristic of radial fans.

The combination of the qualities of axial and radial roof ventilation installations provides diagonal models with an efficiency of up to 80%. With sufficient power, radial roof fans are relatively compact and quiet.

Passage units for a flat reinforced concrete roof

Exiting ventilation channels through the layers of the roofing “pie” of flat roofs is possible only when using a special technical roof passage unit.

This structural element compensates for dynamic and static loads exerted by an operating ventilation device. Also, a ready-made passage unit simplifies waterproofing work in the ventilation exit sector.

On reinforced concrete upper floors, assembled from slabs or poured into formwork on corrugated sheets, passage units can be laid out of brick, formed with a strip foundation or concrete casting.Externally, it looks like a ventilation shaft raised above the roof level, on the head of which a fan is mounted.

However, such a design of the passage unit is ineffective, since it creates difficulties with attaching fans and a lot of difficulties with waterproofing adjacent areas.

A reinforced concrete passage unit, which is an improved version of the Soviet ST series, will allow you to install an exhaust ventilation system on a reinforced concrete floor. This product consists of two reinforced concrete shells (cups) - a cylindrical internal and a four- or hexagonal external parallelepiped.

The support is the outer glass. Thanks to its edges, it is easy to waterproof along the perimeter of the joint with the main roof covered with rolled carpet. The inner glass, shaped like a round pipe, is covered on the outside with thermal insulation. The outer glass of the roof passage unit is equipped with embedded anchor fasteners with a reinforced concrete slab roof base and a roof fan.

Reinforced concrete double-hulled glasses can be installed on floors and gentle slopes with high load-bearing capacity with a slope of up to 12O. It is necessary to select a model that corresponds not only to the parameters of the roof fan, but also with a bottom slope equal to the actual roof slope. The weight of the double-hull reinforced concrete roof passage unit is over 300 kg.

Installation of reinforced concrete glass

Before lifting the glass passage assembly onto the roof, visible metal elements and welds on the reinforced concrete product must be prepared - cleaned, covered with primer, then painted in two layers with an anti-corrosion compound. The outer surface of the outer shell should be puttied and weather-resistant paint applied.

To lift a massive glass (about 300 kg) onto the roof, you need slings and a truck crane. Aligning the outer shell of the cup to the installation site should be done using M200 cement-sand mortar.

Anchoring the reinforced concrete glass to the floor slab is carried out with the installation of embedded parts. If the fastening is carried out to the load-bearing roofing layer of reinforced concrete slabs, then it is better to carry out a through installation of the glass, installing tie rod reinforcing bolts in the seams between the slabs.

Near the walls of the base of the installed glass, an inclined screed is performed with M150 solution. To insulate the perimeter, a mineral wool slab is placed under the screed near the roof passage. A layer of waterproofing roll materials is fused on top of the screed.

Along the line of junction of the waterproofing materials with the glass, their edges overlap its walls, are covered with a galvanized apron and fixed with galvanized dowels. The seam along the line where the apron adjoins the walls of the reinforced concrete cup is filled with sealant (polyurethane, thiokol).

Installing a roof fan in a reinforced concrete cup

The installation of roof fans in monolithic and slab reinforced concrete floors of industrial facilities is carried out using standard double-hull reinforced concrete cups with an internal diameter from 700 to 1450 mm, a height of 400 mm.

Let us remind you that before installing the fan, the glass must become a structural part of the reinforced reinforced concrete roof slab.

To secure the fan, embedded anchor bolts are embedded in the upper part of the reinforced concrete glass with cement-sand mortar, and tubes are placed in the lower part through which bolts are passed to fasten the fan tray. After preparing the anchors, a slope is created from M150 mortar along the top of the glass.

Before installation work, an audit of the fan design and its electric motor is carried out. The gap between the shell (or inlet pipe) and the impeller is checked.

Then a check valve is attached to the roof fan pipe, which automatically opens during operation of the ventilation unit and closes the section of the pipe when it is turned off.

If according to the project a network of air ducts is connected to the fan, the branch pipe (the first link) should be connected to the ventilation unit before its installation in the reinforced concrete casing. Air ducts are fixed to building structures; their weight should not affect the ventilation device.

Sequence of installation work

Given the massiveness of the ventilation device, it must be handled very carefully.

The installation procedure is as follows:

- The fan is manually positioned above the glass using a truck crane or using jacks. The vibration-isolating part of the fan (if the device is equipped with it) is secured with standard bushings and locking bolts;

- The fan is installed on a glass, along the head of which a rubber gasket is placed. Anchor bolts are inserted into the holes of the mounting flange;

- The horizontal position of the device is verified by a level.The visor is mounted. Nuts and locknuts are screwed onto the anchor bolts;

- The gap between the top of the cup and the shell (or pipe) of the ventilation device is filled with construction sealant.

At the end of the installation, the stroke of the self-opening valve is adjusted with a counterweight. From the vibration isolators (if any) on the roof fan, remove the bushings and locking bolts that previously secured the vibration isolators during transportation of the device.

The power supply is connected, the strength of the connection and the free rotation of the impeller are assessed, then the correctness of its rotation when starting (in the direction of the arrow).

We would like to emphasize that placing a condensate tray is mandatory during the colder months. The drainage of collected moisture is ensured by a drainage pipeline with a diameter of 15-20 mm, connected to the coupling at the bottom of the pan.

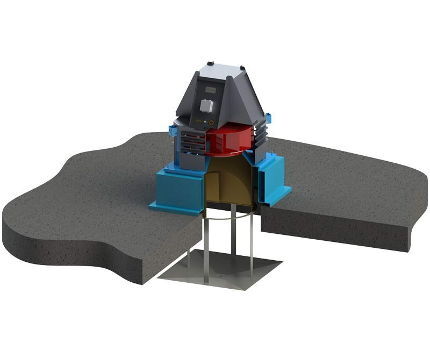

Universal roof passage units

These glasses are prefabricated steel structures from a welded square body and front panels with a height of 400 mm. These passage units can be used on both hard and soft roofs, and with any type of roof covering.

Universal metal cups can be used to complete ventilation systems when placed on roofs with a slope of up to 30O.

The support plates located at the top and bottom of the glass are made of 10 mm steel sheet.Additional reinforcement is provided by stiffening ribs on the base plates. The structural elements of the product are connected by electric welding, the thickness of the seam is at least 6 mm.

The body of the steel roofing passage unit is mounted on a base made of channels, fixed to the load-bearing elements of the roof. There are welded studs at the top of the housing, whose positions coincide with the mounting holes on the fan base.

The double walls of the glass, 10 and 12 mm thick, contain thermal and noise insulation material. Models without insulation inside the walls are also available. By the way, when equipping a building with a smoke exhaust fan, in addition to increased fire resistance, a metal cup may require additional external thermal insulation.

A reed valve or an insulated valve equipped with an electric drive can be installed in the steel cup body. A condensate tray and a grille or the outlet part of the air duct are connected to the air duct of the lower part of the roof passage unit.

Specifics of using a metal cup

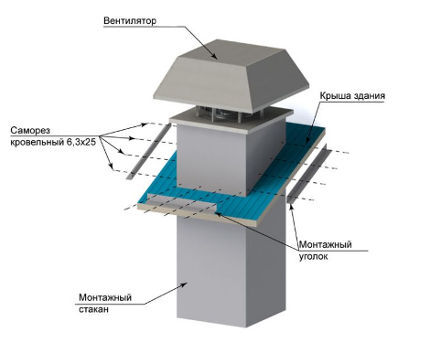

The principle of installing a steel roof passage assembly on a rigid roof is almost identical to the procedure for installing a reinforced concrete glass. Let's look at the features of assembling a metal cup on a soft roof.

If the metal cup is equipped check valve, then the latter must be mounted before installing the passage unit in place. There may be shipping bolts on the valve - they need to be removed. Note that when you try to align the valve on an installed glass, most likely it will be skewed.

Installation of the product is carried out on an opening prepared in the roof, corresponding to the dimensions of the internal section of the glass. It is secured with anchor bolts to the load-bearing part of the roof, or to another load-bearing support capable of holding it and securing it in position. The passage unit is always set strictly vertically!

The final sealing, namely cement-sand screed of the mounting base of the glass, laying out thermal and waterproofing layers, placing skirts and aprons made of galvanized steel and crimp clamps on the contour, is carried out according to the actual conditions at the installation site of the metal passage unit (roof structures, location and material of the support, etc. .).

Before installing the fan on the glass, it is necessary to secure the tray by preparing 14 mm holes for bolted connections on its side walls.

Installation of a roof fan to a metal cup is carried out by securing the device to studs using nuts and washers. Having completed the installation, all that remains is to seal the contour of the gap between the fan and the glass with construction sealant.

The horizontal position of the fan is checked with a level, this is mandatory. Distortions made during installation work will damage the operation of the ventilation unit and shorten its service life.

Conclusions and useful video on the topic

Installation sequence on a rigid roof and the principle of a radial fan:

What is the procedure for installing a roof fan on a soft roof:

Roof ventilation systems are designed for long service life with minimal maintenance.However, they still require some maintenance: checking the strength of connections (riveted, bolted, welded), inspecting the condition of the paintwork of the fan flow area and the blades on the impeller, cleaning from dust and contaminants.

Therefore, free access to the equipment on the roof should be provided in the form of protected paths, which allows not to damage the “pie” of the roof, especially soft ones. Rolled mats made of plastic or rubber are suitable for this purpose.

Do you have useful information on the topic of the article? Have information worth sharing with site visitors? Please leave comments, ask questions about controversial and unclear points, and post photos in the block below.

Hello, I’ve already racked my brains with this ventilation, I need to do it soon, but I can’t decide, a frame extension is being built to the log house, there will be a combined bathroom with shower, an inlet through a valve in the window, but I wanted to make an extractor through the wall , it seems simple and fans with a bunch of bells and whistles are sold, but I came across a multi-channel fan, it’s convenient that there are 4 inputs in one box, in the kitchen you will also need to make an exhaust hood, so I think that it’s better, simpler, more budget-friendly, but also something that works , I also wanted to install turbo deflectors, but its effectiveness is somehow doubtful

The builders installed a fan on my roof. it is constantly covered in snow. I don’t know what to do. They don't answer calls; I don't know the names. The fan seems to be of no use, and water is dripping from the ceiling of the extension. It’s winter now - I’ll look into it in the summer